[PP] creating and operating manual rework production order issued

tags: SAP PP CO07 Order Generate orders

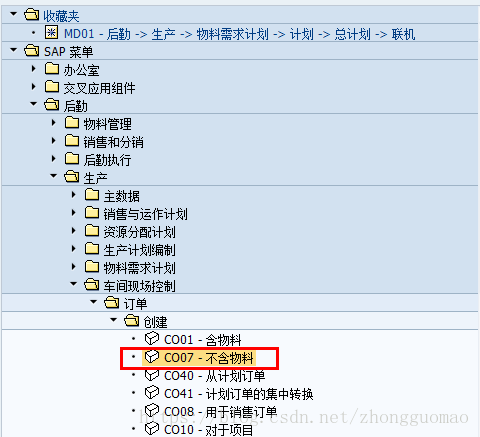

Menu path: SAP menu> Logistics> Production>Shop Floor Control> Order> Create> CO07 - free materials

Transaction code: CO07

Double-click the Mouse

| Field Name |

description |

R/O/C |

User operation and the input value |

Field effect |

| Production plant |

|

O |

factory |

factory |

| Order Type |

|

O |

Factory rework production order |

Distinguish between types of production orders |

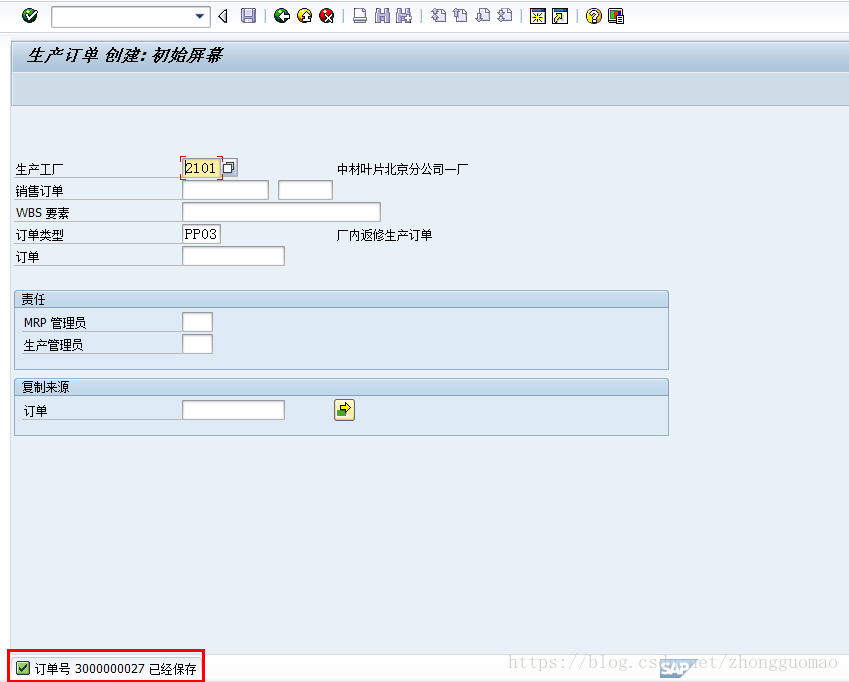

Maintenance of production plant and order type, keyboarding on the Enter key, enter the "Create a production order - payable to" interface.

Note: PP03 types of production orders is the result of storage and shipping for failure detection and issued in-house repair orders.

PP04 type of production order refers to the customer's needs Depot blade repair and rework orders issued.

| Field Name |

Description |

R/O/C |

User operation and the input value |

Field effect |

| materials |

|

O |

SI42.2BJA135009 blank |

|

| The total number |

|

R |

1 |

|

| unit |

|

R |

BRA |

|

| Basic Date - End |

Production orders planned completion time |

O |

2013-03-20 |

|

| Basic dates - Start |

Production orders scheduled start time |

O |

2013-03-19 |

|

| Plan Type |

|

C |

3 Only capacity requirements |

|

Keyboarding on the Enter key, enter "Select process route" small window.

Note: Maintenance material description rules: Material description rework the serial number of the returned product +

Mouse click

- PP03: factory rework production order

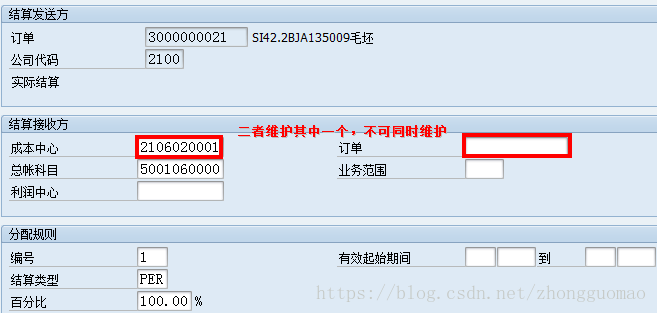

Step 1: Use a fixed "categories: G / L, billing recipient: 5001060000, billing type: PER"

Step 2: Double-click to enter, maintain the transferee: cost center or production order

Note: PP04: sale rework production order

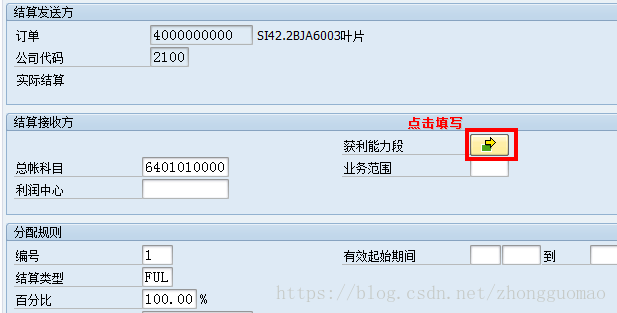

Step 1: Use a fixed "categories: G / L, billing recipient: 6401010000, billing type: FUL"

Step 2: Double-click to enter, maintain profitability segment

Step 3: Click the "profitability segment", fill in the repair of material coding

Press the ENTER key, the system automatically runs short text recipient, and the percentage of settlement billing type. After completion of the above data to fill clicks

| Field Name |

Description |

R/O/C |

User operation and the input value |

Field effect |

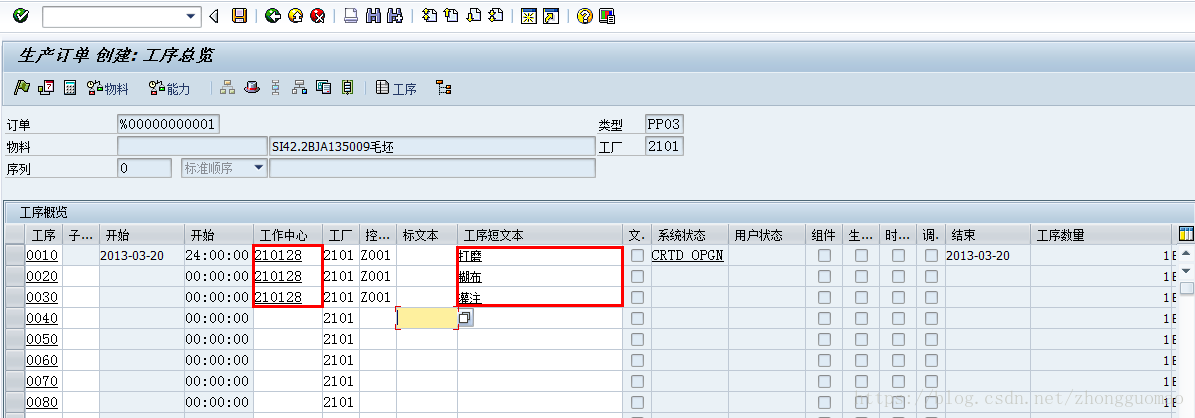

| Work Center |

|

O |

210128 |

|

| Step short text |

Repair job step |

O |

Polished |

|

| Control code |

|

ZOO1 |

|

|

Maintaining the first column line items (i.e., a first channel rework step) and the step of work centers on short text.

After the completion of the first maintenance procedure, double click process (0010), enter "Production Order Create: Operation - details" screen.

| Field Name |

Description |

R/O/C |

User operation and the input value |

Field effect |

| Preparation time |

|

O |

1 |

|

| Processing time |

|

O |

1 |

|

Maintenance Select the standard value, maintenance preparation time, processing time, direct labor, fuel, power, depreciation of machinery, Other manufacturing

standard value.

Note: The preparation time is the time before the start of preparations for the job takes.

Direct labor and processing time means after the preparatory work, it takes time to complete the product.

Depreciation of machinery and fuel and power is the use of machinery and equipment time.

Other manufacturing process is equal to time.

After maintenance is complete, click on

Maintain other processes on this screen and continue to enter the work center processes short text.

After completion of the above values to fill in, press the Enter key, enter "Production Order Create: Operation input device" screen, select the standard value, into the "normal value" screen, fill out the standard value preparation time and processing time.

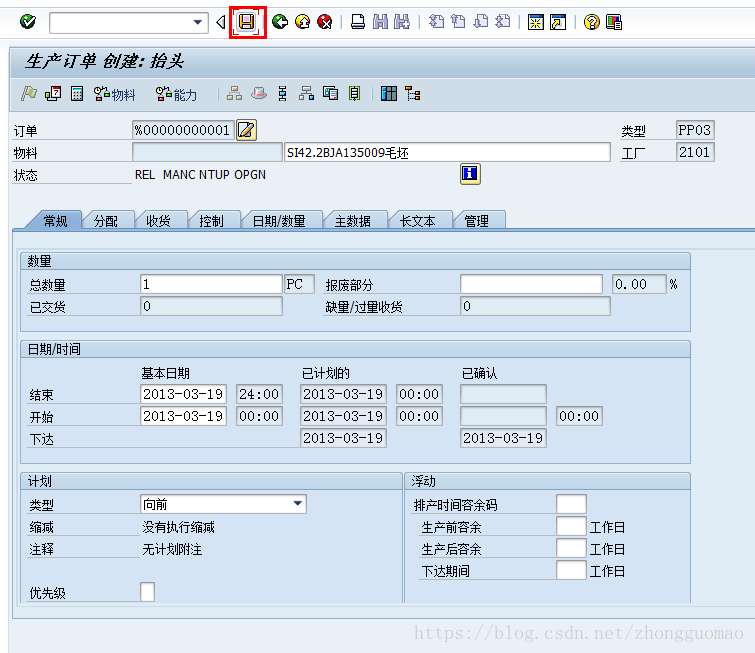

Mouse click

Mouse click

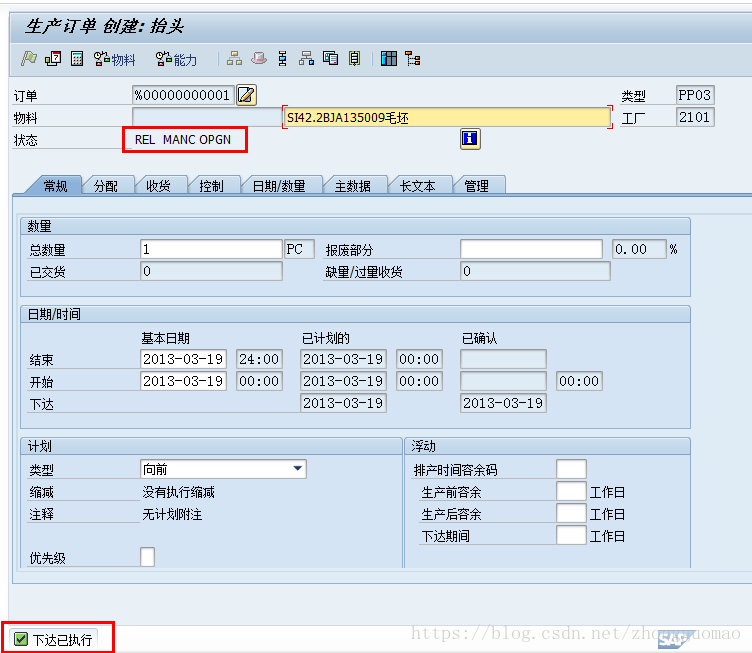

After hit Enter, the system will prompt

Mouse click

Intelligent Recommendation

[PP Operation Manual] Finished product storage and order reporting

First, the finished product storage Menu Path: Logistics -> Material Management -> Inventory Management -> Goods Movement -> Goods Receipt -> Finish Transaction code: MB31 Double-click ...

PP Implementation Sharing (20) - Production Order Status Information Get

PP Implementation Sharing (20) - Production Order Status Information Get The standard function in the SAP system provides a variety of states of production orders. Each state corresponds to related fu...

SAP PP CO02 production work order modification log enhance

Background: In daily operations, customers often find that someone has modified the information of the work order. In order to trace the history of the work order and find the responsible person, the ...

The storage location of the component is modified when the SAP PP CO01 production order is created according to the backflush material identification

When PP CO01 places a production order, you need to modify the storage location of the backflush material in the component. According to the header material, the factory also has a production version ...

[PP Operation Manual] Prototype Plan

Menu Path: Logistics -> Production -> Production Planning -> Demand Management -> Customer Requirements -> MD81 - Create Transaction code: MD81 Double clickGo to the Create Independent ...

More Recommendation

SAP PP MDBT Operation Manual

Special explanation: This article is only used for the application of SAP software, learning communication, and screenshots shown in the article are derived from SAP software, and the corresponding co...

PP production plan - Routing route

PP production plan - Routing route (2017-05-18 16:02:40) Reprint▼ label: sap pp routing Routing classification: SAP_PP production plan ROUTING – Routin...

PP work order status analysis

Turning to the notes of the previous years, I wrote in the beginning of work, for reference only. sap pp work order status analysis When the production order is created, the corresponding system statu...

PP implementation experience sharing (23) - production order status history record_ (Example: after the production order TECO, the query report logic of the report receipt record)

PP implementation experience sharing (23) - production order status history record_ (Example: after the production order TECO, the query report logic of the report receipt record) Recently, a user men...

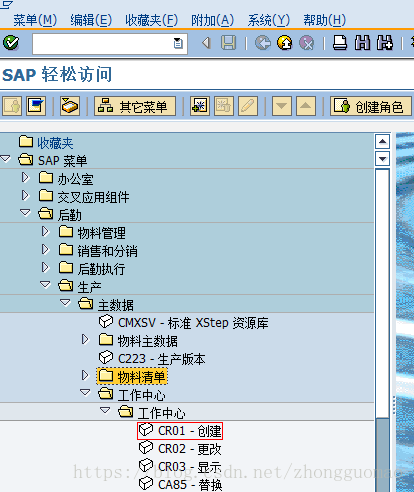

[PP Operation Manual] Maintenance of Work Center

Menu path: Logistics -> Production -> Master Data -> Work Center -> Create -> Finish Transaction code: CR01 Click on the mouse above to enter the "Work Center Creation" interf...