Curing your own meat involves seasoning, table salt, curing salt, and

a whole lot of patience. The time between buying a cut of meat from the butcher to actually serving it at the table can be months. Or even years. That’s when the meat breaks down, unlocking flavor you could never cook into it. If you’re concerned about the wisdom of holding on to a slab of pork for two months before eating it, that’s good. You should be.

But science will keep you safe. The salt and cure mix draw moisture out of the meat, and without moisture, bacteria and pathogens cannot germinate, and the meat doesn’t spoil. You just have to do it right.

First, a Note About Safety

Without proper sanitization, preparation, and storage, illnesses like botulism can flourish—at which point the number of people interested in trying your home-cured salami will drastically diminish. A few tips:

1. Always keep raw meat below 44 degrees Fahrenheit unless you’re about to cook it or start fermenting.

2. Put all equipment (grinder blades, cutting board, bowl, etc.) in the freezer half an hour before you start. When grinding, process a small amount of meat at a time, and grind into a bowl nestled in a larger bowl filled with ice.

3. Sterilize your workstation, equipment, hands, and anything else that may come in contact with meat.

4. Use the right amount of cure mix—table salt and curing salt. The amount

is based on a percentage of the weight of the meat you’re using.

- Steamed sausage (e.g.,bratwurst): 1.5 percent table salt, no curing salt.

- Cooked meat that is consumed cold (e.g., ham): 2.7percent table salt, 0.2 per-cent curing salt.

- Dry cured meat: 2.5 to 4 percent table salt(depending on size), 0.5 percent curing salt.

- Salami: 2.6 percent table salt, 0.2 percent curing salt.

5. During the first stage, keep your meat refrigerated at 33 to 35 degrees.

Gather Your Supplies

Buying Meat

If you have a recipe, it will tell you what cut of meat to use. Most of the time that cut will be pork shoulder, also called pork butt orBoston butt. Relatively inexpensive and with around a 30 percent fat composition, pork butt is perfect for sausage. For meats that require a different proportion of fat, you can also buy a leaner cut and a separate slab of fatback, then grind them together.

💡 Don't freeze natural casings—it ruins their integrity. Keep them in their brine, or, if you've rinsed some and then realized you don't need them all, cover them in salt and refrigerate in a sealed container, where they will last for a full year.

How It All Works

Nitrite (NO2) draws the water out of meat, preventing bacteria such as Clostridium botulinum (which causes botulism) and other pathogens from germinating. Insta Cure No. 1 is a mixture of salt and sodium nitrite (NaNO2) and should be used for short-duration cures that sit for a couple of days to a couple of weeks, like capicola or mortadella.

After that the nitrite becomes inert, and the curing process halts. For longer-curing meats such as chorizo or prosciutto, Insta Cure No. 2 adds sodium nitrate (NaNO3). After the initial nitrite stops working, the nitrate molecules (NO3) give up oxygen atoms and turn into additional nitrite to finish the job.

Make Some Sausage

Before you cure anything, you should learn to make sausage. It’s delicious and doesn’t involve any waiting. Plus, many of the best cured meats, such as kielbasa and salami, start off as sausages.

Cure the Meat

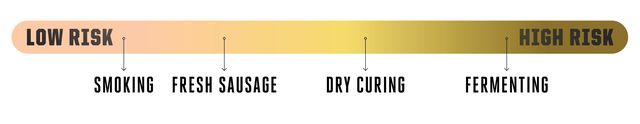

Whether it's sausage or a slab of pork belly, there are three common methods of curing meat: drying, fermenting, and smoking.

Smoking

The easiest of the curing methods, smoking can be done on a standard kettle grill. Here’s how:

• Presoak your choice of wood chips in water for an hour.

• Set charcoal on one side of the grill. When the flame has burned off, add the wood chips.

• Put the meat on the side opposite the coals, close the lid, and open the vents above the meat side of the grill.

• Smoke the meat to an internal temperature of 110 degrees, then put it in an oven set to 300 degrees, slowly bringing the internal temperature of the meat to 155 degrees.

Drying

Dry boxes provide a temperature—and humidity-controlled environment for your meat. You can buy one for around $1,500, or you make your own out of an empty refrigerator, an automatic thermostat, a fan, a humidifier, and a dehumidifier. The dry box keeps the meat at 58 degrees and 83 percent humidity. Your recipe will tell you how long to dry the meat, but as a general rule, meat is ready to eat when it weighs less than half of its initial raw weight.

Fermenting

Tangy sausages like salami are made by adding acid-producing bacteria (available at meat hobbyist sites such as butcher-packer.com). The meat ferments in a climate-controlled chamber—like that dry box you just built, but set to 73 degrees and a humidity level of 95 percent. You’ll need MicroFine pH paper (also available at butcher-packer.com) to periodically test the pH of the meat and determine if enough lactic acid is present to make it safe.

💡 If you see unwanted mold on your salami, wipe it away with vinegar. Its high acidity will lower the pH level, killing the mold and preventing its spread. Vinegar is also a great natural way to keep your dry box sanitized during the curing process. Wipe down the walls of your dry box with a vinegar-soaked cloth twice per week.

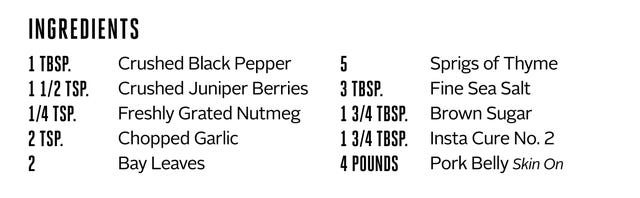

The Starter Recipe: Flat Pancetta

This recipe, from the Olympia Provisions cookbook, gives you the option of cooking meat like bacon after curing or, if you have a dry box, letting it dry, slicing it thing, and really impressing your friends.

Combine spices, salt, sugar, andInsta Cure No. 2. Sprinkle a generous coating of this mix on the bottom of an airtight container. Lay the pork belly on top, then cover with the rest of the mix. Seal the container and refrigerate for one week.

Take the container out of the fridge, flip over the pork belly, then reseal and refrigerate for an additional week.

Open the container, remove the meat, and swish around the liquid sand salt. Put the meat back in, then everything goes in the fridge, un-covered, for four more days.

You’re done—if you want to be. You can cook it now: Rinse the meat off, slice it thin, and fry it up. Perfect as a pizza topping. Or continue to step 5.

Thoroughly rinse the pancetta, then hang it in a dry box for 35 days. Then slice it up and serve.

Kevin is a writer and editor living in Brooklyn. In past lives he’s been an economist, computer salesman, mathematician, barista, and college football equipment manager.