Boeing AEW&C – Research is never wasted! Aerospace cutaways – it's what I do.

It’s not unusual for delays of one type or another to creep into the production of Military cutaways. Typically such delays are visit related, as I await “clearance” to access a specific program and gain permission to collect engineering material. Luckily, I’ve worked with the majority of western manufacturers over the years, so my product and name are fairly well known. Delays though can also occur at the end of the process as the finished cutaway may require clearance, approval for public release by the appropriate service, State Dept., or Export Compliance Officer, depending on the customer and country of origin.

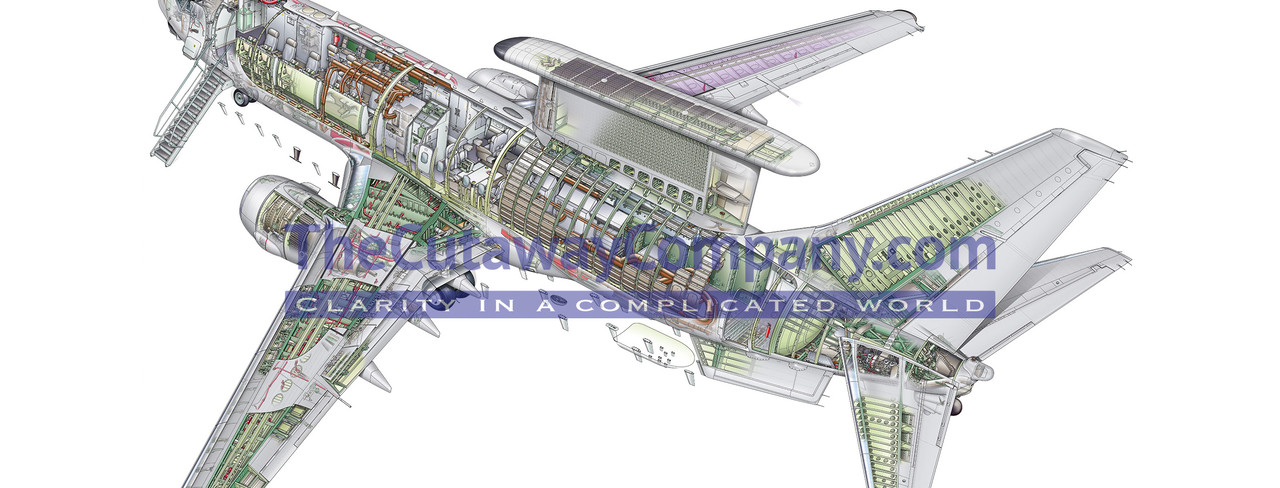

At the end of 2007 I was asked to produce a cutaway of the Boeing AEW&C, commonly known as the “Wedgetail”in Australia, “Peace Eagle”in Turkey and ”Peace Eye” in South Korea. With the firm assurances that the visit would be quickly cleared, I frantically began to reorganise my production schedule. Little did I realise at the time that it would take two and half years before the AEW&C cutaway was finally released, as clearance had to be arranged through the US, Australia, Turkey and South Korea.

Permission for the visit was finally forthcoming in July 2009 and while this late date may have cause magazine editors or program directors some sleepless nights, I could not afford to rest on my laurels, as time performing research is never wasted. At the start of my career I was taught to keep research folders for every cutaway I intended to produce, filling them with any and all subject related material, sourced from company press releases, photos, media technical briefings and airshow/trade-show literature, etc. Such folders have furnished valuable data for cutaway descriptions and keys in the past and would soon assist me with the AEW&C project.

When it finally occurred, I had hoped that the weeklong AEW&C visit to Boeing’s Kent Facility for data collection and Boeing Field for photographs, would be a fairly painless, as I initially intended to update John Marsden’s Boeing 737-700 cutaway, which I had assisted on a decade earlier. Unfortunately when reviewing the engineering data on day one, it rapidly became obvious that the existing airframe depicted this B+W traditional cutaway image was unusable as the basis for a modern high-resolution colour cutaway. So I made the decision to utilise Boeing’s IVT system to collect data for a completely new cutaway from broadly the same viewpoint.

I had not used IVT before, so I spent the next 24 hours working out what could be done with the system, after which the data collection began to move forwards. There were though some additional ITAR restrictions thrust upon me during the visit, ranging from a detailed document indicating where I could walk in the engineering office (specifically detailing how I would visit the restroom), right through to a serious restriction on collecting any material related to the pylon-mounted Multi-role Electronically Scanned Array (MESA)! To simply ignore what was essentially at the heart of the aircraft may have seemed totally unrealistic, but the ITAR restrictions were very specific and I had to adhere to them, as that was my job – I simply could not collect any MESA data from Boeing.

Ordinarily this would have been a major headache to say the least, as the MESA installation not only defined the whole AEW&C platform, it also dominated my cutaway view! It was like Vermeer removing the earring from his girl, or serving a Martini without an olive! What was I to do? Luckily for me, I had my research folder to fall back on, which included a Northrop Grumman press releases and videos showing the MESA installation being assembled and tested – all of which was in the public domain. So, with my callipers in hand, I quickly printed off images and began to scale and assemble the MESA installation the old fashioned way – on tracing paper – before applying it to the gapping hole on the back of the aircraft.

The finished AEW&C cutaway (and copies of the NG MESA publically released material) was sent back to Boeing for checking by the engineering and compliance team, and not a word was mentioned about the MESA installation. After a few changes to the key, a public release number was issued for the illustration and I could breath a sigh of relief and enjoy a well deserved Martini, complete with olive……

Are you are interested in commissioning a cutaway of your aircraft? If so, please feel free to visit our website and checkout cutaway options, uses and services provided to our aerospace customers.

If you found this post interesting, please checkout my previous cutaway articles on Linkedin