If you would like to learn more about the IAEA’s work, sign up for our weekly updates containing our most important news, multimedia and more.

Shrinking nuclear waste and increasing efficiency for a sustainable energy future

Jeffrey Donovan

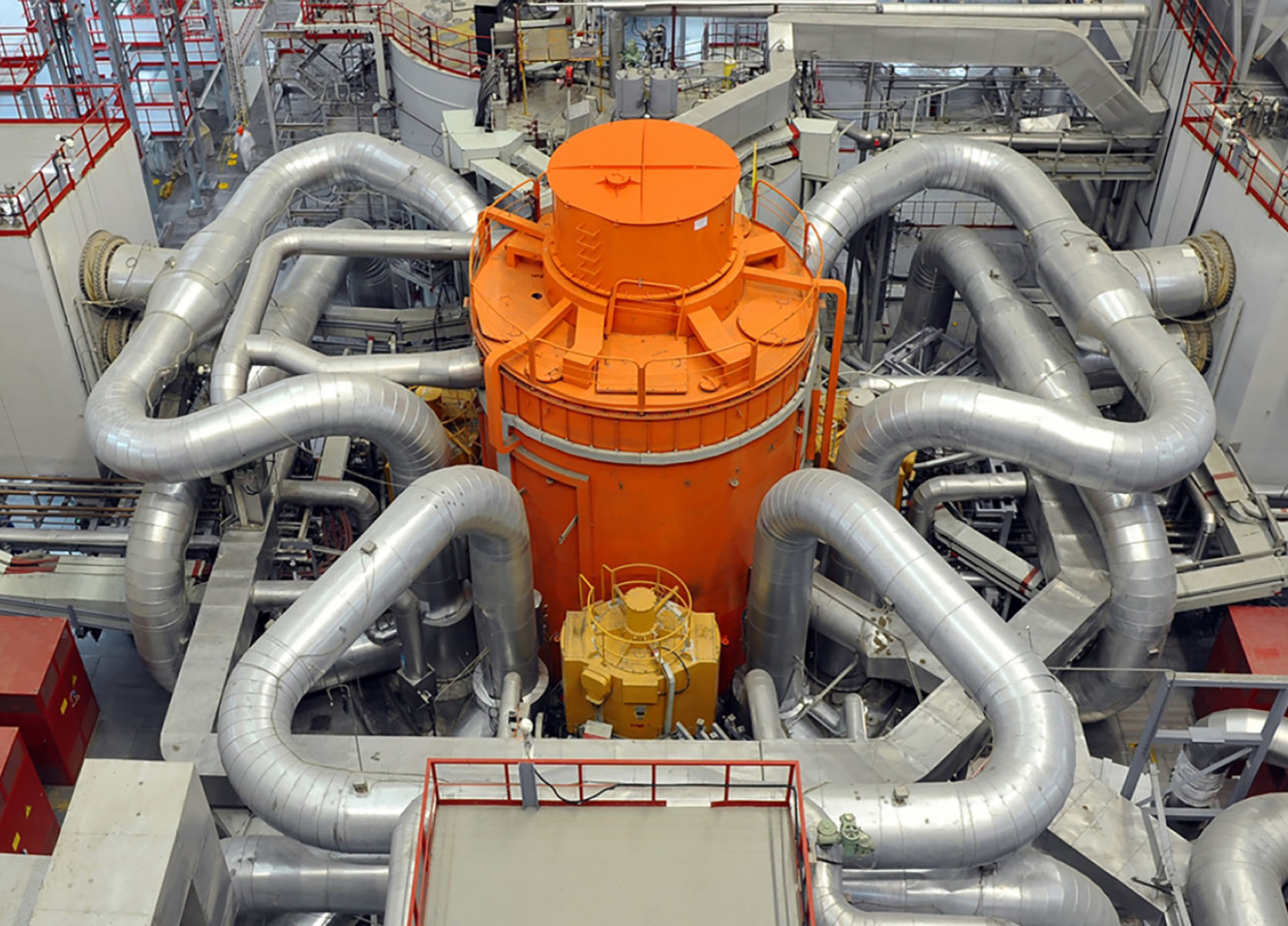

The BN-800 reactor at the Beloyarsk Power Station in Russia. (Photo: Rosenergoatom)

Shrinking nuclear waste and increasing efficiency for a sustainable energy future

Fast neutron reactors can increase efficiency of nuclear energy and shrink the environmental footprint of radioactive waste. Several countries are looking to these innovative reactors to help ensure a sustainable energy future.

Fast reactors use neutrons that are not slowed down by a moderator, such as water, to sustain the fission chain reaction. While only a fraction of natural uranium is used as fuel in existing thermal reactors, fast reactors can use almost all uranium contained in the fuel to extract up to 70 times more energy, reducing the need for new uranium resources.

Fast reactors also operate in what is known as a closed nuclear fuel cycle. A closed fuel cycle is when spent fuel — nuclear fuel after it has been irradiated — is recycled and reused. Such an energy system could potentially be sustainable for thousands of years. This contrasts with an open fuel cycle, where nuclear fuel is used once and the spent fuel is declared as waste for eventual underground disposal in geological repositories.

Fast reactors can also produce or ‘breed’ more fuel than they consume and burn off some of the waste contained in spent fuel, such as minor actinides, which thermal reactors cannot do efficiently. Burning them off significantly reduces the volume, toxicity and lifespan of the longest-living radioactive waste.

“The environmental footprint of an energy source, such as its waste, is a big question for many countries as they look for sustainable ways to deliver clean energy,” said Amparo Espartero Gonzalez, Technical Lead for the Nuclear Fuel Cycle at the IAEA. “The ability to shrink that footprint, while also getting more out of nuclear fuel is a big part of the growing appeal of fast reactors for many countries and what is driving their technological development.”

Making a comeback

Fast reactors were among the first technologies deployed during the early days of nuclear power, when uranium resources were perceived to be scarce. But as technical and materials challenges hampered development, and new uranium deposits were identified, light water reactors (LWRs) eventually became the industry standard. Five fast reactors are now in operation: two operating reactors (BN-600 and BN-800) and one test reactor (BOR-60) in Russia, India’s Fast Breeder Test Reactor (FBTR) and the China Experimental Fast Reactor (CEFR).

New concepts, technologies and advances in materials research, combined with a long-term vision of nuclear power as part of sustainable energy, are now reviving the fast reactor option. These advances generally feature innovative upgrades, such as enhanced safety features and improved and more compact designs that address economics. New designs also include alternative coolants, such as molten salt, lead, lead–bismuth and gas.

“Fast reactors have been under development for decades primarily as fuel breeders and, in recent years, also as long-life battery-type small modular reactors and even microreactors,” said Vladimir Kriventsev, Team Leader for Fast Reactor Technology Development at the IAEA. “Fast reactors can make nuclear power a sustainable energy source for thousands of years and provide significant improvements in nuclear waste management.”

Fast reactors in progress

Fast reactors are under development around the world. The IAEA plays a central role in supporting their development and deployment as well as in sharing information and experience, including through coordinated research projects, technical publications, technical working groups and international conferences.

Already operating two sodium cooled fast reactors, Russia plans to deploy a next generation 1200 megawatt (MW)(e) commercial fast reactor after 2035 as part of a self-sustaining system alongside light water reactors. With help from the fast reactor, spent fuel from the thermal reactors will be reprocessed and reused, with a final waste footprint up to ten times smaller than that of regular nuclear fuel.

India is commissioning the sodium cooled 500 MW(e) Prototype Fast Breeder Reactor, the first of several industrial fast reactors the country is planning. China, which operates a 20 MW(e) experimental fast reactor, is building a large demonstration fast reactor and plans to eventually deploy commercial fast reactors.

In North America, several fast reactor designs using different coolants, including molten salt, are under development. The United States plans to build a test fast reactor to facilitate the technology’s further development as well as a 1.5 MW(e) demonstration micro fast reactor, which will also demonstrate a new type of reprocessed fuel suitable for use in future innovative reactors.

Since the 1950s, the technological viability of fast reactors has been amply demonstrated. France operated the 1200 MW(e) Superphenix commercially for 12 years until 1998 and continues to do research and development on the technology, as do South Korea as well as Japan, which plans to restart an experimental fast reactor.

Still, wider industrial deployment of fast reactors will largely depend on improved economics.

“In a resource-constrained world where the price of uranium is expected to be much higher than now and a greater premium to be put on waste minimization, innovative and compact fast reactors may become more economically competitive compared with traditional thermal reactors,” said Stefano Monti, Head of the Nuclear Power Technology Development Section at the IAEA. “With several countries actively developing fast reactors, we expect them to make an important contribution to clean energy systems in the coming decades.”