Abstract

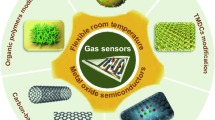

Given the huge economic burden caused by chronic and acute diseases on human beings, it is an urgent requirement of a cost-effective diagnosis and monitoring process to treat and cure the disease in their preliminary stage to avoid severe complications. Wearable biosensors have been developed by using numerous materials for non-invasive, wireless, and consistent human health monitoring. Graphene, a 2D nanomaterial, has received considerable attention for the development of wearable biosensors due to its outstanding physical, chemical, and structural properties. Moreover, the extremely flexible, foldable, and biocompatible nature of graphene provide a wide scope for developing wearable biosensor devices. Therefore, graphene and its derivatives could be trending materials to fabricate wearable biosensor devices for remote human health management in the near future. Various biofluids and exhaled breath contain many relevant biomarkers which can be exploited by wearable biosensors non-invasively to identify diseases. In this article, we have discussed various methodologies and strategies for synthesizing and pattering graphene. Furthermore, general sensing mechanism of biosensors, and graphene-based biosensing devices for tear, sweat, interstitial fluid (ISF), saliva, and exhaled breath have also been explored and discussed thoroughly. Finally, current challenges and future prospective of graphene-based wearable biosensors have been evaluated with conclusion.

Graphical abstract

Graphene is a promising 2D material for the development of wearable sensors. Various biofluids (sweat, tears, saliva and ISF) and exhaled breath contains many relevant biomarkers which facilitate in identify diseases. Biosensor is made up of biological recognition element such as enzyme, antibody, nucleic acid, hormone, organelle, or complete cell and physical (transducer, amplifier), provide fast response without causing organ harm.

Similar content being viewed by others

Introduction

Sensors in medicine and life science have been used to measure internal body parameters in disease diagnosis and health management techniques [1]. Many innovative sensors have been developed in response to the demand for early detection and diagnosis of disease as well as minimally invasive technologies [2]. Biosensing has become a critical strategy because it provides highly desirable qualities such as portablity, high sensitivity, quick findings, and longer shelf life. A biosensor is an analytical instrument made up of two independent parts: biologicals (enzyme, antibody, nucleic acid, hormone, organelle, or complete cell) and physicals (transducer, amplifier). A typical approach is used to immobilize the biological material on the transducer. In this regard, as the immobilized biological material is in close proximity to the transducer, it can precisely interact with analytes (for example, glucose, urea, medication, pesticide) to generate detectable physical, chemical, electrical, or optical signals [3, 4]. Biosensor technologies provide direct connection to human skin, body movement compliance, fast response, enhanced application, point of care testing, and self-health management without causing harm to human organs [5,6,7,8]. In this regard, biofluids (sweat, tears, saliva, and interstitial fluid (ISF)) and exhaled breath play a very important role in wearable device–based biosensing application as all of those can be readily sampled without disrupting the outermost protecting layers of the body’s skin (the stratum corneum). Besides, exhaled breath has also received much attention in the past decade as it contains thousands of components which arise from the lungs, nasal cavities, and have systemic origins in blood [5, 9,10,11]. Moreover, implantable devices also attract considerable interest in the recent past. Wearable (non-invasive) and implantable (invasive) biosensor devices are available in the market. Both types of devices have a good sensitivity and specificity in measuring analyte signals [12]. However, implantable devices can readily injure surrounding tissues because of their sharp edges, stiffness, and design. On the other hand, some characteristics such as wireless power and data transmission capacity significantly increase the need for wearable biosensors for the need of remote monitoring and Internet of thing (IoT)-based sensing. Wristbands, headbands, eyeglasses, mouth guards, bandages, smart garments, wearable gloves, tattoos, and stickers are all examples of wearable biosensor platforms. Moreover, they have exceptional flexibility and stretchability as well as remarkable sensitivity to detect wide-range signals [13, 14]. Interestingly, a variety of nanoscale materials, including metal nanowires, nanoparticles, silicon nanoribbons, carbon black, carbon nanotubes, and graphene have been utilized as sensing materials in wearable devices when they are combined with an elastomer supporting substrate. Especially, graphene has attracted considerable interest after acquiring its single layer by mechanical exfoliation in 2004 [15]. Graphene exhibits excellent electrical, mechanical, thermal, and optical properties such as high thermal conductivity, electron mobility, a large specific surface area, high optical transmittance, exceptional mechanical flexibility, and biocompatible in nature. The atomic thickness of graphene layers allows entire carbon atoms to interact with analytes directly [16]. Interestingly, the recent trends also indicate that wearable biosensors especially graphene-based wearable biosensors attract considerable interest in the recent past as concluded from Table 1.

Graphene has also demonstrated potential in prevention of contagious diseases such as COVID-19. In this regard, wearable e-textiles has played indispensable role in COVID-19 combat [22, 23]. Moreover, graphene and graphene-based materials also exhibit biocompatible property to some extent in terms of wearability. Skin is an ideal bio-integrating platform with graphene-based wearable biosensor and skin is the most usual exposure site for graphene-based materials [24]. Therefore, in order to assess the biocompatibility of graphene in terms of wearability, cutaneous toxicity mechanism of graphene nanomaterials exposed to human HaCaT skin keratinocytes have been studied by few groups. In this regard, mostly, it was observed that few layer graphene (FLG) and graphene oxide (GO) stimulates cytotoxicity as a consequence of persistent mitochondrial depolarization [25]. On the other hand, in vitro cytotoxicity of graphene towards skin keratinocytes and fibroblast has also been investigated in some studies [26]. It was well concluded by the previous works that cytotoxicity of graphene-based materials depends on their oxidative state. As an example, FLG has less toxic effect than that of GO. In addition, micro size graphene structure has high ability to interact with primary human keratinocytes [27]. However, there are too less studies to conclude the biocompatibility of graphene. In order to reduce the toxic effect of graphene-based materials (GBMs), graphene-biomacromolecule-based hybrid materials (graphene biopolymer nanohybrids, graphene polysaccharides) have been synthesized in biomedical and pharmaceutical [28, 29] field. Besides, toxicity can be reduced in a huge margin in case of graphene-based wearable biosensor by avoiding direct contact between GBMs, human body, and biofluids.

In the recent time, there are several literature reviews which mostly focus on either biosensing or wearable application of graphene. For an example, Huang et al. [15] explored all the aspects of the biosensing application of graphene including invasive and non-invasive sampling strategy in the recent times but there is no thorough discussion regarding wearable application of graphene. Healthcare application of graphene in terms of biosensor has been thoroughly discussed by E. Narváez and N. Chauhan et al. [3, 17]. On the other hand, gas and other chemical sensing application of graphene-based flexible sensors have been explored well by Singh et al. [19] with wearable prospective of graphene-based sensors. Similarly, recent advancement and development of graphene-based wearable sensors including physical and chemical sensors have also been well explored by Qian et al. and Kim et al. in their respective literature review [9, 20]. However, all of those reviews failed to provide any detailed insights of wearable biosensing applications of graphene, including non-invasive and minimally invasive sampling strategy. Therefore, this proposed literature review addresses the recent development and advancement of graphene-based wearable sensor for the detection of biofluids such as ISF, sweat, saliva extracted by non-invasive or minimally invasive sampling strategy for the first time. Moreover, discussion regarding detection of analytes from exhaled breath has also been included in this literature review as an extensive application of wearable graphene-based non-invasive biosensor.

In this review, firstly, we have discussed the characteristics and synthesis procedures of graphene, followed by several patterning methods utilized to investigate its application as wearable biosensor along with its sensing mechanism. Moreover, various graphene-based sensing devices based on detection of various analytes from non-invasively collected biofluids sample such as sweat, saliva, ISF, tear as well as exhaled breath have been explored and discussed. Finally, the review has been concluded with challenges and future perspectives for graphene-based wearable biosensors to detect various biofluids. Figure 1 summarizes the prime concept of this review regarding wearable graphene-based biosensors for the detection of biomarkers presence in several biofluids.

Properties and synthesis of graphene

Graphene is a thin-sheet 2D-nanomaterial having honeycomb-like structure with sp2 hybridized carbon atoms. Several forms of the graphene have been discovered so far such as single/mono layer, few layers (2–10), multilayers (> 10), and different derivatives of graphene (e.g., graphene oxide and reduced graphene oxide). Graphene oxide (GO) is a derivative of graphene having surface modified with different functional groups which contain oxygen such as -COOH, -CHO, -COON, OH, and C = O. GO is produced using oxidation of graphite in the presence of some acids [30,31,32]. After oxidation, by applying further steps like ultrasonication and purification, few layers of GO and even mono layer of GO can be obtained. GO has several advantages over pristine graphene such as high surface area, increased binding sites, easier and cheaper fabrication methodologies, easy blending ability with different other materials to produce high quality composites, etc. However, it has low thermal and electrical conductivity than pristine graphene. Therefore, GO is converted to another form of oxidized graphene called reduced graphene oxide (rGO). In this regard, GO is reduced to rGO by removing oxygen containing functional groups [33,34,35,36,37]. Conversion of GO to rGO improves various properties, e.g., thermal conductivity, mechanical properties, electron mobility, etc., which are essential for developing highly selective and ultra-fast biosensing devices. The structure of graphene, GO and rGO are shown in Fig. 2.

Several outstanding physical, chemical, and structural properties of graphene and its derivatives make them one of the most interesting materials for the development of biosensors. In this regard, due to extremely flexible and foldable nature, graphene is considered as a suitable material for the fabrication of wearable biosensor devices [38]. Different properties of graphene are summarized in Table 2. Graphite is made up of several sheets of graphene, one sheet is attached to another sheet by van der Waals force with the interplanar spacing of 1.42 Å between two adjacent sheets. A graphite crystal with 1 mm thickness contains around three million layers of stacked graphene sheets [39]. A graphene sheet contains one atom thick layer of sp2 hybridized carbon atoms where the bond length between adjacent carbon atoms (the C–C bond length) is 1.42 Å, and the thickness of each layer is 0.35 nm [40].

Graphene shows unique electronic and electrical properties. For example, sp2 hybridized carbon atoms contain a high degree of π–π conjugation, where electrons move freely, and this property highly facilitates electrochemical sensing. Besides, graphene possesses high charge carrier mobility (around 200,000 cm2 V−1 s−1) at room temperature [43] and high mechanical strength. For instance, the breaking strength of monolayer graphene is 42 N m−1. Moreover, it also exhibits other remarkable mechanical properties such as Young’s modulus of 1.0 TPa, intrinsic strength of 130 GPa, and third-order elastic stiffness of − 2.0 TPa [44]. In addition, monolayer graphene has a large specific surface area of 2630 m2 g−1 approximately, which provides scope for the attachment of many molecules on its surface. Therefore, it facilitates the development of highly sensitive and miniaturized devices [45]. Furthermore, graphene is also well known for its excellent thermal conductivity. The thermal conductivity of monolayer graphene is found to be in the range from (4.84 ± 0.44) × 103 to (5.30 ± 0.48) × 103 Wm−1 K−1 at room temperature, which is higher than that of single wall (≈ 3.5 × 103 Wm−1 K−1) and multi-wall (≈ 3.0 × 103 Wm−1 K−1) carbon nanotubes. This high thermal conductivity makes graphene a suitable material for electronics devices [46]. The fine structure constant (α = e2/ħc) is used to determine the absorption coefficient of graphene, which means that absorbance and transparency do not depend upon wavelength in this case. A single layer of graphene absorbs approximately 2.3% fraction of incident light over a wide range of wavelength [47]. From the chemistry point of view, pristine graphene is unreactive, but its functionalization with several other elements and materials results in highly increased chemical and electronic properties [48]. Moreover, various layers of graphene show high electrochemical electron transfer rate. The electron transfer occurs due to a redox reaction between graphene surface and a molecule. For example, in case of [Fe(CN)6]3−/4−, the mean electron transfer rates vary from 0.13 (± 0.02) × 10−3 cm s−1 for the bilayer to 2.09 (± 1.27) × 10−3 cm s−1 for 7 layers, with an overall mean value of 0.90 (± 0.13) × 10−3 cms−1 [41]. Electrodes modified with graphene materials demonstrate significant increase in the electroactive surface area. For example, when a glassy carbon electrode surface is modified with GO, for a load of 1.5 mg mL–1, the largest electroactive surface area of 0.0800 cm2 is achieved. Consequently, this modification results in increase in the sensitivity by fourfold and decrease in the limit of detection (LOD) by tenfold, when the electrode is used as sensor for determination of ascorbate [42]. Owing to the extraordinary multiple properties, graphene is a promising 2D material especially for the development of wearable sensors [15].

Methods of graphene synthesis

Theoretical knowledge about graphene existed for over 50 years, but it was not practically explored until 2003. In 2004, Novoselov and Geim isolated and characterized graphene using the “Scotch tape” method [49]. Since then, this material has attracted significant attention in research, as proved by an exponential increase in related published literature. So far, many different methods for graphene synthesis have been established to achieve a better quality of graphene suitable for incorporating in wearable devices. These methods have been grouped into two broad categories: the top-down approach and the bottom-up approach [50, 51]. The top-down approach employs breaking of bulk graphene into monolayer/few-layer of graphene, whereas the bottom-up approach produces graphene from carbon precursors on a particular substrate, usually silicon (Si) or silicon carbide (SiC). Depending upon the requirement of the wearable devices, either of the approaches can be followed. These two synthesis processes have both their own advantages and limitations, as summarized in Table 3. Moreover, different methods for graphene synthesis are also elaborated below along with their respective biosensing and other applications.

Micromechanical exfoliation

The first-ever method applied for graphene synthesis was micromechanical exfoliation. In this method, a sticky tape was used to peel off bulk graphite. In order to obtain a monolayer of graphene, several sticking of tape on graphite was performed (Fig. 3a) [49, 57]. Furthermore, many researchers have applied this method to produce graphene and many improvements have been proposed in this method [58]. Although micromechanical exfoliation is a suitable method to obtain high-quality graphene possessing almost all the properties demonstrated by graphene [59], it is challenging to obtain monolayers of graphene whose lateral dimensions are larger than the order of 10 to 100 µm. Hence, for developing wearable devices, the micromechanical exfoliation method is not viewed as the best choice due to its small-scale limitations.

a Schematic representation of the graphene synthesis by micromechanical exfoliation method. Reprinted with permission from [57]. Copyright 2012 Institute of Physics Publishing. b Schematic process of liquid phase exfoliation (LPE) production of graphene. Reprinted with permission from [60]. Copyright 2009 Springer Nature. c Schematic of a common chemical vapor deposition setup for synthesis of graphene. Reprinted with permission from [61]. Copyright 2020 Multidisciplinary Digital Publishing Institute. d Photograph of the GO before and after reduction with L-ascorbic acid and HRTEM images of reduced GO. Reprinted with permission from [62]. Copyright 2010 Elsevier. e Schematic illustration of fabrication of a laser scribed graphene (LSG) electrodes on a polyimide (PI) sheet. Reprinted with permission from [55]. Copyright 2016Wiley-VCH. f Schematic diagram for synthesis of the 3D graphene aerogel fibers. Reprinted with permission from [63]. Copyright 2012 American Chemical Society

Liquid-phase exfoliation

For the production of wearable devices, liquid-phase exfoliation (LPE) is an efficient and effective way to fabricate few-layer and multilayer graphene. Different graphitic materials such as graphite oxide, natural graphite, graphite intercalation compound (GIC) can be used as a precursor for graphene production. LPE follows a top-down approach for graphene synthesis. Also, the LPE method utilizes solvents such as hydrogen peroxide, sulfuric acid, acetic acid, water, and other solvents for exfoliation of graphite using external forces generated from techniques, e.g., stirring, sonication, shearing forces, ball milling [64, 65], etc. Although, graphene fabricated by LPE is usually a little defective due to the use of solvents, it has several advantages such as cost-efficient, suitable for large-scale production, and the ability of the dispersed graphene to be deposited on various substrates. LPE employs mainly four steps for successful synthesis of graphene: firstly, immersion of graphite into the liquid medium, secondly, intercalation of the graphite, thirdly, the exfoliation of graphene flakes, and finally, the stabilization of the exfoliated materials isolated in the medium. Considering the advantages of the LPE method, there are several LPE-based graphene synthesis methods reported previously. For example, graphene was produced in high yield using liquid-phase exfoliation of graphite [66]. For this production, N-methyl-pyrrolidone was used as a solvent and the external force was provided by sonication. Furthermore, characterization performed by transmission electron microscopy (TEM), Raman spectroscopy and electron diffraction confirmed the successful formation of monolayers of graphene. This method produced a very high quality and unoxidized graphene monolayer, with approximately 1 wt% yield. Moreover, produced layers did not show any significant structural defects as confirmed by X-ray photoelectron spectroscopy (XPS), infrared, and Raman spectroscopies. It was proposed that further solution processing of graphene may open many avenues, such as developing functional electronic devices. Furthermore, a liquid-phase exfoliation method called solvothermal-assisted exfoliation process was also used for the production of monolayer as well as bilayer graphene sheets from expanded graphite (EG) precursors using acetonitrile (Fig. 3b) [60]. In this case, the dipole-induced interactions between acetonitrile and graphene caused the exfoliation of graphene. Monolayer as well as bilayer of graphene was further separated by centrifugation. In this regard, during the production of high yield and high-quality graphene, use of any kind of stabilizer or modifier reagent was strongly avoided. Nascimento et al. [65] realized the production of a few-layer of graphene by LPE using 1-cyclohexyl-2-pyrrolidone (CHP)/water mixtures as a medium. The obtained dispersed graphene has flakes which are mostly thinner than that of 5 layers with low defect density (8.3 × 10−3 nm−2) and lateral dimensions in the order of 100 nm. Low et al. [52] demonstrated liquid phase exfoliation as well as solvothermal growth synthesis of graphene/zinc oxide nanocomposite to develop biosensors. Amperometry and cyclic voltammetry (CV) analysis was used to evaluate the electrochemical performance of graphene/zinc oxide nanocomposite-modified screen-printed carbon electrode (SPCE)-based biosensor. The electrode demonstrated enhancement in electrocatalytic activity by reducing hydrogen peroxide (H2O2). Furthermore, the nanocomposite was also used to fabricate an electrochemical DNA sensor to detect the Avian Influenza H5 gene.

Chemical vapor deposition

Chemical vapor deposition (CVD) follows the bottom-up approach for graphene synthesis. CVD is considered as the best method for the synthesis of graphene with high quality and large surface areas. Moreover, synthesis strategy by CVD is widely employed due to its simple experimental setup in research laboratories as well as for long-term operation in industrial settings. Moreover, it also has large-scale production capacity. CVD is a chemical process in which a solid thin film of graphene is usually deposited onto transition metal (for example, Cu, Co, Fe, Ni, Pd, and Ir) substrates, with the help of hydrogen (H2) gas flow as a precursor, at a very high temperature [67]. Many times, methane (CH4) gas is also used as a reactant. After the discovery of graphene, the first successful production of graphene using the chemical vapor deposition method was reported in 2008 by Coraux et al. [68]. The graphene film was grown on Ir which demonstrated large-scale continuity of its carbon rows with a relatively low density of defects. Furthermore, several studies have been reported on the fabrication of graphene using CVD. For example, a graphene bilayer was prepared on platinum Pt (111) by sequential chemical vapor deposition [69]. This production required a four-step process; in the first step, monolayer graphene was prepared on Pt (111) using thermal decomposition of C2H4. The second step involved deposition of thick Pt film, and in the third step, the fabrication of a second layer of graphene was performed. The last step used post-annealing in which the buried monolayer was diffused entirely to the surface, resulting in the formation of extended bilayer domains of graphene. Characterization by scanning tunneling microscopy unraveled the significant growth of graphene. In another study, graphene was deposited by CVD as a durable anticorrosive coating on copper using ethanol as a carbon source (Fig. 3c) [61]. Methane (CH4) was used as gas precursors to provide stable carbon flow at average growth temperature set around 1000 °C. Consequently, a thin film of double-layered graphene was formed, as confirmed by surface and structural characterization. Graphene-coated copper was kept for more than 1 year at ambient temperature, which exhibited no considerable change in the anticorrosive behavior of graphene.

Graphene has also drawn considerable interest for the development various electronic devices. In this case, for the production of electronic devices, graphene should be grown on a large surface area. In this regard, Li et al. [70] proposed that growing few-layer graphene or large-area graphene films on metal substrates, e.g., Cu and Ni, was promising by the CVD of hydrocarbons. With the CVD method, high quality of graphene with uniform thickness could be obtained, which demonstrates its potential application in the development of electronic devices. One preferable CVD method was used to fabricate functional devices by transferring of graphene on Si or SiO2/Si substrate. However, the process shows some degree of contamination. In order to overcome this issue, Ge (001)/Si (001) substrate has been introduced to transfer graphene. Additionally, electron mobility of graphene grown on Ge(001)/Si(001) is quite high [71, 72]. Vyshkvorkina et al. performed a study to compare CVD-grown and exfoliated graphene for its application in biosensors [53]. The results suggested that CVD-grown graphene can be efficient material for the development of surface plasmon resonance (SPR) and surface-enhanced Raman scattering (SERS)-based biosensors, while the exfoliated graphene can be suitable to develop various nanosensors based on nanoelectromechanical systems (NEMS).

Reduction of graphene oxide

GO does not contain all the properties of pristine graphene. Therefore, it is always imperative to reduce GO back to graphene to restore unique properties required for functional wearable devices. For example, GO is an insulator material, which can be converted into a conductor by reduction. However, complete removal of oxygen is not possible, which results in only partial recovery of sp2 conjugated network of graphene [73]. The obtained material by reduction is called chemically transformed graphene/chemically modified graphene/reduced graphene oxide (rGO). Reduction of GO is performed by many different methods, such as, chemical reduction [33], electrochemical reduction [35], thermal reduction [34, 54], and green reduction [74]. Among the various strategies to reduce GO, the formation of single layer graphene from redried GO by thermal exfoliation or reduction was initially induced by the rapid degradation of epoxy and hydroxyl groups with the generation of gases like CO2 in the interlayer space [45, 75]. The prime advantage of this methodology is the fast reduction process exceeding the diffusion rate of gases. Besides, high annealing temperature leads to clean the carbon sheet resulting in high electrical conductivity. However, it is well noted that a minimum applied temperature of 550 °C is required to facilitate the reduction phenomena [45]. Moreover, some defects related to topology and vacancy still remains on the reduced sheet even after decomposition of the groups with the release of CO2 with high annealing temperature [76]. On the other hand, a special thermal reduction method called laser scribing has been widely used over the last decade [77]. Laser scribing is a facile, fast, and cost-efficient method for the production of graphene. The graphene produced from this method is called laser scribed graphene (LSG) method. Numerous studies have been taken to develop biosensors using LSG method. For example, LSG was fabricated as electrode patterns on a polyimide (PI) sheet (Fig. 3e) and utilized as on-chip electrochemical biosensor for the detection of biomarkers, such as ascorbic acid (AA), uric acid (UA), and dopamine (DA) [55]. Moreover, Scardaci et al. have utilized LSG for humidity sensing application [78]. In this regard, continuous wave (CW) laser beam was employed for the reduction of graphene under different controlled atmospheres, such as air, Ar, N2, and in a 95:5 (v/v) Ar/H2 mixture. The atmosphere of irradiation highly influences the laser scribing effects, such as degree of reduction, chemical composition, and electrical properties of reduced GO. The materials produced in pure Ar yielded the fastest response and highest sensitivity, whereas mixtures of Ar and Ar-H2 produced the highest order in humidity sensing. So, the results suggested the importance of controlling the atmosphere in LSG method. LSG method is also an efficient strategy to produced porous graphene structure. Most of the previously reported methodologies to produce porous graphene structure requires high-temperature processing or chemical synthesis routes with several steps which usually rises the graphene synthesis cost. To make the laser scribed graphene production cost-efficient, use of different commercial polymer sheets with cyclic imide group in their molecular chain have been proposed. For example, Lin et al. used a CO2 infrared laser under ambient conditions to transform polyimide (PI) into porous laser-induced graphene (LIG). Besides, poly(etherimide) could also be converted to porous graphene structure at ambient temperature [79]. Moreover, a laser scribed graphene film could also be produced from polydimethylsiloxane (PDMS) films. The produced graphene films demonstrated excellent flexible properties and high electrical conductivity, thus facilitating its use as flexible conductive layer. A skin-like pressure sensor was also developed using these layers, which exhibited ultrahigh sensitivity (∼ 480 K Pa−1) while maintaining excellent cycle stability (> 4000 repetitive cycles) and fast response/relaxation time (2 μs/3 μs) [80].

On the other hand, femtosecond laser direct writing (FsLDW) is another near infrared (NIR) method for the photoreduction of GO. In contrast with LSG method, FsLDW operates in different optical wavelength (790 nm). Moreover, FsLDW technique facilitates complex designable patterning and controllable photo-reduction of GO thin film in comparison with LSG method. In this regard, 100X objective lens (NA:1.4) is employed to concentrate LASER as reported by Zhang et al. [81]. This technique was utilized to directly produce all-graphene-based devices consisting of GO as the sensing material as well as electrodes. Also, the FsLDW technique surpasses the complex manufacturing process by enabling scalable sensor integration on flexible substrates in a single step which makes it more convenient than that of LSG method.

On the other hand, apart from thermal reduction, some reducing reagents could also be utilized to induce chemical reduction of GO at room temperature by allowing deoxygenation to occur at moderate temperature. In this regard, selective reduction of specific type of oxygen containing group usually takes place. The chemical reduction method is used most frequently for large-scale production of graphene. In this regard, various chemicals, such as borohydrides [82], ascorbic acid [83], hydrohalic acids [84], hydrazine [85], hydroquinone [33], etc., have been utilized for the reduction of graphene oxide. This process takes only 30 min and produces graphene sheets with high bulk electrical conductivity (2.1 × 103 S m−1). Moreover, this reduction results in removal of majority of oxygen-containing functional groups as proved by XPS analysis (Fig. 3d) [62]. Among various chemical reagents, hydrazine can selectively reduce epoxy groups which is initialized by the opening of epoxy ring followed by the generation of amino-aziridine moiety [34, 86]. The amino-aziridine moiety is further transformed to a double carbon bond when di-imide is removed thermally. Strength of chemical reagents play an indispensable role to improve the degree of reduction depending upon the standard reduction potential of the reagents. As an example, standard reduction potential of aluminum powder is quite negative with the value of − 1.68 V than that of the well-known reducing agents such as hydrazine and hydride which stood at − 1.16 V and − 1.24 V, respectively. With the incorporation of hydrochloric acid, aluminum powder can reduce GO more efficiently with high standard reducing potential [62]. In another study, a spontaneous reduction of GO was observed with the incorporation of zinc powder due to the wide gap of standard potential between Zn/Zn2+ (− 0.76 V) and GO (− 0.40 V) [87]. Thus, it is well noted that high standard potential difference between GO and reducing agent plays a prime role to improve the reduction phenomena significantly. Besides, alkaline solution could also play a pivotal role to reduce GO. As an example, in the presence of NaOH, the reduction potential of Al and Zinc are − 2.33 V and − 1.2 V, respectively, which results in faster reduction of GO in case of Al than that of zinc which usually takes longer time to reduce [88]. Therefore, it is well noted that the strength of the reducing agents to reduce GO depends on their standard reduction potential value. Although, reduction of GO is an indispensable key strategy to eliminate oxygen and restore the original graphene structure, most of the above-mentioned reducing methods exhibit significant number of defects. In addition, different residual functional groups still remain on reduced graphene sheet. Moreover, thermally and chemically reduced sheets have high tendency to agglomerate in the presence of adhesion force between the layers. On the other hand, high electrical conductivity as well as thermal stability of reduced GO could also be achieved through the reduction by hydrogen arc discharge exfoliation resulting in magnificent electrical conductivity of 200,000 S/m and high thermal stability with oxidation resistance temperature of 601 °C [89]. However, high current density is still necessary to initialize the arc discharge effect. The reduction methods can also be further assessed in terms of degree of reduction. Degree of reduction is one of the prime parameters which modulates thermal and electrical conductivity as well as mechanical strength and chemical performance of the reduced sheet as per the reduction method of GO [90,91,92,93]. Moreover, the bandgap, work function, and number of defect sites could be measured in terms of the degree of reduction. Usually, it is determined by the content of residual oxygen remained on the reduced sheets as probed by XPS or EDS (energy-dispersive spectroscopy) [94]. In addition, conductivity test is also an alternative strategy where electrical conductivity of the reduced sheet is directly proportional to reduction degree [95]. In case of thermal and hydrothermal reduction method, the degree of reduction could be enhanced to a certain extent by the virtue of increasing reduction time and temperature [95]. For the further improvement of reduction degree, precise chemical tuning is a prime concern. In addition, thermal reduction methods such as LASER scribed method or other photon induced strategies might be beneficial where light power intensity, exposure time and ambient conditions can be tailored to control reduction degree which results in precise manipulation of the depth and electrical conductivity of reduced GO film. Moreover, precise control over LASER scanning speed and shifting pitch is quite efficient to achieve higher degree of reduction with desired microscopic engineering of GO sheet.

Three-dimensional graphene synthesis

Traditionally, graphene has been utilized as a two-dimensional (2D) material. It also can be synthesized, distributed, hybridized into different 3D materials producing structures, such as aerogels, hydrogels, sponges, and foams. These 3D materials have several outstanding properties, e.g., large surface area, low density, high porosity, stable mechanical properties, fast electron, and mass transport. Moreover, 3D graphene materials widely expand their application into different fields like batteries [96], capacitors [97], biosensors [56], environment [98], and catalysts [99].

Synthesis of 3D graphene follows both the top-down and bottom-up approaches. In the top-down approach, a template is required as a skeleton for the growth of graphene. A 3D graphene foam was grown using the CVD method on a porous Cu/Ni foil, followed by removing the Cu/Ni substrate through etching [100]. In the bottom-up approach, the hydrothermal reduction method is widely applied for 3D graphene synthesis. Dabiri et al. firstly prepared GO from graphite and then mixed it with ethylenediamine (EDTA) to synthesize 3D graphene hydrogel by hydrothermal treatment. Further, freeze drying was performed to produce 3D graphene aerogel [101] (Fig. 3f).

3D graphene materials could be categorized into several prototypes as per previously reported works. In this regard, in order to ensure interaction scale of 3D graphene, it can be classified into two subcategories, such as (1) 3D graphene macrostructure with dimension more than 100 µm in one or more directions, e.g., 3D graphene foam, sponge, aerogels, microsphere, fiber [63], film, and micropillar [63, 102,103,104,105,106], and (2) 3D graphene microstructure-based materials with dimension less than 100 µm in all direction, which usually looks powder in macroscopic scale [107, 108]. In order to build a macroscopic 3D graphene, GO is utilized as building block which can be assembled through either self-assembly or reduction of GO. There are two types of interactions facilitating self-assembling of GO including (1) binding interaction generated from hydrogen bonding, π − π interaction, and hydrophobic effect, and (2) 3D interaction from electrostatic repulsion formed by functional groups and hydration [109,110,111]. During the reduction of GO, the enhancement in π − π interaction method could be observed where the cross-linking sites with − CH2 − and − CH2O − moieties could be transformed into conductive sp2 carbon bridges [112].

Methods for patterning graphene

Since 2004, graphene has given hope for scientists and industrialists with its remarkable properties which has proven its potential in various applications. Many researchers have explored the usage of graphene, and the impact of its patterning methods which is considered as a crucial factor for better performance. Graphene patterning can be conducted after synthesis or along with synthesis based on the application for both single layer and multilayer. The choice of patterning could be depended on various factors, such as application, method of synthesis, layers, etc. Some of the most widely used patterning methods are photolithography, electron-beam (E-beam) lithography, focused ion-beam lithography, laser scribing, inkjet printing, and screen printing which have been discussed in detail in the following section. Moreover, the comparison of different patterning techniques used in graphene-based devices is also summarized in Table 4.

Photolithography

The standard photolithography method is used for graphene patterning. As mentioned earlier, the CVD-grown graphene is typically obtained on a copper sheet, while the synthesized graphene is transferred onto the required surface. The CVD-grown graphene thickness is ideal for photolithography, and thus, graphene patterning can be achieved by coating on a photoresist as per need and then treating with plasma etching [122]. As photolithography is a common technique for graphene patterning, it is considered as an easier way for scale-up [123]. A schematic example of device fabrication based on photolithography is presented in Fig. 4a. The simplicity and broad applicability of photolithography made this technique more acceptable in sensor developments. Zhou et al. developed a label-free detection system for detecting cancer biomarkers using graphene field-effect transistor (GFET) based on photolithography [113]. Throughout the innovative graphene device developments, we can see various examples using photolithography [124,125,126].

a Schematic diagram of photolithography process. Reprinted with permission from [122]. Copyright Faculty of Engineering, Chulalongkorn University. b Schematic diagram of e-beam lithography. Reprinted with permission from [122]. Copyright Faculty of Engineering, Chulalongkorn University. c Schematic diagram of focused ion beam lithography used for milling and deposition. Reprinted with permission from [127]. Copyright 2021 Institute of Physics Publishing. d Schematic diagram of DVD laser scribing for graphene patterning. Reprinted with permission from [128]. Copyright 2013 Springer Nature. e Schematic showing water-based inkjet printing of graphene patterning. Reprinted with permission from [129]. Copyright 2021 Elsevier. f Schematic diagram of screen printing of graphene. Reprinted with permission from [130]. Copyright 2019 American Chemical Society

Electron-beam lithography

Electron-beam (E-beam) lithography (EBL) is a method that uses a focused electron beam to produce the desired pattern in a suitable recording medium [122]. E-beam lithography provides lithographic resolution in nanometer-scale and makes it possible to write complex patterns for various applications. Fischbein et al. have demonstrated that the technique can be used to create nanometer-scale pores, slits, and gaps on the graphene surface, with the help of e-beam irradiation from a transmission electron microscope [131]. A schematic diagram of e-beam lithography is shown in Fig. 4b. The method is used to develop different graphene-based sensors, such as peptide-enabled biosensors for detecting different biomarkers, especially cancer biomarkers [114, 115].

Focused ion-beam lithography

Focused ion-beam lithography (FIBL) is a site-specific material removal or material deposition technique used to create the desired patterns [127]. The patterning is achieved typically using the collision of gallium ions [132]. This technique is used for nanofabrication processes, such as milling, etching, etc., with excellent controllability of the size and structure (Fig. 4c). To achieve precise nanofabrication with high resolution, helium ions have been proposed to replace conventional gallium ions [133, 134]. The applications of this specific method is explored by many researchers, and they have developed a biomolecule detection sensor using graphene with focused ion-beam lithography (FIBL) [116].

Laser scribing

Laser scribing is a method in which the laser is used to create small cuts over the material (Fig. 4d). This technique helps to reduce micro cracks during patterning [20, 128]. As this technique is a more efficient method to directly modify graphene, it is widely used for patterning. The pattern is loaded and developed with the help of lasers over carbon sources or polymers. Being an efficient and easier method, this technique is adapted in the development of various biosensors. Vanegas et al. used laser scribed graphene to create a biosensor for the detection of biogenic amines in food samples [117].

Inkjet printing

Inkjet printing is a widely employed technique that uses a programmable controller to spray ink through a well-controlled ejection of ink droplets to obtain the desired pattern [20, 135]. The ink, which can contain various chemicals such as graphene, is sprayed through a nozzle to the substrate. The technique could be used for a lot of applications all around the world with digital and additive patterning. The schematic diagram of inkjet printing is shown in Fig. 4e [129]. Graphene inks could be an excellent replacement for conventional carbon-based inks, as the latter shows limited conductivity [136]. Secor et al. has developed and demonstrated the usage of graphene ink to print highly conductive graphene patterns for flexible electronics [137]. The inkjet printing is highly usable in bio sensing also, such as Xiang et al. developed a biosensor based on FET fabricated by inkjet-based graphene printing on a flexible substrate [118]. Kudr et al. developed a HT-2 mycotoxin immunosensor from graphene oxide printed by inkjet [119].

Screen printing

Screen printing is similar to other printing methods such as inkjet printing and gravure printing [130]. However, the process requires a printable ink, a stencil mesh, and a squeegee as the main elements. The ink is deposited on the stencil in front of the squeegee. Thereafter, the ink is emptied and evenly spread using the squeegee to form the patterns (Fig. 4f). Even though a major part of the ink will be transferred onto the substrate, some parts of the ink will still remain in the mesh. The concept of screen printing is applied also majorly in textile industry [138] and flexible electronics production [120, 121].

For flexible electronics production, mainly conductive inks are used. Therefore, as graphene has really good conductive properties, it is an excellent choice for ink production and screen printing [130]. The prepared graphene ink is transferred on to the substrate to produce thick film patterns for the developments of biosensors and flexible electronics.

Other patterning methods

There are many other conventional and non-conventional patterning methods used by different researchers for the effective patterning according to their need. Some of these techniques are derivatives of the abovementioned methods and some are entirely unconventional. Oliveira et al. has used self-assembly method to develop a graphene-based biosensor to detect urea and penicillin in which they observed improved sensing performance in comparison to the conventional sensors [139]. Secor et al. demonstrated gravure printing technique to directly pattern the surface which removes the need for etching, to develop flexible electronics using graphene [140]. Ameri et al. used direct dry patterning, i.e., direct patterning using a mechanical cutter to develop patterns of graphene for developing epidermal tattoo like sensor [141]. Zhao et al. explored the usage of microwaves for patterning graphene [141]. New patterning methods will likely be introduced according to the need and structure of the pattern. The patterning of graphene layers and graphene derivatives are highly usable to modify the performance of various sensors.

Sensing strategies used in wearable graphene-based biosensors

There are several biosensing strategies followed in graphene-based biosensors such as colorimetry, surface plasmon resonance (SPR), fluorescence spectrometry, mass spectrometry, and gas chromatography. However, most of those techniques require cumbersome or expensive instruments with complex operating or transduction methodology which are not suitable for wearable application of graphene-based biosensors. In order to avoid this major bottleneck, electrochemical-based sensing strategies have been mostly followed in wearable application of graphene-based biosensors owing to their adaptability in wearable format, sensitive response, selectivity, and fast response. Different electrochemical sensing strategies employed in wearable sensors have been discussed in the following.

Chronoamperometry

Amperometry is an electrochemical approach in which variations in current caused by electrochemical oxidation and reduction are recorded directly with time while a constant potential is determined at the working electrode in relation to the reference electrode (Fig. 5a (i, ii)) [142,143,144,145]. In amperometry, platinum is often used as the working electrode to measure oxygen reduction while Ag/AgCl is employed as the reference electrode to measure current at a constant potential [146]. The current generated by the faradaic reaction is proportional to the concentration of the electroactive species in the sample [147, 148]. At constant potential, electron transfer takes place at a diffusion-controlled pace; hence, the process is now governed by mass transfer. The diffusion regulated current I is determined by the diffusion layer thickness \(\delta\), the analyte diffusion coefficient D, the electron transfer number n, the electrode surface area A, the analyte concentration C, and the Faraday number F (96,480 C mol−1) as illustrated in Eq. (1):

where \({C}_{bulk}\) and \({C}_{x=0}\) represent the analyte concentration in the bulk solution and concentration of the surface of the electrode, respectively.

a Measurement setup of chronoamperometry and its corresponding sensing performance. a (i) Reprinted with permission from [144]. Copyright 2020 Springer Nature. a (ii) Reprinted with permission from [149]. Copyright 2021 American chemical society. b Measurement setup of cyclic voltammetry and its corresponding sensing performance. (i) Reprinted with permission from [150]. Copyright 2012 Wiley–VCH. (ii) Reprinted with permission from [151]. Copyright 2018 Elsevier. c Measurement setup of potentiometry and its corresponding sensing performance. (i) Reprinted with permission from [152]. Copyright 2019 Elsevier. (ii) Reprinted with permission from [153]. Copyright 2019 Elsevier. d Measurement setup of conductometry and its corresponding sensing performance. (i) Reprinted with permission from [154]. Copyright 2021 Multidisciplinary Digital Publishing Institute. (ii) Reprinted with permission from [155]. Copyright 2019 Springer Nature. e Measurement setup of EIS and its corresponding sensing performance. (i) Reprinted with permission from [156]. Copyright 2019 Multidisciplinary Digital Publishing Institute. (ii) Reprinted with permission from [157]. Copyright 2021 Elsevier

Chronoamperometry employs pulsed amperometric detection with a few microliters of solution without stirring. For an instance, a wearable sweat sensor has been proposed which was based on rGO/SiO2 nanocomposite, glucose oxidase (GOx) and Nafion (NF) coated conductive and flexible substrate comprised of a carbon nanotube film and polydimethylsiloxane (C-PDMS). Sensing performance of NF/GOx/rGO/SiO2/C-PDMS was evaluated by using amperometric I − T curve analysis for different concentration of glucose at an operating potential of 0.4 V and after 100 s, the equilibrium current values were fitted [149]. The biosensor exhibits glucose detection range of 0.1–9 mM with sensitivity of 60.8 µA mM−1 cm−2. In this regard, one benefit of chronoamperometric analysis is that it can determine the diffusion coefficient even when sluggish heterogeneous electron transfer kinetics are present, because the potential may be stepped to a suitably positive or negative value where the process is under diffusion control. As in this case, mass transport is exclusively regulated by diffusion under these conditions, the current as a function of time reflects the concentration gradient near the electrode surface. As a result, according to the Cottrell equation, the current diminishes with time where n, F, A, C, D, and t are the number of electrons transformed, Faraday’s constant, the surface area, the concentration, the diffusion coefficient, and time, respectively. The current can be related to the concentration of electroactive species as [158] follows by Eq. (2):

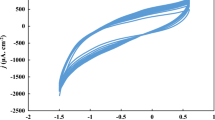

Cyclic voltammetry

Voltammetry is an electrochemical technique that measures current by altering potential. There are several types of voltammetry including polarography (DC voltage) [159], linear sweep, differential staircase, normal pulse, reverse pulse, differential pulse, and others [160]. The voltage is measured between the reference and working electrodes, while the current is measured between the working and counter electrodes as shown in (Fig. 5b (i, ii)) [150, 151]. The Nernst equation governs cyclic voltammetry (CV) and an electrochemical method is used for measuring current under high voltage. The Nernst equation is used to calculate the cell potential in relation to the standard potential and the activities of electroactive species [150, 161] by applying the following equation (Eq. (3)) (where E = reduction potential, E0 = standard potential, R = universal gas constant, T = temperature in Kelvin, n = mole of electrons, F = Faraday constant):

Potentiometry

Potentiometry is a technique to measure the potential difference between working electrode and reference electrode (Fig. 5c (i, ii)) in an electrochemical cell when no or little current flows between them [142, 146, 152, 153, 162]. The Nernst equation already explains the link between concentration and potential. Direct measurement of analyte ion concentration using the Nernst equation is referred to as direct potentiometry. The ion selective electrode (ISE) achieves the lowest detection limit and also functions as a transducer, which is an electrochemical sensor based on a thin film or selective membrane as a recognition element [163]. Potentiometry can readily measure small sample volumes and pH electrode is the most frequent potentiometric device, however other ions such as F−, I−, CN−, Na+, K+, Ca2+, and NH4+ could also detected. Many potentiometric devices use various types of field effect transistor (FET) devices to monitor pH changes, selective ion concentration, and the kinetics of biocatalytic and reaction processes.

Conductometry

Conductometric measurements are connected to a solution’s capacity to conduct an electric current (Fig. 5d (i, ii)) [154]. It is a universal approach for detecting ions that is used to examine ionic species and monitor a chemical reaction by evaluating the electrolytic conductivity of reacting species and the resulting product. It is the most commonly employed to examine enzymatic reactions and various biological membrane receptors using interdigitated microelectrodes, ion conductometric and impedimetric devices [162, 164]. The electrolytic conductance, G, of a medium is equal to the reciprocal of its electrical resistance R in ohms can be expressed as

If we consider the electrolytic cell with two electrodes having cross-sectional area A in m2 and separated by a distance l in m, then the resistance R of electrolytes solution present between the electrodes is

where ρ is the proportionality constant called specific resistivity. Substituting the value of R from (5)

where K is reciprocal of specific resistance called specific conductivity and is measured in Ω−1 m−1. In the SI system, the unit of conductance is “Siemens” (S). Hence, the unit of specific conductivity will be [S m−1], where A is the area of cross section (m2), l is the length (m), and G is the conductance (Ω−1).

Electrochemical impedance spectroscopy

Electrochemical impedance spectroscopy (EIS) is a strong tool for material characterization in electrochemical systems. It is helpful for the monitoring of changes in electrical characteristics caused by biorecognition processes at the surface of modified electrodes. Protein immobilization and antibody-antigen reactions on the electrode surface can be used to evaluate the changes in conductance [165, 166]. The basic strategy of the EIS method is to apply a small amplitude of sinusoidal excitation signal and to measure the response as current, voltage, or another signal of interest (Fig. 5e (i, ii)) [156, 157, 167]. Moreover, it is often monitored with a modest excitation pulse, resulting in a pseudo-linear cell response. The current response to a sinusoidal potential in a linear system will be sinusoidal at the same frequency but displaced in phase, as illustrated below. The excitation signal has shape when expressed as a function of time.

where Et is the potential dependent on time, E0 is the amplitude of signal, and ω is the radial frequency. The relationship between radial frequency ω (expressed in radians/second) and frequency f (expressed in Hertz) is:

In linear system, the response signal, It, is shifted in phase (Ф) and has different amplitude

An expression analogous to ohm’s law allows us to calculate impedance of system as:

As a result, the impedance (Z) is represented in terms of a magnitude, Z0, and a phase shift Ф as mentioned above.

Classification of graphene-based wearable biosensors

Human skin is the most accessible organ of body fluids related to the current health conditions [168]. Body fluids are broadly classified into two categories, such as intracellular and extracellular. Biofluids secreted through the human body are saliva, sweat, tears, and intestinal fluid (ISF). These biofluids are considered as an important source of biomarkers for disease diagnosis as well as monitoring, since it is easy to collect them to provide rapid results. Concentration of different biomolecules depends on the type of the sampled biofluids. For instance, sweat contains high concentration of proteins, hormones, and DNA, making it an attractive biofluid for non-invasive health monitoring [169, 170]. Intestinal fluid is another chemically rich biofluid and contains many molecules similar to those found in blood [171]. On the other hand, saliva is the easiest to obtain biofluid. Moreover, it contains variety of electrolytes including sodium potassium, calcium, magnesium, bicarbonate, and phosphate [172]. However, the concentration of the available biomolecules in saliva are mostly low. Similarly, tear composition also includes high concentration of salts, proteins, lipids etc. In this regard, by detecting the protein level, syndrome such as dry eye can be identified [173]. In addition, exhaled breath is an excellent source for detecting various biomarkers and moisture content [174]. Therefore, wearable sensors based on these biofluids and exhaled breath are the most promising candidate for the next generation diagnosis system and in present [175].

Biofluid sensors and breath sensing devices

Sweat sensing devices

Sweat plays an important role in continuous disease progression monitoring, non-invasive detection, effective data gathering and reading. Sweat as biofluid performs an important excretory role by removing excess micronutrients, metabolic waste, and toxicants from the body [176].The body has three types of sweat glands, i.e., eccrine, apocrine and apoeccrine [177]. Eccrine sweat glands are found almost everywhere on the body's surface and are responsible for the majority of sweat output. Apocrine and apo-eccrine glands, on the other hand, have a minor influence on general sweat production [178]. Human body contains 2–4 million eccrine sweat glands on both glabrous (palms, soles) and non-glabrous (hairy) skin [4]. Sweating can be produced by physical exertion, thermal heating, and stress or iontophoretic activation. Sweat contains metabolites (lactate, glucose, urea, ethanol, or cortisol) along with electrolytes (sodium, potassium, chloride, or ammonium), trace elements (zinc or copper), and a small number of large molecules (proteins, nucleic acid, neuropeptides, or cytokines) [4]. In addition to glucose, lactate is also one of the most important metabolites found in sweat [179]. It is a waste product formed during glycolysis process. Under the normal condition, liver absorbs 70% of the lactate but under abnormal condition, such as liver necrosis, the liver fails to absorb lactate, and it cause muscle fatigue and acidosis. A sensitive and specific immunosensor has been developed for detection of lactate in sweat sample where lactate antibodies were bio-conjugated to the electro reduced graphene oxide (e-RGO) using carbodiimide chemistry (Fig. 6a) [145]. Moreover, sweat lactate is also useful in reflecting the poor oxidative metabolism and in pressure ischemia as reported by few groups [180]. On the other hand, diabetes is a chronic disease related to inadequate insulin synthesis in the cell and is difficult to cure or prevent after being diagnosed. By proper glucose monitoring, measurement technique one can increase treatment efficiency and simplify patient lifestyle [181,182,183]. The classic glucose testing method, “finger pricking,” is a well-known method for detecting blood glucose, but it has a major drawback that leads to patient non-compliance. As a result, there is an urgent need to develop non-invasive glucose monitoring methods since human sweat samples contain a variety of analytes [184,185,186,187]. Skin worn GOx/Pt-modified graphite-based stretchable biosensor has been successfully applied to monitor glucose in human perspiration through the quantification of hydrogen peroxide (H2O2) reduction by chronoamperometry at − 0.35 V vs pseudo-Ag/AgCl. The sensor have a linear range between 0 and 0.9 mM with limit of detection of 0.010 mM [188]. On the other hand, the CVD-grown graphene-based FET sensor hold great promise in continuous glucose monitoring based on wearable platform. In this regard, PET was used as a substrate, and CVD-grown graphene was functionalized on PET with a linker molecule. The fabricated sensor could detect glucose level in the range of 3.3–10.9 mM with limit of detection of 3.3 mM by the precise quantification of Dirac point shift and differential source current [189]. Patch-based flexible and miniaturized electrochemical glucose biosensor comprising of a hybrid working electrode which consists of electrochemically deposited gold/platinum nanoparticles and platinum alloy nanoparticles (AuPt NPs) onto rGO surface and chitosan-glucose oxidase composites was successfully developed to measure glucose in a solution of human sweat. The fabricated biosensor exhibited excellent amperometric response for glucose detection at a detection range of 0–2.4 mM (within the clinical range if glucose in sweat), with a sensitivity of 48 μA/mM cm2, a short response time (20 s), and high linearity (99%). The limit of detection for glucose was calculated as 5 μM (Fig. 6b) [151]. On the other hand, hybrid hydrogel nanocomposites have also shown great potential in glucose level detection. A recent example of the hydrogel-based prototype of glucose biosensor device was fabricated by deposition of polyaniline (PANI) on rGO. The thermally exfoliated graphene oxide (TEGO) helps in the formation of additional crosslink, thereby increasing electrochemical property. The sensor exhibits glucose detection range of 0.2 μM–10 mM with limit of detection of 0.2 μM [190]. Furthermore, it was well noted that graphene doped with gold and combined with a gold mesh has improved electrochemical activity over bare graphene which was sufficient to form a wearable patch for sweat-based diabetes. In this regard, a stretchable device was developed which features a serpentine bilayer of gold mesh with glucose detection range of 10 μM–0.7 mM and limit of detection of 10 μM [191]. Furthermore, a simple and easily wearable device was also developed for simultaneous monitoring of glucose and lactate in human sweat without direct contact of the active part with skin. In this method, glucose oxidase and lactate oxidase were anchored to graphene oxide and chitosan composite (GO-Ch) to achieve stable deposition of the bio-receptors on the electrochemical platform. The device was integrated with the capillary flow system activated by a nitrocellulose strip to collect and deliver sweat on the sensor platform with limit of detection of 9.6 μM and 20 μM for glucose and lactate, respectively [192]. Besides, non-enzymatic and simultaneous detection of glucose and lactate have also attracted considerable interest. In this regard, metal-based organic framework (MOF) electrodes were used as non-enzymatic electrochemical biosensors for detection of glucose and lactate. In this method, the electrode was functionalized by amino-functionalized graphene paper modified with 2D oriented assembly of Cu3(btc)2 (BTC = benzenen 1,3,5-tricarboxylate) nanocubes via facile interfacial synthesis and effective dip-coating. The biosensor shows a linear dynamic range of 0.05 to 22.6 mM with a detection limit down to 5 μM for lactate and 0.05–1775.5 μM with a detection limit down to 30 nM for glucose [193].

a Detection of lactate using graphene embedded screen-printed electrode. Reprinted with permission from. [145]. Copyright 2018 Springer Nature. b Au/rGO/AuPtNP/GOx/Nafion-based miniaturized hybrid working electrode-based wearable biosensor to monitor glucose in real human sweat. Reprinted with permission from [151]. Copyright 2018 Elsevier. c Detection of cytokine using graphene-Nafion biosensor. Reprinted with permission from [194]. Copyright 2021 Wiley–VCH. d Wearable immuno-sensor based on laser-burned graphene with incorporation of Ti3C2Tx MXene for non-invasive sweat cortisol detection. Reprinted with permission from [157]. Copyright 2021 Elsevier. e Flexible wearable electronic devices to measure Na+ ion detection. Reprinted with permission from [195]. Copyright 2021 Wiley–VCH. f A multi-ion sensing system based on multichannel electrochemical all-solid-state wearable potentiometric sensor for real-time sweat ion monitoring. Reprinted with permission from [153]. Copyright 2019 Elsevier

Hormones are secreted by a special group of cells called endocrine glands. They play a pivotal in controlling and regulating the activity of certain cells, and organs in the human body [196,197,198,199,200,201]. Various diseases such as osteoporosis, cardiovascular, adenoma, hyperplasia, and cancer are related to hormone imbalance. Therefore, detection of hormone through the human sweat is an interesting tool in biomarker [202, 203]. Due to psychological and emotional stress, hormones such as cortisol are secreted in human body [204, 205]. A pleiotropic cytokine produced by activating monocytes/macrophages in inflammatory response such as tumor necrosis factor-alpha (TNF-α) is an important biomarker of autoimmune diseases [206,207,208,209]. In this regard, a flexible wearable aptameric graphene–Nafion field-effect transistor-based sensor has been developed for the detection of cytokine biomarker in undiluted sweat sample of human as shown in Fig. 6c. The graphene-Nafion composite film effectively eliminate non-specific adsorption interferences and biosensor has sensitive detection of IFN-γ, a representative inflammatory cytokine with detection range from 0.015 to 250 nM and LOD down to 740 fM [194]. Besides, Ti3C2Tx-MXene nanosheet was successfully incorporated in porous laser burned graphene (LBG) to develop wearable electrochemical immuno-sensor patch with a microfluidic channel to detect cortisol (Fig. 6d). The stretchable patch sensor exhibited linearity and limit of detection of 0.01–100 nM and 88 pM, respectively. The sensor was attached to human skin, and the secreted sweat was passed to the microfluidic channel through a hole under natural pressure [157]. Continuous monitoring of diabetes and kidney failure from wearer sweat was also visualized using cellulose nanofiber/chitosan-graphene oxide-based wearable sensor devices. This colorimetric sensor can readily differentiate glucose and urea level by the naked eye. The sensor exhibit a linear range of 0.1–3 mM with detection limit of 0.1 mM for glucose and a linear range of 30–180 mM with detection limit of 30 mM for urea, respectively [210]. In addition to metabolites and hormones, Na+ and Cl− are the most abundant ions responsible for the production of sweat among all the electrolytes [211].

In this regard, a modification of CFTR protein facilitates the transportation of Na+ and Cl− ion in epithelial secreting cells [212, 213]. Consequently, muscle cramps, dehydration, hyponatremia, and hypokalemia usually occurs owing to the variation of Na+ and K+ ions concentration in sweat [214]. In order to develop graphene-based wearable biosensor for Na+ ion detection, highly conductive, stretchable, and printable ink was fabricated through the incorporation of exfoliated graphene flakes into viscoelastic thermoplastic polyurethane. The wearable biosensor was further employed to measure Na+ ion concentration from the perspiration of a volunteer during physical stretching. The sensing performance was maintained under an extremely high strain level of 300% over 10,000 cycles in a fatigue test. The sensor exhibits detection range from 10−1 to 10−4 M with limit of detection of 2.5 × 10−6 M (Fig. 6e) [195]. In another study, the ion-selective membrane (ISM) on a 3D porous structure comprising a MOF/graphene network is used to monitor ammonium NH4+ ion content. The hydrophobic property of the ion-selective membrane gives an excellent sensing response to NH4+ ion concentration with detection range 10−6 ~ 10−1 M (Fig. 6e) [215]. On the other hand, a multi-ion sensing system based on flexible, all-solid-state, ion-selective electrode (ISE) wearable potentiometric sensor provides information about the quality of persons’ health by monitoring K+, Na+, Cl−, and pH ion concentration in sweat. It could be integrated with a self-powered unit as well as combined with mobile devices for in situ analysis in the field of healthcare and clinical research. The integrated solid ISE has four channels which can detect K+, Na+, Cl−, and pH simultaneously with limit of detection of ~ 6.5 Mm, ~ 49.5, ~ 61.4, and ~ 6.91 for K+ Na+, Cl−, and pH, respectively (Fig. 6f) [153]. Finally, Table 5 summarizes the detection of different analytes in sweat along with the respective sensing strategy.

Interstitial fluid sensing devices

The human body is a treasure of various biofluids such as urine, sweat, saliva, blood, cerebrospinal fluid, gastric juices, and blood [216]. These biofluids contain a complex mixture of substances and are attractive sources for disease diagnosis. However, withdrawing biofluids such as blood by inserting a needle is very painful, sometimes tedious, and makes patients discomfort; therefore, recent emphasis is given on externally secreted biofluids (sweat, saliva, tear). A major component of these non-invasive collected biofluids is water. Thus, analysis of human body fluid has become one of the most promising approaches to discover biomarkers or reveal a path for physiological mechanisms of human disease [217, 218]. Sweat and saliva are easily obtainable biofluid, but they have some limitations and lead to contamination, while other biofluids such as interstitial fluid serve as unique biomarkers in disease diagnosis [219, 220]. ISF is most prevalent accessible fluid in the body, constituting 75% of extracellular fluid and 15 to 25% of body weight. It acts as bridge between blood and cells [221]. ISF is mostly present in the lowermost skin layer of dermis, which is 70% by volume [222]. Some studies have shown that interstitial fluid act as a rich source of information compared to blood. Spaces between cells is filled with ISF, and it is formed by extravasation of plasma from capillaries [223] (Fig. 7a), and which is modified due to metabolic process. ISF fluid flow from blood plasma through endothelial cell wall into interstitial compartments (region between the vasculature and cells) and then return to the blood [221,222,223,224,225]. It acts as mediator between blood vessels and cells in constant supply of nutrients and waste product [226]. Flexible electrochemical glucose sensor integrated with the ISF extraction is used to form wearable devices and which is further utilized for the extraction, dilution, collection, and detection of ISF to realize continuous glucose monitoring. Graphene layer was modified with gold nanoparticles to improve electron transfer rate between the activity center of enzyme and electrode to enhance sensitivity of sensor [227].

a Interstitial fluid moment and skin anatomy showing the outermost epidermal layer the epidermis, dermis, and subcutaneous. Reprinted with the permission from [223]. Copyright 2020 Elsevier. b Transdermal extraction system of ISF fluid for continuous glucose monitoring. Reprinted with the permission from [227]. Copyright 2015 American institute of publishing

Saliva sensing devices

Saliva is considered one of the vital biofluids due to its easy accessibility and large availability [228]. It is proved to be an alternative to blood analysis due to its good correlations with available blood analytes [229]. Also, the presence of a wide range of biomarkers makes it an ideal biofluid for monitoring various kinds of human diseases [230]. It is composed of several kinds of biomarkers such as microbes, antibodies, DNA, RNA, metabolites, lipids, and proteins [231]. The biomarkers present in saliva can originate from different sources such as inflammatory cells that contribute to chronic diseases [232, 233] and molecules produced by the immune system, etc. [234, 235] Various types of portable, non-invasive, and wearable biosensors have been developed to detect different biomarkers in saliva [236,237,238,239].

In the past few years, the production of wearable biosensors by graphene and its derivatives has caught significant attention. For example, Mannoor et al. developed the first graphene-based wearable saliva sensing biosensor [240]. The graphene was firstly printed onto water-soluble silk, and the transfer of biosensors was easily facilitated onto different biomaterials and tooth enamel to detect bacteria. Integration of the oral-cavity biosensors with a resonant coil provided battery-free operation. Antimicrobial peptides were immobilized onto graphene, making the sensors capable of detecting bacteria present in saliva at the single-cell level. This biosensor can be modified to detect some other salivary biomarkers as well.

In a recent study, Mercante et al. designed a biosensor-bioelectronic tongue using zinc oxide (ZnO) nanofibers (NFZ) and graphene derivatives to detect glucose in saliva [241]. Firstly, ZnO nanofibers were fabricated and combined with graphene quantum dots (GQDs) and rGO. Then, glucose oxidase (GOx) was immobilized on this platform to prepare the biosensor. Two biosensor units NFZ-GQDs@GOx and NFZ-rGO@Gox were developed. Both the biosensors utilized electrical impedance measurements and detected glucose in the concentration range of 0.1–6 mM. The NFZ-GQDs@GOx and NFZ-rGO@Gox units showed 32 μM and 14 μM LOD, respectively. Also, the prepared biosensors were employed efficiently to determine glucose in small volumes of artificial saliva. Furthermore, an enzymatic bioelectronic tongue was developed by assembling three different sensing units (NFZ@GOx, NFZ-GQDs@GOx, and NFZ-rGO@GOx) into an array. The bioelectronic tongue was successfully used to detect different glucose concentration levels and the discrimination of glucose from other compounds present in saliva. This study suggested that the bioelectronic tongue could be potentially used to detect other biomarkers associated with various diseases (Fig. 8a).

a Schematic of a bioelectronic tongue developed using zinc oxide and graphene derivatives (rGO and GQDs) for monitoring of glucose present in saliva. Reprinted with permission from [241]. Copyright 2021 Elsevier. b Diagram of a graphene-based wearable contact lens sensor showing glucose sensing with graphene-AgNW. Reprinted with permission from [242]. Copyright 2017 Springer Nature. c The schematic picture of the graphene-based soft, smart contact lens for glucose detection. Reprinted with the permission from [243]. Copyright 2018 American Association for the Advancement of Science. d Schematic of the flexible graphene field-effect transistor (GFET) biosensor fabricated on an ultrathin film, and the device attached onto the artificial eyeball for detection of cytokine. Reprinted with the permission from [244]. Copyright 2020 Multidisciplinary Digital Publishing Institute. e Fabrication process and photographs of corneal microelectrode of corneal biosensors for the in vivo tears testing. Reprinted with the permission from [245]. Copyright 2020 Wiley–VCH. f Schematic illustration of integrated and therapeutic devices for chronic OSI. Reprinted with the permission from [246]. Copyright 2021 American Association for the Advancement of Science

Although saliva has been proved to be an interesting biofluid candidate, few oral-cavities-based wearable biosensors are developed for non-invasive human health monitoring. However, some issues need to be addressed for wide-scale acceptance and saliva sensing biosensors. For example, a low concentration of salivary biomarkers compared with blood biomarkers will require developing a biosensor with high sensitivity. The purity of the biofluid sample is one of the essential things for its continuous and errorless monitoring. A saliva sample is quite easy to obtain compared to other biofluids, but there are always high chances of contamination by exogenously sourced analytes such as from foods and drinks. In such a case, a biosensor should employ an immobilized receptor with high specificity towards the analyte of interest. Contamination of saliva by mouth wounds and gum bleeding also can lead to interference in analyte sensing. Further, one more issue which might arise easily in salivary-based biosensors is biofouling. Various contaminants of saliva (for instance, food residues and oral-cavity bacteria) can accumulate on the surface of the transducer through non-specific interaction, which might affect the biosensor’s performance. Making a protective coating around the biosensor might overcome the issue of biofouling. Moreover, rigorous analysis of saliva will reveal the presence of many more different biomarkers. Developing oral-cavity biosensors to detect multi analytes will be a further advancement in saliva-based wearable devices. Incorporating graphene in the saliva sensing biosensors could be beneficial over other materials in many aspects. It may provide improved mechanical stability and flexibility so that biosensors can withstand the stress due to mouth muscle movements while talking, eating, and drinking.

Tear sensing devices