Value Analysis/Value Engineering - My experience

By: Jose Avendano

I was introduced to VAVE during my career at Maytag Appliances with the Galesburg Refrigeration Products Division. It was probably around 1996. I never thought that participating on such an event would change the way that I would see things as much as it did. Twenty years have gone by and during this time, I have facilitated over 30 events, participated in 50 events, and even developed my own simple training technique as the intro for the events. I have been able to generate ideas that have contributed to over $10MM in cost reductions.

VAVE is a structured method of exploring and deeply analyzing the detail of how value is created. I remember that in 1996, we had just completed the design of the new Maytag refrigerator product line that would be introduced in January 1997. All the engineers and team leaders were invited. The design teams had done a thorough job at designing a refrigerator that would be a top performer, as well as, a very cost competitive product. However, the company wanted more out of the cost and, as a result, a VAVE consultant was brought in to facilitate the event. Most of us were reluctant. How could you get more cost out of the product? We were all in for a surprise.

The technique is based on “VALUE” as it relates to “FUNCTION” and “COST”. “FUNCTION” is something that a product or process must do to make it work and to make it attractive for someone to purchase it. As examples, I will list: Performance, reliability, durability, usefulness. “COST” on the other hand is based on the cost needed to make the product available to the purchaser. This includes: Time, money, people, energy, material, etc.

So, the idea is for us to look at each product to determine the “VALUE”. “FUNCTION” contributes to the “VALUE” in a positive way. On the other hand, “COST” contributes to it, in a negative way. Here is a perfect example. The automobile industry used to place cigarette lighters in cars. Let’s say the current cost to the consumer for this option is $350. Would you pay an extra $350 for this option today?? Most of you would say no. Thus, the “VALUE” of this product is low in most people’s eyes. So, the automobile industry decided to change the “FUNCTION” for this product from a cigarette lighter to a 12V port. Now I ask all of you would you pay $350 for this product? The majority of you would say YES! In fact, people want more and more 12V ports in cars nowadays.

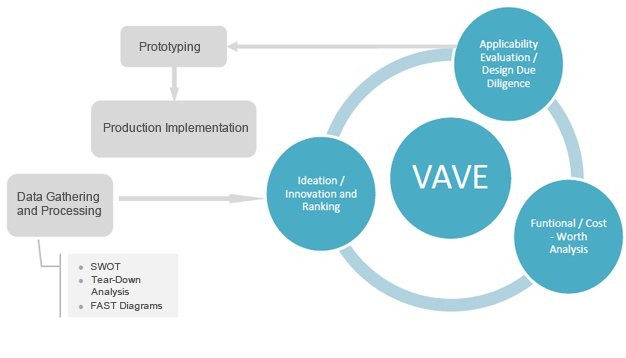

When you conduct a VAVE you must do the following for each component of a product (I have briefly explained this below to keep the article short):

- Identify and prioritize functions.

- Review each component.

- What is the customer paying? What is the customer getting for it? Usually there are very few basic functions.

- Identify secondary functions by asking ‘How is this achieved?’ or ‘What other functions support the basic functions?

- Determine the relative importance of each function.

- Analyze contributing functions.

- Find the components in the assembly that provide the key functions. Again, the question ‘How’ can come in very useful here.

- Measure the cost of each component as accurately as possible, including all material and production costs.

- Seek improvements.

- Eliminate or reduce the cost of components that add little value, especially high-cost components.

- Enhance the value added by components that contribute significantly to functions that are particularly important to customers.

It is imperative that you record every idea that is generated by each team on the VAVE event. The form should include a probability of success for each idea so that you can present cost savings for short, mid, and long term. There are several forms that you can find to record the ideas on the web. If the product that is being reviewed has several systems, I would recommend several teams. For example: In a refrigerator you have: Cabinet assembly, door assembly, internal components, refrigeration system, electrical and lighting, electronics. If you want more focus on each system, you would have six teams on this event.

Encourage the teams to think out of the box, to brainstorm, to stimulate the thinking process. Make sure you mention to the group that “NO IDEA IS A BAD IDEA”. You want them to think about these types of questions during the VAVE review:

- What is the product or process?

- What does it do?

- What does it cost?

- How does the competition do it?

- What else would do the job ……. better?

- What are the costs of the alternative?

- What are the advantages, disadvantages, and risks?

- Can we combine parts?

- Can we switch to a different more cost effective technology?

- Can we improve/change the process to a more cost effective one?

- Can we substitute the material for a more cost effective one?

- Can we eliminate fasteners to reduce labor cost and speed up the manufacturing process?

- Can we standardize with a current part from another product?

As I said, this technique is very powerful. When we completed the Maytag VAVE, we were able to take an additional 20% out of the cost. One thing that I will mention is that as the original design evolved, we had to make changes to it to address different issues. By having the opportunity to conduct a VAVE after the original design was completed, we were able to look at it with a different perspective and, as a result, we were able to generate better approaches and more cost effective approaches for it.

Lesson learned: There is always room for improvement!!! Good luck with your VAVE initiatives!!!!!

Owner, Cabel Integrados

7yA+ = 20/20