201124772 sap-pp-pi-process-flow-docs

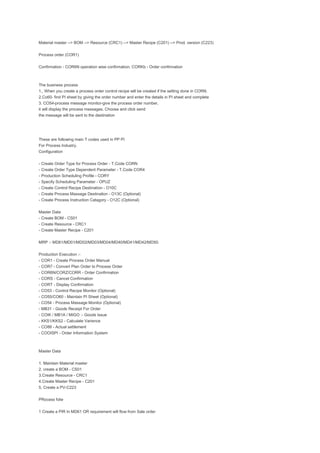

- 1. Material master --> BOM --> Resource (CRC1) --> Master Recipe (C201) --> Prod. version (C223) Process order (COR1) Confirmation - COR6N operation wise confirmation, CORKb - Order confirmation The business process 1,. When you create a process order control recipe will be created if the setting done in CORN. 2.Co60- find PI sheet by giving the order number and enter the details in PI sheet and complete 3. CO54-process message monitor-give the process order number, it will display the process messages. Choose and click send the message will be sent to the destination These are following main T codes used in PP PI For Process Industry. Configuration - Create Order Type for Process Order - T.Code CORN - Create Order Type Dependent Parameter - T.Code COR4 - Production Scheduling Profile - CORY - Specify Scheduling Parameter - OPUZ - Create Control Recipe Destination - O10C - Create Process Massage Destination - O13C (Optional) - Create Process Instruction Catagory - O12C (Optional) Master Data - Create BOM - CS01 - Create Resource - CRC1 - Create Master Recipe - C201 MRP :- MD61/MD01/MD02/MD03/MD04/MD40/MD41/MD42/MD50. Production Execution :- - COR1 - Create Process Order Manual - COR7 - Convert Plan Order to Process Order - COR6N/CORZ/CORR - Order Confirmation - CORS - Cancel Confirmation - CORT - Display Confirmation - CO53 - Control Recipe Monitor (Optional) - CO55/CO60 - Maintain PI Sheet (Optional) - CO54 - Process Massage Monitor (Optional) - MB31 - Goods Receipt For Order - COIK / MB1A / MIGO :- Goods Issue - KKS1/KKS2 - Calculate Varience - CO88 - Actual settlement - COOISPI - Order Information System Master Data 1. Maintain Material master 2. create a BOM - CS01 3.Create Resource - CRC1 4.Create Master Recipe - C201 5, Create a PV-C223 PRocess folw 1 Create a PIR In MD61 OR requirement will flow from Sale order

- 2. 2. run MRP in MD02, or MD01 3. Convert plan order to process order in MD04 or COR7 4. Goods Issue to process order in MB1a or MIGO or in COR6n( if it is auto GI) 5. Confirm operation in COR6N 6. GR for order in MIGO or MB31 or COR6N 7. Calculate over head in KG12/CO43 8. Calculate variance in KKS1 or KKS2 9. Order settlement in ko88 oe co88 Optional CO53 - Control Recipe Monitor CO55/CO60 - Maintain PI Sheet CO54 - Process Massage Monitor STD REPORT COOISPI - Process order information system The below production cycle explains the basic business flow in “Process Industry”. The flow is generally focusing only on Production and Quality Management Simple Production Cycle: Consider all Raw materials are available in plant and production process yet to start, the following stages are to be followed 1. Create Process Order Here we are creating a process order based on the capacity of the equipments and resource availability 2. Release the Process order Once Process order created, it has to be released for production, means system will check the scheduling, material availability, capacity planning, etc., and then release process takes place 3. Goods issue from the Stores Once PO got released, goods issue against the process order will takes place 4. Start processing Product process against the PO will start 5. Confirmation Process

- 3. After production, the final out put confirmation from the process will be entered 6. Goods Receipt Process Goods receipt process plays a major role in any business here we have to do 101 movement type and do the postings. In goods issue process they will issue the goods against PO in 261 movement type. 7. Quality Approval and Release Once GR from the production was made, the material will come to Quality control for approval. Here QC person will check the material and they will do the result recording and usage decision 8. Stock will appear in Unrestricted use for SALE / Further Process Once usage decision was made the material will automatically moved into unrestricted use. The FG is ready for sale By keeping above all points in mind, the following masters and transactions are required to proceed S. No Master Trans- action T-code Description Where has to be used 1 √ MM01 Create Material Used for creating Recipe and further tracking 2 √ CRC1 Create Resource Machine / set of Machines used for making the product 3 √ C201 Create Recipe Here we are calling resource and materials required to make the finished product 4 √ QS21 Create MIC List of specifications to be checked for that concerned finished goods 5 √ QP01 Create Quality Plan Creating Quality Plan 6 √ COR1 Create Process Order Initiating Production Process by creating Process Order 7 √ MIGO with 261 movement Goods Issue Process Goods issue to Manufacturing unit 8 √ CORK Confirmation Process Production Output confirmation Process 9 √ QA32 Quality Approval and Usage Decision QC will approve and release for further process Step by Step Execution Process: Scenario Explanation: REQUIREMENTS: For a leading Process Manufacturing Company ABC, they are selling the product “FG 1”, the raw materials and resource requirements are listed below Raw Materials required for making 50kg of Finished Product, FG 1 are S.No Material Code / Material Description Quantity required Unit of Measurement

- 4. Material Type 1 RM l 1 / ROH Raw Material 1 80 Kg 2 RM 2 /ROH Raw Material 2 20 Kg 3 BP 1 / FERT Byproduct 60 L Resources required for making 50kg of Finished Product FG1 S.No Resource Code Resource Description Capacity 1 CRC-001 Reactor 2KL 2 CRC-002 Vessel 4KL List of MASTERS required for addressing the above scenario 1. Create Materials using MM01 transactions in the following way: In this screen select “select views” button and extend the following fields

- 5. We have selected basic information entries field. Fill the information and finally select the General plant / storage data and give plant as 1100 and storage as 0001 in case of Raw material. The same procedure has to be repeated for finished goods and Co-Products, in plant storage data we have to give Plant 1100 and storage 0004. 2. Create Resource master using CRC 1 Transactio Here we have to mention the Person responsible and standard value type “SAP1 – Normal Production”.

- 6. Here we are planning to give the controlling area and cost center. Finally save the data. The same procedure has to be repeated for CRC-002 3. Create Recipe using resource and material in T-code C201

- 7. In the above screen we have to enter the material we want to produce “FG 1”, and give the plant code and profile “PI01” then enter. In the recipe header we have to enter the status as “4” and Usage as “1” , go for Operations screen

- 8. Here we have to call the resource and the description details, for example in reactor CRC-001, the operations like Heating and transfer process will be carried out the same has been explained in this description field. As per standard value key we have to give the duration for the operation time and labor time. Both will be taken for scheduling. In the material tab, we have to enter the version for the BOM and usage details, after that we have to enter the list of raw materials required for making 50 kg of the FG 1 product. Here co-product is generating so we have to give the co-product “BP 1” 60 L as “Negative” producing after the process (NOT as INPUT) and activate as Co-Product by selecting the line item and press items tab and select co-product tab. In the header level line item we have the base quantity i.e Finished goods quantity, give 50 and save Now Recipe is ready. 4. Create MIC using QS21 transaction

- 9. Here give the short text, field search and int. char.desc as pH and select the Quantitative check box.

- 10. pH have some ranges so, we have to select the limits are upper and lower spec limits. The same way we have to create temperature also 5. Now create the Quality plan using QP01

- 11. Now we are planning to create the quality plans which are to be tested before release from QC Header data details as above Then Go to operations and give control key as QM01, select the line item and go to inspection description tab. Enter the MIC details here. While entering system will ask the upper spec and lower spec limits. Enter limits and save Masters are ready to proceed the Production Cycle We will start Production Cycle using transactions 1. Create Process Order using COR1

- 12. Here give the total quantity as “50” and enter the start date, system will check the scheduling and capacity planning and finally finish date will come. Now, once the process is over check the master data, in that we can find the created recipe group for that material “FG 1”

- 13. Now the PO stated us “Created” Press the Flag button and „Release” the PO for production. After pressing flag button, actually system will checks material availability, scheduling, capacity planning etc., Once it is over the status of the PO will be changed to “Released mode” Save the Process order.

- 14. 2. Goods issue against the Process order using MIGO Transaction Goods issue generally happens from store against the PO with the movement type 261 Once goods issue from the stores is over, the document number will be generated as below

- 15. Now go to process order and check the order status “GMPS” will appear, that means Goods Movement Posted Now Production process was started and completed. We are going to give confirmation using CORK transaction 3. Confirmation using CORK Transaction Once you enter, the yield quantity you have to confirm

- 16. Here in MM01, Quality Management views we have to activate the inspection lot origin “04” for inspection triggering while making Goods receipt using 101 transaction. The following procedure has to be adopted. Select Inspection set up tab and activate 04 inspection type.

- 17. This activity has to be done at the time of creation of Master (MM01) 4. Goods Receipt using MIGO with movement type 101 If you check this screen the outputs finished product 1 and co product 1 with the quantities viz., 50 and 60 will be there. We have activated QM view only for FG 1 and not for BP 1 material. So once GRN was made the material FG 1 will be automatically moved to Quality inspection and BP 1 will be moved to “unrestricted use”. At the time of GRN we are creating the batch for FG 1 as “FG00000001”

- 18. For BP 1 we are creating Batch as “CO00000001”. The batch can be created at the time of creation of Process order also. Here we are mentioning the storage location for the final products “0004” Once GRN made the document number will be generated for Accounting updates

- 19. 5. Quality Approval and Release Now check the MMBE view, in that the material FG 1 appears in “Quality inspection” And at the same time BP 1 in which QM was not activated, the stock appears in Unrestricted use

- 20. Result recording and Usage decision process for the Material FG 1 batch FG00000001 Go to QA32 and give the inspection lot origin as”04” and press enter Check the status. The system status should be “RELEASED” Press “Results” button and do result recording

- 21. After entering the actual value the final screen will be like below Now, go to Usage decision button in the same QA32 Transaction and do accept the batch

- 22. Once you save the inspection stock details will come Enter the stock quantity “50” to unrestricted and check the MMBE view now Material will be moved to unrestricted use . Now sales process will start.

- 23. The above cycle is simple production process generally carried out in “Process industries” CRC1 - Create Resource CR24 - Create Resource Network CR31 - Create Hierarchy C201 - Create Master Recipe C251 - Print Master Recipe C223 - Maintain Production Versions COIO - Order Info System for PP-PI COPD - Print Process Order COPI - Print Process Order ShopFloor Papers COR1 - Create Process Order COR5 - Collective Process Order Release COR6 - Single Process Order Confirmation COR6N - Single Screen Entry of Confirmations COR7 - Convert Planned Order to Proc. Order COR7_PC - Part.Conv.: Plnned Ord. to Proc.Ord. COR8 - Coll.Conv.: Plnned Ord. to Proc.Ord. CORK - Process Order Confirmations (Total) CORM - Mass Processing CORO - Create Process Order w/o Material CORR - Collective Entry of Confirmations CORS - Cancel Process Order Confirmation CORT - Display Process Order Confirmation CORZ - Process Order: Time Event Confirmat. COA6 - Process Order: Archiving COA7 - Process Order: Retrieval - Archive COA8 - Process Order: Archive Management CO56 - Display PI Sheet CO58 - Maintain PI Sheet CO59 - Delete PI Sheet CO60 - Find PI Sheet COPOC - Process Manufacturing Cockpit CO53 - Control Recipe Monitor

- 24. O10C - Assig. Ctrl Rec. Dest./Proc. Instr. O12C - Assign Charact. / Proc. Instr. Cat. MD61 CREATE PLANNED INDEPENDET REQUIREMENT MD11 CREATE PLAANED ORDER MD01 MRP RUN COLLECTIVE MD02 MRP SINGLE ITEM MULTI LEVEL MD03 SINLE ITEM SINGLE LEVEL MD04 STOCK-REQUIREMENT LIST(PLANNEC-PROCESS) MD07 STOCK-REQUIREMENT LIST COLLECTIVE MD40 MPS RUN(MRP - RUN) MD41 Single Item Multilevel MD42 Single Item Singlelevel MD50 Sales Order Planing - Make to order planing MD73 DISPLAY TOTAL REQUIREMENT MD15 CONVERT PLANNED ORDER TO PURCHASE REQ. MD16 DISPLAY PLANNED ORDER MD45 PLANNING RESULT CO24 MISSING PART INFO SYST CM01 CAPACITY PLANING CM02 CAPACITY PLANING CM04 CAPACITY PLANING MDVP COLLECTIVE AVAILABILITY CHECK(PRODUCT WISE) MF63 STAGING SITUATION STORAGE LOCATION LEVEL MD15 CONVERT PLANNED ORDER TO PURCHASE REQUISTION MD14 MS64 COPY VERSION(CHANGE VERSION FROM INACTIVE TO ACTIVE) COR7 CONVERT PLANNED ORDER TO PROCESS ORDER COR8 CONVERT PLANNED ORDER TO PROCESS ORDER COR1 CREATE PROCESS ORDER (MANUALY) COR2 CHANGE PROCESS ORDER COR3 DISPLAY PROCESS ORDER COOISPI PROCESS ORDER INFORMATION SYSTEM COHVPI MASS PROCESSING FOR PROCESS ORDER MC01 LOGISTIC INFORMATION LIBRARY MC02 INFO-LIBRARY MC03 INFO-LIBRARY MR21 PRICE LIST CM05 CHECK FOR CAPACITY OVERLOD MD48 CROSS PLANT EVALUATION COR1 CREATE PROCESS ORDER MANUALLY O0SC CREATE PROCESS ORDER BY SELECTING PRODUCTION VERSION COOISPI PROCESS ORDER INFORMATION SYSTEM COHVPI MASS PROCESSING FOR PROCESS ORDER COR5 COLLECTIVE ORDER RELEASE COR7 CONVERT PLANNED ORDER TO PROCESS ORDER COIK PICIKING LIST MB26 PICK LIST MB25 RSERVATION LIST MB21 CREATE RESERVATION MB22 CHANGE RESERVATION MB31 GOODS RECEIPT FOR ORDER COR6N PHASE CONFIRMATION CORS DELETE PHASE CONFIRMATION CORR COLLECTIVE PHASE CONFIRMATION CO53 CONTROL RECIPE MONITOR CO55 WORK LIST FOR PI SHEET CO54 PROCESS MESSAGE MONITER CO60 FIND PI SHEET

- 25. CO64 WORK LIST FOR PI SHEET CO67 WORK LIST FOR PI SHEET MINING- LIME STONE CRUSHING- RAW MEAL PREPARATION- CLINKER FORMATION- FINISH CEMENT GRINDING- SLAG & CEMENT BLENDING- PACKING Mining - where u get the uncrushed limestone Crushing - where u will make the crushed limestone from uncrushed limestone Raw Meal Preparation - where additive like iron ore etc are added to crushed limestone Clinkerisation - Raw meal is heated in kiln and get the clinker, small rock or pebble like substances. Grinding - Clinker along with gypsum is grinded to make cement. Packing - Cement is either packed in 50 kg bags or in jumbo boxes or in trucks or ships as per facility in factory.