I have two 3D printers already, and am familar with several others that look interesting. In my quest to stay on top of this dynamic field, a few weeks ago I got a da Vinci 1.0 3D printer from Studica (www.studica.com/XYZprinting), a company whose focus is on hardware and software products for education. Studica sells a complete line of 3D printers, but the one that caught my attention was the da Vinci. This machine retails for $499, which is staggeringly low when you look at the system. First, it has a very large print volume – 20cm by 20cm by 20cm. This makes it one of the largest print beds in the under $2,000 printer category. The ABS filament is provided in nicely designed cartridges that don’t cost an arm and a leg. The overall look of the printer is quite elegant. The transparent case lets you see everything as it is printing (especially if you turn on the interior light.) A built-in display lets you do a lot of tasks (such as loading or changing filament) without having a computer attached.

This printer uses a glass print bed that you coat with a thin layer of glue from a regular glue stick. The advantage of this adhesive method is that you don’t generally need to print using a “raft” – a layer of plastic put down by the nozzle before the parts are printed. Another nice touch is that the print nozzle is automatically cleaned after printing and any extra filament strands are placed in a box that can be removed later to get rid of scraps. The internal hardware looks very well designed. In fact, just looking inside this machine made me think I was looking at a very high end printer!

This printer uses a glass print bed that you coat with a thin layer of glue from a regular glue stick. The advantage of this adhesive method is that you don’t generally need to print using a “raft” – a layer of plastic put down by the nozzle before the parts are printed. Another nice touch is that the print nozzle is automatically cleaned after printing and any extra filament strands are placed in a box that can be removed later to get rid of scraps. The internal hardware looks very well designed. In fact, just looking inside this machine made me think I was looking at a very high end printer!

As with any 3D printer, it is essential to be sure the print bed is calibrated properly, otherwise the parts will look awful. The da Vinci printer is calibrated at the factory, but, in shipping, the calibration screws may get jarred from their optimal positions. Fortunately, this is easy to fix, and the technical support team sent me a link to a short video to show, step by step, how to align the print bed. The print head has a special electrode on it that is brought into contact with the build plate hardware at three locations. The built-in display then lets you know what adjustments are needed, or, if it is in the range of automatic alignment, to accept the new settings. In my experience, this task only needs to be done once.

As for printing, you simply connect the printer to your computer using a USB port and run the supplied software. From this program you load a file you’ve created or downloaded in the form of an STL file – the format most often used on 3D printers. Once you press the Print button, the print bed is heated to about 100C while your object model is sliced into layers so the part can be built layer by layer. Once printing has started, the built-in display lets you know how long the print job will take. If you want, you can disconnect your computer from the printer at this point so it can be used for other things (like designing more things to print!)

As for printing, you simply connect the printer to your computer using a USB port and run the supplied software. From this program you load a file you’ve created or downloaded in the form of an STL file – the format most often used on 3D printers. Once you press the Print button, the print bed is heated to about 100C while your object model is sliced into layers so the part can be built layer by layer. Once printing has started, the built-in display lets you know how long the print job will take. If you want, you can disconnect your computer from the printer at this point so it can be used for other things (like designing more things to print!)

Once the printer is finished with a job, the bed is cooled down and moved to the bottom to make it easy to remove your design. The manufacturer provides a plastic scraper to separate the part from the bottom of the build plate. My experience is that, once the part has cooled down, the plastic contracts just a bit, and it is easy to snap the part from the plate, leaving a very smooth finish on the bottom, and the build plate ready to be cleaned and coated with a new thin glue layer.

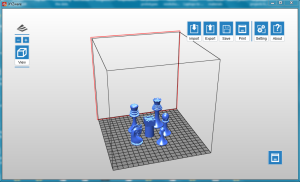

As for print quality, the parts are not quite as nicely finished as those I make on my Afinia printer, but for most school projects it is pretty good. The downside is that this printer takes a lot of time to print projects. In a school setting, time is important; but the large build plate might let you print several student projects at a time, making this less of an issue.

Overall, I rate the industrial design very high. The price is unbelievably low. Technical support is wonderful. The only downsides when compared with more expensive printers is the print time and slightly reduced print quality. Taking everything into consideration, the da Vinci 1.0 is a good buy for those wanting to get involved in 3D printing. Later, some may choose to scale up to more expensive printers with higher print quality and faster speed, but, even then, this printer will get a lot of use!