Académique Documents

Professionnel Documents

Culture Documents

Engine Misfare Bulletin

Transféré par

tuningDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engine Misfare Bulletin

Transféré par

tuningDroits d'auteur :

Formats disponibles

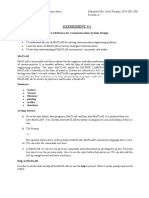

TECHNICAL BULLETIN

MODEL/DERIVATIVE: Bulletin No: 0032

Discovery Series II CDS. ref: L8710BU

Defender Issue: 1

Date: 06.02.02

AFFECTED RANGE:

All Td5 diesel derivatives

PROBLEM:

ENGINE MISFIRE

The engine may misfire and cut out at high revs/min, or misfire, then recover until

the throttle pedal is depressed again. This is most likely to occur when the engine is

warm or hot. The engine check light may also be illuminated.

CAUSE:

Crankshaft Position (CKP) Sensor is too close to the flywheel or the drive plate.

ACTION:

Where a complaint of the above is confirmed, refer to the diagnostic procedure

below to identify the cause of the misfire. Connecting the vehicle to TestBook/T4

will identify any stored fault codes in the Engine Control Module (ECM).

1. Connect TestBook/T4 to the vehicle using the latest version of the Discovery Series

II / Defender Diagnostic CD.

2. Select Diagnostic System.

3. Select model and ‘Td5’ (Defender) or ‘Diesel Engine’ (Discovery II).

4. Check the ECM for misfire faults using ‘Fault Code Diagnostics’. The following

fault will be recorded when the CKP sensor is too close to the flywheel or the

drive plate.

• High-speed crank sync lost fault.

The following faults may also be recorded.

• Noisy crank signal has been detected.

• Injector faults.

• Any injector faults may occur due to gaining and losing crankshaft

synchronization.

5. Note and clear logged fault codes.

6. Disconnect TestBook/T4 from the vehicle.

TECHNICAL BULLETIN NO: 0032 ISSUE: 1 PAGE: 1 OF 3

If fault ‘High-speed crank sync lost fault’ has been recorded follow the rectification

procedure below.

1. Remove the Crankshaft Position (CKP) Sensor.

NOTE: If a shim has already been fitted check the electrical connection to the CKP

sensor. If problem persists replace the crankshaft sensor (refit the shim).

Defender

• Refer to Workshop Manual, part number LRL0410 (2nd edition), Engine

Management System, Sensor - Crankshaft Speed and Position (CKP), repair

number 18.30.12.

Discovery

• Refer to Workshop Manual, part number VDR100090 (5th edition), Engine

Management System - Td5, Sensor - Crankshaft (CKP), repair number 18.30.12.

2. Fit a shim, detailed in PARTS INFORMATION, between the CKP Sensor and the

bell housing / automatic gearbox torque converter housing.

NOTE: Do not fit more than one CKP Sensor shim.

3. Refit the CKP Sensor.

CKP Sensor fault check procedure

Due to the nature of this fault it will only occur when the engine is warm and when

revved towards the top end of the rev range.

4. Park the vehicle in a well ventilated area.

5. Fully apply the handbrake, select neutral (manual gearbox) or park (automatic

gearbox).

6. Run the engine until normal operating temperature is reached then fully depress the

throttle pedal and hold for 10 seconds.

WARNING: Ensure that there is sufficient clearance around the front and rear

of the vehicle and that no pedestrians are walking or standing around the

vehicle during this operation.

7. Road test vehicle, where safe to do so utilise the full rev range of the vehicle up to

3rd gear.

CAUTION: During the road test extreme caution must be applied while

utilising the full rev range of the vehicle.

Local market road and traffic legislations must be adhered to at all times.

8. Connect TestBook/T4 to the vehicle using the latest version of the Discovery Series

II / Defender Diagnostic CD.

9. Select Diagnostic System.

7. Check the ECM for misfire faults using ‘Fault Code Diagnostics’.

8. If any injector faults are recorded, then a separate problem still exists. To obtain

more information on the injector faults refer to the fault code explorer option in

TestBook/T4.

TECHNICAL BULLETIN NO: 0032 ISSUE: 1 PAGE: 2 OF 3

PARTS INFORMATION:

NSJ000010 - Crankshaft Position Sensor shim

WARRANTY CLAIMS:

Use Complaint Code: 7E7A

Use S.R.O.: 18.90.89/30 - CKP Sensor shim- Includes Testbook/T4 diagnosis and

road test.

Time allowance: 0.80 Hrs

TECHNICAL BULLETIN NO: 0032 ISSUE: 1 PAGE: 3 OF 3

Vous aimerez peut-être aussi

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedD'EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedÉvaluation : 4 sur 5 étoiles4/5 (3)

- Daewoo Lift Truck Fault Codes de FalhasDocument4 pagesDaewoo Lift Truck Fault Codes de FalhasM L D R100% (1)

- MOPAR REMANUFACTURED SINGLE BOARD ENGINE CONTROLLER REMOVAL GUIDEDocument7 pagesMOPAR REMANUFACTURED SINGLE BOARD ENGINE CONTROLLER REMOVAL GUIDEgatito1971Pas encore d'évaluation

- Automotive Air Conditioning and Climate Control SystemsD'EverandAutomotive Air Conditioning and Climate Control SystemsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003D'EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Évaluation : 5 sur 5 étoiles5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- DownloadDocument10 pagesDownloadlalo11715100% (1)

- Closed Loop Fueling DiagnosticsDocument9 pagesClosed Loop Fueling DiagnosticsKarl Heinz KerzenschuhPas encore d'évaluation

- Br005-03 - VSC Light On - DTC c1203Document8 pagesBr005-03 - VSC Light On - DTC c120358bjjonesPas encore d'évaluation

- Daewoo Fault PDFDocument4 pagesDaewoo Fault PDFBabei Ionut-MihaiPas encore d'évaluation

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Http://d1.scribdassets - com/ScribdViewer - Swf?document Id 108992419&access Key Key-13davbcdewnewn9m5w02Document4 pagesHttp://d1.scribdassets - com/ScribdViewer - Swf?document Id 108992419&access Key Key-13davbcdewnewn9m5w02Dhoom Dhoom40% (5)

- Mk7 Data SheetDocument4 pagesMk7 Data SheetthsalimPas encore d'évaluation

- RTA-77-y Oil Mist DetectorDocument8 pagesRTA-77-y Oil Mist DetectorCvita CvitićPas encore d'évaluation

- Powertrain DTC SummaryDocument71 pagesPowertrain DTC SummaryplanelPas encore d'évaluation

- 2009-12-27 171410 XtypeDocument98 pages2009-12-27 171410 XtypeDeni WardiniPas encore d'évaluation

- Service 1 Update Teleconference 0808Document6 pagesService 1 Update Teleconference 0808Garcia CruzPas encore d'évaluation

- DTC P050D: Applies ToDocument3 pagesDTC P050D: Applies ToWillie AustinePas encore d'évaluation

- D3 EPB Techbulletin1Document3 pagesD3 EPB Techbulletin1Вячеслав Глушак100% (1)

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P1345Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P1345José Garcia.Pas encore d'évaluation

- Manual RabbitDocument44 pagesManual Rabbitmotaznasser117Pas encore d'évaluation

- Omd Graviner Mk6 ManualDocument90 pagesOmd Graviner Mk6 ManualChristis SavvaPas encore d'évaluation

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750Pas encore d'évaluation

- Graviner MK6 Oil Mist DetectorDocument4 pagesGraviner MK6 Oil Mist DetectorDhanielPas encore d'évaluation

- Powertrain DTC Summaries - EOBD: Quick Reference Diagnostic GuideDocument71 pagesPowertrain DTC Summaries - EOBD: Quick Reference Diagnostic GuideVladiszláv TodyeriskoPas encore d'évaluation

- MID 039 - CID 0171 - FMI 04: TroubleshootingDocument4 pagesMID 039 - CID 0171 - FMI 04: TroubleshootingNerminTurkencePas encore d'évaluation

- Trouble Codes MitsubishiDocument12 pagesTrouble Codes Mitsubishirustyshakel100% (1)

- Ford OBD Trouble CodesDocument26 pagesFord OBD Trouble Codesmike67% (3)

- Engine Misfire DiagnosisDocument13 pagesEngine Misfire Diagnosissungjoo75Pas encore d'évaluation

- Technical Bulletin: SECTION: 307-00Document2 pagesTechnical Bulletin: SECTION: 307-00GPS MPWTPas encore d'évaluation

- TRANSFIX Users Guide MODBUS ProtocolDocument19 pagesTRANSFIX Users Guide MODBUS ProtocolsantoshkumarPas encore d'évaluation

- Xneon Connectores 334Document324 pagesXneon Connectores 334Roger Mirabet RuizPas encore d'évaluation

- Manual de Operación y MantenimientoDocument66 pagesManual de Operación y MantenimientoJohnnatan DuquePas encore d'évaluation

- SB 10105587 9340Document4 pagesSB 10105587 9340Andre RahmanPas encore d'évaluation

- JtecDocument9 pagesJtecJaco Wepener100% (1)

- Fuel Pump Control Circuit DiagnosisDocument5 pagesFuel Pump Control Circuit DiagnosisFaroukPas encore d'évaluation

- 6.0L Diesel Calibration Update-Various TSB 09-24-3 Issues: FordDocument3 pages6.0L Diesel Calibration Update-Various TSB 09-24-3 Issues: FordsesentorodriguezPas encore d'évaluation

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDocument9 pagesSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhPas encore d'évaluation

- Ford OBDOBD2 CodesDocument25 pagesFord OBDOBD2 Codesfabiobonadia100% (1)

- Ford OBDOBD2 Codes PDFDocument25 pagesFord OBDOBD2 Codes PDFfabiobonadiaPas encore d'évaluation

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocument38 pagesOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsangelvhPas encore d'évaluation

- C13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingDocument4 pagesC13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingmihaivulpePas encore d'évaluation

- DTC P0182, P0183 FTT SENSOR Component DescriptionDocument4 pagesDTC P0182, P0183 FTT SENSOR Component DescriptionWillie AustinePas encore d'évaluation

- G32D DTCDocument59 pagesG32D DTCPower NguyenPas encore d'évaluation

- Cylinder Cutout Results for Engine THY07138Document4 pagesCylinder Cutout Results for Engine THY07138Mario BreguPas encore d'évaluation

- Technical Information: Remote Handset Function/Alarm Module Troubleshooting and UpgradeDocument3 pagesTechnical Information: Remote Handset Function/Alarm Module Troubleshooting and Upgradebitxos50Pas encore d'évaluation

- 319-6424 Alt LL6100 - EnglishDocument20 pages319-6424 Alt LL6100 - EnglishEbied Yousif AlyPas encore d'évaluation

- Tests With CodesDocument268 pagesTests With CodesAnimemanuel MuñozPas encore d'évaluation

- BlowerDocument491 pagesBlowerozdemir_kucukler86% (7)

- Gmt95 Ck-2 1995 GM CK Truck Drivability Emissions and Wiring DiagramsDocument1 384 pagesGmt95 Ck-2 1995 GM CK Truck Drivability Emissions and Wiring DiagramsMiguel Angel LopezPas encore d'évaluation

- Acceleration Is Poor or Throttle Response Is PoorDocument6 pagesAcceleration Is Poor or Throttle Response Is Poorfalah100% (2)

- 2.0l EngineDocument312 pages2.0l EngineMike Sumaya Jr.Pas encore d'évaluation

- MR453X7917B050 PDFDocument194 pagesMR453X7917B050 PDFBloorimPas encore d'évaluation

- p0420 Catalyst ErrorDocument7 pagesp0420 Catalyst Errordion132100% (2)

- Test A/C Compressors with CLT1 Hand UnitDocument11 pagesTest A/C Compressors with CLT1 Hand UnitBilal al zeitawiPas encore d'évaluation

- Technical Service Bulletin 2.0L GDI - Various Drivability Concerns And/Or Illuminated Malfunction Indicator Lamp (MIL) 18-2062Document3 pagesTechnical Service Bulletin 2.0L GDI - Various Drivability Concerns And/Or Illuminated Malfunction Indicator Lamp (MIL) 18-2062ocnogueiraPas encore d'évaluation

- 206 09A Anti Lock ControlDocument11 pages206 09A Anti Lock ControlMiguel AngelPas encore d'évaluation

- Fe04a PDFDocument32 pagesFe04a PDFvette512Pas encore d'évaluation

- Manual JD English C13960.Sflb - AshxDocument41 pagesManual JD English C13960.Sflb - AshxPete Okonski100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- "How Do I Convince Investors To Invest in My Start Up - "Document4 pages"How Do I Convince Investors To Invest in My Start Up - "VohahPas encore d'évaluation

- Intiail Download GuideDocument32 pagesIntiail Download GuidejimtramsayPas encore d'évaluation

- Data Networking NotesDocument320 pagesData Networking Notescheese maniaPas encore d'évaluation

- Precision 3581 Spec Sheet - Pdf.externalDocument9 pagesPrecision 3581 Spec Sheet - Pdf.externalMallu SenguptaPas encore d'évaluation

- Ufone Advertisement Review MarketingDocument16 pagesUfone Advertisement Review MarketingMohsyn Syed100% (6)

- VOS 8000FTR Installation ManualDocument12 pagesVOS 8000FTR Installation ManualRamesh BabuPas encore d'évaluation

- Raised Floor For Data Center PDFDocument9 pagesRaised Floor For Data Center PDFMahmood MuftiPas encore d'évaluation

- Project Report MiniDocument27 pagesProject Report Minisumit gandhi86% (21)

- Classic Window Design. High Insulation. KÖMMERLING 70 ADDocument3 pagesClassic Window Design. High Insulation. KÖMMERLING 70 ADVilmos GyeroPas encore d'évaluation

- Wipro Training ModelDocument5 pagesWipro Training Modelprabjotpadwal100% (1)

- Seal Kit Catalog 08Document368 pagesSeal Kit Catalog 08Sarl Gaf PmtpcPas encore d'évaluation

- KONE Full MBM-2 Ride Comfort (Mechanical) For TraineeDocument90 pagesKONE Full MBM-2 Ride Comfort (Mechanical) For TraineeMadpitPas encore d'évaluation

- Sprinter Panelvan 4720 1B301 11 02Document48 pagesSprinter Panelvan 4720 1B301 11 02Shamnas AyoobPas encore d'évaluation

- Wireless H3CDocument40 pagesWireless H3CMichael David Samaniego VillarroelPas encore d'évaluation

- Manual XG5000IEC V2.7 PDFDocument742 pagesManual XG5000IEC V2.7 PDFEkanit ChuaykoedPas encore d'évaluation

- Led TV : Owner'S ManualDocument64 pagesLed TV : Owner'S ManualDiego BernalPas encore d'évaluation

- Hollysys: LK Programmable Logic ControllerDocument17 pagesHollysys: LK Programmable Logic ControllerClear MindPas encore d'évaluation

- Opcdaconnector Doku v1 1 eDocument43 pagesOpcdaconnector Doku v1 1 ekristyan kawayPas encore d'évaluation

- Power Quality and EMC in Smart GridDocument6 pagesPower Quality and EMC in Smart GridMohammed MansoorPas encore d'évaluation

- QoS in Layer 2 Networks with Cisco Catalyst 3550Document12 pagesQoS in Layer 2 Networks with Cisco Catalyst 3550amiramatPas encore d'évaluation

- MATLAB Basics for Communication SystemsDocument19 pagesMATLAB Basics for Communication SystemsSyed F. JPas encore d'évaluation

- Continuity/Insulation Resistance Test FormDocument1 pageContinuity/Insulation Resistance Test FormVictor BiacoloPas encore d'évaluation

- Tecnotest Analizador Gases Dignostico Stargas Family898 495 enDocument12 pagesTecnotest Analizador Gases Dignostico Stargas Family898 495 ennewslemPas encore d'évaluation

- DMI-ST. EUGENE UNIVERSITY BACHELOR OF COMPUTER SCIENCE COURSE NAME: COMPUTER INSTALLATION AND SERVICING ASSIGNMENT NO: 01 ASSIGNMENT TOPIC: CD/DVD ROMDocument9 pagesDMI-ST. EUGENE UNIVERSITY BACHELOR OF COMPUTER SCIENCE COURSE NAME: COMPUTER INSTALLATION AND SERVICING ASSIGNMENT NO: 01 ASSIGNMENT TOPIC: CD/DVD ROMBonaventure Kalaba0% (1)

- Practical Lab 3Document7 pagesPractical Lab 3Vishal KumarPas encore d'évaluation

- Istoria CMM (In Engleza) PDFDocument20 pagesIstoria CMM (In Engleza) PDF26110100% (1)

- GRB100D 6F2S0882-2.1r PDFDocument510 pagesGRB100D 6F2S0882-2.1r PDFAzrul Alif ZailanPas encore d'évaluation

- IJSRD - International Journal for Scientific Research & Development| Vol. 5, Issue 10, 2017 | ISSN (online): 2321-0613Document2 pagesIJSRD - International Journal for Scientific Research & Development| Vol. 5, Issue 10, 2017 | ISSN (online): 2321-0613venturamercia_472121Pas encore d'évaluation

- Pcs Fca140 Leaflet Interactiveonline enDocument4 pagesPcs Fca140 Leaflet Interactiveonline enLyonelPas encore d'évaluation