SHOP

EXPLORE

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

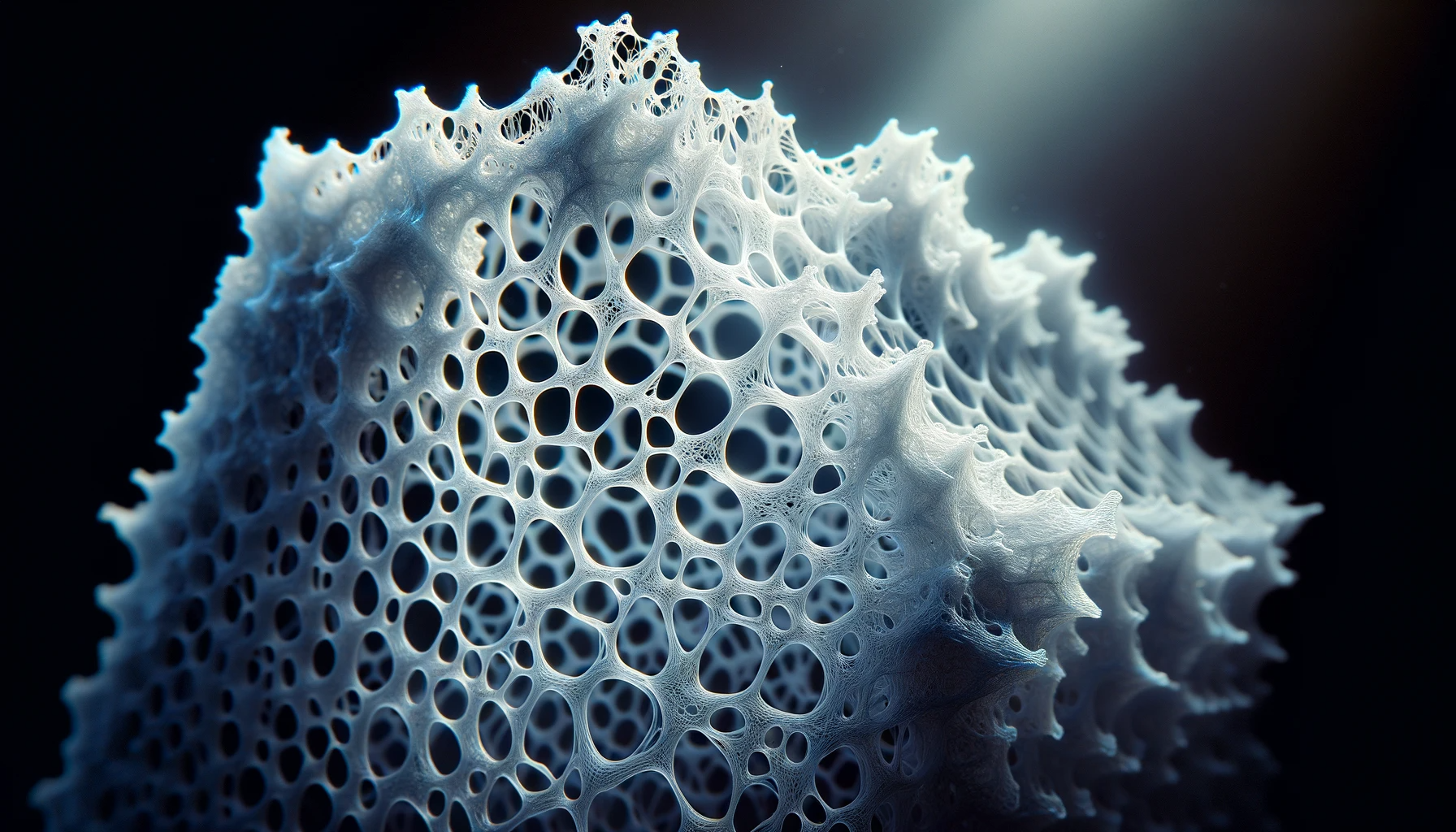

Aerogel - the world's lightest solid

January 09, 2024 2 min read 1 Comment

Aerogels represent a groundbreaking class of materials that are distinguished by their extreme porosity and low density. They are typically derived from a gel in which the liquid component has been replaced with gas. The most common type of aerogel is based on silica, although there are varieties made from other materials like carbon, metal oxides, and more recently, polymers.

The structure of aerogels is characterized by an interconnected nano-architecture. This unique structure is achieved through a process called supercritical drying, which avoids the collapse of the gel network that would occur during conventional evaporation. The result is a material with a very high surface area – up to 1000 m²/g or more. This structure imparts a range of remarkable properties.

Aerogels are known for their low thermal conductivity, making them excellent insulators. This property is a direct result of their porosity, which inhibits the transfer of heat through both convection and conduction. In addition, their low density (they can be up to 99.8% air) and transparency to certain wavelengths of light have opened up applications in areas like insulating performance gear, and spacecraft.

Recent advances in aerogel technology have led to the development of more robust versions, like polymer-reinforced aerogels, which address one of the major limitations of traditional aerogels – their fragility. Moreover, the high surface area and porosity make aerogels ideal for applications in catalysis, environmental remediation (like oil spill clean-up), and as a medium for chemical sensors.

In the realm of theoretical and practical research, aerogels offer exciting avenues for exploration, particularly in terms of nanostructuring and tailoring materials for specific applications, ranging from energy storage and conversion to what we do at Graphene-X, performance gear.

KEY F.A.Q. on Aerogels:

-

How are aerogels made, and what makes them so light and strong?

-

Aerogels are created by removing the liquid component from a gel through a process called supercritical drying. This leaves behind a 'frozen' network of solid material, mostly air, which makes them incredibly lightweight. Despite being up to 99% air, aerogels are strong due to their unique microstructure, where tiny solid strands of material are interconnected, providing structural integrity.

-

-

What are some practical uses of aerogels?

-

Due to their low density and excellent insulation properties, aerogels are used in a variety of applications. They are used for thermal insulation in spacesuits and Mars rovers. Aerogels also have applications in everyday life, like in insulating windows and performance gear. Their ability to absorb oil but repel water has made them useful in environmental clean-up operations, such as oil spill containment.

-

-

What are the limitations of aerogels, and how are scientists working to overcome them?

-

The main limitations of aerogels are their fragility and the high cost of production. Traditional silica aerogels can be quite brittle and can shatter like glass. Researchers are working on making aerogels more durable by reinforcing them with polymers or other materials. Cost-wise, the supercritical drying process is expensive, so finding cheaper and more efficient manufacturing methods is a focus of ongoing research.

-

Giacomo Pasini

January 10, 2024

You must consider to do a sleeping bag in graphene and aerogel.