Rain Water Collection Manual and Handbook

Study guide, Time to build your Rain Water Collection System, Save yourself time and money, read the following short manual for tips and methods to build your system.

Opinions And Direct Excerpts From The – Manual on Rainwater Harvesting,

Full credit and acknowledgement is given to the – Water Development Board for the compilation of this information.

Rainwater harvesting is an ancient technique enjoying a revival in popularity due to the inherent quality of rainwater and interest in reducing consumption of treated water.

Rainwater is valued for its purity and softness. It has a nearly neutral pH, and is free from disinfection by-products, salts, minerals, and other natural and man-made contaminants. Plants thrive under irrigation with stored rainwater.

Appliances last longer when free from the corrosive or scale effects of hard water. Users with potable systems prefer the superior taste and cleansing properties of rainwater.

Archeological evidence attests to the capture of rainwater as far back as 4,000 years ago, and the concept of rainwater harvesting in China may date back 6,000 years. Ruins of cisterns built as early as 2000 B.C. for storing runoff from hillsides for agricultural and domestic purposes are still standing in Israel (Gould and Nissen-Petersen, 1999).

Advantages and benefits of rainwater harvesting are numerous.

-

- The water is free; the only cost is for collection and use.

- The end use of harvested water is located close to the source, eliminating the need for complex and costly distribution systems.

- Rainwater provides a water source when groundwater is unacceptable or unavailable, or it can augment limited groundwater supplies.

- The zero hardness of rainwater helps prevent scale on appliances, extending their use; rainwater eliminates the need for a water softener and the salts added during the softening process.

- Rainwater is sodium-free, important for persons on low-sodium diets.

- Rainwater is superior for landscape irrigation.

- Rainwater harvesting reduces flow to storm water drains and also reduces non-point source pollution.

- Rainwater harvesting helps utilities reduce the summer demand peak and delay expansion of existing water treatment plants.

- Rainwater harvesting reduces consumers utility bills by half.

Perhaps one of the most interesting aspects of rainwater harvesting is learning about the methods of capture, storage, and use of this natural resource at the place it occurs. This natural synergy excludes at least a portion of water use from the water distribution infrastructure: the centralized treatment facility, storage structures, pumps, mains, and laterals.

Rainwater harvesting also includes land based systems with man-made landscape features to channel and concentrate rainwater in either storage basins or planted areas.

When assessing the health risks of drinking rainwater, consider the path taken by the raindrop through a watershed into a reservoir, through public drinking water treatment and distribution systems to the end user.

Being the universal solvent, water absorbs contaminants and minerals on its travels to the reservoir. While in residence in the reservoir, the water can come in contact with all kinds of foreign materials: oil, animal wastes, chemical and pharmaceutical wastes, organic compounds, industrial outflows, and trash.

It is the job of the water treatment plant to remove harmful contaminants and to kill pathogens. Unfortunately, when chlorine is used for disinfection, it also degrades into disinfection byproducts, notably trihalomethanes, which may pose health risks. In contrast, the raindrop harvested on site will travel down a roof via a gutter to a storage tank. Before it can be used for drinking, it will be treated by a relatively simple process with equipment that occupies about 9 cubic feet of space.

Rainwater harvesting can reduce the volume of storm water, thereby lessening the impact on erosion and decreasing the load on storm sewers. Decreasing storm water volume also helps keep potential storm water pollutants, such as pesticides, fertilizers, and petroleum products, out of rivers and groundwater.

But along with the independence of rainwater harvesting systems comes the inherent responsibility of operation and maintenance.

For all systems, this responsibility includes purging the first flush system, regularly cleaning roof washers and tanks, maintaining pumps, and filtering water. For potable systems, responsibilities include all of the above, and the owner must replace cartridge filters and maintain disinfection equipment on schedule, arrange to have water tested, and monitor tank levels. Rainwater used for drinking should be tested, at a minimum, for pathogens.

Rainwater harvesting, in its essence, is the collection, conveyance, and storage of rainwater. The scope, method, technologies, system complexity, purpose, and end uses vary from rain barrels for garden irrigation in urban areas, to large-scale collection of rainwater for all domestic uses.

Some examples are summarized below:

-

- For supplemental irrigation water, theWells Branch Municipal Utility District in North Austin captures rainwater, along with air conditioning condensate, from a new 10,000-square-foot recreation center into a 37,000-gallon tank to serve as irrigation water for a 12-acre municipal park with soccer fields and offices.

- The Lady Bird Johnson WildflowerResearch Center in Austin, -, harvests 300,000 gallons of rainwater annually from almost 19,000 square feet of roof collection area for irrigation of its native plant landscapes. A 6,000-gallon stone cistern and its arching stone aqueduct form the distinctive entry to the research center.

- The Advanced Micro DevicesSemiconductor fabrication plant in Austin, -, does not use utility supplied water for irrigation, saving $1.5 million per year by relying on captured rainwater and collected groundwater.

- Reynolds Metals in Ingleside, – uses storm water captured in containment basins as process water in its metal-processing plant, greatly offsetting the volume of purchased water.

- The city of Columbia, Nuevo León, Mexico, is in the planning stages of developing rainwater as the basis for the city water supply for new growth areas, with large industrial developments being plumbed for storage and catchments.

- On small volcanic or coral islands, rainwater harvesting is often the only option for public water supply, as watersheds are too small to create a major river, and groundwater is either nonexistent or contaminated with salt water. Bermuda, the U.S. Virgin Islands, and other Caribbean islands require cisterns to be included with all new construction.

In Central -, more than 400 full scale rainwater harvesting systems have been installed by professional companies, and more than 6,000 rain barrels have been installed through the City of Austin incentive program in the past decade. Countless DYI have installed systems over the same time period.

An estimated 100,000 residential rainwater harvesting systems are in use in the United States and its territories (Lye, 2002). More are being installed by the urban home gardener seeking healthier plants, the weekend cabin owner, and the homeowner intent upon the green building practices all seeking a sustainable, high-quality water source. Rainwater harvesting is also recognized as an important water conserving measure, and is best implemented in conjunction with other efficiency measures in and outside of the home.

Harvested rainwater may also help some – communities close the gap between supply and demand projected by the – Water Development Board (TWDB), as the state population nearly doubles between 2000 and 2050 (- Water Development Board, 2002).

In fact, rainwater harvesting is encouraged by Austin and San Antonio water utilities as a means of conserving water. The State of – also offers financial incentives for rainwater harvesting systems. Senate Bill 2 of the 77th Legislature exempts rainwater harvesting equipment from sales tax, and allows local governments to exempt rainwater harvesting systems from ad valorem (property) taxes.

Rainwater harvesting systems can be as simple as a rain barrel for garden irrigation at the end of a downspout, or as complex as a domestic potable system or a multiple end-use system at a large corporate campus.

Rainwater harvesting is practical only when the volume and frequency of rainfall and size of the catchments surface can generate sufficient water for the intended purpose.

From a financial perspective, the installation and maintenance costs of a rainwater harvesting system for potable water cannot compete with water supplied by a central utility, but is often cost-competitive with installation of a well in rural settings.

With a very large catchments surface, such as that of big commercial building, the volume of rainwater, when captured and stored, can cost-effectively serve several end uses, such as landscape irrigation and toilet flushing.

Some commercial and industrial buildings augment rainwater with condensate from air conditioning systems. During hot, humid months, warm, moisture-laden air passing over the cooling coils of a residential air conditioner can produce 10 or more gallons per day of water. Industrial facilities produce thousands of gallons 4 per day of condensate. An advantage of condensate capture is that its maximum production occurs during the hottest month of the year, when irrigation need is greatest. Most systems pipe condensate into the rainwater cistern for storage.

The depletion of groundwater sources, the poor quality of some groundwater, high tap fees for isolated properties, the flexibility of rainwater harvesting systems, and modern methods of treatment provide excellent reasons to harvest rainwater for domestic use. The scope of this manual is to serve as a primer in the basics of residential and small-scale commercial rainwater harvesting systems design. It is intended to serve as a first step in thinking about options for implementing rainwater harvesting systems, as well as advantages and constraints.

Chapter 2

Rainwater Harvesting System Components

Rainwater harvesting is the capture, diversion, and storage of rainwater for a number of different purposes including landscape irrigation, drinking and domestic use, aquifer recharge, and storm water abatement.

In a residential or small-scale application, rainwater harvesting can be as simple as channeling rain running off an unguttered roof to a planted landscape area via contoured landscape.

To prevent erosion on sloped surfaces, a bermed concave holding area down slope can store water for direct use by turf grass or plants (Waterfall, 1998). More complex systems include gutters, pipes, storage tanks or cisterns, filtering, pumps), and water treatment for potable use.

This chapter focuses on residential or small-scale commercial systems, for both irrigation and potable use. The local health department and city building code officer should be consulted concerning safe, sanitary operations and construction of these systems.

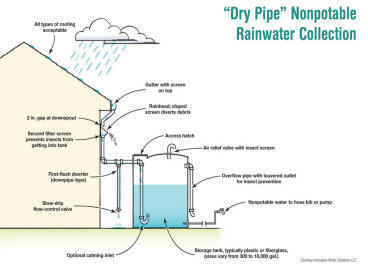

Basic Components – Regardless of the complexity of the system, the domestic rainwater harvesting system (Figure 2-1) comprises six basic components:

- Catchments surface: the collection surface from which rainfall runs off

- Gutters and downspouts: channel water from the roof to the tank

- Leaf screens, first-flush diverters, and roof washers: components which remove debris and dust from the captured rainwater before it goes to the tank

- One or more storage tanks, also called cisterns

- Delivery system: gravity-fed or pumped to the end use

- Treatment/purification: for potable systems, filters and other methods to make the water safe to drink

The Catchments Surface

The roof of a building or house is the obvious first choice for catchments. For additional capacity, an open-sided barn called a rain barn or pole barn can be built. Water tanks and other rainwater system equipment, such as pumps and filters, as well as vehicles, bicycles, and gardening tools, can be stored under the barn.

Water quality from different roof catchments is a function of the type of roof material, climatic conditions, and Figure 2-1. Typical rainwater harvesting

Metal

The quantity of rainwater that can be collected from a roof is in part a function of the roof texture: the smoother the better. A commonly used roofing material for rainwater harvesting is sold under the trade name Galvalume®, a 55 percent aluminum/45 percent zinc alloy coated sheet steel. Galvalume® is also available with a baked enamel coating, or it can be painted with epoxy paint. Some caution should be exercised regarding roof components. Roofs with copper flashings can cause discoloration of porcelain fixtures.

Clay/concrete tile

Clay and concrete tiles are both porous. Easily available materials are suitable for potable or nonpotable systems, but may contribute to as much as a 10-percent loss due to texture, inefficient flow, or evaporation. To reduce water loss, tiles can be painted or coated with a sealant. There is some chance of toxins leaching from the tile sealant or paint, but this roof surface is safer when painted with a special sealant or paint to prevent bacterial growth on porous materials.

Composite or asphalt shingle

Due to leaching of toxins, composite shingles are not appropriate for potable systems, but can be used to collect water for irrigation. Composite roofs have an approximated 10-percent loss due to inefficient flow or evaporation (Radlet and Radlet, 2004).

Wood shingle, tar, and gravel, these roofing materials are some what rare, and the water harvested is usually suitable only for irrigation due to leaching of compounds.

Slate. Slate smoothness makes it ideal for a catchments surface for potable use, assuming no toxic sealant is used; however, cost considerations may preclude its use.

Gutters and Downspouts

Gutters are installed to capture rainwater running off the eaves of a building. Some gutter installers can provide continuous or seamless gutters. For potable water systems, lead cannot be used as gutter solder, as is sometimes the case in older metal gutters. The slightly acidic quality of rain could dissolve lead and thus contaminate the water supply.

The most common materials for gutters and downspouts are half-round PVC, vinyl, pipe, seamless aluminum, and galvanized steel.

Seamless aluminum gutters are usually installed by professionals, and, therefore, are more expensive than other options. Regardless of material, other necessary components in addition to the horizontal gutters are the drop outlet, which routes water from the gutters downward and at least two 45-degree elbows which allow the downspout pipe to snug to the side of the house. Additional components include the hardware, brackets, and straps to fasten the gutters and downspout to the fascia and the wall.

Gutter Sizing and Installation

When using the roof of a house as a catchments surface, it is important to consider that many roofs consist of one or more roof valleys. A roof valley occurs where two roof planes meet. A roof valley concentrates rainfall runoff from two roof planes before the collected rain reaches a gutter. Depending on the size of roof areas terminating in a roof valley, the slope of the roofs, and the intensity of rainfall, the portion of gutter located where the valley water leaves the eave of the roof may not be able to capture all the water at that point, resulting in spillage or overrunning.

Besides the presence of one or more roof valleys, other factors that may result in overrunning of gutters include an inadequate number of downspouts, excessively long roof distances from ridge to eave, steep roof slopes, and inadequate gutter maintenance. Variables such as these make any gutter sizing rules of thumb difficult to apply. Consult you gutter supplier about your situation with special attention to determine where gutter overrunning areas may occur. At these points along an eave, apply strategies to minimize possible overrunning to improve catchments efficiency. Preventative strategies may include modifications to the size and configuration of gutters and addition of gutter boxes with downspouts and roof diverters near the eave edge.

Gutters should be installed with slope towards the downspout; also the outside face of the gutter should be lower than the inside face to encourage drainage away from the building wall.

Leaf Screens

To remove debris that gathers on the catchments surface, and ensure high quality water for either potable use or to work well without clogging irrigation emitters, a series of filters are necessary. Essentially, mesh screens remove debris both before and after the storage tank. The defense in keeping debris out of a rainwater harvesting system is some type of leaf screen along the gutter or in the downspout.

Depending upon the amount and type of tree litter and dust accumulation, the homeowner may have to experiment to find the method that works best. Leaf screens must be regularly cleaned to be effective. If not maintained, leaf screens can become clogged and prevent rainwater from flowing into a tank. Built-up debris can also harbor bacteria and the products of leaf decay. Leaf guards are usually ¼-inch mesh screens in wire frames that fit along the length of the gutter. Leaf guards/screens are usually necessary only in locations with tree overhang. Guards with profiles conducive to allowing leaf litter to slide off are also available.

The funnel-type downspout filter is made of PVC or galvanized steel fitted with a stainless steel or brass screen. This type of filter offers the advantage of easy accessibility for cleaning. The funnel is cut into the downspout pipe at the same height or slightly higher than the highest water level in the storage tank.

Strainer baskets are spherical cage-like strainers that slip into the drop outlet of the downspout.

A cylinder of rolled screen inserted into

the drop outlet serves as another method of filtering debris. The homeowner may need to experiment with various grid sizes, from insect screen to hardware cloth.

Filter socks of nylon mesh can be installed on the PVC pipe at the tank inflow.

First-Flush Diverters

A roof can be a natural collection surface for dust, leaves, blooms, twigs, insect bodies, animal feces, pesticides, and other airborne residues. The first flush diverter routes the first flow of water from the catchments surface away from the storage tank. The flushed water can be routed to a planted area. While leaf screens remove the larger debris, such as leaves, twigs, and blooms that fall on the roof, the first-flush diverter gives the system a chance to rid itself of the smaller contaminants, such as dust, pollen, and bird and rodent feces. The simplest first-flush diverter is a PVC standpipe (Figure 2-2). The standpipe fills with water first during a rainfall event; the balance of water is routed to the tank.

The standpipe is drained continuously via a pinhole or by leaving the screw closure slightly loose. In any case, cleaning of the standpipe is accomplished by removing the PVC cover with a wrench and removing collected debris after each rainfall event. There are several other types of first flush diverters. The ball valve type consists of a floating ball that seals off the top of the diverter pipe (Figure 2-3) when the pipe files with water. Opinions vary on the volume of rainwater to divert. The number of dry days, amount of debris, and roof surface are all variables to consider.

One rule of thumb for first-flush diversion is to divert a minimum of 10 gallons for every 1,000 square feet of collection surface. However, first-flush volumes vary with the amount of dust on the roof surface, which is a function of the number of dry days, the amount and type of debris, tree overhang, and season.

A preliminary study by Rain Water Harvesting and Waste Water Systems Pty Ltd., a rainwater harvesting component vendor in Australia, recommends that between 13 and 49 gallons be diverted per 1,000 square feet. The primary reason for the wide variation in estimates is that there is no exact calculation to determine how much initial water needs to be diverted because there are many variables that would determine the effectiveness of washing the contaminants off the collection surface, just as there are many variables determining the make up of the contaminants themselves. For example, the slope and smoothness of the collection surface, the intensity of the rain event, the length of time between events (which adds to the amount of accumulated contaminants), and the nature of the contaminants themselves add to the difficulty of determining just how much rain should be diverted during first flush. In order to effectively wash a collection surface, a rain intensity of one-tenth of an inch of rain per hour is needed to wash a sloped roof. A flat or near-flat collection surface requires 0.18 inches of rain per hour for an effective washing of the surface.

The recommended diversion of first flush ranges from one to two gallons of First flush diversion for each 100 square feet of collection area. If using a roof for a collection area that drains into gutters, calculate the amount of rainfall area that will be drained into every gutter feeding your system. Remember to calculate the horizontal equivalent of the roof footprint when calculating your

catchments area. (Please refer to the Figure 4-1 in Chapter 4, Water Balance and System Sizing.) If a gutter receives the quantity of runoff that require multiple downspouts, first-flush

First-Flush Diverters

Standpipe

The simplest first-flush diverter is a 6- or 8-inch PVC standpipe (Figure 2-2). The diverter fills with water first, backs up, and then allows water to flow into the main collection piping. These standpipes usually have a cleanout fitting at the bottom, and must be emptied and cleaned out after each rainfall event. The water from the standpipe may be routed to a planted area. A pinhole drilled at the bottom of the pipe or a hose bibb fixture left slightly open (shown) allows water to gradually leak out. If you are using 3 diameter PVC or similar pipe, allow 33 length of pipe per gallon; 4 diameter pipe needs only 18 of length per gallon; and a little over 8 of 6 diameter pipe is needed to catch a gallon of water.

Standpipe with ball valve

The standpipe with ball valve is a variation of the standpipe filter. The cutaway drawing (Figure 2-3) shows the ball valve. As the chamber fills, the ball floats up and seals on the seat, trapping first-flush water and routing the balance of the water to the tank.

Figure 2-2. Standpipe first-flush diverter

Figure 2-3. Standpipe with ball valve diversion devices will be required for each downspout.

Roof Washers

The roof washer, placed just ahead of the storage tank, filters small debris for potable systems and also for systems using drip irrigation. Roof washers consist of a tank, usually between 30-and 50-gallon capacity, with leaf strainers and a filter (Figure 2-4). One commercially available roof washer has a 30-micron filter. (A micron, also called a micrometer, is one-millionth of a meter. A 30-micron filter has pores about one-third the diameter of a human hair.)

All roof washers must be cleaned. Without proper maintenance they not only become clogged and restrict the flow of rainwater, but may themselves become breeding grounds for pathogens. The box roof washer (Figure 2-4) is a commercially available component consisting of a fiberglass box with one or two 30-micron canister filters (handling rainwater from 1,500- and 3,500-square-foot catchments, respectively). The box is placed atop a ladder-like stand beside the tank, from which the system owner accesses the box for cleaning via the ladder. In locations with limited drop, a filter with the canisters oriented horizontally is indicated, with the inlet and outlet of the filter being nearly parallel.

Storage Tanks

The storage tank is the most expensive component of the rainwater harvesting system.

The size of storage tank or cistern is dictated by several variables: the rainwater supply (local precipitation), the demand, and the projected length of dry spells without rain, the catchments surface area, aesthetics, personal preference, and budget.

A myriad of variations on storage tanks and cisterns have been used over the centuries and in different geographical regions: earthenware cisterns in the BC times, large pottery containers in Africa, above-ground vinyl-lined swimming pools in Hawaii, concrete or brick cisterns in the central United States, and, common to old homesteads in -, galvanized steel tanks and attractive site-built stone-and-mortar cisterns, polyethylene plastic above and below ground tanks.

For purposes of practicality, this manual will focus on the most common, easily installed, and readily available storage options in -, some still functional after a century of use.

Storage tank basics

1. Storage tanks must be opaque, either upon purchase or painted later, to Figure 2-4. Box roof washer inhibit algae growth.

2. For potable systems, storage tanks must never have been used to store toxic materials.

3. Tanks must be covered and vents screened to discourage mosquito breeding.

4. Tanks used for potable systems must be accessible for cleaning.

Storage tank site

Tanks should be located as close to supply and demand points as possible to reduce the distance water is conveyed. Storage tanks should be protected from direct sunlight, if possible. To ease the load on the pump, tanks should be placed as high as practicable. Of course, the tank inlet must be lower than the lowest +downspout from the catchments area. To compensate for friction losses in the trunk line, a difference of a couple of feet is preferable. When converting from well water, or if using a well backup, site the tanks near the well house, this facilitates the use of existing plumbing.

Water runoff should not enter septic system drain fields, and any tank overflow and drainage should be routed so that it does not affect the foundation of the tanks or any other structures (Macomber, 2001).

– does not have specific rules concerning protection of rainwater systems from possible contamination sources; however, to ensure a safe water supply, underground tanks should be located at least 50 feet away from animal stables or above-ground application of treated wastewater. Also, runoff from tank overflow should not enter septic system drain fields. If supplemental hauled water might be needed, tank placement should also take into consideration accessibility by a water truck, preferably near a driveway or roadway.

Water weighs just over 8 pounds per gallon, so even a relatively small 1,500-gallon tank will weigh 12,400 pounds. A leaning tank may collapse; therefore, tanks should be placed on a stable, level pad. If the bed consists of a stable substrate, such as caliche, a load of sand or pea gravel covering the bed may be sufficient preparation. In some areas, sand or pea gravel over well-compacted soil may be sufficient for tank. County agents have experience and will assist on request.

When in doubt, a concrete pad should be constructed. When the condition of the soil is unknown, enlisting the services of a structural engineer may be in order to ensure the stability of the soil supporting the full cistern weight.

Another consideration is protecting the pad from being undermined by either normal erosion or from the tank overflow. The tank should be positioned such that runoff from other parts of the property or from the tank overflow will not undermine the pad. The pad or bed should be checked after intense rainfall events.

Polyethylene tanks (Figure 2-6) are available for all manner of water and chemical storage uses. Standard tanks must be installed above ground. For buried installation, specially reinforced tanks are designed to with stand soil expansion and compaction. They are relatively inexpensive and durable, lightweight, and long lasting. Polyethylene tanks are available in capacities from 50 gallons to 15,000 gallons. Plastic tanks for outdoor be bought as opaque

Black or Green plastic tanks. The fittings of these tanks are easy modifications to make in the field. Although easy to plumb, properly installed there will be no leakage. In use for over 40 years they are a long term water storage solution.

Fiberglass tanks (Figure 2-5) are built in standard capacities from 50 gallons to 15,000 gallons and in both vertical Figure 2-5. Two 10,000-gallon fiberglass tanks cylinder and low-horizontal cylinder configurations. Fiberglass tanks under 1,000 gallons are expensive for their capacity, so polyethylene might be preferred. Tanks for potable use should have a USDA approved food-grade resin lining and the tank should be opaque to inhibit algae growth. The durability of fiberglass tanks has been tested and proven, weathering the elements for years in – oil fields.

Wood tanks, similar to wood water towers at railroad depots, were historically made of redwood. Modern wood tanks are usually of pine, cedar, or cypress wrapped with steel tension cables, and lined with plastic. For potable use, a food-grade liner must be used. These tanks are available in capacities from 700 to 37,000 gallons, and are site built by skilled technicians. They can be dismantled and reassembled at a different location. Figure 2-6. Low-profile 5,000-gallon polypropylene tanks Figure 2-7. Installation of a 25,000-gallon Timbertank in Central – showing the aesthetic appeal of these wooden tanks Figure 2-9. Concrete tank fabricated from stacking rings of concrete Figure 2-8.

Galvanized metal tanks are usually fitted with a food-grade plastic liner. Metal Galvanized sheet metal tanks (Figure 2- 8) are also an attractive option for the urban or suburban garden. They are available in sizes from 150 to 2,500 gallons, and are lightweight and easy to relocate. Tanks can be lined for potable use. Most tanks are corrugated galvanized steel dipped in hot zinc for corrosion resistance. They are lined with a food-grade liner, usually polyethylene or PVC, or coated on the inside with epoxy paint. The paint, which also extends the life of the metal, must be FDA- and NSF-approved for drinking water.

Concrete tanks are either poured in place or prefabricated (Figure 2-9). They can be constructed above ground or below ground. Poured-in-place tanks can be integrated into new construction under a patio, or a basement, and their placement is considered permanent.

A type of concrete tank familiar to residents of the – Hill Country is constructed of stacked rings with sealant around the joints. Other types of prefabricated concrete tanks include new septic tanks, conduit stood on end, and concrete blocks. These tanks are fabricated off-site and dropped into place.

Concrete may be prone to cracking and leaking, especially in underground tanks in clay soil. Leaks can be easily repaired although the tank may need to be drained to make the repair. Involving the expertise of a structural engineer to determine the size and spacing of reinforcing steel to match the structural loads of a poured-in-place concrete cistern is highly recommended. A product that repairs leaks in concrete tanks, Xypex, is now also available and approved for potable use.

One possible advantage of concrete tanks is a desirable taste imparted to the water by calcium in the concrete being dissolved by the slightly acidic 14 rainwater. For potable systems, it is essential that the interior of the tank be plastered with a high-quality material approved for potable use.

Ferrocement is a low-cost steel and mortar composite material. For purposes of this manual, GuniteTM and ShotcreteTM type will be classified as ferrocements.

Both involve application of the concrete and mortar under pressure from a gun. Gunite, the dry-gun spray method in which the dry mortar is mixed with water at the nozzle, is familiar for its use in swimming pool construction. Shotcrete uses a similar application, but the mixture is a prepared slurry. Both methods are cost-effective for larger storage tanks. Tanks made of Gunite and Shotcrete consist of an armature made from a grid of steel reinforcing rods tied together with wire around which is placed a wire form with closely spaced layers of mesh, such as expanded metal lath. A concrete-sand-water mixture is applied over the form and allowed to cure. It is important to ensure that the ferrocement mix does not contain any toxic constituents. Some sources recommend painting above-ground tanks white to reflect the suns rays, reduce evaporation, and keep the water cool. Ferro cement structures (Figure 2-10) have commonly been used for water storage construction in developing countries due to low cost and availability of materials. Small cracks and leaks can easily be repaired with a mixture of cement and water, which is applied where wet spots appear on the tanks exterior. Because walls can be as thin as 1 inch, a Ferro cement tank uses less material than concrete tanks, and thus can be less expensive. As with poured in-place concrete construction, assistance from a structural engineer is encouraged.

Rain barrel

One of the simplest rainwater installations, and a practical choice for urban dwellers, is the 50- to 75-gallon drum used as a rain barrel for irrigation of plant beds. Some commercially available rain barrels are manufactured with overflow ports linking the primary barrel to a second barrel. A screen trap at the water entry point discourages mosquito breeding. A food-grade plastic barrel used for bulk liquid storage in restaurants and grocery stores can be fitted with a bulkhead fitting and spigot for garden watering. Other options include a submersible pump or jet pump.

Pressure Tanks and Pumps

The laws of physics and the topography of most homesteads usually demand a pump and pressure tank between water storage and treatment, and the house or end use. Standard municipal water pressure is 40 pounds per square inch (psi) to 60 psi. Many home appliances clothes washers, dishwashers, hot-water on-demand water heaters require a minimum of 2030 psi for proper operation. Even some drip irrigation system need 20 psi for proper irrigation. Water gains 1 psi of pressure for every 2.31 feet of vertical rise. So for gravity flow through a 1-inch pipe at 40 psi, the storage tanks would have to be more than 90 feet above the house.

Since this elevation separation is rarely practical or even desirable, two ways to achieve proper household water pressure are (1) a pump, pressure tank, pressure switch, and check valve (familiar to well owners), or (2) an on-demand pump. Pumps are designed to push water rather than to pull it. Therefore, the system should be designed with the pumps at the same level and as close to the storage tanks as possible.

Pump systems draw water from the storage tanks, pressurize it, and store it in a pressure tank until needed. The typical pump-and-pressure tank arrangement consists of a ¾- or 1-horsepower pump, usually a shallow well jet pump or a multistage centrifugal pump, the check valve, and pressure switch. A one-way check valve between the storage tank and the pump prevents pressurized water from being returned to the tank. The pressure switch regulates operation of the pressure tank. The pressure tank, with a typical capacity of 40 gallons, maintains pressure throughout the system. When the pressure tank reaches a preset threshold, the pressure switch cuts off power to the pump. When there is demand from the household, the pressure switch detects the drop in pressure in the tank and activates the pump, drawing more water into the pressure tank.

The cistern float filter (Figure 2-11) allows the pump to draw water from the storage tank from between 10 and 16 inches below the surface. Water at this level is cleaner and fresher than water closer to the bottom of the tank. The device has a 60-micron filter. An external suction pump, connected via a flexible hose, draws water through the filter. On-demand pump

The new on-demand pumps eliminate the need for a pressure tank. These pumps combine a pump, motor, controller, check valve, and pressure tank function all in one unit. They are self-priming and are built with a check valve incorporated into the suction port. Figure 2-12 shows a typical installation of an on-demand pump and a 5-micron fiber filter, 3-micron activated charcoal filter, and an ultraviolet lamp. Unlike conventional pumps, on-demand pumps are designed to activate in response to a demand, eliminating the need, cost, and space of a pressure tank. In addition, some on-demand pumps are specifically designed to be used with rainwater.

Treatment and Disinfection Equipment

For a nonpotable system used for hose irrigation, if tree overhang is present, leaf screens on gutters and a roof washer

Figure 2-11. Cistern float filter diverting 10 gallons for every 1,000 square feet of roof is sufficient. If drip irrigation is planned, however, sediment filtration may be necessary to prevent clogging of emitters. As standards differ, the drip irrigation manufacturer or vendor should be contacted regarding filtering of water.

For potable water systems, treatment beyond the leaf screen and roof washer is necessary to remove sediment and disease-causing pathogens from stored water. Treatment generally consists of filtration and disinfection processes in series before distribution to ensure health and safety.

Cartridge Filters and Ultraviolet (UV) Light

The most popular disinfection array in – is two in-line sediment filters the 5-micron fiber cartridge filter followed by the 3-micron activated charcoal cartridge filter followed by ultraviolet light. This disinfection set-up is placed after the pressure tank or after the on-demand pump.

It is important to note that cartridge filters must be replaced regularly. Otherwise, the filters can actually harbor bacteria and their food supply. The 5-micron filter mechanically removes suspended particles and dust. The 3-micron filter mechanically traps microscopic particles while smaller organic molecules are absorbed by the activated surface. In theory, activated charcoal can absorb objectionable odors and tastes, and even some protozoa and cysts (Macomber, 2001).

Filters can be arrayed in parallel for greater water flow. In other words, two 5-micron fiber filters can be stacked in one large cartridge followed by two 3-micron activated charcoal filters in another cartridge. The ultraviolet (UV) light must be rated to accommodate the increased flow.

NSF International (National Sanitation Foundation) is an independent testing and certification organization. Filter performance can be researched using a simple search feature by model or manufacturer on the NSF website. (See References.) It is best to purchase NSF certified equipment.

Maintenance of the UV light involves cleaning of the quartz sleeve. Many UV lights are designed with an integral wiper unit. Manual cleaning of the sleeve is not recommended due to the possibility of breakage.

UV lamps are rated in gallons per minute. For single 5-micron and 3-micron in-line filters, a UV light rated at 12 gallons per minute is sufficient. For Figure 2-12. Typical treatment installation of an on-demand pump, 5-micron fiber filter, 3-micron activated charcoal filter, and an ultraviolet lamp (top).

19 filters in parallel installation, a UV light rated for a higher flow is needed. In-line flow restrictors can match flow to the UV light rating.

UV lights must be replaced after a maximum of 10,000 hours of operation. Some lights come with alarms warning of diminished intensity.

Ozone

Chemically, ozone is O3: essentially a more reactive form of molecular oxygen made up of three atoms of oxygen. Ozone acts as a powerful oxidizing agent to reduce color, to eliminate foul odors, and to reduce total organic carbon in water. For disinfection purposes, an ozone generator forces ozone into storage tanks through rings or a diffuser stone. Ozone is unstable and reacts quickly to revert to O2 and dissipates through the atmosphere within 15 minutes.

A rainwater harvesting system owner in Fort Worth uses an ozone generator to keep the water in his 25,000 gallons of storage fresh by circulating ozone through the five tanks at night. A standard sprinkler controller switches the ozone feed from tank to tank. Membrane Filtration (Reverse Osmosis and Nanofiltration) Membrane filtration, such as reverse osmosis and nanofiltration work by forcing water under high pressure through a semi permeable membrane to filter dissolved solids and salts, both of which are in very low concentrations in rainwater. Membrane processes, however, have been known empirically to produce sweeter water, perhaps by filtering out dissolved metals from plumbing.

A certain amount of feed water is lost in any membrane filtration process. Reject water, referred to as brine, containing a concentrate of the contaminants filtered from the feed water, is discharged. The amount of reject water, however, is directly proportional to the purity of the feed water. Rainwater, as a purer water source to begin with, would generate less brine. Reverse osmosis membranes must be changed before they are fouled by contaminants. Reverse osmosis (RO) equipment for household use is commercially available from home improvement stores such as Lowes and Home Depot.

Chlorination

For those choosing to disinfect with chlorine, automatic self-dosing systems are available. A chlorine pump injects chlorine into the water as it enters the house. In this system, appropriate contact time is critical to kill bacteria. A practical chlorine contact time is usually from 2 minutes to 5 minutes with a free chlorine residual of 2 parts per million (ppm). The time length is based on water pH, temperature, and amount of bacteria. Contact time increases with pH and decreases with temperature. K values (contact times) are shown in Table 3-3.

Chapter 3 Water Quality and Treatment

The raindrop as it falls from the cloud is soft, and is among the cleanest of water sources. Use of captured rainwater offers several advantages.

Rainwater is sodium-free, a benefit for persons on restricted sodium diets. Irrigation with captured rainwater promotes healthy plant growth. Also, being soft water, rainwater extends the life of appliances as it does not form scale or mineral deposits.

The environment, the catchments surface, and the storage tanks affect the quality of harvested rainwater. With minimal treatment and adequate care of the system, however, rainfall can be used as potable water, as well as for irrigation. The falling raindrop acquires slight acidity as it dissolves carbon dioxide and nitrogen. Contaminants captured by the rain from the catchments surface and storage tanks are of concern for those intending to use rainwater as their potable water source. The catchments area may have dust, dirt, fecal matter from birds and small animals, and plant debris such as leaves and twigs. Rainwater intended for domestic potable use must be treated using appropriate filtration and disinfection equipment, discussed in Chapter 2, Rainwater Harvesting System Components. Total dissolved solids (TDS) in rainwater, originating from particulate matter suspended in the atmosphere, range from 2 milligrams per liter (mg/l or ppm)1 to 20 mg/l across -, compared with municipal water TDS 1 For dilute aqueous solutions mg/l is approximately equal to ppm because a liter of water weighs one kilogram, ranges of 100 ppm to more than 800 ppm.

The sodium content of some municipal water ranges from 10 parts per million (ppm) to as high as 250 ppm. Rainwater intended solely for outdoor irrigation may need no treatment at all except for a screen between the catchments surface and downspout to keep debris out of the tank, and, if the tank is to supply a drip irrigation system, a small-pore filter at the tank outlet to keep emitters from clogging.

Considerations for the Rainwater Harvesting System Owner It is worth noting that owners of rainwater harvesting systems who supply all domestic needs essentially become owners of their water supply systems, responsible for routine maintenance, including filter and lamp replacement, leak repair, monitoring of water quality, and system upgrades.

The rainwater harvesting system owner is responsible for both water supply and water quality. Maintenance of a rainwater harvesting system is an ongoing periodic duty, to include:

- monitoring tank levels,

- cleaning gutters and first-flush devices,

- repairing leaks,

- repairing and maintaining the system, and ? adopting efficient water use practices. In addition, owners of potable systems must adopt a regimen of:

- changing out filters regularly, 22 ? maintaining disinfection equipment, such as cleaning and replacing ultraviolet lamps, and ? regularly testing water quality.

Water Quality Standards

No federal or state standards exist currently for harvested rainwater quality, although state standards may be developed in 2006.

The latest list of drinking water requirements can be found on the United States Environmental Protection Agencys website. (See References.) The next section discusses the potential vectors by which contaminants get into rainwater. For those intending to harvest rainwater for potable use, the microbiological contaminants E. coli, Cryptosporidium, Guardia lamblia, total coliforms, legionella, fecal coliforms, and viruses, are probably of greatest concern, and rainwater should be tested to ensure that none of them are found (Lye, 2002). County health department and city building code staff should also be consulted concerning safe, sanitary operations and construction of rainwater harvesting systems.

Factors Affecting Water Quality pH (acidity/alkalinity)

As a raindrop falls and comes in contact with the atmosphere, it dissolves naturally occurring carbon dioxide to form a weak acid. The resultant pH is about 5.7, whereas a pH of 7.0 is neutral. (A slight buffering using 1 tablespoon of baking soda to 100 gallons of water in the tank will neutralize the acid, if desired. Also, a concrete storage tank will impart a slight alkalinity to the water.) While Northeast – tends to experience an even lower pH (more acidic) rainwater than in other parts of the state, acid rain is not considered a serious concern in -.

Particulate matter

Particulate matter refers to smoke, dust, and soot suspended in the air. Fine particulates can be emitted by industrial and residential combustion, vehicle exhaust, agricultural controlled burns, and sandstorms. As rainwater falls through the atmosphere, it can incorporate these contaminants. Particulate matter is generally not a concern for rainwater harvesting in -. However, if you wish, geographic data on particulate matter can be accessed at the Air Quality Monitoring web page of the – Commission on Environmental Quality (TCEQ). (See References.)

Chemical compounds

Information on chemical constituents can also be found on the TCEQ Air Quality website. (See References.) In agricultural areas, rainwater could have a higher concentration of nitrates due to fertilizer residue in the atmosphere (Thomas and Grenne, 1993). Pesticide residues from crop dusting in agricultural areas may also be present. Also, dust derived from calcium-rich soils in Central and West – can add 1 mg/l to 2 mg/l of hardness to the water. Hard water has a high mineral content, usually consisting of calcium and magnesium in the form of carbonates. In industrial areas, rainwater samples can have slightly higher values of suspended solids concentration and turbidity due to the greater amount of particulate matter in the air (Thomas and Grenne, 1993).

Catchments surface

When rainwater comes in contact with a catchments surface, it can wash bacteria, molds, algae, fecal matter, other organic matter, and/or dust into storage tanks. The longer the span of continuous number of dry days (days without rainfall), the more catchments debris is washed off the roof by a rainfall event (Thomas and Grenne, 1993; Vasudevan, 2002).

Tanks

The more filtering of rainwater prior to the storage tanks, the less sedimentation and of organic matter will occur within the tanks. Gutter screens, first-flush diverters, roof washers, and other types of pre-tank filters are discussed in Chapter 2. Sedimentation reduces the capacity of tanks, and the breakdown of plant and animal matter may affect the color and taste of water, in addition to providing nutrients for microorganisms.

Most storage tanks are equipped with manholes to allow access for cleaning.

Sediment and sludge can be pumped out

or siphoned out using hose with an inverted funnel at one end without draining the tank annually.

Multiple linked tanks allow one tank to be taken off line for cleaning by closing the valve on the linking pipe between tanks.

Water Treatment

The cleanliness of the roof in a rainwater harvesting system most directly affects the quality of the captured water. The cleaner the roof, the less strain is placed on the treatment equipment. It is advisable that overhanging branches be cut away both to avoid tree litter and to deny access to the roof by rodents and lizards.

For potable systems, a plain galvanized roof or a metal roof with epoxy or latex paint is recommended. Composite or asphalt shingles are not advisable, as toxic components can be leached out by rainwater. See Chapter 2 for more information on roofing material. To improve water quality, several treatment methods are discussed. It is the responsibility of the individual installer or homeowner to weigh the advantages and disadvantages of each method for appropriateness for the individual situation. A synopsis of treatment techniques is shown in Table 3-1.

Table 3-1. Treatment Techniques

Treatment Screening, leaf screens and strainers gutters and downspouts prevent leaves and other debris from entering tank Settling Sedimentation within tank settles out particulate matter Activated charcoal before tap removes chlorine*

Filtering

- Roof washer before tank eliminates suspended

- Material In-line/multi-cartridge after pump sieves sediment

- Activated charcoal after sediment filter removes chlorine, improves Taste

- Slow sand separate tank traps particulate matter

- Microbiological treatment /Disinfection

- Boiling/distilling before use kills microorganisms

Chemical treatments

(Chlorine or Iodine) within tank or at pump (liquid, tablet, or granular) before activated charcoal filter kills microorganisms

Ultraviolet light after activated charcoal filter, before tap kills microorganisms Ozonation after activated charcoal filter, before tap kills microorganisms

Nanofiltration before use; polymer membrane (pores 10-3 to 10-6 inch ) removes molecules

Reverse osmosis before use: polymer membrane (pores 10-9 inch) removes ions (contaminants and microorganisms)

*Should be used if chlorine has been used as a disinfectant.

Chlorination

Chlorination is mentioned here more for its historical value than for practical application. Chlorine has been used to disinfect public drinking water since 1908, and it is still used extensively by rainwater harvesters in Hawaii, the U.S. Virgin Islands, and in older rainwater harvesting systems in Kentucky and Ohio. Chlorine must be present in a concentration of 1 ppm to achieve disinfection. Liquid chlorine, in the form of laundry bleach, usually has 6 percent available sodium hypochlorite. For disinfection purposes, 2 fluid ounces (¼ cup) must be added per 1,000 gallons of rainwater. Household bleach products, however, are not labeled for use in water treatment by the Food and Drug Administration. A purer form of chlorine, which comes in solid form for swimming pool disinfection, is calcium hypochlorite, usually with 75 percent available chlorine. At that strength, 0.85 ounces by weight in 1,000 gallons of water would result in a level of 1 ppm. In either case, it is a good idea to carefully dilute the chlorine source in a bucket of water, and then stir with a clean paddle to hasten mixing (Macomber, 2001). Chlorine contact times are show in Table 3-2. The use of chlorine for disinfection presents a few drawbacks. Chlorine combines with decaying organic matter in water to form trihalomethanes. This disinfection by-product has been found to cause cancer in laboratory rats. Also, some users may find the taste and smell of chlorine objectionable. To address this concern, an activated carbon filter may be used to help remove chlorine.

Chlorine does not kill Guardia or Cryptosporidium, which are cysts protected by their outer shells. Persons with weakened or compromised immune systems are particularly susceptible to these maladies. To filter out Guardia and Cryptosporidum cysts, an absolute 1-micron filter, certified by the NSF, is needed (Macomber, 2001).

Table 3-2. Contact Time with Chlorine Water pH

Water temperature 50 F or warmer

45 F 40 F or colder

Contact time in minutes

UV Light

UV light has been used in Europe for disinfection of water since the early 1900s, and its use has now become common practice in U.S. utilities. Bacteria, virus, and cysts are killed by exposure to UV light. The water must go 26 through sediment filtration before the ultraviolet light treatment because pathogens can be shadowed from the UV light by suspended particles in the water. In water with very high bacterial counts, some bacteria will be shielded by the bodies of other bacteria cells. UV lights are benign: they disinfect without leaving behind any disinfection by-products. They use minimal power for operation. One should follow manufacturers recommendations for replacement of bulbs.

Testing

Harvested rainwater should be tested before drinking and periodically thereafter. Harvested rainwater should be tested both before and after treatment to ensure treatment is working. It is advisable to test water quarterly at a minimum, if used for drinking. Harvested rainwater can be tested by a commercial analytical laboratory, the county health departments of many – counties, or the – Department of Health.

Before capturing rainwater samples for testing, contact the testing entity first to become informed of requirements for container type and cleanliness, sample volume, number of samples needed, and time constraints for return of the sample.

For instance, for total coliform testing, water must usually be captured in a sterile container issued by the testing entity and returned within a maximum of 30 to 36 hours. Testing for pH, performed by commercial analytical laboratories must be done on site; other tests are less time-critical.

A list of county health departments that will test for total and fecal coliform can be found on the – Department of State Health Services (TDSHS) website. (See References.) The testing fee is usually between $15 and $25. Homeowners should contact the health department prior to sample collection to procure a collection kit and to learn the proper methods for a grab sample or a faucet sample.

– Department of State Health Services will test for fecal coliforms for a fee of $20 per sample. (See References.) A collection kit can be ordered from TDSHS at (512) 458-7598.

Commercial laboratories are listed in telephone Yellow Pages under LaboratoriesAnalytical & Testing. For a fee, the lab will test water for pathogens. For an additional fee, labs will test for other contaminants, such as metals and pesticides.

Chapter 4

Water Balance and System Sizing The basic rule for sizing any rainwater harvesting system is that the volume of water that can be captured and stored (the supply) must equal or exceed the volume of water used (the demand). The variables of rainfall and water demand determine the relationship between required catchments area and storage capacity. In some cases, it may be necessary to increase catchments surface area by addition of a rain barn or outbuilding to capture enough rainwater to meet demand. Cistern capacity must be sufficient to store enough water to see the system and its users through the longest expected interval without rain. The following sections describe ways to determine the amount of rainfall, the estimated demand, and how much storage capacity is needed to provide an adequate water supply.

Intended End Use

The first decision in rainwater harvesting system design is the intended use of the water. If rainwater is to be used only for irrigation, a rough estimate of demand, supply, and storage capacity may be sufficient. On the other hand, if rainwater is intended to be the sole source of water for all indoor and outdoor domestic end uses, a more precise reckoning is necessary to ensure adequate supply.

How Much Water Can Be Captured?

In theory, approximately 0.62 gallons per square foot of collection surface per inch of rainfall can be collected. In practice, however, some rainwater is lost to first flush, evaporation, splash-out or overshoot from the gutters in hard rains, and possibly leaks. Rough collection surfaces are less efficient at conveying water, as water captured in pore spaces tends to be lost to evaporation. Also impacting achievable efficiency is the inability of the system to capture all water during intense rainfall events. For instance, if the flow-through capacity of a filter-type roof washer is exceeded, spillage may occur. Additionally, after storage tanks are full, rainwater can be lost as overflow.

Figure 4-1. Catchments areas of three different roofs For planning purposes, therefore, these inherent inefficiencies of the system need to be factored into the water supply calculation. Most installers assume an efficiency of 75 percent to 90 percent. In most – locations, rainfall occurs seasonally, requiring a storage capacity sufficient to store water collected during rainy times to last through the dry spells. In West -, total annual rainfall might not be sufficient to allow a residence with a moderate-sized collection surface to capture sufficient water for all domestic use. Some residences might be constrained by the area of the collection surfaces or the volume of storage capacity that can be installed.

Collection Surface

The collection surface is the footprint of the roof (Figure 4-1). In other words, regardless of the pitch of the roof, the effective collection surface is the area covered by collection surface (length times width of the roof from eave to eave and front to rear). Obviously if only one side of the structure is guttered, only the area drained by the gutters is used in the calculation.

Rainfall Distribution

In -, average annual rainfall decreases roughly 1 inch every 15 miles,

Figure 4-2. Average annual precipitation in -, in inches. From east to west (Figure 4-2), from 56 inches per year in Beaumont to less than 8 inches per year in El Paso. As one moves westward across the state, the prevalence and severity of droughts must also be considered.

To ensure a year-round water supply, the catchments area and storage capacity must be sized to meet water demand through the longest expected interval without rain. For instance, in West -, the historic longest span of continuous dry days has exceeded three months. For reference purposes, a contour map of historical maximum number of dry days in – is shown in Figure 4-3 (Krishna, 2003). If the rainwater harvesting system is intended to be the sole water source for a household, the designer must size the system to accommodate the longest anticipated time without rain, or otherwise plan for another water source, such as a well backup or hauled water. Also, rainfall from high-intensity, short duration rainfall events may be lost to overflow from storage tanks or splash out from the gutters. Although these intense rainfall events are considered part of the cumulative annual rainfall, the total available volume of such an event is rarely captured.

Another consideration is that most rainfall occurs seasonally; annual rainfall is not evenly distributed throughout the 12 months of the year. The monthly distribution of rainfall is an important factor to consider for sizing a system. Monthly rainfall data for selected – cities is given in Appendix B.

Monthly Rainfall

Two different estimators of monthly rainfall are commonly used: average rainfall and median rainfall. Average annual rainfall is calculated by taking the sum of historical rainfall and dividing by the number of years of recorded data. This information is available from numerous public sources, including the National Climate Data Center website. (See References.) Median rainfall is the amount of rainfall that occurs in the midpoint of all historic rainfall totals for any given month. In other words, historically for the month in question, half of the time the rainfall was less than the median and half of the time rainfall was more than the median. Median values and average rainfall values for representative – cities are provided in Appendix B.

Median rainfall provides for a more conservative calculation of system sizing than average rainfall. The median value for rainfall is usually lower than the average value since large rainfall events tend to drive the average value higher. In other words, the sum of monthly medians is lower than the annual average due to the fact that the arithmetic average is skewed by high-intensity rainfall events. For planning purposes, median monthly rainfall can be used to estimate water availability to a Figure 4-3. Maximum number of dry days

For example, in the sample calculations at the end of this chapter, the average annual rainfall for Dallas is about 35.0 inches, but the sum of the monthly medians is only 29.3 inches.

Calculating Storage Capacity

Once the median or average potential for rainfall capture is known from rainfall data and catchments area, it will be necessary to calculate storage capacity. The decision of whether rainwater will be used for irrigation, potable and domestic use, or both, will dictate water demand, and therefore, capacity. A simple method of roughly estimating storage capacity popular among professional installers is to size the storage capacity to meet quarterly demand. The system is sized to meet estimated demand for a three-month period without rain. Annual estimated demand is divided by four to yield necessary storage capacity using this approach. This approach, however, may result in a more expensive system due to higher storage costs.

If a rainwater harvesting system is to be the sole water supply, overbuilding ensures a safety margin. As with many things in life, it helps to hope for the best but plan for the worst. Even when budget constraints may not allow the user to install as much storage capacity as a sizing method may indicate, it is important to provide for an area where additional tanks or cisterns can be installed at a later date when finances permit.

The Water Balance Method Using Monthly Demand and Supply One method of determining the feasibility of a proposed system is the monthly water balance method. This method of calculation is similar to maintaining a monthly checkbook balance. Starting with an assumed volume of water already in the tanks, the volume captured each month is added to the previous balance and the demand is subtracted. The initial volume of water in the tanks would be provided by hauling or capturing water prior to withdrawing water from the system. An example is presented at the end of this chapter.

Data and calculations can be entered on an electronic spreadsheet to enable the user to compare different variables of catchments area and storage. It is suggested that homeowners experiment with different variables of storage capacity and, if applicable, catchments surface to find individual levels of comfort and affordability for catchments size and storage capacity.

As mentioned above:

Catchments area and rainfall determine supply, and demand dictates required storage capacity.

A commitment to conserving water with water-saving fixtures, appliances, practices indoors, and low-water-use landscaping outdoors is an essential component of any rainwater harvesting system design. Not only is conservation good stewardship of natural resources, it also reduces the costs for storage capacity and related system components. If the amount of rainwater that can be captured calculated from roof area and rainfall is adequate or more than adequate to meet estimated demand, and meets the physical constraints of the building design, then storage capacity can be sized to meet estimated demand. If the monthly amount of water that can be captured, accounting for dry spells, is less than monthly estimated demand, then additional catchments area or supplemental supplies of water (such as groundwater from a well) will need to be considered.

In drier areas, no matter how large the storage capacity, catchments area may need to be increased with a rain barn or additional roof area to meet demand. At the end of this chapter, an example of a water balance calculation is shown for the City of Dallas.

Estimating Demand

A water-conserving household will use between 25 and 50 gallons per person per day. (Note that total gallons per capita per day figures published for municipalities divide all the water distributed by the population, yielding a much larger amount per capita than actual domestic consumption.) Households served previously by a water utility can read monthly demand from their meter or water bill to find monthly demand for purposes of building a new rainwater harvesting system. Divide the monthly total by the number of people in the house, and the days in the month to get a daily per capita demand number. Water conservation is covered later in this chapter. Households solely dependent upon rainwater should adopt efficient water use practices both indoors and outdoors.

Estimating indoor water demand Indoor water demand is largely unaffected by changes in weather, although changes in household occupancy rates depending upon seasons and ages of household members, more water use during the hot summer months, and very minor changes in consumption of water due to increases in temperature may be worth factoring in some instances. The results of a study of 1,200 single-family homes by the American Water Works Association (AWWA) in 1999 found that the average water conserving households used approximately 49.6 gallons per person per day (American Water Works Association, 1999).

Table 4-1 can be used to calculate indoor

water demand. Many households use less than the average of 49.6 gallons per person found in the 1999 report by the AWWA, Residential End Uses of Water. The water volumes shown in the table assume a water-conserving household, with water-conserving fixtures and good practices, such as shutting off the water while brushing teeth or shaving. Overall demand in showers, baths, and faucet uses is a function of both time of use and rate of flow. Many people do not open the flow rate as high as it could be finding low or moderate flow rates more comfortable. In estimating demand, measuring flow rates and consumption in the household may be worth the effort to get more accurate estimates.

Table 4-1. Estimating Indoor Daily Domestic Demand

A. Water consumption using conserving fixtures

B. Assumptions from AWWA Residential End- Use Study

C. Adjustments to assumptions (adjust up or down according to actual use)

D. Number of persons in household

E. Household monthly demand

A x (B or C )x D x 30

Toilets (use only appropriate type)

ULFT 1.6 gal/flush 6 flushes/ person/day

Dual Flush 1 gal/flush liquids

1.6 gal/flush solids

6 flushes/ person/day

Baths & showers

Showerhead 2.2 gal/min 5 minutes/ person/day

Bath 50 gal/bath NA

Faucets (personal hygiene, cooking, and cleaning of surfaces)

2.2

gal/faucet/min 5 minutes/ person/day

Appliances or uses which are measured on a per-use basis (not a per-person basis):

Clothes washer Front-loading (horizontal-axis)

1825 gal/load 2.6 loads/week

Dishwasher 8 gal/cycle 0.7 cycles/day

Miscellaneous other

Total

Indoor water conservation

Indoor domestic water conservation can be achieved by a combination of fixtures, appliances, and water conserving practices. The advantage of water-conserving appliances is that they require no change in household routine.

Some water-conserving practices need user action, such as turning off the water while brushing teeth or shaving; washing vegetables in a pan rather than under a stream; washing only full loads of laundry and dishes; and keeping a pitcher of water in the refrigerator, rather than waiting for cold water to arrive from a faucet.

Water conservation appliances include:

- Ultralow flush toilets (ULFTs). Since 1993, only ULFTs with 1.6 gallons per flush may be sold in the United States. Older toilets should be replaced with the more efficient models. Some of the ULFTs require special early closing flappers to maintain their low-flow rates, so care should be taken in purchasing the correct replacement flapper for leaking toilets. If purchasing a new toilet, those that do not use early closure flappers are recommended. Dual-flush toilets (using less volume for liquid wastes) are also a good choice for a water-wise household.

- Faucet aerators and efficient showerheads. These fixtures are designed to use 2.2 gallons per minute at 60 psi, or 2.5 gpm at 80 psi (Table 4-1). Studies have shown that most people feel comfortable at less than full flow rates, so using the new fixtures (which are the only ones sold in the United States since 1992) should provide you with an efficient and comfortable experience.

- Hot water on demand. These wall mounted units heat water just prior to use, eliminating the waste of waiting for hot water from the water heater while cold water is allowed to flow down the drain. Hot water loop systems keep hot water continuously circulating to achieve the same goal, but can use more energy. Another on demand unit heats water quickly only when activated by a pushbutton, rather than circulating water through a loop, saving both water and energy. A rebate from San Antonio Water System (SAWS) is available for installation of this type of on-demand circulation system.

Horizontal-axis (front-loading) clothes washers. Because clothes are tumbled through a small volume of water in the bottom of the drum (rather than washed in a full tub of water), this appliance can save up to half the water of a traditional clothes washer. It is also as much as 42 percent more energy efficient. A list of frontloading, horizontal-axis clothes washers is maintained by the Consortium for Energy Efficiency online. (See References.) Several municipal utilities in -, including offer rebates for the purchase of these energy- and water-efficient appliances.

Call us today to discuss how we can assist you with a rain water collection system.