Repair Welds

Completion requirements

Mark/locate welds defects

Prepare tools and equipment

Remove defects

Perform re-welding

1. Mark/locate weld defects and Remove defects

Weld

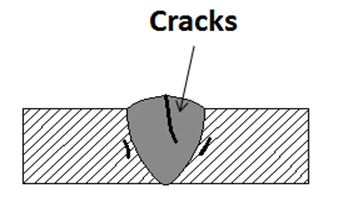

Crack

•The most serious type of welding defect

is a weld crack and it’s not accepted almost by all standards in the industry.

It can appear on the surface, in the weld metal or the area affected by the

intense heat.

There are different types of cracks, depending on the temperature at which they occur:

•Hot

cracks. These can occur during the welding process or during the

crystallization process of the weld joint. The

temperature at this point can rise over 10,000C.

•Cold

cracks. These cracks appear after the weld has been completed and the

temperature of the metal has gone down. They can form hours or even days after

welding. It mostly happens when welding steel. The cause of this defect is

usually deformities in the structure of steel.

•Crater

cracks. These occur at the end of the welding process before the operator

finishes a pass on the weld joint. They usually form near the end of the weld.

When the weld pool cools and solidifies, it needs to have enough volume to

overcome shrinkage of the weld metal. Otherwise, it will form a crater crack.

Causes of cracks

•Use of

hydrogen when welding ferrous metals.

•Residual

stress caused by the solidification shrinkage.

•Base

metal contamination.

•High

welding speed but low current.

•No

preheat before starting welding.

•Poor

joint design.

•A high content of sulfur and carbon in

the metal.

Remedies•Preheat

the

metal as required.

•Provide

proper cooling of the weld area.

•Use

proper joint design.

•Remove

impurities.

•Use

appropriate metal.

•Make

sure to weld a sufficient sectional area.

•Use

proper welding speed and amperage current.

•To prevent crater cracks make sure that

the crater is properly filled

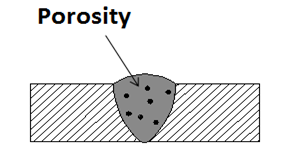

Porosity•Porosity

occurs

as a result of weld metal contamination. The trapped gases create a

bubble-filled weld that becomes weak and can with time collapse.

Causes of porosity:

•Inadequate

electrode deoxidant.

•Using

a longer arc.

•The

presence of moisture.

•Improper

gas shield.

•Incorrect

surface treatment.

•Use

of too high gas flow.

•Contaminated

surface.

Presence

of rust, paint, grease or oil

Remedies

•Clean

the

materials before you begin welding.

•Use

dry electrodes and materials.

•Use

correct arc distance.

•Check

the gas flow meter and make sure that it’s optimized as required with proper

with pressure and flow settings.

•Reduce

arc travel speed, which will allow the gases to escape.

•Use

the right electrodes.

•Use a

proper weld technique.

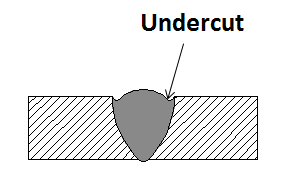

Undercut

•This welding imperfection is the groove

formation at the weld toe, reducing the cross-sectional thickness of the base

metal. The result is the weakened weld and workpiece.

Causes:

•Too

high weld current.

•Too

fast weld speed.

•The

use of an incorrect angle, which will direct more heat to free edges.

•The

electrode is too large.

•Incorrect

usage of gas shielding.

•Incorrect

filler metal.

•Poor

weld technique.

Remedies

•Use

proper electrode angle.

•Reduce

the arc length.

•Reduce

the electrode’s travel speed, but it also shouldn’t be too slow.

•Choose

shielding gas with the correct composition for the material type you’ll be

welding.

•Use

of proper electrode angle, with more heat directed towards thicker components.

•Use

of proper current, reducing it when approaching thinner areas and free edges.

•Choose

a correct welding technique that doesn’t involve excessive weaving.

Use

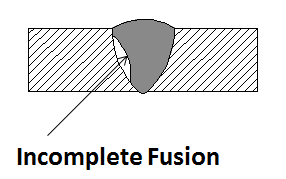

the multi-pass techniqueIncomplete Fusion

•This type

of welding defect occurs when there’s a lack of proper fusion between the base

metal and the weld metal. It can also appear between adjoining weld beads. This

creates a gap in the joint that is not filled with molten metal.

Causes:

•Low

heat input.

•Surface

contamination.

•Electrode

angle is incorrect.

•The

electrode diameter is incorrect for the material thickness you’re welding.

•Travel

speed is too fast.

•The

weld pool is too large and it runs ahead of the arc.

Remedies

•Use a

sufficiently high welding current with the appropriate arc voltage.

•Before

you begin welding, clean the metal.

•Avoid

molten pool from flooding the arc.

•Use

correct electrode diameter and angle.

•Reduce

deposition rate.

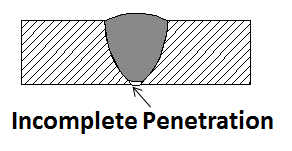

Incomplete Penetration

•Incomplete

penetration

occurs when the groove of the metal is not filled completely, meaning the weld

metal doesn’t fully extend through the joint thickness.

Causes:

•There

was

too much space between the metal you’re welding together.

•You’re

moving the bead too quickly, which doesn’t allow enough metal to be deposited

in the joint.

•You’re

using a too low amperage setting, which results in the current not being strong

enough to properly melt the metal.

•Large

electrode diameter.

•Misalignment.

•Improper

joint.

Remedies

•Use proper

joint

geometry.

•Use a

properly sized electrode.

•Reduce

arc travel speed.

•Choose

proper welding current.

•Check

for proper alignment.

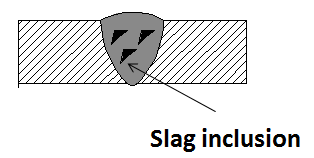

Slag Inclusion

•Slag inclusion

is one of the welding defects that are usually easily visible in the weld. Slag

is a vitreous material that occurs as a byproduct of stick welding,

flux-cored arc welding and submerged arc welding. Is can occur when the flux,

which is the solid shielding material used when welding, melts in the weld or

on the surface of the weld zone.

Causes

•Improper

cleaning.

•The

weld speed is too fast.

•Not

cleaning the weld pass before starting a new one.

•Incorrect

welding angle.

•The

weld pool cools down too fast.

•Welding

current is too low.

•Increase

current

density.

•Reduce

rapid cooling.

•Adjust

the electrode angle.

•Remove

any slag from the previous bead.

•Adjust the welding speed.

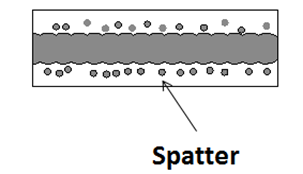

Spatter•Spatter occurs when small particles from the weld

attach themselves to the surrounding surface. It’s an especially common

occurrence in gas metal arc welding. No matter how hard you try, it can’t be

completely eliminated. However, there are a few ways you can keep it to a

minimum.

Causes

•The running

amperage is too high.

•Voltage

setting is too low.

•The

work angle of the electrode is too steep.

•The

surface is contaminated.

•The

arc is too long.

•Incorrect

polarity.

•Erratic

wire feeding.

Remedies•Clean

surfaces

prior to welding.

•Reduce

the arc length.

•Adjust

the weld current.

•Increase

the electrode angle.

•Use

proper polarity.

•Make sure you don’t have any feeding

issues

Perform re-welding

• Repair welding is an essential process in fabrication of some structures. Properly repaired structures may have equivalent static strength, ductility, fracture toughness and fatigue strength levels as the base structures. Repair welding can be carried out as a logical procedure that ensures the production of a usable and safe component, or it can be approached haphazardly. The latter approach results in poor-quality workmanship and can lead to failed parts, large warranty claims and dissatisfied customers.

The logical sequence of successful repair welding is as follows:

•Welding procedure: the welding procedure must be accessible to the use of the welders. It must include the process that is used and specific information concerning the welding joint technique required.

•Welding equipment: sufficient welding equipment should be supplied, then delays will not occur. Standby equipment may also be required. This not only comprises welding equipment, but also includes sufficient holders, grinders, wire feeders if required, cables, etc.

•Materials: sufficient materials must be accessible to the entire job. This includes the filler metals, which should be stored properly for use on the repair. It also includes materials such as insert pieces, reinforcing pieces, etc. Materials also include fuel for maintaining preheat and interpass temperature, shielding gases if used, and fuel for engine powered welding machines

•Alignment markers: before weld making, alignment markers are occasionally employed. These can be nothing more than centre punch marks made across the joint at various locations.

•Welding Sequences: the welding sequence should be well described in the welding procedure.

•Safety: ultimately, safety cannot be overlooked throughout the welding operation. For instance, when fuel gases are used for preheating, etc., ventilation must be provided

• Weld quality: the quality of the weld must be constantly checked. The final weld should be smooth and there should be no notches and reinforcing. In order to use it, it should flowed smoothly throughout the existing structure. In fact, grinding should be done to maintain smooth flowing contours

•Repair welding can be in one of three general categories:

•Repair of weld defects;

•Repair of failed parts

•Repair of worn parts