Supervisor's Facility and Administrative Inspection Checklist

Supervisor's Facility and Administrative Inspection Checklist

Supervisor's Facility and Administrative Inspection Checklist

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

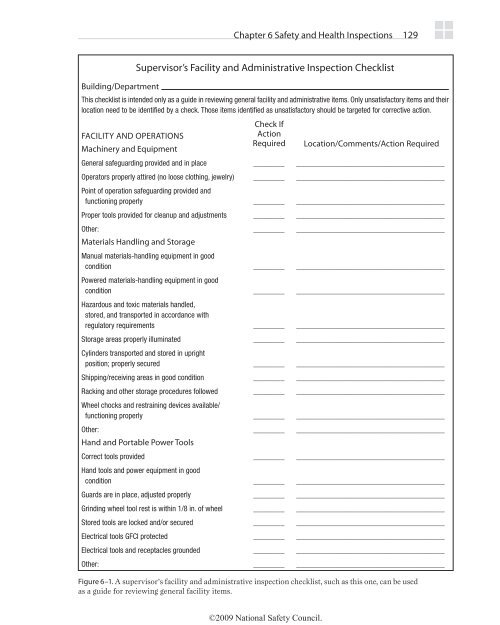

Chapter 6 Safety <strong>and</strong> Health <strong>Inspection</strong>s 129<br />

Supervisor’s <strong>Facility</strong> <strong>and</strong> <strong>Administrative</strong> <strong>Inspection</strong> <strong>Checklist</strong><br />

Building/Department<br />

This checklist is intended only as a guide in reviewing general facility <strong>and</strong> administrative items. Only unsatisfactory items <strong>and</strong> their<br />

location need to be identified by a check. Those items identified as unsatisfactory should be targeted for corrective action.<br />

Check If<br />

FACILITY AND OPERATIONS<br />

Action<br />

Required<br />

Machinery <strong>and</strong> Equipment<br />

Location/Comments/Action Required<br />

General safeguarding provided <strong>and</strong> in place ________ ______________________________________<br />

Operators properly attired (no loose clothing, jewelry) ________ ______________________________________<br />

Point of operation safeguarding provided <strong>and</strong><br />

functioning properly ________ ______________________________________<br />

Proper tools provided for cleanup <strong>and</strong> adjustments ________ ______________________________________<br />

Other: ________ ______________________________________<br />

Materials H<strong>and</strong>ling <strong>and</strong> Storage<br />

Manual materials-h<strong>and</strong>ling equipment in good<br />

condition ________ ______________________________________<br />

Powered materials-h<strong>and</strong>ling equipment in good<br />

condition ________ ______________________________________<br />

Hazardous <strong>and</strong> toxic materials h<strong>and</strong>led,<br />

stored, <strong>and</strong> transported in accordance with<br />

regulatory requirements ________ ______________________________________<br />

Storage areas properly illuminated ________ ______________________________________<br />

Cylinders transported <strong>and</strong> stored in upright<br />

position; properly secured ________ ______________________________________<br />

Shipping/receiving areas in good condition ________ ______________________________________<br />

Racking <strong>and</strong> other storage procedures followed ________ ______________________________________<br />

Wheel chocks <strong>and</strong> restraining devices available/<br />

functioning properly ________ ______________________________________<br />

Other: ________ ______________________________________<br />

H<strong>and</strong> <strong>and</strong> Portable Power Tools<br />

Correct tools provided ________ ______________________________________<br />

H<strong>and</strong> tools <strong>and</strong> power equipment in good<br />

condition ________ ______________________________________<br />

Guards are in place, adjusted properly ________ ______________________________________<br />

Grinding wheel tool rest is within 1/8 in. of wheel ________ ______________________________________<br />

Stored tools are locked <strong>and</strong>/or secured ________ ______________________________________<br />

Electrical tools GFCI protected ________ ______________________________________<br />

Electrical tools <strong>and</strong> receptacles grounded ________ ______________________________________<br />

Other: ________ ______________________________________<br />

Figure 6–1. A supervisor’s facility <strong>and</strong> administrative inspection checklist, such as this one, can be used<br />

as a guide for reviewing general facility items.<br />

©2009 National Safety Council.

130 Supervisors’ Safety Manual<br />

Fire Protection<br />

Provided as required ________ ______________________________________<br />

Inspected as marked ________ ______________________________________<br />

Location identifi ed ________ ______________________________________<br />

Locations are readily accessible ________ ______________________________________<br />

Alarm system tested (as required) ________ ______________________________________<br />

Fire doors in good operating condition ________ ______________________________________<br />

Exits marked <strong>and</strong> accessible ________ ______________________________________<br />

Fire detectors working ________ ______________________________________<br />

Other: ________ ______________________________________<br />

Electrical<br />

Outlet boxes covered ________ ______________________________________<br />

Electric cords properly placed ________ ______________________________________<br />

Outlet circuits properly grounded ________ ______________________________________<br />

Portable electric tools:<br />

• GFCI protected ________ ______________________________________<br />

• Double insulated ________ ______________________________________<br />

• Grounded as required ________ ______________________________________<br />

Switches in clean, closed boxes ________ ______________________________________<br />

Switches properly identifi ed ________ ______________________________________<br />

Circuit fuses, circuit breakers identifi ed ________ ______________________________________<br />

Motors are clean, free of oil, grease, <strong>and</strong> dust ________ ______________________________________<br />

Approved extension cords in good condition ________ ______________________________________<br />

Other: ________ ______________________________________<br />

Housekeeping/Maintenance<br />

Work areas maintained in clean <strong>and</strong> orderly condition _______ _______________________________________<br />

Floors, aisles, work areas free of obstruction,<br />

slipping <strong>and</strong> tripping hazards ________ ______________________________________<br />

Washrooms <strong>and</strong> change facilities clean <strong>and</strong> well<br />

maintained ________ ______________________________________<br />

Tools, equipment, <strong>and</strong> materials properly stored<br />

when not in use ________ ______________________________________<br />

Waste materials stored in appropriate containers<br />

<strong>and</strong> disposed of in a safe manner ________ ______________________________________<br />

Scheduled maintenance ________ ______________________________________<br />

General ventilation systems ________ ______________________________________<br />

Local exhaust systems (paint booths, welding areas, etc.) ________ ______________________________________<br />

Machinery (lubrication, belts, servicing, etc.) ________ ______________________________________<br />

Figure 6–1. (Continued)<br />

©2009 National Safety Council.

Chapter 6 Safety <strong>and</strong> Health <strong>Inspection</strong>s 131<br />

Personal Protective Equipment<br />

Equipment (determined by exposure):<br />

• Head protection ________ ______________________________________<br />

• Eye protection ________ ______________________________________<br />

• Ear protection ________ ______________________________________<br />

• Foot protection ________ ______________________________________<br />

• Clothes ________ ______________________________________<br />

• H<strong>and</strong> protection ________ ______________________________________<br />

• Respiratory protection ________ ______________________________________<br />

Personal protective equipment procedure in place ________ ______________________________________<br />

Other: ________ ______________________________________<br />

<strong>Administrative</strong><br />

Training records: ________ ______________________________________<br />

• Safety <strong>and</strong> health orientation ________ ______________________________________<br />

• Hazard communication (right to know) ________ ______________________________________<br />

• Safe operating procedures ________ ______________________________________<br />

• Confi ned space entry procedures ________ ______________________________________<br />

• Lockout/tagout ________ ______________________________________<br />

• Evacuation emergency response ________ ______________________________________<br />

• Equipment/vehicle operation ________ ______________________________________<br />

• Fire protection equipment use ________ ______________________________________<br />

• Other ________ ______________________________________<br />

Plans: ________ ______________________________________<br />

• Disaster preparedness ________ ______________________________________<br />

• Chemical emergencies/spills ________ ______________________________________<br />

• Fire/evacuation ________ ______________________________________<br />

• Emergency medical ________ ______________________________________<br />

• Equipment maintenance ________ ______________________________________<br />

• Other ________ ______________________________________<br />

Records/reports ________ ______________________________________<br />

• Injury/illness ________ ______________________________________<br />

• Accidents/incidents ________ ______________________________________<br />

• MSDSs ________ ______________________________________<br />

• <strong>Inspection</strong> summaries ________ ______________________________________<br />

• Noise surveys ________ ______________________________________<br />

• Equipment service logs ________ ______________________________________<br />

• Other: ________ ______________________________________<br />

Other: ________ ______________________________________<br />

• OSHA-required postings ________ ______________________________________<br />

• Emergency phone listings ________ ______________________________________<br />

• Required labeling ________ ______________________________________<br />

• Defective equipment procedure in place ________ ______________________________________<br />

Completed by: _______________________________<br />

Date: _______________________________<br />

Route to:<br />

❍ Maintenance ❍ Engineering ❍ Other<br />

Figure 6–1. (Concluded)<br />

©2009 National Safety Council.