INTERNAL SUB-CONTRACT PROCESS

Internal Sub-Contracting

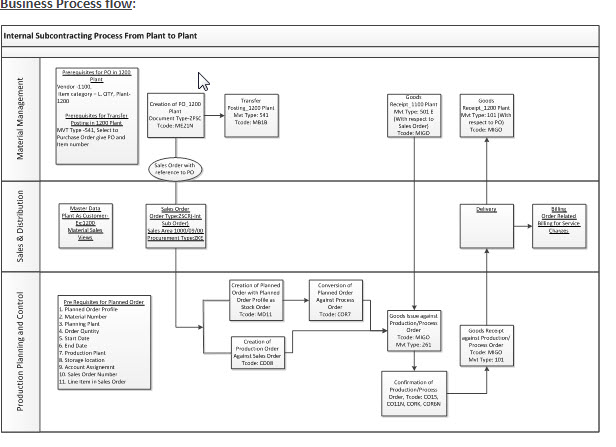

Business Process Activities to be followed

Modules Involved: MM, SD, PP and FICO

Pre-Requisites of Master Data:

Materials Management: Master Data in Both Plants

1. Material Master Should be available in both Plants

2. Valuation Category is mandatory in accounting view in split valuation

3. Extend Valuation Type for Materials

4. Vendor Master should be created with ZPLT account group

5. Vendor master need to be assigned with customer

Sales and Distribution:

6. Receiving Plant as Customer

Note: Vendor needs to be updated in customer master

7. Material Sales Views

8. Service Material

Production Planning and Control:

1. Material Master need to be available in both plants (MRP Views)

2. Bill of Material Need to be available in both Plants

3. Work Centres/ Resources must be available in Production Plant

4. Routing/ Master Recipe must be available in Production Plant.

Materials Management:

1. Creation of Purchase Order

Transaction Code: ME21N

Field Name

|

Input Value in the field

|

Description

|

Vendor

|

XXXX

|

Internal Sub Contract Vendor

|

Document Type

|

XXXX

|

Sub-Contracting Document Type

|

Item Category

|

L

|

Sub-Contracting

|

Materials

|

SFG

| |

Organisation Data

|

Pur. Organisation/Pur. Group/Company Code

| |

Payment Terms

|

Sub-Contracting Payment terms

| |

Item Level

|

Material/Qty./ Net Price(Job Work Charges)/ Plant

| |

Invoice

|

V0

|

Assign Tax Code

|

Reason for Order

|

Reason for Order

| |

Explode BOM

|

Explode BOM

|

2. Transfer Posting

Transaction Code: MB1B

Field Name

|

Input Value in the field

|

Description

|

Document Date

|

Document Date

| |

Posting Date

|

Posting Date

| |

Movement Type

|

541

|

Transfer Posting to Stock with Sub-Contractor from Un-restricted

|

Plant

|

Issuing Plant

|

Note-1: Select “To-Purchase Order” Tab and choose Purchase Order number and Item Number and select “Enter” button on the bottom of the screen.

Note-2: Assign “Storage Location” and “Batch Numbers” and select “Adopt + Details” Tab on the top of the screen and click on the “Save” Button on the top of the screen

Sales and Distribution:

3. Creation of Sales Order

Transaction Code: VA01

Field Name

|

Input Value in the field

|

Description

|

Sales Order Type

|

XXXX

|

Internal Sub Contract Order

|

Sales Area

|

XXXX/XX/XX

|

Central Sales Org./ STO sales/Common Division

|

Customer

|

XXXX

|

HBL VSEZ

|

Materials

|

SFG/Service Materials

| |

Plant

|

XXXX

|

Production Plant

|

Procurement Type

|

ZKE

|

Internal Sub Contracting Requirement Type

|

Price

|

Maintain Price for SFG/Service Material

|

Material Management:

Transaction Code: MIGO

Note-1: Goods Receipt against Sales Order with Movement Type 501E in Production Plant

Production Planning and Control:

4. Creation of Production Order against Sales Order in Production Plant

Note: If the Material is Process Ordered, then a Planned Order must be created with respect to sales order and then the planned order needs to be converted to Process Order.

Pre-Requisites for Creation of Planned Order:

Field Name

|

Input Value in the field

|

Description

|

Planned Order Profile

|

LA

|

Stock Order

|

Material Number

|

Material Number for which Sales Order has been raised

| |

Planning Plant

|

XXXX

|

Plant for which Sales Order raised

|

Order Quantity

|

100 kg

|

Sales Order Quantity

|

Start Date

|

Start & Finish Date

| |

End Date

| ||

Production Plant

|

XXXX

|

Plant at which production is carried out

|

Storage Location

|

XXXX

|

Storage location where the material is being receipted

|

Account Assignment Category

|

E

|

Ind. Cust.W. KD-CO

|

Sales Order Number

|

XXXX

|

Sales Document Number

|

Line Item

|

XXXX

|

Sales Order Line Item Number

|

5. Goods Issue against Production/Process Order with Movement type 261 (Only the respective Sales Order Materials can be issued)

Note-1: If the material from the respective production plant is being consumed then the material must be first transferred to the sales order and then the consumption needs to be taken place

Note-2: No accounting document is being generated during consumption of the materials against the production/Process Order

6. Confirmation of Production/Process Order

7. Goods Receipt against Production Order/Process Order with Movement type 101 (With respect to sales order in Production Plant)

Note-1: The material need to be receipted against the Production/Process Order in the respective Production Plant.

Note-2: No accounting document is being generated during receipt of the materials against the production/Process Order

Transaction Codes to be followed:

Transaction Code

|

Description

|

CO08

|

Creation of Production Order against Sales Order (Direct)

|

MD11

|

Creation of Planned Order

|

COR7

|

Conversion of Planned Order to Process Order

|

CO15

|

Confirmation of Production Order

|

CO11N

|

Operation wise Confirmation of Production Order

|

CORK

|

Confirmation of Process Order

|

COR6N

|

Operation wise Confirmation of Process Order

|

MIGO

|

Goods Receipt against Production/Process Order

|

Sales and Distribution:

8. Outbound Delivery

Transaction Code: VL01N

Field Name

|

Input Value in the field

|

Description

|

Shipping Point

|

XXXX

|

Shameerpet Shipping Point

|

Selection Date

|

Delivery Date

| |

Sales Order Number

|

Sub-Con. Sales Document Number

| |

Line Item

|

0010

|

Sales Order Line Item Number

|

Delivery Quantity

|

100 kg

|

Delivery Quantity

|

Plant

|

XXXX

|

Plant at which production is carried out

|

Storage Location

|

XXXX

|

Storage location where the material is being receipted

|

Picking Quantity

|

Deliverable Quantity

| |

Batch Number

|

Unique Batch Number

|

Material Management:

9. Goods Receipt:

Transaction Code: MIGO

Note-1: Goods Receipt against Purchase Order with Movement Type 101 in Receiving Plant

10. Billing

Transaction Code: VF01

Field Name

|

Input Value in the field

|

Description

|

Sales Order Number

|

Sub-Con. Sales Order Number

|

Note: Order related billing for service charges

Finance and Controlling:

11. Release Commercial Invoice to accounts

Comments

Post a Comment