10 Jul Resilient Channel: If You Use It, Don’t Screw It Up!

According to building codes, party floor/ceiling assemblies must provide a minimum Sound Transmission Class (STC) rating of 50. To achieve this level of isolation, designers often spec resilient channel (aka rez bar or Z bar) with two layers of gypsum wallboard.

However, there’s a myth that says resilient channel can’t support multiple layers of gypsum wallboard in floor/ceiling assemblies. While we’re not sure where the myth originates, evidence shows that resilient channel attached to the underside of floor joists can successfully support two layers of 1/2-inch or 5/8-inch gypsum wallboard.

Tests conducted by United States Gypsum, a manufacturer of resilient channel, demonstrate that resilient channel can support multiple layers of wallboard. In addition, the Institute for Research in Construction, a division of the Canadian National Research Council, has performed sound isolation tests on both one and two layers of wallboard supported from resilient channel. In fact, such floor assemblies are listed in the Canadian National Building Code.

Some contractors and suppliers recommend installing one layer of wallboard directly to the underside of the joists, strapping that with resilient channel, and then adding a second layer of wallboard to the resilient channel. Yet this construction wastes the acoustical benefits of the second layer of wallboard.

For example, consider the F4d floor in the Canadian National Building Code, which consists of the following:

- 5 mm plywood, OSB, or waferboard, or 17 mm tongue-and-groove lumber;

- 38 mm x 235 mm wood joists spaced at no more than 600 mm o.c.;

- absorptive material in the cavity; and

- two layers of 12.7 mm Type X gypsum wallboard on the ceiling side.

This floor has a typical STC rating of 36 and an Impact Insulation Class rating (IIC) of 32.

If the F4d floor assembly is modified with a layer of resilient channel between the two layers of wallboard, the assembly becomes an F7d floor with an STC rating of 37 and IIC rating of 30.

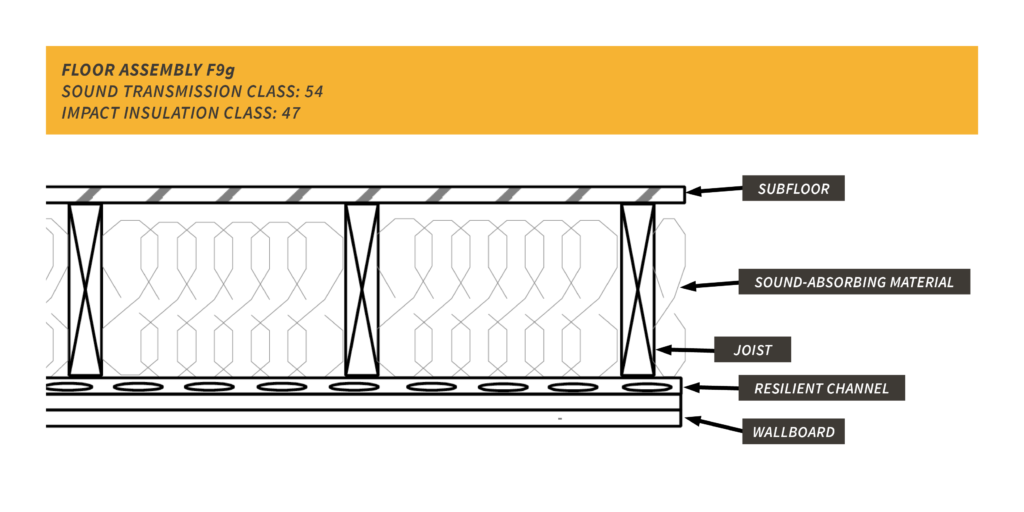

However, if the resilient channel is placed between the wallboard and the floor joists with 400 mm spacing between the channels, the assembly becomes an F9g floor. This assembly has an STC rating of 54 and IIC rating of 47.

By installing resilient channel in the correct location, you can optimize the sound and impact isolation qualities of floor and ceiling partitions—and if your plan already calls for resilient channel, you won’t need to upgrade your building materials.

Short Circuiting Resilient Channel

Another problem can occur when installers unintentionally thread screws through the drywall into the joists. It’s a common mistake when longer screws are used. By penetrating the joist, a screw “short circuits” the isolated wallboard, and creates a path for noise to travel through the floor assembly. Understandably, short circuits are difficult to identify and often limit the acoustical benefits of any floor/ceiling or wall assembly.

By using resilient clips, you can secure wallboard while preventing short circuits. Designs vary among manufacturers, e.g., Genie Clip, IsoMax, SonusClip, or RSIC-1, yet most resilient clips work the same way: They make sure that both the wallboard and the screws are isolated from the joists. In addition, resilient clips are compatible with any length of screw, so installers don’t have to deal with the hassle of carrying multiple lengths of fasteners.

Good acoustical design leads to fewer noise complaints. This can save you from expensive remedial work in the future. Remember, whether your project is a residential, commercial, or mixed-use development, don’t believe the myths. Instead, get in touch with us.

Our team of acoustical engineers can review project drawings to assess the acoustical performance of floors, ceilings, and walls, as well as windows and building envelopes. We have the experience and skills to provide insightful, analysis-based recommendations to improve sound isolation, control noise from mechanical systems, and limit traffic and community noise and vibration.

Pawel Pelc

Posted at 05:26h, 14 JulyHi. I need help soundproofing my kids bedroom. I live in a attached duplexe . my home was built in the 50s, so no insulation in ceiling just a 5/8 ceiling. I was thinking adding a resillient channel with 5/8drywall. Option 2 would be resilient chanel with 2 5/8 drywalls with green glue. Option 3 the most expensive and not sure if its worth the hassel to remove the ceiling , add fiberglass insulatio n add the resilient chanel and 2 layers of 5/8. The question is … Is option 3 worth it ? Not sure what the stc is between those. Let me know if you would have any advice. Thanks and stay safe.

Mark Bliss

Posted at 09:46h, 17 AugustHi Pawel, It sounds like your Option 1 is similar to our F7d example above and your Option 3 is similar to our F9g example above – F9g is dramatically better than F7d. Hope this helps!

Sabina Sokolo

Posted at 14:28h, 02 DecemberHi

I’m trying to find a way to upgrade a ceiling that is done STC 37 to STC 54 .

the existing ceiling is 5/8 drywall – Sound bar and 5/8 drywall.

I’m hoping you can gave some advise for me how to upgrade it to a STC 54.

If I can do another layer of 5/8 drywall with Green Glue or if I have to take the full ceiling down.

Thank you

Rick W

Posted at 09:13h, 13 DecemberHi, I could use a bit of advice soundproofing between two commercial spaces. The construction is metal roof/trusses and concrete floor with CMU walls front and back and metal stud walls between the businesses. I’m dealing with a 6″ metal stud wall, 16″ OC with both sides, resilient channel (RC) and one layer 5/8″ fire rated drywall with R12 in the cavity. I need to isolate the barking dogs on one side of the wall from the business on the other side of the wall. What is the best option? I can only work with the one side of the wall. I am considering another layer of RC and 5/8″ drywall or a only a second layer of 5/8″ drywall perhaps with green glue, or a second 4″ wall with RC and 2 layers of 5/8″ drywall, one sided. I realize the 2nd wall might be the best option, but wondering if it is necessary or just overkill.

Mark Bliss

Posted at 12:21h, 01 FebruaryJust give us a call, Rick, and we can talk through it, look forward to chatting!

David Redd

Posted at 07:28h, 11 JanuaryHi .. I am doing a duplex conversion and looking to do a similar install to the F9G above, but adding some isolation to the RC by mounting the RC with rubber washers to the underside and top side of the RC at the mounting point to the floor joists. My thought is either rubber washers to mount or a rubber strip and using metal roofing screws similar to Paulin #10 x 1-1/2 -inch Hex Head Self-Sealing Roofing / Siding Screws -.. Any and all thoughts are appreciated. thank you

Mark Bliss

Posted at 12:23h, 01 FebruaryHi David, If you want to do better than standard RC then we recommend a clip like those mentioned in the article, cheers!