Professional Documents

Culture Documents

7.service Manual

Uploaded by

Orlando MantillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.service Manual

Uploaded by

Orlando MantillaCopyright:

Available Formats

Steelflex® Horizontal and Vertical Couplings • Installation & Maintenance

Types T50 & T70 • Sizes 1030 thru 1200 (Page 1 of 7)

How to Use This Manual Types T50/T70

This manual provides detailed instructions on installation,

maintenance, and parts identification for Steelflex couplings,

Types T50 & T70. Use the table of contents below to locate

required information.

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . Page 1

Lube Fittings . . . . . . . . . . . . . . . . . . . . Page 1

Limited End Float . . . . . . . . . . . . . . . . . . Page 1

Lubrication . . . . . . . . . . . . . . . . . . . Pages 1-2

Installation & Alignment Instructions. . . . . . . . Pages 3-4

Annual Maintenance, Relube & Disassembly . . . . . Page 5 LUBRICATION

Installation & Alignment Data . . . . . . . . . . . . Page 6 Adequate lubrication is essential for satisfactory operation. Because of

Parts Identification & Parts Interchangeability . . . . . Page 7 its superior lubricating characteristics and low centrifuge properties,

Falk Long Term Grease (LTG) is highly recommended. Sizes 1030T to

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS 1090T are furnished with a pre-measured amount of LTG grease for

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE each coupling. The grease can be ordered for larger size couplings.

FREE SERVICE. Steelflex couplings initially lubricated with LTG will not require

re-lubrication until the connected equipment is stopped for servicing.

INTRODUCTION The use of general purpose grease requires re-lubrication of the

This manual applies to standard coupling Types T50 and T70. For coupling at least annually. If a coupling leaks grease, is exposed to

couplings furnished with special features, refer to assembly drawing extreme temperatures, excessive moisture, or experiences frequent

furnished with coupling for proper assembly arrangement and any reversals; more frequent lubrication may be required.

additional installation or maintenance requirements. Type T50

couplings with floating shaft, are designed to connect equipment USDA Approval

with large spans between shaft ends. Type T70 couplings are LTG has the United States Department of Agriculture Food Safety &

BALANCED for close coupled high speed applications. DO NOT Inspection Service approval for applications where there is no

mix parts between Type T50 and T70 couplings. These couplings are possibility of contact with edible products. (H-2 ratings).

designed to operate in either the horizontal or vertical position.

However, the addition of an elastomer gap disc is required in the Long Term Grease (LTG)

lower Type T50 coupling for vertical operation. The high centrifugal forces encountered in couplings separate the

CAUTION: Consult applicable local and national safety codes base oil and thickener of general purpose greases. Heavy

for proper guarding of rotating members. Observe all safety thickener, which has no lubrication qualities, accumulates in the

rules when installing or servicing couplings. grid-groove area of Steelflex couplings resulting in premature hub

or grid failure unless periodic lubrication cycles are maintained.

WARNING: Lockout starting switch of prime mover and remove all

external loads from drive before installing or servicing couplings. Falk Long Term Grease (LTG) was developed specifically for

couplings. It resists separation of the oil and thickener. The

LUBE FITTINGS consistency of Falk LTG changes with operating conditions. As

manufactured, it is an NLGI #1/2 grade. Working of the

Covers have 1/8 NPT lube holes for Size 1140T and smaller

lubricant under actual service conditions causes it to become

and 3/8 NPT lube holes for Size 1150T and larger. Use a

semifluid, while the grease near the seals will set to a heavier

standard grease gun and lube fitting.

grade, helping to prevent leakage.

CAUTION: Remove all grease fittings and make certain all plugs

LTG is highly resistant to separation, easily out performing all

have been inserted after lubricating.

other lubricants tested. The resistance to separation allows the

lubricant to be used for relatively long periods of time.

LIMITED END FLOAT

Although LTG grease is compatible with most other coupling

When electric motors, generators, and other machines are fitted

greases, the mixing of greases may dilute the benefits of LTG.

with sleeve or straight roller bearings, limited axial end float kits

are recommended for protecting the bearings. Falk Steelflex CAUTION: Do not use LTG in bearings.

couplings are easily modified to limit end float; refer to Manual WARNING: Mixing grid coupling components from different

428-820 for instructions. manufacturers may cause premature failure and personal or

property damage from flying debris.

MORE>

The Falk Corporation, P.O. Box 492, Zip 53201-0492 428-510

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 April 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com Supersedes 7-97

Installation & Maintenance • Steelflex Horizontal & Vertical Couplings

®

(Page 2 of 7) Types T50 & T70 • Sizes 1030 thru 1200

Packaging

14 oz. (397g) CARTRIDGES — Individual or case lots or 10 TABLE 1 — General Purpose Greases H

or 60.

0°F to 150°F –30°F to 100°F

35 lb. (16kg) PAILS, 120 lb. (54kg) KEG & 400 lb. DRUMS. Ambient Temperature Range

(–18°C to +66°C) (–34°C to +38°C)

Manufacturer Lubricant Lubricant

Specifications — Falk LTG (Long Term Grease)

Amoco Oil Co. Amolith Grease #2 Amolith Grease #2

TEMPERATURE RANGE — –20°F (–29°C) to 250°F (121°C). BP Oil Co. Energrease LS-EP2 Energrease LS-EP1

Minimum Pump = 20°F (-7°C). Chevron U.S.A. Inc. Dura-Lith EP2 Dura-Lith EP1

MINIMUM BASE OIL VISCOSITY — 3300SSU (715cST) @ Citgo Petroleum Corp. Premium Lithium Grease EP2 Premium Lithium Grease EP1

Conoco Inc. EP Conolith Grease #2 EP Conolith Grease #2

100°F (38°C)

Exxon Company, USA Unirex N2 Unirex N2

THICKENER — Lithium & Soap Polymer. E.F. Houghton & Co. Cosmolube 2 Cosmolube 1

CENTRIFUGE SEPARATION CHARACTERISTICS — ASTM Imperial Oil Ltd. Unirex N2L Unirex N2L

Kendall Refining Co. Lithium Grease L421 Lithium Grease L421

#D4425-84 Centrifuge Test — K36 = 2/24 maximum, very

high resistance to centrifuging. Keystone Div. (Pennwalt) 81 EP-2 81 EP-1

Lyondell Petrochemical (ARCO) Litholine H EP 2 Grease Litholine H EP 2 Grease

NLGI GRADE (ASTM D-217) — 1/2 Mobil Oil Corp. Mobilux EP111 Mobilith AW1

Petro-Canada Products Multipurpose EP2 Multipurpose EP1

CONSISTENCY — (ASTM D-217) — 60 stroke worked penetration Phillips 66 Co. Philube Blue EP Philube Blue EP

value in the range of 315 to 360 measured @ 77°F (25°C).

Shell Oil Co. Alvania Grease 2 Alvania Grease 2

DROPPING POINT — 350°F (177°C) minimum. Shell Canada Ltd. Alvania Grease 2 Alvania Grease 2

MINIMUM TIMKEN EP O.K. LOAD — 40 lbs (18 kg). Sun Oil Co. Ultra Prestige 2EP Ultra Prestige 2EP

Texaco Lubricants Starplex HD2 Multifak EP2

ADDITIVES — Rust and oxidation inhibitors that do not corrode Unocal 76 (East & West) Unoba EP2 Unoba EP2

steel or swell or deteriorate synthetic seals. Valvoline Oil Co. Multilube Lithium EP Grease ...

H Grease application or re-lubrication should be done at temperatures above

20°F (7°C). If grease must be applied below 20° F (7°C), consult The Falk

Corporation. Lubricants listed may not be suitable for use in the food

processing industry; check with lube manufacturer for approved lubricants.

General Purpose Grease

ANNUAL LUBRICATION — The following specifications and Specifications — General Purpose Coupling Lubricants

lubricants for general purpose grease apply to Falk Steelflex

couplings that are lubricated annually and operate within ambient The values shown are typical and slight variations are permissible.

temperatures of 0° to 150°F (–18° to 66°C). For temperatures DROPPING POINT — 300°F (149°C) or higher.

beyond this range (See Table 1), consult the Factory. CONSISTENCY — NLGI No. 2 with 60 stroke worked

If a coupling leaks grease, is exposed to extreme temperatures, penetration value in the range of 250 to 300.

excessive moisture or experiences frequent reversals, more SEPARATION AND RESISTANCE — Low oil separation rate and

frequent lubrication may be required. high resistance to separation from centrifuging.

LIQUID CONSTITUENT — Possess good lubricating properties,

General Purpose Greases Meeting

equivalent to a high quality, well refined petroleum oil.

Falk Specifications

INACTIVE — Must not corrode steel or cause swelling or

Lubricants listed in Table 1 are typical products only and should

deterioration of synthetic seals.

not be construed as exclusive recommendations.

CLEAN — Free from foreign inclusions.

428-510 The Falk Corporation, P.O. Box 492, Zip 53201-0492

April 2000 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

Supersedes 7-97 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Steelflex Horizontal and Vertical Couplings • Installation & Maintenance

®

Types T50 & T70 • Sizes 1030 thru 1200 (Page 3 of 7)

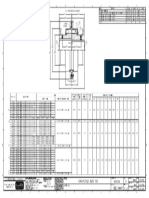

INSTALLATION OF TYPE T50 & T70 TABLE 2— Minimum Clearance

STEELFLEX HORIZONTAL AND SIZE M SIZE M

VERTICAL COUPLINGS 1030 3.06 1130 8.66

1050 3.70 1140 9.24

Installation 1070

1080

4.06

5.28

1150

1160

10.56

11.30

Only standard mechanics tools, wrenches, straight edge, spacer 1090 5.66 1170 12.00

bar and feeler gauges are required to install Falk Steelflex 1100 7.14 1180 13.00

couplings. Clean all parts using a non-flammable solvent. Check 1110 7.50 1190 13.76

1120 8.66 1200 14.40

hubs, shafts and keyways for burrs.

INTERFERENCE FIT HUBS — Standard for both designs and all 1— Mount Cover, Gasket, Seal & Hubs

sizes. Furnished without setscrews. Heat hubs to 275°F (135°C)

using an oven, torch, induction heater or an oil bath. To prevent

damage DO NOT heat hubs beyond a maximum temperature of M MINIMUM

CLEARANCE

400°F (205°C). SEE TABLE 2

When an oxy-acetylene or blow torch is used, use an excess

acetylene mixture. Mark hubs near the center of their length in

several places on hub body with a temperature sensitive crayon,

275°F (135°C) melt temperature. Direct flame towards hub bore

using constant motion to avoid overheating an area. SEAL

GASKET

WARNING: If an oil bath is used, the oil must have a flash point of

350°F (177°C) or higher. Do not rest hubs on the bottom of the

container. Do not use an open flame in a combustible atmosphere

or near combustible materials. Assemble seal in cover and coat seal bore with grease. Place cover

(with seal) on shaft before mounting hub. Place gasket on shaft.

Mount hubs on their respective shafts so that hub face is flush with

Maximize Performance & Life the end of its shaft. Allow hubs to cool before proceeding. Seal

The performance and life of couplings depend largely upon keyways to prevent leakage. Insert setscrews (if required) and

how you install and maintain them. Before installing couplings, tighten. Position equipment in approximate alignment with

make certain that foundations of equipment to be connected approximate hub gap.

meet manufacturers’ requirements. Check for soft foot. The use

of stainless steel shims is recommended. Measuring 2 — Gap & Angular Alignment

misalignment and positioning equipment within alignment

tolerances is simplified with an alignment computer. These

calculations can also be done graphically or mathematically,

and allow the incorporation of “cold offsets”, which will

compensate for shaft position changes due to thermal growth.

Alignment is shown using spacer bar and straight edge. This

practice has proven to be adequate for many industrial

applications. However, for superior final alignment, the use of dial

indicators (see Manual 458-834 for instructions), lasers, alignment

computers or graphical analysis is recommended.

MORE>

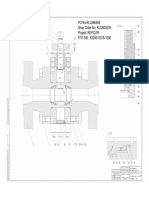

Installation of Type T70 Steelflex Tapered

Grid Couplings

Use a spacer bar equal in thickness to the gap specified in

Prior to mounting hubs on shafts, make sure that cover side of

Table 3 on Page 6. Insert bar, as shown above, to same depth

coupling is mounted on a shaft long enough so that cover can

at 90° intervals and measure clearance between bar and hub

be backed off to allow for coupling alignment and grid

face with feelers. The difference in minimum and maximum

installation. See illustration in Step 1 and Table 2 for minimum

measurements must not exceed the INSTALLATION ANGULAR

clearance required.

limit specified in Table 3 on Page 6.

The Falk Corporation, P.O. Box 492, Zip 53201-0492 428-510

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 April 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com Supersedes 7-97

Installation & Maintenance • Steelflex Horizontal and Vertical Couplings

®

(Page 4 of 7) Types T50 & T70 • Sizes 1030 thru 1200

3 — Offset Alignment INSTALLATION OF TYPE T50 STEELFLEX

TAPERED GRID COUPLINGS WITH

FLOATING SHAFT

1 — Mount Covers, Gaskets, Seals and Hubs –

Refer to Step 1 on Page 3.

2 — Position First Drive and Floating Shaft —

For horizontal applications, set the drive most difficult to move

to true level and bolt it in place. Set the floating shaft on

V-blocks and position in line with fixed drive shaft. For vertical

Align so that a straight edge rests squarely (or within the limits applications, set the bottom drive in the proper position and

specified in Table 3) on both hubs as shown above and also at bolt it in place. Center the elastomer gap disc(s) on top of the

90° intervals. Check with feelers. The clearance must not bottom drive hub face (Coupling sizes 1030 thru 1070 use two

exceed the INSTALLATION PARALLEL OFFSET limit specified in elastomer gap discs). Bring the floating shaft into position on

Table 3. Tighten all foundation bolts and repeat Steps 2 and 3. top of gap disc(s). Secure floating shaft, covers and gaskets into

Realign coupling if necessary. a position so that grids can be installed.

4 — Insert Grid 3 — Gap and Angular Alignment — Refer to Step 2

on Page 3.

GAP GAP

V-BLOCKS

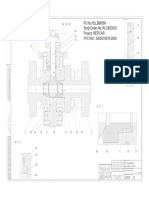

Pack gap and grooves with lubricant before inserting grid.

When grids are furnished in two or more segments, install them

so that all cut ends extend in the same direction (as detailed in

the inset picture above). Spread the grid slightly to pass over the 4 — Parallel Offset Alignment — Refer to Step 3 at left.

coupling teeth and then seat with a soft mallet.

5 — Position Second Drive and Align —

5 — Pack with Grease & Assemble Covers Position second drive in line with floating shaft. Align the second

drive to the floating shaft per Steps 2 and 3. Make alignment

corrections by moving the drive; do not move the floating shaft.

Tighten foundation fasteners and repeat Steps 2 and 3. Realign

coupling if necessary.

6 — Insert Grids — Refer to Step 4 at left.

7 — Pack with Grease & Assemble Covers —

Pack the spaces between and around the grid with as much

lubricant as possible, and wipe off excess flush with top of grid.

Remove the lube plugs in the cover to ease cover assembly.

Pack the spaces between and around the grid with as much Assemble cover with gasket to flanged hub. Insert fasteners and

lubricant as possible, and wipe off excess flush with top of grid. tighten to torque specified in Table 3. Remove V-block supports.

Remove the lube plugs in the cover to ease cover assembly. Insert lube fitting in cover. Fill with recommended lubricant until

Fasten cover with gasket to flanged hub. The hardware provided an excess appears at the opposite hole. Remove lube fitting and

for “T70" couplings are matched sets and must not be mixed or install lube plugs before operating.

substituted. For Size 1140T70 and smaller, true-up cover flange

O.D. to rotating axis to within .002 T.I.R. For Size 1150T70 and

larger, assemble cover to flanged hub with mating match mark

letters aligned. True-up cover flange O.D. to hub flange O.D. to

within .002 T.I.R.. Tighten fasteners to torque specified in Table 3.

Insert lube fitting in cover. Fill with recommended lubricant until

an excess appears at the opposite hole. Remove lube fitting and

install lube plugs before operating.

428-510 The Falk Corporation, P.O. Box 492, Zip 53201-0492

April 2000 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

Supersedes 7-97 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Steelflex Horizontal and Vertical Couplings • Installation & Maintenance

®

Types T50 & T70 • Sizes 1030 thru 1200 (Page 5 of 7)

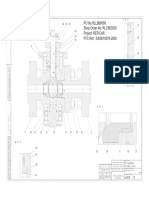

ANNUAL MAINTENANCE Periodic Lubrication

For extreme or unusual operating conditions, check coupling

more frequently.

1. The alignment can be checked without disassembling the

coupling as shown below.

“T70" Type The required frequency of lubrication is directly related to the type

of lubricant chosen and the operating conditions. Steelflex

Parallel Offset Misalignment Angular Misalignment couplings lubricated with common industrial lubricants, such as

those shown in Table 1, Page 2, should be relubed annually. The

1a. For “T70" Type couplings, mount dial indicator on cover and use of Falk Long Term Grease (LTG) will allow relube intervals to

indicate surface shown by rotating shafts with coupling. The be extended beyond five years. When relubing, remove both lube

parallel offset T.I.R. value divided by 2, must not exceed the plugs and insert lube fitting. Fill with recommended lubricant until

OPERATING PARALLEL OFFSET limit shown in Table 3. The an excess appears at the opposite hole. CAUTION: Make certain

angular T.I.R. value, must not exceed the OPERATING all grease fittings have been removed and all plugs have been

ANGULAR limit shown in Table 3. Realign equipment to within inserted after lubricating.

the installation limits if either operating limit value is exceeded.

Coupling Disassembly & Grid Removal

Y

“T50" Type

Safely support floating shaft of “T50" Type couplings. Whenever

1b. For “T50" Type couplings, determine misalignment by it is necessary to disconnect the coupling, remove the cover

measuring distances “X” max. and “Y” min. between pilot fasteners, draw back cover and remove grid as follows. A round

hub an cover using a depth mic or feeler gages. The

rod or screwdriver that will conveniently fit into the open loop

difference between “X” max. and “Y” min. must not exceed

ends of the grid is required. Begin at the open end of the grid

the OPERATING ANGULAR limit value given in Table 3.

Check at each coupling end. Realign equipment to within section and insert the rod or screwdriver into the loop ends. Use

the installation limits if operating limit value is exceeded. the teeth adjacent to each loop as a fulcrum and pry the grid

out radially in even, gradual stages, proceeding alternately from

2. Inspect seal ring and gasket to determine if replacement is side to side.

required; if leaking grease, replace.

3. Check tightening torques of all fasteners.

4. When connected equipment is serviced, disassemble, clean

grease from coupling, inspect for wear, and replace worn

parts. Check alignment per steps on Pages 3 and 4. Install

coupling per this manual using new gaskets and seals.

The Falk Corporation, P.O. Box 492, Zip 53201-0492 428-510

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 April 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com Supersedes 7-97

Installation & Maintenance • Steelflex Horizontal and Vertical Couplings

®

(Page 6 of 7) Types T50 & T70 • Sizes 1030 thru 1200

INSTALLATION & ALIGNMENT DATA Example: 1150T70 max. operating misalignment is .012"

(.305mm) PARALLEL OFFSET plus .062" (1.57mm) angular.

Maximum life and minimum maintenance for the coupling

and connected machinery will result if couplings are NOTE: For applications requiring greater misalignment, refer

accurately aligned. Coupling life expectancy between initial application details to the Factory.

alignment and maximum operating limits is a function of Angular misalignment is dimension X minus Y as illustrated below.

load, speed and lubrication. PARALLEL OFFSET misalignment is distance P between the hub

Values may be combined for an installation or operating condition. center lines as illustrated below.

End float (with zero angular and PARALLEL OFFSET misalignment) is

the axial movement of the hubs(s) within the cover(s) measured from

“O” gap.

ANGULAR MISALIGNMENT PARALLEL OFFSET MISALIGNMENT END FLOAT

Y F F

P

X GAP

TABLE 3 — Misalignment & End Float

Installation Limits Operating Limits

Cover

End Float Fastener Lube Wt

Normal Gap Parallel Angular Allow.

Parallel Offset – P Angular Physical Limit Torque

SIZE ± 10% Offset – P (x - y) Speed

(x - y) (Min) 2 x F

H Type T70

Type T50 Type T70 Type T70 †

Max Max

Max Max Max Max Max Max Inch mm Max Max Inch mm (lb-in) Nm lb kg

Inch mm

Inch mm Inch mm Inch mm Inch mm

1030T .002 0,0508 .003 0,0762 .003 0,0762 .125 3 .006 0,152 .012 0,305 .238 6,05 90 10 .09 0,0408 10000

1050T .002 0,0508 .004 0,102 .004 0,102 .125 3 .008 0,203 .016 0,406 .240 6,10 330 37 .15 0,068 9000

1070T .002 0,0508 .004 0,102 .005 0,127 .125 3 .008 0,203 .020 0,508 .281 7,14 825 93 .25 0,113 8200

1080T .002 0,0508 .004 0,102 .006 0,152 .125 3 .008 0,203 .024 0,610 .311 7,90 1640 185 .38 0,172 7100

1090T .003 0,0762 .004 0,102 .007 0,178 .125 3 .008 0,203 .028 0,711 .315 8,00 1640 185 .56 0,254 6000

1100T .003 0,0762 .005 0,127 .008 0,203 .188 5 .010 0,254 .033 0,838 .439 11,15 2940 332 .94 0,426 4900

1110T .003 0,0762 .005 0,127 .009 0,229 .188 5 .010 0,254 .036 0,914 .434 11,02 2940 332 1.12 0,508 4500

1120T .003 0,0762 .006 0,152 .010 0,254 .250 6 .011 0,279 .040 1,02 .551 14,00 825 93 1.62 0,735 4000

1130T .004 0,102 .006 0,152 .012 0,305 .250 6 .011 0,279 .047 1,19 .552 14,02 825 93 2.0 0,907 3600

1140T .004 0,102 .006 0,152 .013 0,330 .250 6 .011 0,279 .053 1,35 .562 14,27 1640 185 2.5 1,14 3300

1150T .004 0,102 .006 0,152 .016 0,406 .250 6 .012 0,305 .062 1,57 .565 14,35 2940 332 4.3 1,95 3000

1160T .005 0,127 .006 0,152 .018 0,457 .250 6 .012 0,305 .070 1,78 .565 14,35 2940 332 6.2 2,81 2600

1170T .005 0,127 .006 0,152 .020 0,508 .250 6 .012 0,305 .079 2,00 .565 14,35 2940 332 7.7 3,49 2400

1180T .005 0,127 .008 0,203 .022 0,559 .250 6 .015 0,381 .089 2,26 .565 14,35 2940 332 8.3 3,75 2100

1190T .006 0,152 .008 0,203 .024 0,610 .250 6 .015 0,381 .097 2,46 .565 14,35 2940 332 9.7 4,40 1950

1200T .006 0,152 .008 0,203 .027 0,686 .250 6 .015 0,381 .107 2,72 .565 14,35 4560 515 12.4 5,62 1800

H Refer to Selection Guide for maximum bores and Engineering 427-108 for reboring instructions.

† Allowable speed for the Type T50 coupling is generally based on the floating shaft length and diameter. Refer to Selection Guide to determine the allowable speed for

the application.

428-510 The Falk Corporation, P.O. Box 492, Zip 53201-0492

April 2000 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

Supersedes 7-97 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Steelflex Horizontal and Vertical Couplings • Installation & Maintenance

®

Types T50 & T70 • Sizes 1030 thru 1200 (Page 7 of 7)

PARTS IDENTIFICATION AND PART PARTS INTERCHANGEABILITY

NUMBER LOCATION GRIDS — Size 1030T thru 1200T Steelflex couplings use blue

Coupling parts have identifying size and part numbers as illustrated grids. Older models, 30T thru 200T, use orange grids.

below. When ordering parts, always SPECIFY SIZE, TYPE, HUB CAUTION: Blue grids may be used in all applications, but DO

BORE, KEYWAY and PART NUMBER found on each item. NOT substitute orange grids for blue.

Contact your Falk Distributor or Falk for price and availability. Do not substitute “T70" Type components with ”T50" Type

components. “T70" Type hardware are matched sets and must

not be mixed or substituted. For Sizes 1150T70 and larger,

covers are balanced with flanged hubs (and match marked) and

must be replaced as an assembly.

ORDER INFORMATION

1030 T 70 1. Identify part(s) required by

SIZE &

name shown.

COUPLING

TYPE

SIZE PART NUMBER 2. Furnish the following information.

PRODUCT EXAMPLES:

CLASSIFICATION

GASKET FLANGED HUB Coupling Size: 1030

PART T HUB

SEAL LUBE PLUG

NUMBER (T70)

GRID Coupling Type: T70

Flanged Hub Bore: 1.375

Keyway: .312 x .156

T Hub Bore: 1.250

Keyway: .250 x .125

or

SIZE Coupling Size: 1030

COVER

SIZE,PART Coupling Type: T50

NUMBER Bore: 1.375

& BORE

Keyway: .312 x .156

Bore: 1.250

FASTENERS Keyway: .250 x .125

PILOT HUB Distance between shafts:

(T50) 20 inches

Operating Speed: 1750 RPM

The Falk Corporation, P.O. Box 492, Zip 53201-0492 428-510

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 April 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com Supersedes 7-97

You might also like

- KZ1000 KZ1100Document370 pagesKZ1000 KZ1100motomech100% (12)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- International StandardDocument24 pagesInternational StandardOrlando MantillaNo ratings yet

- Santi Kulprathipanja, James E. Rekoske, Daniel Wei, Robert v. Slone, Trung Pham, Chunqing Liu - Modern Petrochemical Technology - Methods, Manufacturing and Applications-Wiley-VCH (2021)Document313 pagesSanti Kulprathipanja, James E. Rekoske, Daniel Wei, Robert v. Slone, Trung Pham, Chunqing Liu - Modern Petrochemical Technology - Methods, Manufacturing and Applications-Wiley-VCH (2021)AnonyNo ratings yet

- Delayed COker in Hysys 1Document201 pagesDelayed COker in Hysys 1nbsmaniannNo ratings yet

- How To Use This Manual: Types T50 & T70 Sizes 1030 Thru 1200 (Page 1 of 7)Document7 pagesHow To Use This Manual: Types T50 & T70 Sizes 1030 Thru 1200 (Page 1 of 7)Ashraful HasanNo ratings yet

- 428 110 Falk Steelflex Type T10, Sizes 20 140,1020 1140 Grid Couplings Installation ManualDocument6 pages428 110 Falk Steelflex Type T10, Sizes 20 140,1020 1140 Grid Couplings Installation ManualJunior Francisco QuijanoNo ratings yet

- Falk 1130T10bDocument6 pagesFalk 1130T10bLeonardo Rios RuizNo ratings yet

- How To Use This Manual: Type T20 Steelflex CouplingDocument6 pagesHow To Use This Manual: Type T20 Steelflex CouplingGriffithNo ratings yet

- How To Use This Manual: Type G72Document8 pagesHow To Use This Manual: Type G72dparoNo ratings yet

- Instalación y Mantención Acople Rexnord GL20Document6 pagesInstalación y Mantención Acople Rexnord GL20RodrigoNo ratings yet

- How To Use This Manual: Types G20/G32/G52 Sizes 1080-1300 & 2080-2300 (Page 1 of 10)Document10 pagesHow To Use This Manual: Types G20/G32/G52 Sizes 1080-1300 & 2080-2300 (Page 1 of 10)pankaj_pawar89No ratings yet

- TID00019 Manual Acople Falk FLDDocument7 pagesTID00019 Manual Acople Falk FLDNatalia BeltránNo ratings yet

- Falk G CouplingDocument8 pagesFalk G CouplingdenisNo ratings yet

- 458 110 Falk Lifelign Type G, Sizes 1010 1070 Gear Couplings Installation ManualDocument8 pages458 110 Falk Lifelign Type G, Sizes 1010 1070 Gear Couplings Installation ManualrezandriansyahNo ratings yet

- How To Use This Manual: Sizes 1010 Thru 1070G & GP & Sizes 1 Thru 7GF (Page 1 of 8)Document8 pagesHow To Use This Manual: Sizes 1010 Thru 1070G & GP & Sizes 1 Thru 7GF (Page 1 of 8)dparoNo ratings yet

- Gmax LTG-couplings PDFDocument4 pagesGmax LTG-couplings PDFannica reclosadoNo ratings yet

- TM 10 4310 392 13 and PDocument43 pagesTM 10 4310 392 13 and PVitor FreitasNo ratings yet

- Tema 5. Motores de Corriente AlternaDocument2 pagesTema 5. Motores de Corriente AlternaRichard ZapataNo ratings yet

- Falk-Long-Term-Grease PDFDocument2 pagesFalk-Long-Term-Grease PDFdaniel atachaguaNo ratings yet

- Delo Grease Ep 00-0-1 2Document3 pagesDelo Grease Ep 00-0-1 2Michael Puma ZeaNo ratings yet

- Purus-FS-ATFDocument2 pagesPurus-FS-ATFJorge ForeroNo ratings yet

- Cat Oil Fdao SynDocument2 pagesCat Oil Fdao SynDesta 77No ratings yet

- Shell Spirax S2 ALS 85W-140Document2 pagesShell Spirax S2 ALS 85W-140report2510100% (1)

- Shell Gadus S2 High Speed Coupling Grease Technical Data SheetDocument3 pagesShell Gadus S2 High Speed Coupling Grease Technical Data Sheetjuan felipe diazgranados santosNo ratings yet

- Made in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnDocument2 pagesMade in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnsheilaNo ratings yet

- Essotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Document2 pagesEssotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Kaly7No ratings yet

- GPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSDocument3 pagesGPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSAlNo ratings yet

- Chevron Starplex EP-2 MSDSDocument2 pagesChevron Starplex EP-2 MSDSCrystal RojasNo ratings yet

- SKF LGMT 2Document2 pagesSKF LGMT 2muhammad saputraNo ratings yet

- Castrol Syntrans Z Long Life 75W-80: DescriptionDocument2 pagesCastrol Syntrans Z Long Life 75W-80: DescriptionwindiNo ratings yet

- Shell Gadus S2 High Speed Coupling GreaseDocument3 pagesShell Gadus S2 High Speed Coupling GreaseAnonymous oAbjbl4HNo ratings yet

- Shell Spirax S3 G80WDocument2 pagesShell Spirax S3 G80WNokiabhre WijayaNo ratings yet

- Volvo Grease Protects Construction EquipmentDocument12 pagesVolvo Grease Protects Construction EquipmentBalaji BalaNo ratings yet

- Pehj0007-03 - Cat Arctic Tdto SynDocument2 pagesPehj0007-03 - Cat Arctic Tdto SynOscar Delgado100% (1)

- 094c1183ad68b1bb PDF Preview MediumDocument2 pages094c1183ad68b1bb PDF Preview MediumGerChuLu C.D.No ratings yet

- Service Instruction: Selection of Suitable Operating Fluids For Rotax 2-Stroke Ul Engines SI-2ST-008Document7 pagesService Instruction: Selection of Suitable Operating Fluids For Rotax 2-Stroke Ul Engines SI-2ST-008ddNo ratings yet

- SKF Coupling MaintananceDocument4 pagesSKF Coupling MaintananceDavinder MakhijaNo ratings yet

- Shell Tivela S 220: Advanced Synthetic Gear OilsDocument2 pagesShell Tivela S 220: Advanced Synthetic Gear OilsViruzfhmNo ratings yet

- Spruit Transmissies Rexnord SteelflexDocument48 pagesSpruit Transmissies Rexnord SteelflexPhan Công ChiếnNo ratings yet

- Kopr Kote Oilfield TdsDocument1 pageKopr Kote Oilfield Tdsbob smithNo ratings yet

- Shell Rotella T5 Ultra 10w-30 TDSDocument2 pagesShell Rotella T5 Ultra 10w-30 TDSmdziubakNo ratings yet

- AGIP ROTRA JD/F Multi-Purpose Tractor LubricantDocument2 pagesAGIP ROTRA JD/F Multi-Purpose Tractor LubricantJan HendriksNo ratings yet

- LUBCON Automotive Industry enDocument7 pagesLUBCON Automotive Industry enOmin PostingNo ratings yet

- Shell Spirax S3 T Technical Data SheetDocument2 pagesShell Spirax S3 T Technical Data Sheetrstec pyNo ratings yet

- Valplex EP NLGI 2: Specifications and Approvals ApplicationsDocument2 pagesValplex EP NLGI 2: Specifications and Approvals Applicationsdiah ayuNo ratings yet

- Gear Synt TDL 75W-90: Lubricant For Heavily Loaded Transmissions and Long Drain Service. 100% SyntheticDocument1 pageGear Synt TDL 75W-90: Lubricant For Heavily Loaded Transmissions and Long Drain Service. 100% SyntheticManuel GironNo ratings yet

- Geo Sng-4 Sae 40-Pi SheetDocument2 pagesGeo Sng-4 Sae 40-Pi SheetDana Group - Valvoline LubricantNo ratings yet

- Mtds SKF Grease k2k Din - 51825Document2 pagesMtds SKF Grease k2k Din - 51825Business DevelopmentNo ratings yet

- Engen Genlex SeriesDocument3 pagesEngen Genlex Seriespalraj_suriNo ratings yet

- PDSDetail PageDocument3 pagesPDSDetail PageEduleofNo ratings yet

- Eaton Fuller TRSM 0190 Mid Range Transmission Service Manual en UsDocument66 pagesEaton Fuller TRSM 0190 Mid Range Transmission Service Manual en UsHernandez ManuelNo ratings yet

- Multifak EP - Data SheetDocument2 pagesMultifak EP - Data SheetJeremias UtreraNo ratings yet

- Cat NGEO EL350: (Natural Gas Engine Oil)Document2 pagesCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNo ratings yet

- Engine Oil 15W 40 PDFDocument2 pagesEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Molub Alloy 860Document3 pagesMolub Alloy 860akshatmalhotraNo ratings yet

- Technical Data Sheet for Manual Transmission and Gear OilDocument2 pagesTechnical Data Sheet for Manual Transmission and Gear OilJorge Arrieta TorresNo ratings yet

- Shell Alvania Grease CG: For Couplings Used in Industrial EquipmentDocument3 pagesShell Alvania Grease CG: For Couplings Used in Industrial EquipmentOrlando MantillaNo ratings yet

- Multifak EP: Specialty Industrial GreaseDocument2 pagesMultifak EP: Specialty Industrial GreaseMahmoud TaroutiNo ratings yet

- TITAN ATF 4000 Multi-Purpose Automatic Transmission FluidDocument1 pageTITAN ATF 4000 Multi-Purpose Automatic Transmission FluidM.TayyabNo ratings yet

- Boston Gear 832B15KM1 ManualDocument6 pagesBoston Gear 832B15KM1 Manualoscar ivan mendezNo ratings yet

- Regreasing Double-Shielded BearingsDocument4 pagesRegreasing Double-Shielded BearingsOrlando MantillaNo ratings yet

- Impeller O'Ring Lower Diffuser Diffuser Housing Fluid Dir. 2 Pc. Ring Head ShaftDocument1 pageImpeller O'Ring Lower Diffuser Diffuser Housing Fluid Dir. 2 Pc. Ring Head ShaftOrlando MantillaNo ratings yet

- Instrumentation Schematic Suction: Foundation FrameDocument1 pageInstrumentation Schematic Suction: Foundation FrameOrlando MantillaNo ratings yet

- Shell Alvania Grease CG: For Couplings Used in Industrial EquipmentDocument3 pagesShell Alvania Grease CG: For Couplings Used in Industrial EquipmentOrlando MantillaNo ratings yet

- Gear Box LufkinDocument34 pagesGear Box LufkinOrlando MantillaNo ratings yet

- A See Chart 169338 Flange, Lap Joint See Chart: DB 4/27/05 4/28/05 Material TitleDocument1 pageA See Chart 169338 Flange, Lap Joint See Chart: DB 4/27/05 4/28/05 Material TitleOrlando MantillaNo ratings yet

- Flush PlanDocument1 pageFlush PlanOrlando MantillaNo ratings yet

- DATA-SHEET Allowable Nozzle Loadings-6x4Document2 pagesDATA-SHEET Allowable Nozzle Loadings-6x4Orlando MantillaNo ratings yet

- Plano A.G. 165056-NR-20100309Document1 pagePlano A.G. 165056-NR-20100309Orlando MantillaNo ratings yet

- Plano BP Project Draft WG SPS PID REV 0Document1 pagePlano BP Project Draft WG SPS PID REV 0Orlando MantillaNo ratings yet

- Plano 179776-Flush PlanDocument1 pagePlano 179776-Flush PlanOrlando MantillaNo ratings yet

- MANUAL Vector VII Product Data Book - 8-15-09 FINALDocument38 pagesMANUAL Vector VII Product Data Book - 8-15-09 FINALOrlando MantillaNo ratings yet

- Surface Pumping System: BP Project-Florena FieldDocument1 pageSurface Pumping System: BP Project-Florena FieldOrlando MantillaNo ratings yet

- 169124-Coupling Flex (Motor)Document1 page169124-Coupling Flex (Motor)Orlando MantillaNo ratings yet

- 100RLCB03039 Isolation Valve Sectional Valvula de La ManguerraDocument3 pages100RLCB03039 Isolation Valve Sectional Valvula de La ManguerraOrlando MantillaNo ratings yet

- 100RLCB03039 Bleed Valve SectionalDocument3 pages100RLCB03039 Bleed Valve SectionalOrlando MantillaNo ratings yet

- DATA-SHEET Allowable Nozzle Loadings-6x4Document2 pagesDATA-SHEET Allowable Nozzle Loadings-6x4Orlando MantillaNo ratings yet

- 100RLCB03032 Valvula de CortadoDocument84 pages100RLCB03032 Valvula de CortadoOrlando MantillaNo ratings yet

- 100RLCB03039 Bleed Valve SectionalDocument3 pages100RLCB03039 Bleed Valve SectionalOrlando MantillaNo ratings yet

- 100RLCB03031 BombasDocument76 pages100RLCB03031 BombasOrlando MantillaNo ratings yet

- Empowering EmployeesDocument2 pagesEmpowering EmployeesOrlando MantillaNo ratings yet

- International Standard: - GFF$ &K&@ .-GDocument59 pagesInternational Standard: - GFF$ &K&@ .-GOrlando MantillaNo ratings yet

- Equipment CatalogDocument66 pagesEquipment Catalogcristian pedrazaNo ratings yet

- Method D - Hydrophilic Fluorescent Inspection PDFDocument1 pageMethod D - Hydrophilic Fluorescent Inspection PDFOrlando MantillaNo ratings yet

- Liquid Penetrant Testing: Standard Practice ForDocument11 pagesLiquid Penetrant Testing: Standard Practice ForErick SanabriaNo ratings yet

- Chapter 3 - Mineral and Power Resources: NCERT Solutions For Class 8 Social Science GeographyDocument2 pagesChapter 3 - Mineral and Power Resources: NCERT Solutions For Class 8 Social Science GeographyKalpna SharmaNo ratings yet

- 揽瓜阁逻辑做题小分队合辑volume2Document119 pages揽瓜阁逻辑做题小分队合辑volume2Edward WangNo ratings yet

- Water-Based Non-Ionic Polymeric Surfactants As Oil Spill Dispersants PDFDocument7 pagesWater-Based Non-Ionic Polymeric Surfactants As Oil Spill Dispersants PDFAfzal AktharNo ratings yet

- Atmospheric DistillationDocument114 pagesAtmospheric DistillationAhmed Mohamed Khalil67% (3)

- ECCE 1106 013 Environmental Risk Compliance For Nature GasDocument16 pagesECCE 1106 013 Environmental Risk Compliance For Nature GasO.O.SulaimanNo ratings yet

- Fuel Change-Over Guidelines For MARPOL Annex VI Compliance in ECADocument2 pagesFuel Change-Over Guidelines For MARPOL Annex VI Compliance in ECAswapneel_kulkarniNo ratings yet

- Combined-Cycle Power PlantsDocument22 pagesCombined-Cycle Power PlantsAnonymous Iev5ggSRNo ratings yet

- Neoflo 1-68i (IO)Document3 pagesNeoflo 1-68i (IO)Kinni ShenoldNo ratings yet

- PORAM Heating Instructions Recd Nov 2014Document1 pagePORAM Heating Instructions Recd Nov 2014lu asenNo ratings yet

- ScienceDocument10 pagesScienceISHIKA MahajanNo ratings yet

- CV Edzarliando 20Document4 pagesCV Edzarliando 20ikhzan cadetNo ratings yet

- Luis Oswaldo Rodriguez Perez 2Document2 pagesLuis Oswaldo Rodriguez Perez 2api-248854453No ratings yet

- Oxidation Stability of Distillate Fuel Oil (Accelerated Method)Document6 pagesOxidation Stability of Distillate Fuel Oil (Accelerated Method)Pablo Fabian Del RossoNo ratings yet

- BLTN11184 6431880 01Document35 pagesBLTN11184 6431880 01جمال سلطانNo ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- India - Mineral Yearbook 2005Document15 pagesIndia - Mineral Yearbook 2005jfgarciadelrealNo ratings yet

- Argus European ProductsDocument14 pagesArgus European ProductsMihaElla_07No ratings yet

- Uses of Bryophytes Saxena y Harinder, 2004Document10 pagesUses of Bryophytes Saxena y Harinder, 2004Caro Feuillet-HurtadoNo ratings yet

- Natural GasDocument660 pagesNatural Gasrichardsena100% (2)

- Booklet Indonesia Conventional Oil & Gas 2017Document64 pagesBooklet Indonesia Conventional Oil & Gas 2017dimas1andreasNo ratings yet

- Petroleum Refinery Engineering MCQs PDFDocument36 pagesPetroleum Refinery Engineering MCQs PDFRizwan Ali83% (6)

- Paper and Poster Competition Preliminary Case Booklet IPFEST 2024Document9 pagesPaper and Poster Competition Preliminary Case Booklet IPFEST 2024almas fauziahNo ratings yet

- Colombia Oil Almanac V 0.9Document149 pagesColombia Oil Almanac V 0.9tatagalgo100% (1)

- Ielts Writing Task 1 - Pie ChartDocument53 pagesIelts Writing Task 1 - Pie ChartAmy HicksNo ratings yet

- Calculated Cetane Index of Distillate Fuels: Standard Test Method ForDocument4 pagesCalculated Cetane Index of Distillate Fuels: Standard Test Method ForzzapiecheNo ratings yet

- Crude Assay - Lecture NotesDocument18 pagesCrude Assay - Lecture Notessam joseph100% (1)

- Aliapur 2009 Reference DocumentDocument15 pagesAliapur 2009 Reference DocumentBeta AnalyticNo ratings yet

- BMI Iran Oil and Gas Report Q2 2017 PDFDocument82 pagesBMI Iran Oil and Gas Report Q2 2017 PDFMuhammad JahangirNo ratings yet