ASGCO®’s Armorite® Increases Wear-Plate Life at Copper Mine Concentrator.

Objective: To provide a wear plate that proved to provide both impact and abrasion resistance in tough mining conditions.

Problem: Due to the highly abrasive ore properties and the occasional 2”-3” steel balls from the SAG mills made this application very difficult for the mine. The average life of previous wear plates from two different manufacturers was on average about 6-8 weeks. Both the Sandvik® HX900 and the ESCO® Kwik-Lok® carbide wear plates were cracking due to the high impact of the ore and simply do not provide the wear protection the mine was looking for.

[line]

The Armorite® Wear Liners provided 6 times longer wear life than the previous brand wear plates!!!

[line]

Based on those results the plant proceeded with a study to look at other high wear and impact applications where the Armorite would prove successful. ASGCO®’s Armorite® proved to be both impact and wear resistant, demonstrating “one year of wear life”, and proved to be extremely cost effective and a great savings for the mine in both dollars and time…

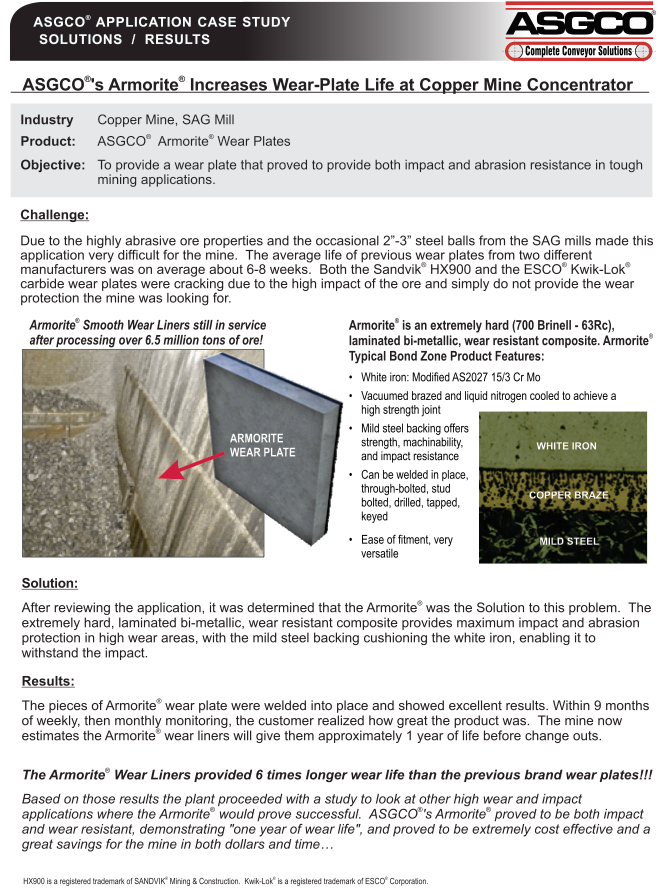

Armorite® is an extremely hard (700 Brinell – 63Rc), laminated bi-metallic, wear resistant composite. Armorite® Typical Bond Zone Product Features:

- White iron: Modified AS2027 15/3 Cr Mo

- Vacuumed brazed and liquid nitrogen cooled to achieve a high strength joint

- Mild steel backing offers strength, machinability, and impact resistance

- Can be welded in place, through-bolted, stud bolted, drilled, tapped, keyed

- Ease of fitment, very versatile

[line]

Other Armorite® Applications:

- CHUTE LININGS

- ROCK-BOX EDGES

- GRIZZLY CAPS/SCREENS