International Elastomer Conference - Rubber Division

International Elastomer Conference - Rubber Division

International Elastomer Conference - Rubber Division

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>International</strong><br />

<strong>Elastomer</strong> <strong>Conference</strong><br />

<strong>International</strong> <strong>Rubber</strong> & Advanced Materials In Healthcare Expo,<br />

The elastomeric profession’s 184th most Technical valuable Meeting, resource. Educational Symposium, and<br />

Advanced Materials In Healthcare <strong>Conference</strong><br />

Show Guide<br />

October 7 - 10, 2013 • I-X Center • Cleveland, OH USA<br />

Download our <strong>Conference</strong> App!<br />

Manage your schedule, view the exhibitor list and expo floor plan,<br />

connect with other attendees…and receive the chance to win $100!<br />

Join our LinkedIn Group:<br />

Join our LinkedIn Group:<br />

<strong>Rubber</strong> <strong>Division</strong>, American American Chemical Chemical Society Society<br />

Follow us us on on Twitter:<br />

@<strong>Rubber</strong><strong>Division</strong><br />

@<strong>Rubber</strong><strong>Division</strong><br />

A Twitter follower attending the conference will<br />

#Int<strong>Elastomer</strong>Conf2013<br />

receive the chance to win $100!<br />

#<strong>Rubber</strong>Expo2013<br />

#Int<strong>Elastomer</strong>Conf2013 #<strong>Rubber</strong>Expo2013

We compound rubber.<br />

We deliver consistency.<br />

Take the Virtual Tour at<br />

www.airbossofamerica.com

Schedule of Events<br />

Date Time Event Facility Room Floor<br />

Monday<br />

10.07.2013<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS members are welcome to attend all open committee meetings.<br />

*Closed meeting<br />

7:00 a.m. - 5:00 p.m. Registration The I-X Center East Lobby Main Level<br />

7:00 a.m. - 4:30 p.m. Speaker’s Prep The I-X Center Meeting Room #12 Lower Level<br />

8:00 a.m. - 9:00 a.m. Steering Committee Breakfast* Hyatt Regency at The Arcade 1890 At The Arcade Lower Level<br />

9:00 a.m. - 12:00 p.m. Steering Committee Meeting* Hyatt Regency at The Arcade Emanuele C Lower Level<br />

12:30 p.m. - 2:00 p.m. Membership Committee Meeting The I-X Center Meeting Room #5 Lower Level<br />

1:00 p.m. - 2:00 p.m. Student Affairs Committee Meeting Hyatt Regency at The Arcade Kaiser B Lower Level<br />

2:00 p.m. - 3:00 p.m. Membership Joint Committee Caucus (EEMM) The I-X Center Meeting Room #5 Lower Level<br />

2:00 p.m. - 5:00 p.m. Program Planning Committee Meeting Hyatt Regency at The Arcade St. Hubert Lower Level<br />

3:00 p.m. - 5:00 p.m. Education & Publications Committee Meeting The I-X Center Meeting Room #6 Lower Level<br />

3:30 p.m. - 5:00 p.m. Area Directors Meeting* Hyatt Regency at The Arcade Emanuele A&B Lower Level<br />

4:00 p.m. - 5:00 p.m. History Committee Meeting Hyatt Regency at The Arcade Kaiser B Lower Level<br />

5:00 p.m. - 6:00 p.m. Best Paper Committee Meeting Hyatt Regency at The Arcade Emanuele C Lower Level<br />

Schedule Exhibitor List of Events<br />

Tuesday<br />

10.08.2013<br />

Wednesday<br />

10.09.2013<br />

Thursday<br />

10.10.2013<br />

7:00 a.m. - 5:00 p.m. Registration The I-X Center East Lobby Main Level<br />

7:00 a.m. - 5:00 p.m. Speaker’s Prep The I-X Center Meeting Room #12 Lower Level<br />

8:00 a.m. - 12:00 p.m. Course: Material Considerations for Medical Devices and<br />

Pharmaceutical Products The I-X Center Meeting Room #8 Lower Level<br />

8:30 a.m. - 5:00 p.m. 184th Technical Sessions The I-X Center Meeting Rooms #13, 15, 16, 18<br />

Lower Level<br />

8:30 a.m. - 9:15 a.m. Nominating Committee Meeting The I-X Center Meeting Room #2 Lower Level<br />

9:00 a.m. - 11:00 a.m. Southern <strong>Rubber</strong> Group Meeting The I-X Center Meeting Room #10 Lower Level<br />

10:00 a.m. - 10:15 a.m. <strong>International</strong> <strong>Rubber</strong> & Advanced Materials In Healthcare Expo<br />

Opening Ceremony & Ribbon Cutting The I-X Center Entrance of Exhibit Hall Main Level<br />

10:15 a.m. - 5:00 p.m. <strong>International</strong> <strong>Rubber</strong> & Advanced Materials In Healthcare Expo The I-X Center Expo Floor Main Level<br />

11:00 a.m. - 12:00 p.m. Keynote Speaker Address: Joe Walker, Freudenberg NOK<br />

Sealing Technologies The I-X Center Grand Ballroom Main Level<br />

1:00 p.m. - 3:00 p.m. Exhibits & Meeting Sites Committee Meeting The I-X Center Meeting Room #5 Lower Level<br />

1:00 p.m. - 4:00 p.m. Course: Selecting the Right <strong>Elastomer</strong> for Your Sealing Application The I-X Center Meeting Room #8 Lower Level<br />

3:00 p.m. - 4:00 p.m. Marketing Committee Meeting The I-X Center Meeting Room #10 Lower Level<br />

5:15 p.m. - 6:45 p.m. Welcome Reception - Open To All Attendees The I-X Center Grand Ballroom Main Level<br />

6:00 a.m. 5K Walk/Run Shuttles begin to depart from official hotels<br />

7:00 a.m. - 5:00 p.m. Registration The I-X Center East Lobby Main Level<br />

7:00 a.m. - 5:00 p.m. Speaker’s Prep The I-X Center Meeting Room #12 Lower Level<br />

7:30 a.m. - 10:30 a.m. Advisory Committee on Testing Procedures The I-X Center Meeting Room #6 Lower Level<br />

8:00 a.m. - 9:00 a.m. Service Awards Committee Meeting The I-X Center Meeting Room #10 Lower Level<br />

8:00 a.m. - 12:00 p.m. Course: Chemistry & Technology of Polyurethane <strong>Elastomer</strong>s The I-X Center Meeting Room #8 Lower Level<br />

8:30 a.m. - 4:30 p.m. Course: Introduction to <strong>Rubber</strong> Technology for Non-Technologists The I-X Center Meeting Room #9 Lower Level<br />

8:30 a.m. - 4:45 p.m. 184th Technical Sessions The I-X Center Meeting Rooms #15, 16, 18 Lower Level<br />

9:00 a.m. - 11:00 a.m. Finance & Budget Committee Meeting The I-X Center Meeting Room #4 Lower Level<br />

9:00 a.m. - 5:00 p.m. 10th Annual Student Colloquium The I-X Center Meeting Room #13 Lower Level<br />

10:00 a.m. - 11:00 a.m. Subdivision Advisory Committee Meeting The I-X Center Meeting Room #2 Lower Level<br />

10:00 a.m. - 5:00 p.m. <strong>International</strong> <strong>Rubber</strong> & Advanced Materials In Healthcare Expo The I-X Center Expo Floor Main Level<br />

10:00 a.m. - 5:00 p.m. 10th Annual Student Poster Session The I-X Center Expo Floor Main Level<br />

11:30 a.m. - 1:00 p.m. 25-Year Club Reception & Luncheon The I-X Center Meeting Room #7 Lower Level<br />

1:00 p.m. - 3:00 p.m. S&T Awards Committee Meeting* The I-X Center Meeting Room #4 Lower Level<br />

1:00 p.m. - 5:00 p.m. Course: Chemistry and Technology of Functional Coatings for<br />

Medical Devices The I-X Center Meeting Room #8 Lower Level<br />

3:00 p.m. - 4:00 p.m. Partnership Development Committee Meeting The I-X Center Meeting Room #4 Lower Level<br />

3:00 p.m. - 4:30 p.m. Area Directors Caucus* The I-X Center Meeting Room #10 Lower Level<br />

3:00 p.m. - 5:30 p.m. Editorial Board Meeting* The I-X Center Meeting Room #6 Lower Level<br />

5:30 p.m. - 7:30 p.m. E. 4th Street Block Party E. 4th Street, Downtown Cleveland<br />

7:00 a.m. - 3:00 p.m. Registration The I-X Center East Lobby Main Level<br />

7:00 a.m. - 4:30 p.m. Speaker’s Prep The I-X Center Meeting Room #12 Lower Level<br />

8:00 a.m. - 9:00 a.m. Steering Committee Meeting* The I-X Center Meeting Room #4 Lower Level<br />

8:00 a.m. - 11:00 a.m. Course: Introduction to Carbon Black: Manufacture, Testing and<br />

Influence on <strong>Rubber</strong> Compound Properties The I-X Center Meeting Room #8 Lower Level<br />

8:00 a.m. - 4:15 p.m. 184th Technical Sessions The I-X Center Meeting Room #13,<br />

15, 16, 18 Lower Level<br />

9:00 a.m. - 10:30 a.m. Executive Committee Meeting The I-X Center Meeting Room #1 Lower Level<br />

10:00 a.m. - 2:00 p.m. Career Fair The I-X Center Concourse Exhibit Hall Lower Level<br />

10:00 a.m. - 3:00 p.m. <strong>International</strong> <strong>Rubber</strong> & Advanced Materials In Healthcare Expo The I-X Center Expo Floor Main Level<br />

11:00 a.m. - 12:00 p.m. Business & Awards Meeting The I-X Center Theater Expo Floor<br />

INTERNATIONAL ELASTOMER CONFERENCE 1

Exhibitor List<br />

<strong>International</strong><br />

<strong>Elastomer</strong> <strong>Conference</strong><br />

Show Guide Contents<br />

Welcome to Cleveland!<br />

Schedule of Events ................................. 1<br />

Leonard Thomas, Chair 2013 ................ 2<br />

Sponsors .................................................... 4<br />

From the Mayor ........................................ 5<br />

Chair’s Welcome<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS Moving Forward<br />

Leonard Thomas – 2013 Chair<br />

© Courtesy of travelcleveland.com<br />

Special Events .......................................... 6<br />

Exhibitor List ...................................... 10-50<br />

Expo Floor Plan ............................... 36 - 37<br />

Theater Schedule .................................. 51<br />

184 th Technical Meeting ................ 52-60<br />

Speaker Index ........................................ 61<br />

10th Annual Student Colloquium<br />

and Poster Session ............................... 63<br />

Educational Symposium ...................... 64<br />

Business & Awards Meeting ............. 65<br />

Hotel Information ................................... 66<br />

Executive Committee and<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS Staff ................ 67<br />

General Information .............................. 68<br />

As your 2013 <strong>Rubber</strong> <strong>Division</strong>, ACS Chair, I would<br />

like to welcome you to the <strong>International</strong> <strong>Elastomer</strong><br />

<strong>Conference</strong>. The vision of <strong>Rubber</strong> <strong>Division</strong>, ACS<br />

is to enhance science, technology and business<br />

across the evolving elastomeric community, and our mission is to expand<br />

the elastomeric profession and individual development through educational,<br />

technical and interactive activities. This conference encompasses<br />

many opportunities for you and your organization throughout the week.<br />

Whether you attend the <strong>International</strong> <strong>Rubber</strong> & Advanced Materials In<br />

Healthcare Expo, 184th Technical Symposia, Educational Symposia or<br />

the Advanced Materials In Healthcare <strong>Conference</strong>, you will get to meet<br />

colleagues, make new contacts and discuss innovations within the<br />

industry. We have over 230 organizations exhibiting during the <strong>International</strong><br />

<strong>Rubber</strong> & Advanced Materials In Healthcare Expo, from a dozen<br />

countries throughout the world. This year, we are offering six technical<br />

and regulatory courses throughout the Educational Symposium sponsored<br />

by Trostel, Ltd. We also have more than 22 students presenting their<br />

research during the 10th Annual Student Colloquium & Poster Session<br />

(these are the future chemists, engineers and scientists of the elastomer<br />

industry). On Tuesday, you have the opportunity to attend a great keynote<br />

address titled, “An Industrial Comparative of the Custom Molded <strong>Rubber</strong><br />

Business,” by Joe Walker, Corporate Director, Materials Development &<br />

Chemical Regulatory Compliance - Americas, Freudenberg-NOK Sealing<br />

Technologies. This will be followed by technical presentations and a<br />

Welcome Reception at 5:15 p.m. within the IX Center. On Thursday, at 10<br />

a.m.-2 p.m., we are holding a Career Fair where employers will feature<br />

tabletop presentations with job openings and other opportunities. And<br />

finally, I am very excited about welcoming our first Student Chapter at the<br />

University of Akron, College of Engineering, during our Thursday Business<br />

& Awards Meeting. If you have any questions during the week, please<br />

see the <strong>Division</strong> staff, any of the Executive Committee members or me.<br />

Again, welcome to what will be a fun and informative week.<br />

2 INTERNATIONAL ELASTOMER CONFERENCE

Our chemists aren’t<br />

chained to the lab.<br />

If you think all chemists work in the lab, think again.<br />

At Akrochem, we have chemists in our on-site labs<br />

and many more in technical support and sales. It’s our<br />

formula for your success. Other elements that set us apart<br />

include processing improvements and factory solutions,<br />

remarkable quality control standards and an extensive<br />

inventory available for quick shipment. As specialists in<br />

compounding ingredients and color concentrates for<br />

the rubber, plastics and adhesives industries, Akrochem<br />

believes great relationships begin with great chemistry.<br />

Contact us. We’ll prove it.<br />

800.321.2260<br />

akrochem.com<br />

Providing the most complete line of compounding materials in the industry.

<strong>Rubber</strong> <strong>Division</strong>, ACS Would Like To Thank Our<br />

Valued Annual Gold & Silver Sponsors And Our<br />

Exclusive <strong>Conference</strong>/Expo Sponsors!<br />

Be sure to stop by their booths to learn<br />

more about these great companies.<br />

Booth #2808 Booth #2014 Booth #214<br />

Booth #614<br />

Booth #1348 Booth #424<br />

Booth #308 Booth #1014<br />

Booth #1230<br />

Booth #1436

From Exhibitor the Mayor List<br />

October 7, 2013<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS<br />

411 Wolf Ledges Parkway<br />

Suite 201<br />

Akron, OH 44311<br />

Dear Attendees of the <strong>International</strong> <strong>Elastomer</strong> <strong>Conference</strong>:<br />

On behalf of the City of Cleveland, I would like to welcome you to the <strong>International</strong> <strong>Elastomer</strong> <strong>Conference</strong> -<br />

featuring the <strong>International</strong> <strong>Rubber</strong> & Advanced Materials in Healthcare Expo, 184 th Technical Meeting,<br />

Educational Symposium, and Advanced Materials in Healthcare <strong>Conference</strong>.<br />

Currently, there is an enormous amount of capital being invested in Cleveland – from a new Global Center for<br />

Health Innovation to a redeveloped lakefront area. Furthermore, the region is home to four world-class<br />

healthcare institutions, 80+ biomedical companies and four higher education institutions dedicated to health<br />

and technology education, research, and workforce training.<br />

I am confident that Cleveland will provide a perfect meeting destination that not only meets, but exceeds,<br />

your expectations in the quality, affordability and availability of accommodations, amenities, attractions and<br />

overall customer service.<br />

While in town, make sure to discover PlayhouseSquare, our elegantly-restored performing arts center that is<br />

the second largest in the nation and University Circle, the most concentrated square mile of arts, culture and<br />

educational institutions in the country.<br />

Cleveland offers unique dining experiences and wonderful nightlife in the downtown districts of East Fourth<br />

Street, the Warehouse District and the Flats, as well as neighborhood hotspots in Tremont, Little Italy and<br />

Ohio City. Whether you want to rock with your idols at the Rock and Roll Hall of Fame and Museum or root<br />

for your favorite sports teams at Progressive Field, “The Q” Arena or FirstEnergy Stadium, Cleveland has<br />

something for everyone.<br />

Cleveland is an interesting and vibrant city filled with a wide range of opportunities and friendly people ready<br />

to welcome you.<br />

On behalf of the City of Cleveland, I want to again welcome you to Cleveland. If you have any questions or<br />

concerns during your stay, please don’t hesitate to reach out to Positively Cleveland at<br />

www.Positivelycleveland.com or 800.321.1001.<br />

Sincerely,<br />

Frank G. Jackson, Mayor<br />

INTERNATIONAL ELASTOMER CONFERENCE 5

Special Exhibitor Events List<br />

Special Events<br />

Why Join?<br />

Please join us at the Career Fair where employers will feature<br />

tabletop presentations with job openings and other opportuni-<br />

<strong>International</strong> <strong>Rubber</strong> & Advanced Materials In 10th Annual Student Poster Session<br />

Healthcare Expo Ribbon Cutting<br />

Wednesday, October 9, 2013<br />

Tuesday, October 8, 2013<br />

10:00 a.m. - 5:00 p.m.<br />

10:00 a.m. - 10:15 a.m.<br />

www.rubber.org<br />

I-X Center – Expo Floor, Main Level<br />

I-X Center – Exhibit Hall Entrance, Main Level<br />

Attend the official opening ceremony ribbon cutting for the <strong>International</strong><br />

<strong>Rubber</strong> & Advanced Materials In Healthcare Expo. We look<br />

forward to welcoming you and have you help us kick off our expo! support to the future of our industry.<br />

“The <strong>Rubber</strong> <strong>Division</strong>, which has been a<br />

Keynote Speaker career-long Address experience 25-Year Club for Reception me, began & Luncheon when<br />

Tuesday, October 8, 2013<br />

Wednesday, October 9, 2013<br />

11:00 a.m. - 12:00 p.m. my father, the 11:30 President a.m. - 1:00 p.m. of H. M. Royal, Inc.,<br />

I-X Center – Grand Ballroom, Main Level I-X Center – Meeting Room #7, Lower Level<br />

Joe Walker – Corporate told Director, me that somebody should get out to<br />

Materials Development & Chemical<br />

Regulatory Compliance, Akron and get<br />

registered<br />

involved<br />

attendees.<br />

with<br />

Reservations<br />

the <strong>Division</strong>.<br />

are required.<br />

Freudenberg-NOK Sealing Technologies<br />

The year was 1961, the first year I started to<br />

Welcome Reception<br />

E. 4th St. Block Party<br />

Tuesday, October 8, 2013<br />

work, and I took Wednesday, a <strong>Rubber</strong> October Technology 9, 2013 course.<br />

5:15 p.m. - 6:45 p.m.<br />

5:30 p.m. - 7:30 p.m.<br />

I-X Center – Grand Ballroom, Main Level Who would have ever thought after all the<br />

Come join the fun!<br />

This event is open to all registered attendees of the <strong>International</strong> <strong>Rubber</strong> <strong>Elastomer</strong> Group and National meetings, including<br />

establishments!<br />

<strong>Conference</strong>. The reception features complimentary hors d’oeuvres,<br />

drinks, entertainment and giveaways.<br />

the technical presentations, that I would be<br />

Career Fair<br />

elected to be Chair Thursday, of October the 10, <strong>Division</strong>. 2013 Why join<br />

5K Walk/Run<br />

10:00 a.m. - 2:00 p.m.<br />

Wednesday, October 9, 2013 the <strong>Division</strong>? The<br />

6:00 a.m. - Shuttles begin picking up at official hotels<br />

Concourse<br />

friends<br />

Exhibit<br />

I<br />

Hall,<br />

have<br />

Lower<br />

made<br />

Level<br />

and the<br />

Runners, walkers and guests are invited to participate. knowledge Shuttle gained sticks with me even in<br />

service will be provided from all official hotels to the 5K Walk/Run<br />

at 6:00 a.m. Return service will be provided at the conclusion of the ties.<br />

partial retirement and is just part of the story.”<br />

event. Registration will take place at the start site.<br />

Sponsored by:<br />

10th Annual Student Colloquium<br />

Wednesday, October 9, 2013<br />

9:00 a.m. - 5:00 p.m.<br />

I-X Center – Meeting Room #13, Lower Level<br />

The 10th Annual Student Colloquium will include presentations by<br />

graduate students. Keynote speaker, Christopher Mitchell - Group<br />

Business Manager, <strong>Rubber</strong> Additives of Rhein Chemie Corporation,<br />

will be presenting from 9 a.m. to 10 a.m., followed by the<br />

student presentations.<br />

© Courtesy of travelcleveland.com<br />

Concurrent with the student presentations is the Poster Session,<br />

located on the expo floor. Graduate and undergraduate students<br />

will be available to discuss their work. Stop by to show your<br />

Come celebrate members or affiliate members who have been<br />

active in the rubber industry for 25 consecutive years. Open to all<br />

Stop by E. 4th Street in downtown Cleveland and just show your<br />

badge to receive specials and discounts at participating<br />

Business & Awards Meeting<br />

Thursday, Toms October Royal 10, 2013<br />

11:00 a.m. - 12:00 p.m.<br />

RoyalT, LLC<br />

In the Theater on the Expo Floor<br />

Join us at the semi-annual Business & Awards Meeting of<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS. It includes general business of the<br />

<strong>Division</strong>, plus the announcement of award winners for<br />

Student Colloquium, Service and more. Reservations are not<br />

required.<br />

Visit us at booth #1010 for more information.<br />

6 INTERNATIONAL ELASTOMER CONFERENCE

Exhibitor List<br />

<strong>Rubber</strong> <strong>Division</strong>, ACS Booth #1802<br />

Industry, technical and business books, technical paper<br />

downloads (individual and full set) and <strong>Rubber</strong> <strong>Division</strong>, ACS<br />

merchandise will be sold at the <strong>Rubber</strong> <strong>Division</strong>, ACS booth.<br />

Daily Drawings for $200<br />

Drop off your raffle drawing ticket at the <strong>Rubber</strong> <strong>Division</strong>,<br />

ACS booth for your chance to win $200! Drawings will take<br />

place in the theater on the expo floor at 4:45 p.m. Tuesday<br />

and Wednesday and 2:45 p.m. on Thursday. You must be<br />

present to win. Membership drawings will also take place at<br />

this time.<br />

Stay Social…and Win $100!<br />

Engage with us and Tweet #<strong>Rubber</strong>Expo2013 and/or<br />

#Int<strong>Elastomer</strong>Conf2013 and also download our conference<br />

app and you could be selected to win a $100 Visa gift card!<br />

One will be given away to an attendee who uses those<br />

hashtags and tweets about the conference/expo and another<br />

will be given to a lucky attendee who downloads and uses<br />

our new conference app.<br />

8 INTERNATIONAL ELASTOMER CONFERENCE

<strong>Rubber</strong> <strong>Division</strong>, ACS (American Chemical<br />

Society) is an organization committed to<br />

enhancing science, technology and business<br />

across the evolving elastomeric community.<br />

We work to expand the elastomeric profession<br />

and individual development through educational,<br />

technical and interactive activities.<br />

<strong>Conference</strong>s & Expos<br />

Our highly respected expos, technical meetings and<br />

educational symposiums attract professionals across all<br />

areas of the rubber, elastomeric and advanced materials<br />

in health care industries.<br />

Education<br />

When it comes to elastomers education, we’re your best<br />

resource. We offer instructor led and e-Learning training<br />

covering materials supply to end-use production in rubber,<br />

plastics, polymers and other advanced materials. From<br />

basic to advanced rubber technology to hot industry topics,<br />

we cover it all.<br />

Publications<br />

Stay informed about the latest rubber industry issues,<br />

trends and events through a subscription to <strong>Rubber</strong> Chemistry<br />

and Technology, the leading industry journal on rubber<br />

science and technology research. Articles date back to 1928.<br />

We also offer more than 110 technical and business books.<br />

Library Services<br />

Our librarian can help answer your questions regarding the<br />

science and business of rubber. Our librarian conducts<br />

searches and provides access to the latest scientific<br />

information and scholarly research, as well as industry<br />

statistics and market information.<br />

Membership<br />

Join<br />

Now!<br />

Joining <strong>Rubber</strong> <strong>Division</strong>,<br />

ACS is an investment that pays<br />

big dividends through exclusive members-only<br />

savings and benefits, including free online<br />

access to the <strong>Rubber</strong> Chemistry and Technology<br />

journal and significant discounts on our<br />

technical meetings, expos, educational<br />

components and library services.<br />

Stay Social!<br />

Follow us on Twitter:<br />

@<strong>Rubber</strong><strong>Division</strong><br />

Join our LinkedIn Group: <strong>Rubber</strong> <strong>Division</strong>,<br />

American Chemical Society<br />

VISIT RUBBER.ORG FOR MORE INFORMATION.

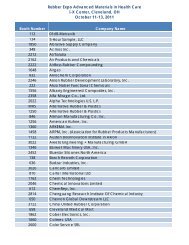

Exhibitor List<br />

*Also affiliated with the healthcare industry<br />

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

3M Advanced Materials ............................. 220<br />

3M Advanced Materials <strong>Division</strong><br />

6744 33rd St. North<br />

Oakdale, MN 55128<br />

Ph: 651 736-7051<br />

Email: jmiller3@mmm.com<br />

www.mmm.com<br />

3M’s broad range of high performance fluoroelastomers<br />

are engineered to meet demanding<br />

sealing applications by providing long-term<br />

protection against high temperatures and chemically<br />

aggressive environments. We offer a wide<br />

selection of advanced fluoropolymer materials,<br />

but the 3M advantage goes beyond technology.<br />

It’s also skilled, dedicated people, with a boundless<br />

passion for solving tough problems – and<br />

helping you achieve your business goals.<br />

Abrasive Supply Company ....................... 1844<br />

25240 State Rt. 172<br />

Minerva, OH 44657<br />

Ph: 330 894-2818<br />

Email: sales@polyblast.com<br />

www.polyblast.com<br />

Abrasive Supply Company manufactures blast<br />

cleaning equipment, both manual and automated,<br />

as well as plastic blast media (urea,<br />

melamine and acrylic). They are also involved in<br />

every aspect of cryogenic deflashing including<br />

the manufacturing of cryogenic deflashing equipment,<br />

cylindrical polycarbonate deflashing media<br />

used in both cryogenic and ambient applications<br />

as well as operating a deflashing job shop. Abrasive<br />

Supply Company can also provide complete<br />

testing services for dry blasting and deflashing.<br />

All of ASC’s products and services are backed<br />

by our commitment to quality as part of our ISO<br />

9001-2008 Certification.<br />

Air Products and Chemicals .................... 2032<br />

7201 Hamilton Blvd.<br />

Allentown, PA 18195<br />

Ph: 610 481-5598<br />

Email: gigmrktg@airproducts.com<br />

www.airproducts.com/cryogenics<br />

For decades, rubber and polymer industries have<br />

relied on Air Products’ industrial gas supply,<br />

technologies and technical know-how to help<br />

improve their processes. Our specialists take a<br />

total solutions approach by providing technical<br />

support for a range of gas applications including<br />

deflashing, grinding, process cooling, inerting<br />

and hydrogenation. With an unequaled on-time<br />

delivery record of more than 99.9% and an<br />

outstanding safety performance, Air Products<br />

provides worry-free gas supply and services that<br />

can help you to operate efficiently and safely.<br />

Booth personnel: Svetlana Ivanova, Glenn<br />

Stroup, Bridget Nyland, Biren Shah and Nancy<br />

Easterbrook<br />

AirBoss <strong>Rubber</strong> Compounding ............... 3002<br />

101 Glasgow St.<br />

Kitchener, ON, Canada N2G 4X8<br />

Ph: 519 576-5565<br />

Email: jtomins@airboss.ca<br />

www.airbossrubbercompounding.com<br />

Worry-Free. What other polymer rubber compounding<br />

company can make that promise?<br />

Here’s how we do it. AirBoss is one of North<br />

America’s leading custom rubber mixers with<br />

the capacity to supply over 250 million pounds<br />

annually. We continually invest in our manufacturing.<br />

Our main facility in Kitchener, ON, is<br />

supplemented by a state-of-the-art mixing facility<br />

in Scotland Neck, North Carolina and Acton<br />

Vale, Quebec. AirBoss specializes in rubber<br />

compounding including EPDM rubber, styrenebutadiene<br />

rubber, compression molding rubber,<br />

CPE rubber, CBM rubber, synthetic rubber, bunan<br />

rubber, nitrile rubber, rubber calender and<br />

elastomeric rubber compounds. We want every<br />

customer to feel completely confident in their<br />

relationship with us. We encourage customers<br />

to meet our people and tour our facilities. Your<br />

key contacts at AirBoss will always be fully<br />

aware of your requirements, and they will have<br />

the tools and authority to ensure you get exactly<br />

what you need.<br />

Booth personnel: Robert Dodd, John Tomins,<br />

Ted Nelson, John Bergman, George Papazotos,<br />

Michael Denford and Sue Hedrick<br />

Airgas ............................................................. 2242<br />

21610 Alexander Rd.<br />

Oakwood Village, OH 44146<br />

Ph: 440-232-7833<br />

Email: donald.madda@airgas.com<br />

www.airgas.com<br />

Booth personnel: Donald Madda<br />

Akrochem Corporation* ............................ 1630<br />

3770 Embassy Pkwy.<br />

Akron, OH 44333<br />

Ph: 800 321-2260<br />

Email: jaysilver@akrochem.com<br />

www.akrochem.com<br />

For more than 80 years, Akrochem has strived<br />

to provide only the very best in rubber chemicals<br />

and compounding materials. Today we use our<br />

experience to bring you the exact products you<br />

need and expert technical advice on how to<br />

use them. Akrochem has the right ingredients<br />

because we have the best line of materials<br />

anywhere.<br />

Akron <strong>Rubber</strong> Development Laboratory,<br />

Inc.* ............................................................... 2440<br />

2887 Gilchrist Rd.<br />

Akron, OH 44305<br />

Ph: 330-794-6600<br />

Email: macw@ardl.com<br />

www.ardl.com<br />

ARDL is an ISO 9001:2008, A2LA accredited<br />

and FDA registered international independent<br />

lab dedicated to providing testing, development<br />

and problem solving services to all facets of<br />

the rubber and plastic industries. Established in<br />

1962, ARDL has the experience, expertise and<br />

resources to be a single-source lab, not only for<br />

standardized testing and analysis, but for custom<br />

non-routine services also. ARDL’s diverse technical<br />

staff strives to build personal relationships<br />

with clients in order to better understand their<br />

unique challenges. ARDL capabilities include<br />

physical testing, chemical services, microscopy,<br />

custom testing, compounding, dynamic testing<br />

and technical consulting.<br />

Akzo Nobel Functional Chemicals .......... 810<br />

525 W. Van Buren St.<br />

Chicago, IL<br />

Ph: 312-544-7382<br />

Email: william.nan@akzonobel.com<br />

www.akzonobel.com/polymer<br />

AkzoNobel is one of the world’s leading industrial<br />

companies. Our company is consistently<br />

ranked as one of the chemicals industry leaders<br />

on the Dow Jones sustainability world indexes<br />

(DJSI). We have operations in more than 80<br />

countries, and employ around 55,000 people<br />

worldwide. AkzoNobel’s functional chemicals<br />

business makes organic peroxides, metal alkyls,<br />

organometallic specialties, and polymer additives.<br />

We supply essential products used in<br />

the production and processing of thermoplastic<br />

resins, and thermoset and elastomeric materials.<br />

We believe that what is good for you today in<br />

not necessarily good enough for you tomorrow.<br />

AkzoNobel is committed to helping you further<br />

improve your curing systems.<br />

Albany Engineered Composites, Inc. .... 1142<br />

112 Airport Dr.<br />

Rochester, NH 03867<br />

Ph: 603 330-2405; Fx: 603 330-5801<br />

Email: gordon.varney@albint.com<br />

www.pyropel.com<br />

Albany Engineered Composites will display<br />

Pyropel polyimide insulation products for use<br />

insulating molding equipment and tooling. Pyropel<br />

MD-18 is a tough lightweight material that<br />

can be easily applied to the perimeter of mold<br />

and dies reducing heat loss. The benefits of this<br />

type of insulation are improved temperature<br />

uniformity, faster start up and energy savings<br />

resulting in increased product quality and lower<br />

operating cost. Pyropel MD-60 is a compression<br />

resistant grade used for platen or tool base<br />

insulator plates. The major benefit of this material<br />

is improved pressure distribution and longer<br />

insulator life resulting in more uniform molded<br />

parts and significant decrease in equipment<br />

maintenance cost.<br />

Booth Personnel: Gordon Varney<br />

10 INTERNATIONAL ELASTOMER CONFERENCE

See us at<br />

Booth No. 810<br />

The world’s<br />

leading brands<br />

of crosslinking<br />

peroxides<br />

Companies all over the world depend<br />

on our Trigonox ® and Perkadox ®<br />

organic peroxide brands. Why?<br />

Because they are an important<br />

ingredient in the production of<br />

everything from hi-tech automotive<br />

parts such as hoses and belts to shoe<br />

soles and power distribution cables.<br />

Examples include:<br />

Perkadox PD-50S-ps<br />

extruded silicione rubber articles such as<br />

auto ignition cable, seals & gaskets<br />

Perkadox BC<br />

wire & cable, footwear, technical rubber<br />

goods<br />

Perkadox 14<br />

<br />

wire & cable, technical rubber goods<br />

Trigonox T<br />

wire & cable<br />

Trigonox 101<br />

PEX pipes, polymer modification,<br />

technical rubber goods<br />

Trigonox 145<br />

PEX pipes, rotomolding<br />

Trigonox 311<br />

PEX pipes, rotomolding, engineering<br />

plastics<br />

All our organic peroxides can be supplied<br />

neat or in a formulated form. What do you<br />

need? We’re happy to meet and discuss your<br />

target formulation.<br />

E polymerchemicals.na@akzonobel.com<br />

T +1 800 828 7929<br />

www.akzonobel.com/polymer

Exhibitor List<br />

*Also affiliated with the healthcare industry<br />

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

Alfa Mirage Co., Ltd. ....................................... 438<br />

3-2-19, Miyakojimahondori, Miyakojima-Ku<br />

Osaka , Japan<br />

Ph: 81-6-6924-2631<br />

Email: t-tamahiro@alfamirage.com<br />

www.alfamirage.com<br />

Alpha Coatings .............................................. 2850<br />

622 S. Corporate Dr.<br />

Fostoria, OH 44830<br />

Ph: 419 436-1255; Fx: 419 436-1245<br />

Email: info@alpha-coatings.com<br />

www.alpha-coatings.com<br />

Whitford is a global manufacturer and supplier<br />

of the world’s largest, most complete line of<br />

high-performance coatings for markets including<br />

industrial, petrochemical, automotive, aeronautics,<br />

marine, food processing, and electrical.<br />

These coatings solve many problems, including<br />

corrosion, abrasion, lubrication, high-temperature,<br />

friction, insulation, and release.<br />

In 2006, Whitford purchased Alpha, manufacturer<br />

and applicator of low-friction coatings that improve<br />

the performance of flexible substrates. Alpha<br />

applies these coatings to automotive sealing<br />

systems to solve problems of “itch and squeak”,<br />

weathering, abrasion, etc. Alpha formulates its<br />

own line of coatings, Resilon®, that allow for improved<br />

processing and outstanding performance<br />

over rubber and plastic substrates.<br />

Alpha Technologies U.S.L.P.* ................... 1202<br />

306 Hollywood Ave.<br />

Akron, OH 44313<br />

Ph: 330 836-5006<br />

Email: jasezna01@earthlink.net<br />

www.alpha-technologies.com<br />

Alpha Technologies is the leading manufacturer<br />

of test instruments for the rubber industry. These<br />

instruments measure the viscoelastic properties of<br />

raw rubbers and rubber compounds by measuring<br />

changes in compounds before, during, and after<br />

vulcanization. Products include Mooney viscometers,<br />

MDR rotorless cure meters, ODR oscillating<br />

disk rheometers, RPA <strong>Rubber</strong> Process Analyzers<br />

(variable strain, frequency and temperature test<br />

conditions), PPA Production Process Analyzers,<br />

tensile testers, DisperGrader dispersion analyzers,<br />

and density and hardness testers. Alpha Technologies<br />

also offers a full range of data management<br />

software. Also offered are applications support<br />

and calibration and maintenance services.<br />

Alternative <strong>Rubber</strong> & Plastics .................. 1638<br />

200 Creekside Dr.<br />

Amherst, NY 14228<br />

Ph: 716 691-2141<br />

Email: jeff@altrubber.com<br />

www.altrubber.com<br />

Alternative <strong>Rubber</strong> & Plastics, Inc. is an ISO 9001<br />

certified distribution company for raw materials to<br />

the <strong>Rubber</strong> and Plastics Industry. Our product lines<br />

are recognized by our customers to be of the finest<br />

quality. Our sales teams are among the most innovative<br />

in the industry and we distinguish ourselves<br />

with outstanding support and service. Some of<br />

the industries we supply and service: Adhesive/<br />

sealants, automotive, building and construction,<br />

coating and sealants, hose/belting, medical, rubber<br />

and plastic (industrial), textile, wire and cable.<br />

Products: chlorinated polyethylene (CPE), chlorosulfonated<br />

polyethylene (CSM), reclaim rubber<br />

(butyl, whole tire), EPDM, white, polychloroprene<br />

(CR), nitrile butadiene rubber (NBR)<br />

styrene butadiene (SB) copolymers (1006, 1009),<br />

high styrene resin, NBR/PVC (OZO), nitrile (NBR)<br />

powder, rubber-to-metal adhesives, high performance<br />

coatings<br />

polyisoprene (IR)/butyl rubber (IIR), natural rubber,<br />

poly-separator sheeting, tire crumb/powder, mold<br />

release, anti-tack, phenolic resin.<br />

Booth personnel: Jerry Fasolino Sr., Jerry Fasolino<br />

Jr., Nick Fasolino, Jeff Wiedeman, John Fahy,<br />

James Colangelo, Greg Donovan, Dhiru Radadia<br />

Altman Manufacturing Co., Inc. ................ 3136<br />

1990 Ohio St.<br />

Lisle, IL 60532<br />

Ph: 630 963-0031<br />

Email: brian@altmanmfg.com<br />

www.altmanmfg.com<br />

Altman Manufacturing Co., Inc. specializes in the<br />

design and building of automated systems for finishing<br />

rubber parts. These systems include male<br />

and female trimming dies, vision inspection systems,<br />

slitting systems, assembly, pressure testing,<br />

lathe trimming, hydraulic and pneumatic presses<br />

and buffing machines. Altman Manufacturing Co.<br />

has been designing systems since 1942.<br />

American Chemical Society....................... 2846<br />

1155 16th St., NW<br />

Washington, DC 20036<br />

Ph: 800 227-5558<br />

Email: e_hite@acs.org<br />

www.acs.org<br />

American Chemical Society supports the global<br />

chemical science community by offering a variety<br />

of activities and resources and collaborating with<br />

scientists and engineers worldwide. Among the<br />

many resources that ACS offers, access to cuttingedge<br />

information, connecting to an international<br />

network and tools for advancing careers are especially<br />

valuable. Discover the best in chemistry with<br />

ACS, the world’s largest scientific society with<br />

more than 163,000 members worldwide.<br />

Booth personnel: Elizabeth Hite<br />

American Kuhne, Inc. .................................... 630<br />

401 Main St.<br />

Ashaway, RI 02804<br />

Ph: 401 326-6206<br />

Email: dcitron@americankuhne.com<br />

www.americankuhne.com<br />

Americas <strong>International</strong>, Inc. ................. 2418<br />

3517 Embassy Parkway, Ste. 100<br />

Akron, Ohio 44333<br />

Ph 800 503-3055; 330 396-5941; Fx: 330 664-<br />

1646<br />

Email: margaret@americasinternational.com<br />

www.americasinternational.com<br />

Americas <strong>International</strong>, Inc., is a leading North<br />

American distributor of rubber and rubber<br />

chemicals. Americas <strong>International</strong>, Inc. is also<br />

the distributor of Therminol heat transfer fluids<br />

serving the Western U.S. Founded in 1997,<br />

Americas <strong>International</strong>, Inc. has grown from<br />

its birthplace and headquarters in Akron, Ohio<br />

to include regional sales offices in Atlanta,<br />

Chicago, and Los Angeles, and a network of<br />

warehouse operations that ensure on-time<br />

deliveries of the right product to the right place.<br />

Americas <strong>International</strong>, Inc. represents many of<br />

the world’s leading chemical companies from<br />

the United States, Europe, and Asia. Together<br />

with our technical product expertise, dedicated<br />

customer service staff, and unmatched logistical<br />

support, we create positive solutions that<br />

optimize long-term growth opportunities and<br />

customer loyalty.<br />

ARKEMA Inc.* ........................................... 1350<br />

2000 Market St.<br />

Houston, TX 77070<br />

Ph: 215 419-7000<br />

Email: marianne.bullock@arkema.com<br />

www.arkema.com<br />

In crosslinking applications, organic peroxide<br />

products act on the polymer itself, not the<br />

initial monomer. The organic peroxide “builds<br />

bridges” between the polymer chains to<br />

improve the mechanical properties and heat<br />

resistance of the product. In rubber, they are an<br />

excellent alternative to traditional vulcanization<br />

systems (sulfur) to provide nitrosamine-free<br />

solutions. Arkema has over 50 years of experience<br />

in manufacturing organic peroxides.<br />

These products include organic peroxides sold<br />

under the Luperox, Di-Cup, and Vul-Cup trade<br />

names.<br />

ARPM, Inc. (Association for <strong>Rubber</strong> Products<br />

Manufacturers) .......................................... 1148<br />

7321 Shadeland Station Way<br />

Indianapolis, IN 46256<br />

Ph: 317 863-4072<br />

Email: jtaylor@arpminc.org<br />

www.arpminc.org<br />

The ARPM has been the association of choice<br />

for rubber manufacturers since 2010. ARPM<br />

provides its members with a dynamic range<br />

of ideas, resources and networking events<br />

throughout the year. Services include best<br />

practices and industry studies, company savings<br />

programs and more. Find out more at<br />

www.arpminc.org.<br />

12 INTERNATIONAL ELASTOMER CONFERENCE

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

Ph: 403 527-1121<br />

Lancashire, UK PR5 8AQ<br />

Email: randy_leclair@cancarb.com<br />

www.cancarb.com<br />

Cancarb is a leader in the development, manufacture<br />

and global marketing of thermal carbon<br />

black. With a capacity of 45,000 metric tons per<br />

year, Cancarb’s plant in Medicine Hat, Alberta,<br />

Canada is the world’s largest of its kind. The<br />

company’s Thermax brand products are supported<br />

by local distributors in over 50 countries.<br />

With a stable source of natural gas as our feed<br />

stock and zero particulate emissions Cancarb<br />

is positioned to meet North America’s growth<br />

projections.<br />

Ph: 44 1772-322-888; Fx: +44 1772 315 853<br />

Email: sales@cilbond.com<br />

www.cilbond.com<br />

Chemical Innovations Limited (CIL) will be<br />

promoting the Cilbond range of rubber to metal<br />

primers and bonding agents. Cilbond is formulated<br />

to give high-performance bonding for the<br />

toughest in-service environments, and the range<br />

includes one-coat bonding systems, as well as<br />

conventional primer/cover-coat products. CIL is<br />

ISO 9001:2008 accredited and has experienced<br />

distributors throughout North America.<br />

Booth personnel: Bruce Ward, Aissa Benarous,<br />

Andy Couch, Brian Jones and Marcus Hunter<br />

Blachford* ..................................................... 3024<br />

2323 Royal Windsor Dr.<br />

Mississauga, ON L5J 1K5<br />

Canada<br />

Ph: 905 823-3200; Fx: 905 823-9290<br />

Email: hkennedy@blachford.ca<br />

www.blachford.ca<br />

Blachford is a leading supplier of anti-tack coatings<br />

and process aids designed to facilitate and<br />

enhance the rubber manufacturing process.<br />

We are proud to have supplied products and<br />

services to the rubber industry for over 90 years.<br />

In particular, our extensive research and development<br />

on anti-tack coatings – both slab dips<br />

and pellet dips - has led to more environmentally<br />

friendly, high performing products at low solid<br />

levels. These can help increase manufacturing<br />

efficiency while achieving substantial cost<br />

savings. With Blachford’s wide variety of highperformance<br />

products to choose from, we can<br />

supply comprehensive rubber manufacturing<br />

solutions.<br />

Booth personnel: John Blachford, Howard Kennedy,<br />

Rebekah Davis, Dan Smythe, Bob Chaffin,<br />

Joe Farella, Mike Cundari, Jean Reid, Sam Yang<br />

and Phil Kerneghan<br />

Bosch Rexroth Corporation ....................... 936<br />

5150 Prairie Stone Pkwy.<br />

Hoffman Estates, IL 60192-3707<br />

Ph: 847 645-3612<br />

Email: j.p.lanz@boschrexroth-us.com<br />

www.boschrexroth-us.com<br />

Budzar Industries, Inc. ............................... 1414<br />

38241 Willoughby Pkwy.<br />

Willoughby, OH 44094<br />

Ph: 440 918-0505; Fx: 440 918-0606<br />

Email: sales@budzar.com<br />

www.budzar.com<br />

Budzar Industries has specialized in process<br />

fluid heat transfer systems since 1975 and<br />

has earned a global reputation for quality and<br />

ingenuity in the design, engineering, and manufacturing<br />

of temperature control systems. Budzar<br />

Industries equipment and engineering gives the<br />

producer precise controls over process variables.<br />

Budzar Industries’ chillers, hot water systems,<br />

hot oil systems, cooling towers, and pump tank<br />

systems equal greater productivity, extended<br />

equipment life, increased productive capacity,<br />

and power and resources conservation, which<br />

equates to time and bottom line savings. Budzar<br />

Industries is committed to operating with complete<br />

integrity and delivering the highest quality<br />

equipment and services available today.<br />

Booth personnel: Joe Caja, Fred Feliciano and<br />

Dave Young<br />

Cancarb Limited ............................................ 832<br />

Box 130<br />

Medicine Hat<br />

Alberta, Canada<br />

Canterbury Engineering............................... 230<br />

1057 Vijay Dr.<br />

Chamblee, GA 30341<br />

Ph: 770 458-4882; 800 241-7650; Fx: 770 454-<br />

9021<br />

Email: contact.us@cec75.com<br />

www.genca.com<br />

Canterbury Engineering Company has a full line<br />

of screws and barrels for all types of plastic<br />

processing. The company has an 80,000 square<br />

foot manufacturing facility located in Atlanta<br />

Georgia. We have the capabilities of manufacturing<br />

screws over 300 inches in length and we<br />

offer custom designs and engineering services<br />

for extrusion, injection molding, and the rubber<br />

industry. In addition to high temperature and<br />

highly corrosive applications, Canterbury utilizes<br />

all types of exotic metal selections. We offer total<br />

refurbishing/rebuilding of screws and barrels.<br />

We serve all plastic market segments including,<br />

wire and cable, medical, extrusion, injection,<br />

rubber/tire and specialty markets.<br />

Chem Technologies, Ltd.* ........................ 1546<br />

14875 Bonner Dr.<br />

Middlefield, OH 44062<br />

Ph: 440 632-9311<br />

kcohill@chemtechnologiesltd.com<br />

www.chemtechnologiesltd.com<br />

Chem Technologies, Ltd. is a unique manufacturer<br />

of custom mixed rubber and chemical dispersions<br />

under one roof, integrating dispersions into our<br />

compound operation to provide customers with<br />

unsurpassed batch-to-batch consistency through<br />

our value-added product. Our custom mix operation<br />

utilizes state-of-the-art equipment to mix quality<br />

black and color organic elastomer compounds, custom<br />

or proprietary, in continuous strips, slabs, diced<br />

pellets, and preformed sheets. We have tangential<br />

and intermesh mixing technology. Our dispersion<br />

provides custom single and multiple ingredient<br />

blends in bulk or preweighed prepackaging. Our<br />

products are ready to add to your mixer, in standard<br />

cardboard boxes or in returnable containers.<br />

Chemical Innovations Limited .................. 918<br />

217 Walton Summit Rd.<br />

Bamber Bridge, Preston<br />

ChemRep, Inc. ................................................ 214<br />

33. W. Higgins Rd.<br />

Ste. 4000<br />

S. Barrington, IL<br />

Ph: 800 433-8982<br />

Email: tim@chemrep.com<br />

www.chemrep.com<br />

ChemRep has been a supplier of raw materials<br />

and rubber-to-metal adhesives used in the<br />

polymer industry since 1977. Based in South<br />

Barrington, Illinois, we are a regional distributor<br />

serving the north-central portion of the United<br />

States. We distribute adhesives, mold releases,<br />

clays, carbon blacks, zinc oxide, CPE, ECO, polynorbornene,<br />

and polyacrylates. We also serve<br />

as a manufacturers’ representative for Cray<br />

Valley USA, Polychem Dispersions, and Arnold<br />

Machine.<br />

Chemroy Canada, Inc. ................................ 2918<br />

106 Summerlea Rd.<br />

Brampton, Ontario L6T 4X3<br />

Canada<br />

Ph: 905 789-0701; Fx: 905)789-7170<br />

Email: sales@chemroy.ca<br />

www.chemroy.ca<br />

ChemSpec, Ltd.* .......................................... 2624<br />

3570 Executive Dr., Ste. 211<br />

Uniontown, OH 44685<br />

Ph: 330 958-4316<br />

Email: cwagner@chemspecltd.com<br />

www.ChemSpecLtd.com<br />

ChemSpec is a growing specialty chemical distribution<br />

company. A majority of our customers<br />

work in the plastic, rubber, and adhesive/sealant<br />

markets, but we’ve found that our chemicals<br />

work well and are price competitive in numerous<br />

manufacturing industries. The demands of<br />

the chemical industry are constantly changing,<br />

and we possess the technical knowledge and<br />

experience which enables us to continually accommodate<br />

our customers’ business needs in an<br />

ever-changing business environment. Some of<br />

our products are the following: silanes, plasticizers,<br />

fillers, oxides, chemical foaming agents, process<br />

aids, accelerators, co-agents/curing agents,<br />

Exhibitor List<br />

INTERNATIONAL ELASTOMER CONFERENCE 13

Exhibitor List<br />

*Also affiliated with the healthcare industry<br />

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

PEG, polymers, antioxidants, and antiozonant/<br />

PE waxes.<br />

Booth personnel: Dave Moreland, Richard Dee,<br />

Jon Sias, Nick Incarnato, Brian Sears, Luc Moreland,<br />

Chris Ryan, Anthony Mariniello and Chris<br />

Wagner<br />

Chenguang Fluoro & Silicone <strong>Elastomer</strong>s<br />

Co., Ltd. ....................................................... 1750<br />

168, 6th Tengfei Rd.<br />

Southwest Shuangliu Airport Economic Development<br />

Zone<br />

Chengdu, Sichuan<br />

China<br />

Ph: 86-28-85730628; Fx: 86 28 85730469<br />

Email: j.kwok@cgfse.com<br />

www.cgfse.com<br />

Chenguang Fluoro and Silicone <strong>Elastomer</strong>s<br />

Co., Ltd. (FSE) is the leading supplier of fluoroelastomer<br />

(FKM) materials from China. We<br />

specialize in R&D and production of fluoroelastomer<br />

precompounds and full-compounds. Full<br />

range of fluoroelastomer materials including<br />

bisphenol curable grades with fluorine content<br />

66%, 68% and 69%, peroxide curable grades,<br />

perfluoroelastomer (FFKM) are available. With<br />

ISO 9001:2008 certified facilities and quality<br />

management, our 4 production lines enable us<br />

to produce over 2, 000 tons of fluoroelastomer<br />

products of high performance and consistency.<br />

Think of FKM, think of FSE. You can count on our<br />

materials for the applications to deal with the<br />

extremely harsh environments.<br />

Booth personnel: Liu Hao, Zhang Lin and Guo<br />

Huatao<br />

Chevron Global Downstream LLC ............ 836<br />

6001 Bollinger Canyon Rd.<br />

San Ramon, CA<br />

Ph: 925 842-8788<br />

Email: adrianoueno@chevron.com<br />

www.chevron.com<br />

Because Chevron Premium Process Oils are<br />

produced by all-hydroprocessing, their chemical<br />

properties make them an excellent choice as<br />

a processing aid or extender oil in rubber compounding.<br />

They have excellent compatibility with<br />

rubber polymers. They can reduce the amount of<br />

time required for mixing, minimize the amount<br />

of heat generated, and maximize the dispersion<br />

of components. Additionally, they can extend<br />

product volume while maintaining the physical<br />

properties of the rubber compound. Chevron is<br />

one of the world’s leading integrated energy<br />

companies, with subsidiaries that conduct business<br />

worldwide.<br />

China United <strong>Rubber</strong> Corporation ............ 102<br />

F/15 Entry C, No.19<br />

Xiaoying Rd<br />

Beijing, China<br />

Email: expo@chrubber.com<br />

www.chrubber.com<br />

China United <strong>Rubber</strong> Corporation (short as CURC)<br />

was established in 1993. After the development<br />

of nearly 20 years, it has become a reputable<br />

company for trading and exhibition service in<br />

the rubber industry at home and abroad. CURC<br />

is mainly engaged in the business of trading<br />

and exhibition.The trading business includes the<br />

import and export as well as domestic distribution<br />

of rubber raw materials, tire and rubber products<br />

and machineries. Meanwhile, the exhibition business<br />

includes organization of <strong>Rubber</strong>Tech China<br />

(China <strong>International</strong> Tire and <strong>Rubber</strong> Technology<br />

Exhibition) and Reifen China (Asian Essen Tire<br />

Show), as well as participation service for relative<br />

foreign exhibitions.<br />

CIMBAR Performance Minerals ............. 1044<br />

25 Old River Rd.<br />

P.O. Box 250<br />

Cartersville, GA 30120<br />

Ph: 800 852-6868; Fx: 770 607-3799<br />

www.cimbar.com<br />

Cober, Inc. ....................................................... 1848<br />

30 Moffitt St.<br />

Stratford, CT 06615<br />

Ph: 203 855-8755; Fx: 203 855-7511<br />

Email: mkrieger@coberelectronics.com<br />

www.cober.com<br />

Founded in 1966, Cober is the leader in continuous<br />

vulcanization systems for the automotive<br />

industry. Cober provides a complete line of curing<br />

ovens including infrared and hot air shock<br />

preheaters, microwave and high velocity hot air<br />

ovens, batch systems and large bale preheaters<br />

which we design and manufacture end to end<br />

in Connecticut and sell worldwide. Cober is also<br />

expert in industrial heating systems and applications<br />

requiring precision drying, serving industries<br />

including automotive pharmaceutical and food.<br />

Cober manufactures standard ovens as well as<br />

custom systems. We provide support worldwide<br />

via a field service team and remotely using our<br />

Internet-based support and diagnostics capability.<br />

Cold Jet LLC* ................................................. 3042<br />

78 Chilmark St.<br />

Worcester, MA 01604<br />

Ph: 800 337-9423<br />

rtaylor@nirtofreeze.com<br />

www.coldjet.com<br />

In-machine mold cleaning using dry ice. Since<br />

1986, Cold Jet has developed innovative, environmentally<br />

responsible cleaning solutions<br />

that help rubber and plastic companies reduce<br />

maintenance costs, enhance product quality,<br />

prolong equipment life, and improve productivity<br />

and worker safety. Cold Jet’s extensive line of dry<br />

ice systems are used around the world, making<br />

productive use of recycled carbon dioxide while<br />

eliminating the need for chemicals and brushes<br />

in the cleaning process. Cold Jet is a private<br />

company with global headquarters in Loveland,<br />

Ohio and international operations in Europe, Asia,<br />

Middle East, Canada and Mexico.<br />

Colmec USA*................................................... 1346<br />

2490 Black Rock Turnpike #349<br />

Fairfield, CT 06825<br />

Ph: 203 292-5889<br />

Email: sales@colmecusa.com<br />

www.colmecusa.com<br />

Colmec is a premier rubber processing equipment<br />

manufacturer. We have been supplying the highest<br />

quality rubber processing machinery to the<br />

rubber industry for nearly 40 years. Our product<br />

selection ranges from mixers to extruders and curing<br />

ovens, as well as downstream equipment. Our<br />

mixers handle all of the common polymers from<br />

EPDM, nitrile, fluoropolymers and silicone to name<br />

just a few. Colmec’s extrusion machinery capabilities<br />

run the gamut from hose to profiles. We also<br />

manufacture a complete line of curing ovens utilizing<br />

the latest technologies in infrared, ultra high<br />

velocity hot air, microwave and salt. We are able<br />

to supply complete turnkey systems, install them<br />

and train operators how to run and maintain them.<br />

Booth personnel: Martin Yonnone and Ubaldo<br />

Colombo<br />

Conitex Sonoco .............................................. 3148<br />

1302 Industrial Pike<br />

Gastonia, NC 28052<br />

Ph: 704 833-1357; Fx: 704 865-7926<br />

Email: lbalwinski@conitex.com<br />

www.conitex.com<br />

Conitex Sonoco has global presence in the manufacturing<br />

and distribution of packaging products<br />

including FIBC bags and Corrugated Pallets. With<br />

corporate offices in the U.S. and Spain, we offer<br />

a team of sales and service personnel throughout<br />

the world to provide solutions to meet your<br />

specific applications. Let us carry the bulk of your<br />

business.<br />

Corporate Consulting, Services &<br />

Instruments, Inc. ......................................... 2630<br />

221 Beaver St.<br />

Akron, OH 44304<br />

Ph: 330 376-3600<br />

Email: m.warner@ccsequipment.net<br />

www.ccsi-inc.com<br />

Corporate Consulting Service & Instruments, Inc.<br />

(CCSi) was founded in 1986 and is now managed<br />

by a new team led by David Warner, Frank Orlando<br />

and Michael Warner. CCSi continues to provide<br />

quality ISO/IEC 17025 calibration and on-site services.<br />

Our field service team is now managed by<br />

David Mandrych. CCSi also provides the industry<br />

with laboratory testing instrumentation, processing<br />

equipment, specimen preparation apparatus<br />

and the OREC Ozone testing chamber and ancillary<br />

equipment. CCSi recently joined with Gibitre<br />

Instruments (Italy) to form Gibitre NA, which will<br />

provide a complete line of fully supported testing<br />

instruments.<br />

14 INTERNATIONAL ELASTOMER CONFERENCE

Small<br />

footprint,<br />

big output.<br />

numberS<br />

count.<br />

While our Strainext ® straining systems<br />

may be compact, its innovative technology<br />

will increase your production significantly.<br />

Strainext processes rubber compounds up<br />

to 4500 kg/h and changing the screen only<br />

takes 5 seconds.<br />

VMI <strong>Rubber</strong>. Thinking forward.<br />

See vmi-rubber.com for details.

Custom<br />

Compounds.<br />

Precision<br />

Performance.<br />

Looking for a<br />

Custom Mixer<br />

for Silicone?<br />

• 20 million pounds<br />

of mixing capacity<br />

• Full-service research lab<br />

• In-house silicone chemist<br />

Portage Precision Polymers is a<br />

privately held custom rubber and silicone<br />

manufacturer. We deliver results for our<br />

customers through the right mix of:<br />

• Personalized service<br />

• Technical expertise<br />

• Superior quality<br />

• Competitive pricing<br />

• Global raw material sourcing<br />

Visit us on the web at www.pppmixing.com<br />

or call us at 330.296.6327.

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

Davis-Standard also supplies extrusion heads,<br />

custom feedscrew designs, curing systems,<br />

laboratory and downstream equipment, and<br />

integrated process control systems to provide<br />

solutions for every application.<br />

Booth personnel: Joe Wnuk, Tom Bishop and<br />

Tom Malec, Jim Shroyer<br />

Cray Valley USA .......................................... 1624<br />

468 Thomas Jones Way<br />

Exton, PA 19341<br />

Ph: 484 875-5263<br />

Email: todd.speece@crayvalleyus.com<br />

www.crayvalley.com<br />

Cray Valley is part of Total’s Refining and<br />

Petrochemicals division. Cray valley delivers a<br />

broad line of premium sulfur and peroxide-cure<br />

technologies to the rubber market to help you<br />

get the most out of your applications. Cray Valley<br />

additives include liquid polybutadiene resins and<br />

liquid butadiene-styrene copolymers, with or<br />

without functionalization, metallic coagents and<br />

activators, and hydrocarbon resins. They will:<br />

Improve crosslinking efficiency and dynamical<br />

properties, improve rolling resistance and grip<br />

in tires, improve flex fatigue, abrasion, tear and<br />

heat aging, improve processing, compatibilization<br />

and dispersion of fillers and improve adhesion<br />

to reinforcement fibers and metals.<br />

Booth personnel: Todd Speece<br />

Cross Oil Refining & Marketing Co.,<br />

Inc .................................................................. 202<br />

484 East 6th<br />

Smackover, AR 71762<br />

Ph: 870 881-8700<br />

Email: Dallas.Kirkendol@martinmlp.com<br />

www.crossoil.com<br />

Cross Oil is a U.S. refiner exclusively producing<br />

severely hydrotreated naphthenic base and<br />

process oils at our Smackover, Arkansas facility.<br />

Customer-oriented and product focused Cross<br />

Oil is committed to supplying quality basestocks<br />

that have found wide acceptance in the tire and<br />

rubber industries. All Cross Oil products meet<br />

IP 346 requirements. Cross Oil produces refined<br />

products with viscosities ranging from 35-3500<br />

SUS.<br />

Cryogenic Institute of New England,<br />

Inc. ............................................................... 3040<br />

78 Chilmark St.<br />

Worcester, MA 01604<br />

Ph: 508 459-7447; Fx: 508 459-7426<br />

Email: info@nitrofreeze.com<br />

www.nitrofreeze.com<br />

Nitrofreeze Cryogenic Solutions has provided<br />

cryogenic services to the medical, aerospace,<br />

defense, electronic and consumer industries<br />

since 2003. These services include cryogenic<br />

deflashing and deburring, dry ice blast cleaning,<br />

cryogenic treatment, among many others.<br />

Nitrofreeze’s cryogenic deflashing and deburring<br />

process is utilized by manufacturers of silicone<br />

and rubber parts, as well as plastics, and certain<br />

metals. The company’s dry ice blasting process<br />

is used to clean mold tooling. Nitrofreeze also<br />

provides equipment for manufacturers seeking<br />

to bring Nitrofreeze capabilities in-house.<br />

Booth personnel: Ryan Taylor, Len Nicoletti and<br />

Robin Rhodes<br />

Cryogenic Systems & Parts ......................1342<br />

1030 Ortega Way, Ste. A<br />

Placentia, CA 92870<br />

Ph: 714 241-7793; Fx: 714 241-7261<br />

Email: cryo@cryomatic.com<br />

www.cryomatic.com<br />

In spite of the way the economy has been our<br />

company, Cryogenic Systems & Parts has managed<br />

to carry on meeting the needs of the rubber<br />

industry on a worldwide base. We still manufacture<br />

a quality cryogenic finishing machine in<br />

four different sizes. Plus we have always been<br />

able to support the hundreds of machines that<br />

are out in industry today. It is our goal to carry on<br />

as we have for almost 30 years giving the rubber<br />

and plastics industry quality cryogenic finishing<br />

machines.<br />

D.S. Brown Company ................................. 2450<br />

300 E Cherry St.<br />

North Baltimore, OH 45872<br />

Email: cyoungless@dsbrown.com<br />

www.dsbrown.com<br />

Founded in 1890, The D.S. Brown Company is a<br />

leading worldwide designer, supplier and manufacturer<br />

of engineered products for the bridge<br />

and highway industry. D.S. Brown’s home office<br />

and manufacturing facilities are located in North<br />

Baltimore, Ohio. D.S. Brown is fully integrated,<br />

performing and controlling all manufacturing<br />

processes internally: Research and development,<br />

engineering design/CAD detailing, extruding,<br />

molding and testing, custom steel fabrication<br />

and machining. Our engineered rubber products<br />

division provides the following products and<br />

services: custom mixed compound in black and<br />

colors, custom extruded shapes - continuous and<br />

cut to length, custom molded products, rubber<br />

to metal bonding, silicone products, water jet<br />

cutting services.<br />

Daikin America, Inc. .................................... 414<br />

85 Winter St.<br />

Hanover, MA 02339<br />

Ph: 845 365-9518<br />

www.daikin-america.com<br />

Davis Standard, LLC* ....................................802<br />

1 Extrusion Dr.<br />

Pawcatuck, CT 06379<br />

Ph: 860 599-1010; Fx: 860 599-6258<br />

Email: cmaxam@davis-standard.com<br />

www.davis-standard.com<br />

Davis-Standard manufactures, installs and<br />

services single and coextrusion systems for the<br />

rubber industry. Complete systems are available<br />

for automotive sealing, hose, silicone, industrial,<br />

and medical tubing applications. The company<br />

offers an extensive range of elastomer extruders<br />

including multipurpose, hot and cold feed, silicone,<br />

vacuum vented, pin barrel, smooth barrel<br />

and custom designs, as well as gear extruders<br />

used as strainers and stabilizing gear pumps.<br />

Denka Corporation ....................................... 110<br />

780 Third Ave., 15th Floor<br />

New York, NY 10017-2024<br />

Email: ryuji-endo@denka.us.com<br />

Ph: 212 688-8700<br />

www.denka.us.com<br />

Denka is a chemicals manufacturer developing<br />

business on a global scale in a wide range of<br />

fields, from inorganic and organic materials to<br />

electronic materials and pharmaceuticals. Denka<br />

is a leading polychloroprene manufacturer in<br />

the world and provides a copolymer of ethylene,<br />

vinyl acetate and acrylic esters (Denka ER). Our<br />

corporate headquarters is located in Tokyo,<br />

Japan.<br />

Desma ............................................................. 2214<br />

2195 Arbor Tech Dr.<br />

Hebron, KY 41048<br />

Ph: 859 525-6610<br />

Email: maggie.markwalter@desma.biz<br />

www.desma-usa.com<br />

Desma is a Germany based producer of elastomer<br />

injection molding machines and tooling.<br />

Desma USA offers complete services for North<br />

American molders including engineering and<br />

design plus mold and cold runner manufacturing.<br />

In addition, they offer a demonstration laboratory<br />

for mold testing and process development.<br />

They also offer a sizable spare inventory for after<br />

sales support. Desma USA provides sales and<br />

technical support for Wickert Hydraulic presses.<br />

The company employs 7 domestic service technicians<br />

and a service manager for prompt support.<br />

Desma USA is the only company in North<br />

America that provides complete solutions for<br />

your molding needs.<br />

Deublin Company ........................................ 3036<br />

2050 Norman Dr. West<br />

Waukegan, IL 60085<br />

Ph: 847 689-8600; Fx: 847 689-8690<br />

Email: info@deublin.com<br />

www.deublin.com<br />

Deublin Company will be displaying rotary<br />

unions for mixers, Banburies, calenders, extruders<br />

and other machinery used for rubber product<br />

manufacturing. In December 2012, Deublin acquired<br />

Barco. In addition to the Deublin products,<br />

Barco Rotary Unions, plane and self-aligning<br />

swivels will also be on display. Recently, the<br />

Deublin product line has expanded and now<br />

includes electrical slip rings. These are rotating<br />

electro-mechanical devices used for the purpose<br />

of transmitting signal and/or current into rotating<br />

Exhibitor List<br />

INTERNATIONAL ELASTOMER CONFERENCE 17

Exhibitor List<br />

*Also affiliated with the healthcare industry<br />

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

machinery. A single slip ring may have multiple Dynamic Air manufactures a complete line of<br />

channels to conduct a variety of electrical signal dense phase and dilute phase, vacuum and<br />

and/or current. Booth personnel: Afzal Ali, Michael<br />

Hyde and Greg Schatko<br />

vibratory equipment for handling a wide variety<br />

pressure pneumatic conveying systems and<br />

of dry bulk granular materials, such as carbon<br />

black, for the rubber industry. We manufacture<br />

custom engineered equipment, including<br />

complete PLC systems. With over 15, 000<br />

installations worldwide, Dynamic Air provides<br />

complete integrated systems, including weighing<br />

and batching, electrical and mechanical<br />

design, structural engineering, field installation<br />

and start-up services. We offer sixteen (16) different<br />

pneumatic conveying concepts from high<br />

pressure dense phase to low pressure vacuum<br />

systems.<br />

Doss Visual Solution SRL ......................... 2836<br />

Via Bellini<br />

1 24060 , BG, Italy<br />

Ph: 39 0307703191<br />

Email: francesca.giusti@doss.it<br />

www.DossVisualSolution.com<br />

In 1990 Doss Visual Solution S.r.l. (Erbusco–BS)<br />

took its first steps in the field of industrial software<br />

for the numerical control of machine tools.<br />

It expanded its know-how to the mechanical,<br />

electric and electronic engineering production<br />

phases (especially vision software) enlarging its<br />

business by building its own mechanical shop.<br />

Up to more of 600 machines are produced and<br />

functioning all around the world. The request of<br />

reliable and severe quality controls have enabled<br />

Doss to develop innovative machines. Its optical<br />

inspection machines are based on the latest artificial<br />

vision technologies and applied to a vast<br />

range of markets.<br />

Dow Chemical ............................................... 424<br />

Email: KLZastrow@dow.com<br />

www.dow.com/elastomers<br />

As the world’s largest producer of polyolefin<br />

elastomers (POEs) and a leader in ethylene<br />

propylene diene monomer (EPDM), Dow’s innovation-rich<br />

product portfolio and deep industry<br />

expertise continue to deliver solutions for applications<br />

across the specialty elastomers industry.<br />

Dow recently announced it will build a new<br />

world scale plant for the increased production<br />

of Nordel IP hydrocarbon rubber products, the<br />