You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

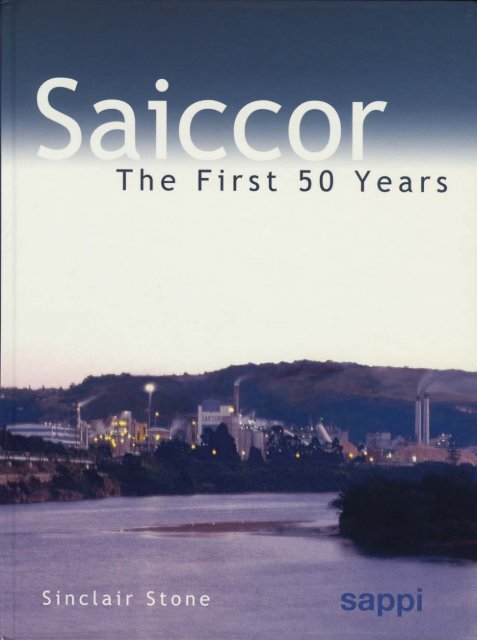

<strong>Saiccor</strong><br />

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

Sinclair Stone<br />

i

Copyright © 2002 by the author<br />

All rights reserved� No part of this publication may be reproduced or<br />

transmitted in any form or by any means without the prior written<br />

permission of the publisher�<br />

ISBN 1 919780 52 1<br />

<strong>First</strong> edition, first impression 2002<br />

Published by Rollerbird Press<br />

An imprint of Troupant Publishers<br />

P�O� Box 3622<br />

Pinegowrie 2123<br />

e-mail bvr@iafrica�com<br />

Cover design by Sally Whines<br />

Typesetting by Lebone Publishing Services, Kempton Park<br />

Printed and bound by ABC Press, Cape Town<br />

Although <strong>Sappi</strong> has funded the publishing of this book, the conclusions<br />

and opinions expressed in this book are those of the author�

Foreword<br />

In the typical Sinclair Stone manner, this history of <strong>Saiccor</strong> has been<br />

thoroughly researched, is precise in its rendering and is, where<br />

necessary, blunt in its comments�<br />

While parts of the work are necessarily technically detailed, the<br />

work is largely the story of the people who have worked at <strong>Saiccor</strong>;<br />

and appropriately so, for it is the people associated with <strong>Saiccor</strong> who<br />

have made it what it is�<br />

Sinclair Stone stands front and centre of this host of good people,<br />

with his unwavering commitment to the business and his real<br />

affection for the disciples of <strong>Saiccor</strong>�<br />

It is fitting that this legacy has been given to us by the man who<br />

is, in himself, a legend at <strong>Saiccor</strong>, and it is with sincere gratitude that<br />

I acknowledge the work that Sinclair has put into this history,<br />

compiled on the eve of his retirement after thirty years with the<br />

Company� No one else could pretend to take on the task�<br />

Anyone aspiring to make a career at <strong>Saiccor</strong>, or wishing to<br />

understand what makes <strong>Saiccor</strong> tick, should read this book�<br />

ALAN TUBB<br />

Umkomaas<br />

April 2002<br />

iii

Preface<br />

Not only is the story of <strong>Saiccor</strong> an important part of South African<br />

industrial history, it is also a fascinating tale of enterprise and<br />

endeavour that deserves to be preserved for posterity�<br />

<strong>The</strong> pioneers of <strong>Saiccor</strong> have all died, but the legacy they created<br />

grew into a highly successful business which, as the twenty-first<br />

century approached, was the world leader in its field�<br />

It is the only South African company outside of the mining<br />

industry that has successfully survived for <strong>50</strong> years by exporting its<br />

entire production� It is also unique in the history of immigration,<br />

where a large number of people from a small area of Italy emigrated<br />

at the same time to a small area in South Africa�<br />

<strong>The</strong> secret of <strong>Saiccor</strong>’s success has been its people� During its first<br />

<strong>50</strong> years some 10 000 people have been employed by <strong>Saiccor</strong>� In a<br />

story of this nature, it is only possible to mention a few of these<br />

employees� However, each and every one of the 10 000 people made<br />

a contribution to <strong>Saiccor</strong>’s success�<br />

Numerous outside companies and individuals have also worked<br />

for <strong>Saiccor</strong> from its inception, and they too have contributed to its<br />

success�<br />

Sinclair Stone<br />

March 2002<br />

iv

Contents<br />

References vi<br />

Acknowledgements vii<br />

1 <strong>The</strong> Cantacuzene period, 1952–1965 1<br />

2 <strong>The</strong> Yeomans period, 1966–1967 55<br />

3 <strong>The</strong> Wharton period, 1967–1970 63<br />

4 <strong>The</strong> Tainton period, 1971–1983 71<br />

5 <strong>The</strong> Dell period, 1983–1985 101<br />

6 <strong>The</strong> Campbell period, 1986–1987 119<br />

7 <strong>The</strong> Mackenzie period, 1987–1989 129<br />

8 <strong>The</strong> Mazery period, 1989–1996 141<br />

9 <strong>The</strong> Tubb period, 1996– 165<br />

v

References<br />

Aldred, F C, ‘SAICCOR – Where it started’, Paper Southern Africa,<br />

January 1982, reproduced in <strong>Sappi</strong> News-Nuus, September 1988�<br />

Bernstein, M, ‘<strong>The</strong> Story of <strong>Saiccor</strong>’, CBI Report SAI1323L2�<br />

Cantacuzene, M S, Trials and Tribulations of a Tumbleweed (privately<br />

published),1999�<br />

‘Flood Report’, July 1959�<br />

Hastie, W, Factory Report, April 1954�<br />

Hastie, W, Factory Report, June 1957�<br />

<strong>The</strong> Digester, 1995–2002�<br />

<strong>The</strong> Raypulp Recorder (<strong>Saiccor</strong> Magazine), Vol� 1 Nos 1, 2, 3 (1960);<br />

Vol� 2 Nos 1, 2, 3 (1961); Vol�3 Nos 1, 2 (1962)�<br />

<strong>Saiccor</strong> News, 1986–1988�<br />

SAICI Contract Blue Book, May 1954�<br />

Torviscosa, SAICI brochure (1967)�<br />

<strong>The</strong> following were also consulted:<br />

<strong>Saiccor</strong> archives, photographs and documentation�<br />

Works Manager/Director monthly factory reports from September<br />

1953�<br />

Minutes of Board meetings from 4 October 1951�<br />

vi

Acknowledgements<br />

During the course of the writing of this book, I was grateful for<br />

discussions with Ferruccio Monte, Silvano Moro, Enoc Baldin and<br />

Eridanio di Marco, particularly on the early years, and with Norman<br />

Boulter and Ted Beesley on events in the 1960s� Jacqui Bertossi was<br />

helpful in supplying dates from personnel records� My thanks to my<br />

wife Yvonne, Alfredo Battiston, Alan Tubb and Derek Weightman<br />

for proof reading, and to Linda Johns for typing text and arranging<br />

pictures� Mike Gangle scanned the photographs� I am grateful to all<br />

those employees, both past and present, who provided photographs<br />

from their personal collections�<br />

vii

Dedication<br />

For all those people who worked for –<br />

or performed work for – <strong>Saiccor</strong>

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> Cantacuzene Period<br />

(1952 –1965)<br />

<strong>Saiccor</strong>’s first Managing Director<br />

(although the title at the time was<br />

General Manager) was Michel<br />

Cantacuzene, or more properly,<br />

Prince Michel Surgueyevitch<br />

Cantacuzène, Count Spéransky, a<br />

Russian aristocrat who had fled with<br />

his family to France in 1919 during<br />

the Russian Revolution when he was<br />

six years old� (<strong>The</strong> family name has<br />

been traced back to the eleventh<br />

century in Russia�)<br />

Cantacuzene joined Courtaulds<br />

(France) in September 1933 after his<br />

father had put in a good word with<br />

John Hanbury-Williams, a senior<br />

director of Courtaulds (London) who<br />

was married to Cantuzene’s cousin�<br />

In January 19<strong>50</strong>, Cantacuzene<br />

married Barbara, his second cousin,<br />

Michel Surgueyevitch Cantacuzene,<br />

Managing Director of <strong>Saiccor</strong>, 1952–1965<br />

and daughter of Hanbury-Williams (by then Sir John, and Chairman of Courtaulds)�<br />

In September 1952, Cantacuzene was asked to run <strong>Saiccor</strong> by Sir John Hanbury-<br />

Williams and Dr Franco Marinotti (Count of Torviscosa), President of SNIA�<br />

1

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

<strong>The</strong> origins of <strong>Saiccor</strong>, however, go back to 1912 when<br />

a young Scots immigrant, Major Peter Rattray (later<br />

DSO), purchased a farm in Kwambonambi� <strong>The</strong><br />

area was completely underdeveloped when Rattray<br />

started cultivating sugar cane and cattle ranching� During his absence<br />

at World War I, his wife Ethel planted some Eucalyptus saligna (blue<br />

gums) around a shack as a windbreak� On his return, Rattray noticed<br />

the phenomenal growth of these trees, which he discussed with a<br />

Government Forestry Officer who encouraged him to embark on an<br />

extensive saligna-planting programme�<br />

<strong>The</strong> first plantation started in 1922 and in 1928 the first commercial<br />

trees were felled and sold as props for the mining industry� In 1928,<br />

Rattray had his timber tested for making paper by the Imperial<br />

Institute in London, but it was found to be unsuitable because of the<br />

short fibres� In 1933 the mines expanded and Rattray sold his timber<br />

plantation to Hunt, Leuchars and Hepburn, who set up a mining<br />

timber mill at Kwambonambi� (Rattray continued planting�) This<br />

encouraged others to grow timber in the area� In 1937, Major Rattray<br />

died from an attack of malaria, and his son, Loring Rattray, took over<br />

the family interests�<br />

Saligna plantations had expanded to the point where a surplus<br />

was developing� In 1941, Loring Rattray founded the Waterton timber<br />

mill, the first sawmill in Zululand to produce sawn timber<br />

commercially� This, however, was not sufficient to mop up the surplus<br />

and Rattray contacted the Imperial Institute to see whether saligna<br />

could be used to make rayon pulp (now more commonly called<br />

dissolving pulp, as wood pulp is first dissolved in chemicals and then<br />

reformed into rayon or viscose or cellophane)� When the tests proved<br />

positive, Rattray started to look for overseas interests to build a rayon<br />

pulp mill on the Nseleni River, near Kwambonambi�<br />

Courtaulds, a large British textile fibre producer, on a visit to the<br />

Imperial Institute, learned of the surplus timber in Zululand, and<br />

was attracted by the possibilities� <strong>The</strong> original Courtaulds were a<br />

Huguenot family who in 1686 sought religious freedom in London,<br />

where they became gold and silversmiths� <strong>The</strong> first to enter the textile<br />

industry was George Courtauld (1761-1823), whose son Samuel set<br />

up his own silk factory in Bocking, Essex, in 1816� In 1828 the<br />

company converted into a partnership, then a private company in<br />

1891, called Samuel Courtaulds and Company Limited� <strong>The</strong> firm<br />

became a public company in 1904 and was reorganised under the<br />

title Courtaulds Limited in 1913�<br />

Legend has it that Courtaulds received a kick-start by supplying<br />

black silk to the courtiers of Queen Victoria after the death of Prince<br />

Albert� <strong>The</strong> company produced silk and silk products such as crepe<br />

2<br />

Major Peter Rattray<br />

Loring Rattray in a<br />

saligna plantation,<br />

1960<br />

Loring Rattray

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

ABOVE: Before the saligna plantations, c�1920<br />

BELOW: <strong>The</strong> first nursery, in the 1920s<br />

de Chine and chiffon� In 1904, they bought the patent rights of the<br />

viscose process for producing textile yarn from the cellulosic solution,<br />

discovered and developed by British chemists Cross, Bevan and Beadle�<br />

A new factory, the first commercially successful venture for the<br />

manufacture of viscose rayon, was set up in Coventry in 1905� <strong>The</strong>y<br />

expanded the business in the UK, then into the USA in 1910, into<br />

Canada in 1925, and helped develop the industry in France, Germany,<br />

Italy and Spain� Sir John Hanbury-Willliams was appointed chairman<br />

of Courtaulds in 1946�<br />

Until the end of World War II, Courtaulds bought all their wood<br />

pulp on the open market� After the war, they were encouraged by<br />

the British Government to search within the Commonwealth (to<br />

keep expenditure in sterling) for a source of raw material from which<br />

cellulose could be extracted� <strong>The</strong> Zululand timber they heard about<br />

at the Imperial Institute sounded ideal� Courtaulds soon<br />

demonstrated to their own satisfaction that here was a very promising<br />

raw material for the production of rayon pulp� <strong>The</strong>y then looked for<br />

a partner with pulp-making experience, which they lacked, to form<br />

a joint venture in South Africa� <strong>The</strong>y found SNIA (Societa Nazionale<br />

3<br />

Sir John Hanbury-Williams,<br />

Chairman of Courtaulds<br />

1946–1962

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

December 1960 <strong>The</strong> Raypulp Recorder 5<br />

Samuel Courtaulds and Company’s stand at the Rand Easter Show, April, 1960<br />

TODAYS RANGE OF COURTAULDS PRODUCTS INCLUDES:<br />

MAN-MADE FIBRES – viscose rayon, acetate, triacetate,<br />

regenerated protein, alginate, acrylic, and polythene yarns and<br />

fires. Nylon yarn and staple is manufactured by an associate<br />

company.<br />

CHEMICALS – sulphuric acid, carbon disulphide, petrochemicals,<br />

acetate flake, methyl cellulose, etc.<br />

PACKAGING – transparent cellulose film, polythene and other<br />

films, conversion and printing of packaging films, fine fluted<br />

corrugated paper, metallic capsules, foil, collapsible tubes,<br />

steel drums, tin boxes, cans, waxed cartons, etc.<br />

PAINT – industrial, marine, aircraft, transport and decorative paints<br />

and finishes.<br />

PLASTICS – acetate moulding powders, transparent film,<br />

extrusions and sheet; moulded articles and components in<br />

different types of plastic; developing extruded sheeting in<br />

polystyrene, polythene and polypropylene.<br />

ENGINEERING – EHQ provide an authoritative service on all<br />

architectural, civil, mechanical and electrical engineering<br />

matters. <strong>The</strong> Engineering Production Shops manufacture<br />

specialist machinery.<br />

WOODPULP – Cellulose Pulp from <strong>Saiccor</strong> and Kraft Pulp from<br />

Usutu.<br />

FABRICS AND GARMENTS – using man-made fibres, silk and<br />

blends.<br />

STEEL TYRE CORD – being developed.<br />

Jacquard woven fabric by Courtaulds used<br />

RESEARCH – eight main research laboratories.<br />

for a hallroom model by Victor Stiebel<br />

TRADE DEVELOPMENT – a large staff of technologists have at<br />

their disposal a wide range of textile machinery and experimental<br />

plants to promote the use of Courtaulds products.<br />

An excerpt from <strong>The</strong> Raypulp Recorder (December 1960), advertising the<br />

range of products produced by Courtaulds<br />

Industria Applicazioni), a large Italian chemical company whose<br />

subsidiary SAICI (Societa Agricola Industriale Cellulosa Italiana)<br />

operated a rayon pulp mill at Torviscosa, in the northern Italian region<br />

of Friuli (north-east of Venice, bordering on Austria and Slovenia),<br />

and who were also using Eucalyptus as an alternative raw<br />

material�SAICI was the brainchild of SNIA’s president, Dr Franco<br />

Marinotti� <strong>The</strong> increasing demand for rayon in the years before World<br />

War II encouraged Marinotti to build a pulp mill� As Italy had no<br />

timber resources, Marinotti urged his laboratories to develop a method<br />

to make pulp from the reed Arundo donax (similar to sugar cane)� <strong>The</strong><br />

4

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

laboratories succeeded and in the year Marinotti became President of<br />

SNIA, 1937, a marshland north-east of Venice was developed into<br />

Arundo donax plantations (the total site including plant and equipment<br />

covered 5 300 hectares)�<br />

<strong>The</strong> pulp mill was built in 1938-39, eventually reaching a capacity<br />

of 100 000 tons per annum� Benito Mussolini officially opened the<br />

site on 21 September 1938� Also on the site was a chloralkali plant,<br />

an alcohol distillery, a caprolactam plant and a dairy herd of some<br />

2 <strong>50</strong>0 head� SAICI were the first to successfully produce dissolving<br />

pulp from Eucalyptus, previously considered unsuitable, and set up<br />

an associate company, SNIACE, to build the first Eucalyptus (globulus)<br />

dissolving pulp mill (in operation in 1951) in Torrelavega, Spain� (At<br />

the time of building <strong>Saiccor</strong>, SAICI also built a similar mill in<br />

Chihuahua, (Mexico) but with a prehydrolysis stage for softwoods�<br />

SAICI later built two further mills in South America, two in Russia<br />

and one in India�)<br />

<strong>The</strong> first Courtaulds/SNIA mission came to South Africa in<br />

September 19<strong>50</strong> (two members of the mission arrived on the last<br />

flying boat to land on the Vaal Dam on a scheduled flight from<br />

London)� In the mission from Courtaulds were W G Daroux, D R B<br />

Mynors, and F C Aldred; from SAICI, A Brunetti and E Stefanelli� All<br />

in time became directors of <strong>Saiccor</strong>�<br />

<strong>The</strong> other members of the mission were Dr W D Spencer<br />

of Courtaulds and Mr D Bassi and Col� A Hancock of SNIA�<br />

5<br />

Dr Franco Marinotti, Count of<br />

Torviscosa, President of SNIA<br />

1937–1956<br />

An Arundo donax plantation� This reed was utilised at first for the production of pulp and alcohol

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

Fred Aldred, a bright young chemist, had a close association with<br />

<strong>Saiccor</strong> until his retirement in the 1980s� From the mid 1960s as a<br />

technical adviser to Lord Kearton, then Chairman of Courtaulds, he<br />

was a powerful figure at <strong>Saiccor</strong>� Fred would often appear<br />

unannounced in the plant dressed in a tweed sports jacket, with<br />

leather patches on the elbows, and a camera slung around his neck�<br />

He would discuss what he had seen with the local management, and<br />

he certainly knew what he was looking at, and then report back to<br />

Kearton� Oakley Tainton, then MD of <strong>Saiccor</strong>, would soon know of<br />

anything that displeased Kearton� Thus the relationship between<br />

Aldred and Tainton became strained and the story of an exchange of<br />

telexes between the two is as follows:<br />

Aldred: ‘I will be arriving on the 18 th � ’<br />

Tainton: ‘That will not be convenient as I will be away�’<br />

Aldred: ‘As I am a director, it is not absolutely necessary that you<br />

are there when I visit�’<br />

Tainton: ‘I have instructed the gate guard not to let you in�’<br />

Fred kept in touch with <strong>Saiccor</strong>’s process, gave advice on expansion<br />

plans, and was quite involved in the development of the flock plant�<br />

When Kearton retired from Courtaulds in 1975 to run British North<br />

Sea Gas, Aldred’s power base disappeared and he ceased to be a force<br />

at <strong>Saiccor</strong>� He retired to the Lake District in 1982 and died in 1993�<br />

<strong>The</strong> mission’s objectives were to confirm the timber supply, to<br />

find a suitable site for the mill that had an adequate water supply (at<br />

least 100 000 m 3 /day, according to SAICI), access to a port (for the<br />

product) and to find a local partner�<br />

<strong>The</strong> mission first called on the local pulp and paper company <strong>Sappi</strong>,<br />

in Johannesburg, where they received a cool reception� <strong>Sappi</strong> had<br />

already decided to build a paper mill on the Tugela, and were not<br />

keen to have a competitor for timber� <strong>The</strong> mission then went to<br />

Durban to consult Mark Bernstein of Campbell Bernstein and Irving<br />

(CBI) on what rivers, other than the Tugela, could supply 100 000<br />

m 3 /day� <strong>The</strong> choice was either the Mkomazi or Mzimkulu� <strong>The</strong><br />

Mkomazi was selected as it was closer to the port of Durban, and of<br />

course closer to the forests in Zululand� A visit to Rattray’s plantations<br />

in Zululand impressed the mission and confirmed all they had heard�<br />

<strong>The</strong> mission sought and found a local partner, the Industrial<br />

Development Corporation (IDC)� <strong>The</strong> IDC had been set up in 1940<br />

as a parastatal organisation to help develop industry in South Africa<br />

and had been involved in the formation of such well-known<br />

companies as <strong>Sappi</strong>, Sasol, Foscor, Safmarine and Masonite�<br />

<strong>The</strong> mission went back to prepare feasibility studies� SNIA started<br />

the plant design with Dr Alessandro Brunetti, MD of SAICI, heading<br />

6<br />

Fred Aldred of Courtaulds<br />

had a close association<br />

with <strong>Saiccor</strong> until his<br />

retirement in the 1980s

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

A photo taken in 19<strong>50</strong> of the original team that investigated the feasibility of the <strong>Saiccor</strong> project� From LEFT TO RIGHT<br />

are: FC Aldred, Dr WD Spencer, WG Daroux (all from Courtaulds), L Rattray (a Natal tree farmer), D Bassi, I<br />

Stefanelli, A Brunetti and Col� A Hancock (all from SNIA-Viscosa)<br />

the team� <strong>The</strong>y also conducted pilot plant studies which were not<br />

completely successful, for although it made a good pulp, it was too<br />

soft to go through the drying machine� <strong>The</strong> IDC selected the site and<br />

examined the supply of services such as timber, electric power and<br />

water�<br />

Courtaulds produced a proposal for a 110 ton/day pulp mill� <strong>The</strong><br />

company, the South African Industrial Cellulose Corporation, soon<br />

to become SAICCOR, was registered on 12 September 1951, with<br />

Courtaulds, SNIA and the IDC each having a third of the<br />

shareholding� SNIA were to design, build and commission the plant<br />

(which they welcomed as they not only had the expertise but were<br />

overmanned at the time after having to re-employ all former<br />

employees returning from the war)� <strong>The</strong> IDC supplied all the local<br />

expertise and were responsible for all external services and logistics�<br />

Courtaulds wanted the product, and had the overall responsibility<br />

for the success of the project� <strong>The</strong> project was to be managed by the<br />

<strong>Saiccor</strong> Board�<br />

<strong>The</strong> first Board of Directors was appointed on 3 October 1951 and<br />

consisted of Claude Cornish-Bowden (Chairman) (IDC), Alessandro<br />

Brunetti (SAICI) and Wilfred Sheldon (Courtaulds)� <strong>The</strong> first Board<br />

meeting was held in Johannesburg on 4 October 1951, followed by a<br />

further four in 1951, and eight in 1952� From November 1953 the<br />

venue moved to Durban and from November 1954 to Umkomaas�<br />

7<br />

<strong>The</strong> original <strong>Saiccor</strong> logo designed<br />

by Piero Miniutti was in use until<br />

the 1960s, even though one of the<br />

‘hands’, SNIA, sold its interests in<br />

1956

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

From 1953 Dr Hendrik van Eck took over the Chairmanship of both<br />

IDC and <strong>Saiccor</strong>, although Cornish-Bowden remained on the <strong>Saiccor</strong><br />

Board until July 1956� Also from 1953 the number of Board members<br />

increased to 12 (four from each partner)� Courtaulds kept the<br />

chairmanship of <strong>Saiccor</strong> for IDC chairmen: Claude Cornish-Bowden,<br />

Hendrik van Eck, Siegfried Kushke, Jan Kittshoff, Oakley Tainton<br />

(an IDC man although not chairman), and Koos van Rooy� <strong>The</strong> only<br />

non-IDC man to be Chairman of <strong>Saiccor</strong> (until the <strong>Sappi</strong> purchase<br />

in 1988), was Norman Wooding, deputy Chairman of Courtaulds<br />

who had the chair from 1983-1985� In 1961, Wilfred Sheldon became<br />

the first <strong>Saiccor</strong> employee to achieve 10 years service (he resigned<br />

from the Board on 29 October 1964)�<br />

SNIA (through SAICI) started placing orders for plant and<br />

equipment in September 1952� At the same time <strong>Saiccor</strong> bought land<br />

for the factory, some 4 km upstream of the Mkomazi River mouth,<br />

from the Illovo Sugar Estates (established in 1890)�<br />

<strong>The</strong> first sod was turned in November 1952 and work commenced<br />

with Rush and Tomkins doing the earthworks, Roberts Construction/<br />

Concor (the local contracting company)– with Douglas Roberts in<br />

charge – doing the civils and buildings, all under the control of<br />

consultants CBI, headed by Mark Bernstein� Prof� L Manfredini of<br />

SAICI had overall charge of all civil and building design and<br />

construction� <strong>The</strong> rail line to the factory was opened on 5 November<br />

1953 and the road in January 1954� (In 1862 the Natal government<br />

built a harbour at the Mkomazi River mouth and for a short time<br />

cargo vessels used it� Twin townships (North and South Barrow),<br />

were laid out on its north and south banks� <strong>The</strong>se names persisted<br />

until 1924 when the whole area was renamed Umkomaas�)<br />

In January 1953 Cantacuzene set up an office in Albany House<br />

in Durban while the factory was being built� Each of <strong>Saiccor</strong>’s<br />

partners had representatives at this office� From SNIA was Camillo<br />

Pianto (Cantacuzene’s deputy), from Courtaulds was Bill Hastie,<br />

Works Manager, and from the IDC were Oakley Tainton,<br />

Commercial Manager, John Carrick, Secretary and Chief Accountant<br />

(who retained the position until he retired at the end of April 1978;<br />

he was appointed to the <strong>Saiccor</strong> Board in 1976), Stan Gay, Buyer<br />

and Jock Mitchell, the Zulu-speaking Personnel Officer� Alec L<br />

Thomson, Oakley Tainton and John Carrick became the first<br />

employees to achieve 20 years service in 1973� Tainton was the first<br />

to achieve 30 years in 1983�<br />

Timberland was bought, with trees, from Rattray for £<strong>50</strong>0 000<br />

(including Waterton Timbers)� Although Cantacuzene signed the<br />

cheque, the deal had been negotiated with the IDC, leaving<br />

Rattray somewhat bitter because he felt he had not been given a<br />

fair price�<br />

8<br />

Wilfred Sheldon

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> original South Barrow Hotel (c� 1920)<br />

<strong>Saiccor</strong> bought the New South Barrow Hotel in 1953 to accommodate<br />

the Italian artisans� Once <strong>Saiccor</strong> was in operation, Cantacuzene tried<br />

to sell the hotel but could not, and so decided to run it as a business�<br />

He renamed it <strong>The</strong> Lido, gave it a facelift, and hired an Austrian,<br />

Hans Ainhirn, to run it� As the hotel was only just ‘jogging along’,<br />

Cantacuzene added an Olympic size swimming pool in 1957 and a<br />

small nightclub� <strong>The</strong> dance floor was level with the bottom of the<br />

pool and the dividing wall between the two had a plate-glass window<br />

through which the night revellers could watch the swimmers� <strong>The</strong><br />

Lido soon became very popular with people from Durban, particularly<br />

for Sunday lunch at the pool and Saturday night at the nightclub,<br />

and was the venue of most <strong>Saiccor</strong> functions, including some lavish<br />

affairs like the Carnevale di Venezia, and beauty pageants� However,<br />

its popularity waned and it was sold in 1986 by Gordon Campbell� It<br />

<strong>The</strong> New South Barrow Hotel (c� 1930), purchased by <strong>Saiccor</strong> in 1953 to<br />

accommodate the large influx of Italian artisans<br />

9<br />

Alec L Thomson, TOP,<br />

(joined 5 January 1953),<br />

Oakley Tainton, MIDDLE,<br />

(joined 1 March 1953)<br />

and John Carrick,<br />

BOTTOM, (joined 1 July<br />

1953) became the first<br />

employees to achieve 20<br />

years service in 1973

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

<strong>The</strong> Lido Hotel (c� 1980), originally the South Barrow Hotel, became a<br />

popular haunt for <strong>Saiccor</strong> employees until its sale in 1986<br />

<strong>The</strong> Lido pool and gardens overlooking the Mkomazi River<br />

changed hands numerous times after the sale and is currently the<br />

Sea Fever Lodge�<br />

In 1953 Arturo Bozzone arrived in Umkomaas from Johannesburg<br />

(he had immigrated to Pretoria from Italy as a young man of 18 in<br />

1928) to cater for the Concor workers, operating from the Shotley<br />

Hotel� When Concor left he lost his job� Undaunted, he set up a warm<br />

and often lively Italian restaurant in Umkomaas, which was soon<br />

recognised as the best in Natal outside Durban� In 1957 Bozzone took<br />

over the shops in <strong>Saiccor</strong> Village� <strong>The</strong>re, in the butchery shop, Ferruccio<br />

Monte – one of the Italian artisans who came out in 1954 – started<br />

making Italian meats in his spare time, which was natural enough as<br />

10

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> first location of Bozzone’s Italian Restaurant, in Umkomaas, 1960<br />

both his father and grandfather were<br />

butchers� In 1963 Ferruccio married<br />

Bozzone’s daughter Renée, and in 1970 he<br />

left <strong>Saiccor</strong> to go into business with<br />

Bozzone� He set up and ran Italian Meat<br />

Products, an Italian delicatessen and meat<br />

factory� From small beginnings, the Italian<br />

meat factory became very well known<br />

throughout the country, processing one and<br />

a half tons of meat a week, mainly pork and<br />

beef, specialising in salami, prosciutto, coppa<br />

and pancetta� Today Ferruccio’s son<br />

Piercarlo still runs the business, with a little<br />

help from his father�<br />

Meanwhile, in July 1961 the ristorante moved<br />

to larger premises, where its great popularity<br />

persisted for many years through the efforts of<br />

Arturo, sons Ezio and Roberto and son-in-law<br />

Ferruccio, with homemade food, homemade<br />

music, and dance� <strong>The</strong> sight of the Bozzone<br />

family having lunch became a familiar one in<br />

Umkomaas, with 10 to 15 of them sitting at<br />

a restaurant table, none eating or drinking<br />

until the ‘old man’, who was invariably late,<br />

took his place at the head of the table� <strong>The</strong><br />

ceremony could then commence�<br />

Alas, all that remains of this once thriving<br />

enterprise is the ‘<strong>The</strong> Whaler’�<br />

Legendary restaurateurs� TOP, Roberto and Ezio Bozzone and<br />

Ferruccio Monte and BOTTOM Ferruccio Monte and Arturo Bozzone<br />

11

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

In early 1954 the factory buildings had progressed to the point where<br />

preparations had to be made to bring out the Italian technicians and<br />

artisans from SAICI to erect the plant and equipment� <strong>The</strong> Italian<br />

government wanted as many people as possible to participate (in<br />

order to help with their unemployment problem)� While the South<br />

African government was happy enough to accept the Italians, they<br />

were certainly not prepared to accept any communists� As a result,<br />

the South African authorities scrutinised each and every applicant,<br />

despite the fact that SAICI’s Dr Fabio Fonda had handpicked them<br />

all� This caused delays and frustrations�<br />

In March 1954 Francesco Nardi, the Erection Manager, Francesco<br />

Dose, Enea Corrado and six artisans arrived in advance of the main<br />

groups – including Gino della Martina, who stayed on at <strong>Saiccor</strong> until<br />

his retirement in 1987 at 69 years old� He died in 1997� Gino was,<br />

throughout his career at <strong>Saiccor</strong>, the Building Manager, where he made<br />

concrete as hard as granite (nothing ever fell down) and ran his<br />

department in a typically Italian autocratic fashion� In 1973 he was<br />

also appointed Group Building Manager� He was for some time the<br />

Chairman of the Italian Club in Umkomaas� Today his son Lorenzo<br />

is a leading member of the Italian community in Durban�<br />

<strong>The</strong> first group, comprising 58 people, including two women, a<br />

nurse and a cook, arrived by Constellation on 23 April 1954 and started<br />

work three days later� <strong>The</strong> last of the four plane loads arrived on 6<br />

August, bringing in total 222 pulp experts to Umkomaas, in what at<br />

the time was the biggest commercial airlift in South Africa’s history�<br />

A further 30 arrived by sea in early October�<br />

Work progressed rapidly, with 2<strong>50</strong> Italians and 400 Zulus� <strong>The</strong><br />

employment conditions for the Zulus were negotiated between<br />

Cantacuzene and the nkosi of the Umnini Reserve at a lengthy ndaba�<br />

(This sizeable reserve on the north side of the Mkomazi River had<br />

been given to Nkosi Luthuli, by signed grant from Queen Victoria,<br />

when the Zulus were moved from their land on the Bluff�)<br />

<strong>The</strong> first group of Italians en route to Durban, April 1954<br />

12<br />

Francesco Nardi<br />

Gino della Martina

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> <strong>Saiccor</strong> factory under construction, 1954<br />

Innumerable problems had to be solved� One of the earliest problems,<br />

that of finding an Italian-speaking, South African trained nurse,<br />

proved intractable, whereas a transport problem had a rough and<br />

ready solution: ‘transport from the New South Barrow hotel to the<br />

factory site has now been finalised in the form of two ten ton lorries<br />

each of which will be carrying 70 men� This will necessitate two<br />

trips and it is anticipated that half the men will start at 7:30 and the<br />

other half at 08:00’ (Hastie, 1954)<br />

When the authorities refused to allow the boiler and turbine parts<br />

across either the rail or road bridges, a makeshift bridge was<br />

successfully constructed across the river for the purpose�<br />

Among those who started in 1954 were Luigi de Corte, Rino Boem,<br />

Silvano Moro, Bepi Trevisan, Alison Mthuli and Armando Zerman, who<br />

became the first employees to achieve 40 years service at <strong>Saiccor</strong> in 1994�<br />

Moro was the first to achieve 45 years in 1999� Although Enoc Baldin<br />

and Edi Taverna started in 1954 and were still employed in 1994 and<br />

1999, both had broken service�<br />

Luigi de Corte started as a Boilermaker in the workshops making<br />

doors and windows for the factory� Once the factory was operational,<br />

he worked as a Boiler Operator under Gino Salotto for three years�<br />

He then moved back to the workshop, and in 1961 was transferred<br />

to the plant, where he worked in the woodyard, liquor plant and<br />

digesters where he became a Chargehand� He retired in 1995�<br />

Throughout his career he was super-energetic, working like a Trojan�<br />

For many years he worked with Giordano Soldat, and together they<br />

made a comical team as Giordano was twice ‘Gigi’s’ size�<br />

13<br />

Armando Zerman

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

Rino Boem started as a bricklayer and remained in the building<br />

department throughout his long and successful career (a large part of<br />

which was under the watchful gaze of his uncle, Gino della Martina)�<br />

He was promoted to Chargehand and then to Engineering Assistant�<br />

He knew more about the underground drainage system than anyone<br />

else at <strong>Saiccor</strong>, and prevented a catastrophe many times� He retired<br />

in 1998�<br />

Silvano Moro started as part of the erection crew, installing<br />

equipment� Once the factory started he became an Operator in the<br />

waterworks� In the middle of 1956 Fonda insisted that all Italians<br />

had to be inside the factory and Silvano moved to first screening as<br />

an Operator; then to the chlorine plant, then bleaching where he<br />

became a Chargehand, and in 1970 a Superintendent� In 1987 he was<br />

promoted to Production Manager of the magnesium plant, where he<br />

stayed until 1999 when he retired, having achieved his objective of<br />

45 years of service� Silvano tackled everything with great enthusiasm<br />

and dedication� When offered the job of Production Manager he<br />

responded ‘God bless you’ and proceeded to work night and day to<br />

keep the plant in good order� From his house he could see the<br />

magnesium plant and would often pop in at odd hours because it did<br />

not look quite right� He probably also made the best coffee in <strong>Saiccor</strong>�<br />

Bepi Trevisan started as a fitter but moved into the boilers for three<br />

years as an operator once the factory was operating� He then<br />

From LEFT TO RIGHT: Luigi de Corte, Rino Boem, Silvano Moro, Bepi Trevisan and Alison Mthuli, the first <strong>Saiccor</strong><br />

employees to achieve 40 years service in 1994<br />

14

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

transferred to the workshop, and in 1961 to Pulp<br />

Preparation, where he was promoted to Chargehand,<br />

then Assistant Engineer and finally Divisional Engineer<br />

of digesters� He retired in 1997 and died the same year�<br />

Bepi was thoroughly competent, hardworking and<br />

dedicated� For his innovation of bypassing No 4 silo he<br />

was awarded the <strong>Sappi</strong> EAA Gold Award in 1992�<br />

Alison Mthuli worked in the company garage and then<br />

transferred to the mechanical workshops, where he is<br />

remembered as being very quiet with a permanent smile<br />

on his face�<br />

Armando Zerman and Carletto Scarpa were two<br />

highly talented young cabinetmakers who arrived at<br />

<strong>Saiccor</strong> in 1954 and developed their skills under master<br />

craftsman Luigi Soldat� Armando was promoted to<br />

Chargehand and finally to Engineering Assistant� He<br />

retired in 1994 and died in early 2001� Although he often<br />

behaved like a prima donna, his work was superlative –<br />

good examples being <strong>Sappi</strong>’s executive suite at Kings Park <strong>The</strong> author, with Zerman’s model of the <strong>Saiccor</strong> factory<br />

(prior to 2000, when it was refurbished), done with<br />

Carletto Scarpa; his model of the <strong>Saiccor</strong> factory, achieved almost<br />

single-handed (with some coaxing); and the desk in the magnesium<br />

control room� Luigi Soldat sadly died young in 1970, but both his<br />

sons, Giorgio and Giordano (Sack), became <strong>Saiccor</strong> employees, the<br />

latter for the past 35 years�<br />

<strong>The</strong> town of Umkomaas changed dramatically on 23 April 1954� <strong>The</strong><br />

proposed £7,5 million rayon factory in Umkomaas had sparked heated<br />

debate since 8 January 1952, when the Marquis Fracassi di Torre<br />

Rossano, Minister Plenipotentiary for Italy, announced while on<br />

holiday in Durban that 700 Italians would be coming out to build it�<br />

(<strong>The</strong> Italian government was hoping for this number�)<br />

An article from the Natal Mercury on 11 January 1952 gives some<br />

indication of the level of controversy surrounding the proposed influx<br />

of Italians:<br />

Umkomaas Speaks Mind on<br />

Factory<br />

<strong>The</strong> building of a £7,<strong>50</strong>0,000 rayon<br />

factory at Umkomaas might change<br />

its character from a little piece of<br />

‘English Suburbia’ to that of a<br />

cosmopolitan South African<br />

industrial town�<br />

When the slightly bewildered<br />

ENGLISH SUBURBIA OR LITTLE ITALY?<br />

Umkomaas people got over the<br />

initial shock of the 600 Italians<br />

coming to the township, their<br />

opinions fell into two clearly<br />

defined channels�<br />

People with business interests were<br />

in favour of the idea of Umkomaas<br />

‘waking up at last,’ but the<br />

majority of the residents, compri-<br />

15<br />

sing mostly English people who<br />

have retired, hope that Umkomaas<br />

will ‘sleep on’�<br />

One elderly retired resident who has<br />

been in Umkomaas for the past 20<br />

years declared: ‘I am definitely not in<br />

favour of being turned into an<br />

industrial town and I am strongly<br />

opposed to foreigners�’

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

<strong>The</strong> debate raged through letters to the press, centred mainly on the issue of the Italians, some for and<br />

some against� To quote a few examples:<br />

<strong>The</strong> new types will frighten away the thousands of regular visitors� Imagine the beach and bathing pool at weekends,<br />

with hundreds of Italian wives and children within walking distance� (J Hall, Daily News, January 1952)<br />

<strong>The</strong>re need be no fear that Umkomaas or any other equally underdeveloped spot in South Africa would not benefit<br />

tremendously by the creative and hardworking genius of the Italians� (Natal Mercury, 25 February 1952)<br />

Eventually an Italian ‘Monti’ joined the fray:<br />

Italians are guilty of having two big faults; of being poor and, above all, of being intelligent� For the first, we are<br />

despised and for the second we are envied� Now, if they like, they can continue, but I just want them to know that we are<br />

superior to these offences� (Natal Mercury, 31 January 1952)<br />

‘Dopo-Domani at Umkomaas’, a cartoon which appeared in <strong>The</strong> Natal Mercury, 16 January 1952, summed up<br />

the feelings of local residents at the time<br />

16

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

A cartoon by Robin in the Natal Mercury of 16 January 1952 entitled<br />

‘Dopo-Domani at Umkomaas’ summed up some of the feelings at<br />

the time� Three years later, in 1955, the situation was neatly summed<br />

up by the Natal Mercury (13 September):<br />

2<strong>50</strong> IMPORTED ARTISANS HAVE BROUGHT NEW LIFE TO RESORT�<br />

When quiet, sedate Umkomaas,<br />

with its elderly retired couples,<br />

international golf course and<br />

select holiday trade, heard that<br />

its population was to be<br />

increased by nearly one-third<br />

overnight with the arrival of 2<strong>50</strong><br />

Italian artisans, the village was<br />

frankly concerned about its<br />

future�<br />

A few residents, fearing a local<br />

industrial revolution, with<br />

possible racial overtones, sold<br />

up and left�<br />

Some 70 of the Italians were accommodated in the New South Barrow<br />

Hotel, and most of the others filled up the other hotels in Umkomaas<br />

– Robin Hood, Goodrest, Fairway, Ocean Park and Golf Course – while<br />

24 went into three self-catering houses, soon to be known as Spirit<br />

house, Devil house and King’s house�<br />

As the Italians tended to be ostracised by the people of Umkomaas,<br />

they became a close-knit family unit, socialising largely among<br />

themselves� <strong>The</strong> most popular leisure activity was naturally soccer,<br />

which they played with a passion, practising where No 2 continua<br />

now stands� Parties with song and dance were frequent and regular,<br />

while a train ride to Durban for shopping and ‘bioscope’ was also<br />

popular� In their new and strange environment the young Italians<br />

managed to create a lot of fun�<br />

Mass at the Town Hall in Umkomaas, c� 1955<br />

17<br />

But today Umkomaas is finding<br />

that the influx of new blood<br />

and the coming of industry<br />

have brought new life and<br />

prosperity�

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

<strong>The</strong>re was no Catholic Church in Umkomaas and the Town Hall<br />

had to be used for services, with a visiting German priest from<br />

Umzinto� Father Umberto Ceselin, a priest from Friuli, arrived in<br />

Umzinto in 1956�<br />

About half the Italians were married, and wives started arriving<br />

from 1955� Some of the single men arranged proxy marriages to<br />

girlfriends in order to bring wives out, since the company would pay<br />

for a wife’s fare, but not a girlfriend’s� One of the first, in September<br />

1955, was Renzo Scarpa, whose son Flavio and daughter Mannie<br />

Rivetti still work for <strong>Saiccor</strong>� <strong>The</strong>re were 25 proxy marriages – in a<br />

few cases the couples did not even know each other – and most were<br />

successful� <strong>The</strong> first couple to get married in South Africa was Silvano<br />

Moro and Imperia Martelossi, in July 1957 at Umzinto�<br />

<strong>The</strong> Zulus solved their accommodation and travel problems by<br />

simply building a village on the small hill across the road opposite<br />

the woodyard (where No 4 continua stands today), named Villaggio<br />

Roma by the Italians� <strong>The</strong>re were also some Pondos in the village,<br />

which gave rise to occasional clashes�<br />

<strong>The</strong> Zulu employees in the 19<strong>50</strong>s built themselves a small village, named<br />

Villaggio Roma by the Italians<br />

In May 1955 Dr Fabio Fonda, an experienced Chemical Engineer,<br />

arrived from SAICI� He was in charge of the start-up, and brought<br />

with him Dr Brusa, the Laboratory Manager, and his assistant Dr<br />

Gianpietri (later to become Technical Manager at Mondi Merebank)�<br />

Fred Aldred, the Courtaulds’ representative, arrived on 7 June with<br />

Dr Bruce and John More (a long-time <strong>Saiccor</strong> associate until his<br />

retirement in the mid-1980s) and 10 engineers, chemists and analysts�<br />

Five ‘cooks’ were made towards the end of June 1955 and 17 in July�<br />

<strong>The</strong> first 440 pound bale of unbleached pulp was made on 16 July<br />

1955 (bleached pulp started at the end of September)� In August the<br />

factory was running on a continuous basis, six days a week� <strong>The</strong><br />

18<br />

Dr Fabio Fonda

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

discharge of effluent into the sea at the river mouth commenced on<br />

11 August and the foam was of some concern to the local authorities�<br />

By this time, 27 white South Africans had been employed – there<br />

were language problems�<br />

<strong>Saiccor</strong> factory, 1956<br />

SO Recovery was in operation from the end of November and in<br />

2<br />

December 1955 the first rayon pulp acceptable to SNIA was made�<br />

(Courtaulds were unhappy with the quality and would not accept<br />

the pulp�) SNIA and Courtaulds officially accepted 1 December 1955<br />

as the date of commencement of<br />

production�<br />

In the <strong>Saiccor</strong> process wood chips are<br />

‘cooked’ with calcium bisulphite liquor in a<br />

digester (like a large domestic pressure<br />

cooker), at high temperature and pressure to<br />

dissolve most of the lignin in the wood� <strong>The</strong><br />

liquor is made by burning sulphur and<br />

reacting the resultant sulphur dioxide with<br />

a limestone slurry� After cooking, the spent<br />

cooking liquor is washed out of the pulp�<br />

Knots and uncooked pieces of wood are then<br />

screened out before the pulp is bleached�<br />

After bleaching the pulp is screened again<br />

and then dried, cut into sheets and baled� Third floor digesters<br />

19

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

SAICI designed the plant for 110 tons per day� <strong>The</strong>re<br />

were five mild steel brick-lined digesters (280 m 3 )<br />

operating at 6-bar, each with its own washpit� Chips<br />

were conveyed to each digester and then gravity fed<br />

into the digester through a movable hopper�<br />

<strong>The</strong>re was a Lurgi roaster to make sulphur dioxide<br />

from pyrites (imported from Northern Rhodesia, now<br />

Zambia), the flue gas went through an electrostatic<br />

precipitator before reacting with crushed limestone in<br />

a set of four packed Hagglund towers� Limestone<br />

arrived in big pieces, up to 400 mm in size, and was<br />

first broken up by hand with 14-pound hammers<br />

before going to a jaw crusher and ball mill� <strong>The</strong><br />

woodyard consisted of a huge log pile, from which<br />

massive cranes dumped logs into a canal� From here<br />

they were dragged by hand, using metal poles with a<br />

hook at the end, to a 72-inch Murco 10-knife chipper<br />

(No 1), housed in what is now the magnesium oxide<br />

store�<br />

Chips were fed to three chip silos� <strong>First</strong> screening<br />

had four vibratory knotters for first stage and one for<br />

second stage, followed by four Lindblad screens for<br />

first stage and one for second stage, followed by one<br />

Ahlfors screen for tailings� <strong>The</strong>re was a four-stage<br />

bleach plant, chlorine, caustic soda, hypo and an acid<br />

stage (chlorine dioxide was installed in December<br />

1963)� All except the caustic stage were low<br />

consistency as there were no high density pumps<br />

available at the time� Adjustments were made to hypo<br />

flow to each one of the four hypo towers to control<br />

viscosity� Second screening consisted of Ahlfors<br />

screens, four for first stage, one second and one third<br />

stage�<strong>The</strong> screens have long gone, but the name of<br />

the plant has stuck�<br />

<strong>The</strong> wet end of the pulp machine (No1 continua)<br />

was made by Utita and an L-type Flakt dryer by<br />

Pignone�<br />

Pulp bales (not units) were loaded by overhead crane<br />

into rail trucks in the pulp store (road transport and<br />

units were introduced in 1975)�<br />

<strong>The</strong>re were three coal-fired boilers from Breda (No’s<br />

1-3) MCR 30 t/h and two Tosi turbines MCR 3,8 MW�<br />

Effluent was discharged via an open concrete channel<br />

to the outfall into the ocean at the river mouth� SAICI’s<br />

cost estimate for the plant and equipment was<br />

20<br />

<strong>The</strong> woodyard, showing the log pile and canal<br />

No 1 continua under construction (TOP)<br />

and (BOTTOM) in operation

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

Bales showing the <strong>Saiccor</strong> logo<br />

£5 460 954, according to the Contract Blue Book, May 1954, which<br />

details each and every item with costs, down to nuts and bolts,<br />

workshop hand tools and office furniture�<br />

At the end of December 1955 SAICI, having achieved their objective<br />

in the <strong>Saiccor</strong> project, sold their share in the company to Courtaulds�<br />

<strong>Saiccor</strong> became two-thirds Courtaulds and one-third IDC� This<br />

remained so until 1988, when both partners sold their shares to <strong>Sappi</strong>�<br />

At the beginning of 1956, SAICI announced they would officially<br />

hand over the factory at Umkomaas to <strong>Saiccor</strong> on 28 January� For<br />

the official opening Cantacuzene ‘wanted everything to be of the<br />

best, starting with Krug champagne’� At that time there was none<br />

in the country, but he managed to order <strong>50</strong>0 bottles of Charles<br />

Heidsieck from his Polish aristocrat friend Dom Radziwill, who was<br />

21<br />

Pulp bales being loaded onto a rail<br />

truck<br />

Eastern view from the Chemical Plant, 1956 Southern view from the Engineering Block, 1956

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

the agent�<strong>The</strong> official opening was performed by the Governor<br />

General of the Union of South Africa, Dr E G Jansen� Invited<br />

guests included the Minister of Economic Affairs (represented<br />

by the Secretary for Commerce and Industry, P de Waal Meyer),<br />

the Governor of the Reserve Bank, Dr M H de Kock, Natal’s<br />

Provincial Administrator Denis Shepstone, the Chairman of<br />

Courtaulds Sir John Hanbury-Williams, the President of SNIA<br />

(represented by Alessandro Brunetti), Loring Rattray and the<br />

<strong>Saiccor</strong> Board�<strong>The</strong> celebrations started on the morning of 27<br />

January with Zulu dancing at Mnini, followed by sheep and<br />

beef on the spit for the Zulu employees� A feast was held in the<br />

<strong>Saiccor</strong> canteen for the white workforce, where the Board and<br />

some of their wives signed the first sheet of <strong>Saiccor</strong> dissolving<br />

pulp (now housed in the Club Comunita Italiana in Umkomaas)�<br />

That evening Loring Rattray gave a cocktail party for the dignitaries<br />

at his home in Durban� <strong>The</strong> official ceremony on 28 January started<br />

with lunch and speeches at the New South Barrow Hotel, followed<br />

by the ribbon cutting at the factory� A message from the Minister of<br />

Economic Affairs, Dr J J van Rhijn, was read out� ‘I welcome every<br />

new undertaking that promises to save or earn South Africa additional<br />

foreign exchange�’<br />

Press photo of the official opening of <strong>Saiccor</strong>, 28 January 1956, which<br />

appeared in the Natal Mercury with the following caption: ‘His<br />

Excellency the Governor-General photographed after he had officially<br />

opened the rayon pulp plant of the South African Industrial Cellulose<br />

Corporation (SAICCOR) at Umkomaas� With him are (LEFT TO RIGHT)<br />

Sir John Hanbury-Williams, chairman of Courtaulds Ltd�, Mr Alessandro<br />

Brunetti, of Snia Viscosa, and Dr H� J� van Eck, chairman of the South<br />

African Industrial Development Corp� <strong>The</strong> tablet near which they are<br />

standing is in three languages, English, Afrikaans and Italian, evidence of<br />

the collaboration of three nations to the enterprise�’<br />

22<br />

(CLOCKWISE) Dr Hendrik van<br />

Eck, Sir John Hanbury-Williams<br />

and Dr Franco Marinotti, and<br />

BELOW <strong>The</strong> Board of Directors<br />

Extracts from the brochure produced<br />

for the official opening of the <strong>Saiccor</strong><br />

factory on 28 January 1956�

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> Governor-General, Dr EG Jansen, said, ‘<strong>Saiccor</strong> had been a<br />

contribution of large magnitude to the establishment of new<br />

industries on a decentralised basis�’<br />

‘I trust that the example will be followed,’ chairman of the IDC,<br />

Dr van Eck said� ‘This is only a beginning� Soon there may be similar<br />

factories along the Natal South Coast�’<br />

<strong>The</strong> Governor General of the Union of South Africa, Dr EG Jansen, was<br />

presented by <strong>Saiccor</strong> with an antique marble head dug from marshes at<br />

Torviscosa at the opening ceremony on 28 January 1956<br />

Dr van Eck, on behalf of <strong>Saiccor</strong>, presented the Governor-General with<br />

a head carved in marble, dug from marshes at Torviscosa� <strong>The</strong> piece<br />

of sculpture, described as being ‘of great antiquity and value’, was<br />

given to <strong>Saiccor</strong> by Dr Marinotti for presentation to Dr Jansen�<br />

At the opening it was made known that <strong>Saiccor</strong> had cost nearly £8,5<br />

million, with share capital of £6 million (£2 million from each partner)<br />

and a loan of £2 million from the Commonwealth Development<br />

Finance Company� <strong>The</strong> sum of £1 million had been spent on 15 000<br />

hectares of plantations in Zululand, and 3 000 hectares of land in the<br />

Natal midlands, £0,5 million in housing, and presumably the<br />

23

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

An interesting article on the history of rayon, which appeared in the brochure at the official opening of the <strong>Saiccor</strong><br />

factory in January 1956 (author unknown)<br />

24

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

remainder on plant, infrastructure and services� It was estimated the<br />

company would have an annual turnover of £3 million�<br />

For the opening, Dr van Eck wrote, ‘the potential requirements of<br />

a future local rayon producing industry have not been overlooked’�<br />

<strong>The</strong> issue had obviously been pursued, for on 30 May 1956 SNIA<br />

Viscosa (Milan) submitted a proposal to <strong>Saiccor</strong> for a 30 t/d viscose<br />

staple fibre plant� This was never followed up�<br />

After the official opening all the SNIA people resigned from the <strong>Saiccor</strong><br />

Board except for Alessandro Brunetti, who was asked to stay on in his<br />

personal capacity until 8 March 1957� <strong>The</strong> Board then comprised: H J<br />

van Eck (Chairman), A Brunetti (Italian), M Cantacuzene (French), J<br />

Charlton, A C M Cornish-Bowden, R V D Devos (Belgian), C F<br />

Kearton (British), G S J Kuschke and C W Sheldon (British)�<br />

Changes to the Board over this period were:�<br />

April 1956 – Charlton resigned (died the following year)<br />

July 1956 – Cornish-Bowden resigned<br />

March 1957 – Brunetti resigned�<br />

February 1960 – Devos resigned and was replaced by D R B Mynors (British)<br />

October 1960 – W F Hastie (British) appointed as Courtaulds<br />

Representative<br />

October 1964 – Sheldon resigned, replaced by O W Tainton (not<br />

representing any shareholder)<br />

January 1966 – Cantacuzene resigned, replaced by J L Yeomans (British)<br />

On 1 February 1956 Dr Fabio Fonda joined <strong>Saiccor</strong> as Technical<br />

Manager and Deputy Works Manager� Reporting to the Works<br />

Manager, he was responsible for the factory’s production� <strong>The</strong> first<br />

operating management team was now complete�<br />

<strong>The</strong> <strong>First</strong> <strong>Saiccor</strong> Operating Management Team<br />

R O Fowler, Secretary of the Management Committee, is not shown�<br />

Michel Cantacuzene –<br />

General Manager<br />

Bill Hastie – Works Manager<br />

(responsible for overall factory<br />

performance)<br />

25<br />

Alessandro Brunetti<br />

Fabio Fonda –<br />

Technical Manager<br />

(responsible for production)

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

Oakley Tainton –<br />

Commercial Manager<br />

(responsible for raw<br />

materials)<br />

John Carrick – Chief<br />

Accountant and<br />

Company Secretary<br />

This committee remained unchanged until Fonda resigned to return<br />

to Italy at the end of February 1959� <strong>The</strong> structure of the company is<br />

outlined on p 27 (it remained so until about 1967, after which it<br />

slowly expanded)�<br />

Two certificated engineers joined the company on 1 October 1955,<br />

Viggo Melkjorsen as a Plant Engineer and Graham Mortimer as<br />

Electrical Engineer� Mortimer managed the electrical department until<br />

his retirement in April 1973, ably assisted by Angelo Serravalle and<br />

Bruno Trevisan, who together created a huge, complex electrical<br />

system over 20 years� Mortimer became Plant Engineer in November<br />

1962, and endeared himself to the Italians when his daughter married<br />

an Italian (who still runs a restaurant in Durban North) and by driving<br />

an Alfa Romeo! Melkjorsen was a Swede who loved parties� He joined<br />

as Assistant Plant Engineer and became Chief Engineer in November<br />

1960, when he was elected to the management committee� He left<br />

<strong>Saiccor</strong> in 1965�<br />

In February 1956, Tom Harman of Courtaulds took general control<br />

of engineering� From 1 December 1957, Ken Reed was appointed<br />

Develop-ment Manager (he had been seconded to <strong>Saiccor</strong> from<br />

Courtaulds)�<br />

<strong>The</strong> Mechanical Engineer was Rosicarelli, who took over from Nardi<br />

when he left in September 1955� Enea Corrado was workshop<br />

Foreman� Assuero Bramuzzo was Services Engineer and Tom<br />

Fitzgerald was Chief Draughtsman�<br />

Dr Mortarino and Dr Bruce were Production Managers, each<br />

responsible for half of the factory� Shift Superintendents were Gino<br />

Rivetti, Marcello Malpiedi, Domenico Sabbatini and Alfonso de Faveri�<br />

Dr Brusa was Laboratory Manager�<br />

Towards the end of December 1955, the plant was producing an<br />

average of 70 t/d, and Fonda was confident the plant and equipment<br />

would reach design capacity early in the new year� He was, however,<br />

26<br />

Viggo Melkjorsen<br />

Graham Mortimer

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> management structure of <strong>Saiccor</strong>, until 1967<br />

27

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

so concerned about the South African operators (both white and<br />

black), that he wrote a letter (on a SAICI letterhead) on 3 January<br />

1956 on behalf of the SAICI Start-up Team Management to the <strong>Saiccor</strong><br />

General Management concluding that, ‘if something were not done<br />

about the standard of the operators, the plant could not operate�’ He<br />

found the South African operators inefficient, uncooperative, ill<br />

disciplined and unwilling to learn, compounded by a high turnover<br />

of whites�<br />

<strong>The</strong> Italians had come out in 1954 on a two-year contract to build<br />

and start up <strong>Saiccor</strong> and were due to return to Italy in 1956� Because<br />

of Fonda’s concerns, <strong>Saiccor</strong> management offered all the Italians the<br />

opportunity of signing a further three-year contract with a ‘signing<br />

on’ bonus of £300 (about 10 months’ salary)� Although their wages<br />

were relatively low by today’s standards (30 cents an hour), their<br />

standard of living in Umkomaas was better than it had been in Italy�<br />

About half the Italians signed the new three-year contract, while the<br />

other half started returning to Italy from 20 April 1956� Many of the<br />

artisans who stayed on were employed as operators�<br />

Production increased steadily from 78 t/d in January 1956 to 163<br />

t/d in April 1959, achieving the design capacity of 110 t/d from July<br />

1956 onwards� <strong>The</strong> yearly figures were:<br />

1956: 105 t/d 1957: 130 t/d 1958: 148 t/d<br />

Although numerous minor alterations were made to the plant, like<br />

increasing pipe and motor sizes, the increase in production was<br />

achieved largely by learning how to get the maximum output out of<br />

each and every piece of equipment�<br />

For example, the following alterations were made to the drying<br />

machine over the period�<br />

A new 200 mm steam line<br />

Removing rashig rings from the air water heat exchanger<br />

Increasing the air flow through the dryer<br />

Improved felts and wires<br />

Improved vacuum at the suction presses<br />

With these relatively minor changes, the output of the machine<br />

increased from its design of 110 t/d in early 1956 to average around<br />

1<strong>50</strong> t/d in the second half of 1958� <strong>The</strong> first time 181 t (200 short<br />

tons) was achieved was on 22 August 1958�<br />

Naturally the output of all other plants had to match the drying<br />

machine and all increased accordingly�<br />

A fatality unfortunately occurred on 10 February 1956� Foreman<br />

Instrument Mechanic Ego del Bianco was killed by the digester lift�<br />

A block of flats under construction in <strong>Saiccor</strong> Village at the time was<br />

named Del Bianco Court in honour of Ego, as was a street in the<br />

village�<br />

28

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

<strong>The</strong> first plant to prove troublesome was the digesters�<br />

In May 1956 the carbon brick lining of No 5 digester collapsed and<br />

had to be rebuilt� <strong>The</strong> other digesters soon followed� It became<br />

apparent that rebuilding digester linings was a fulltime occupation�<br />

Solutions to the collapse of the brick linings were being sought when<br />

it became necessary to order No 6 digester� It was decided to buy an<br />

improved type of digester from the German company Esseners,<br />

consisting of a mild steel shell clad with stainless steel� No 6 digester<br />

was commissioned in January 1960 and operated at 6,6 bar (10 per<br />

cent higher than No’s 1-5)�<br />

Between December 1960 and June 1962 the brick linings on No’s<br />

1-5 digesters were replaced with loose stainless steel linings – a vacuum<br />

between the stainless steel and the mild steel shell had to be<br />

maintained� <strong>The</strong> stainless steel linings were a great improvement on<br />

the bricks, but also collapsed from time to time� No 7 digester, a repeat<br />

of No 6, was commissioned in May 1961� When the order was ready<br />

to be placed for No 8 digester, Avesta (Sweden) were making cold<br />

stretched digesters, but Lloyds of London would not approve the<br />

design of these vessels� An order was consequently placed on Canzler<br />

of Germany for another clad stainless steel one� No 8 digester was<br />

commissioned in January 1962�<br />

From No�9 digester onwards all digesters were Avesta coldstretched<br />

stainless steel� Ingemar Johanssen of Avesta,<br />

the patent holder of the cold stretching process, was<br />

a regular visitor during the construction of these<br />

digesters� No 9 was commissioned in 1963, No 10 in<br />

1964, No 11 in 1967, No 12 in March 1969, No 13 in<br />

December 1969, and No 14 in 1973� No’s 15-17 were<br />

bought secondhand (11 years old) from Vallvik in<br />

Sweden in 1975� <strong>The</strong>se digesters were cut in half,<br />

across the centre, and transported to South Africa� A<br />

piece was welded in to make the digester 1,2 m longer<br />

(the same volume as the others, 285 m 3 )� No’s 18-20<br />

digesters were commissioned with the magnesium<br />

plant in May 1985� No’s 21-23 were commissioned<br />

with the Mkomazi plant in January 1995�<br />

A programme to replace No’s 1-8 digesters was<br />

started in 1980; they were commissioned as follows:<br />

No 1 – 1983 No 2 - 1982 No 3 - 1981<br />

No 4 – 1982 No 5 – 1980 No 6 – 1990<br />

No 7 – 1987 No 8 - 1989<br />

No’s 9 and 10 operated at 6 bar, while from No 11 on<br />

the operating pressure was increased to 10 bar, the<br />

higher pressure giving a better quality pulp, particularly Construction of digesters 18, 19 and 20 in 1984<br />

29

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

with wattle� From 1970 wattle was only cooked in 10 bar digesters,<br />

after No’s 9 and 10 were re-stretched with strips added to convert<br />

them from 6 to 10 bar� Since 1990 all digesters have worked at 10 bar,<br />

which has made the operation of digesters far easier and has produced<br />

a more consistent pulp�<br />

<strong>The</strong> digester plant has undergone a greater transformation than<br />

any other plant in <strong>Saiccor</strong>’s <strong>50</strong>-year history�<br />

From an engineering perspective two untiring men, Piero Mian<br />

and Henry Zan, drove the transformation, together with a team that<br />

included Bepi Trevisan, Sergio Govetto, Silvano Rigotti, Luigi de Corte<br />

and Giordano Soldat� Piero Mian worked in the digesters from the<br />

start of the factory, then as a section Foreman from 1960, Assistant<br />

Engineer from 1970 and finally as Divisional Engineer from 1979 until<br />

he reached retirement age in 1984� At that stage he moved to the<br />

magnesium plant, where he stayed until he actually retired in 1989,<br />

just before he turned 70, at which time he was still running up and<br />

down inside the evaporator like a spring chicken� Today at 81 he<br />

remains fit and strong� Piero was another autocratic Italian manager,<br />

overseeing everything personally, and as a consequence working day<br />

and night� He was tough on his people but would protect them with<br />

his life; it would have been easier to take off his right arm than to<br />

take away one of his people� He was diligent to the finest detail and<br />

would persevere with a problem until it was solved� His work on<br />

solving the problems on circulation pumps, their packings and<br />

corrosion on the digester vessels, was outstanding�<br />

Henry Zan (son of Ennio) took over as Divisional Engineer in digesters<br />

when Piero moved out in 1984� Henry was <strong>Saiccor</strong>’s first Technikon<br />

graduate mechanical engineer and has, in pursuing a similar strategy,<br />

carried on the transformation of digesters started by Piero� For his work<br />

in solving the problems of digester valves and gaskets in particular,<br />

Henry was awarded a <strong>Sappi</strong> EAA Bronze award in March 2000� As an<br />

Assistant Engineering Manager, he is still in charge of digesters�<br />

Two other people, although not <strong>Saiccor</strong> employees, have made a<br />

major contribution to the digesters, namely Allan Lofstrand and<br />

Franco Scarpa� Between the two of them they have built all but two<br />

(No’s 9 and 11) of <strong>Saiccor</strong>’s existing digesters� Allan, a Swede, worked<br />

for Avesta and was in India in 1964 when he was asked to go to<br />

<strong>Saiccor</strong> to build No10 digester� Once the digester was commissioned<br />

he went back to Sweden, returning on 5 January 1969 to build No<br />

12� He married a local girl, Maria, and has stayed in South Africa ever<br />

since, being involved with every digester after No 11� He joined LHL<br />

Engineering in 1969 for a year, then Durban Engineering� In 1971 he<br />

joined Axel Johnson (who represented Avesta) and in 1978 became<br />

Managing Director of ND Engineering, where he is today (although<br />

the company name has changed a few times and is currently Metso)�<br />

30<br />

Piero Mian<br />

Henry Zan<br />

Allan Lofstrand and Franco Scarpa

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

Digesters 9-17 were ordered from Avesta, but from 1980 onwards all<br />

digesters were from ND Engineering (although the plate came from<br />

Avesta, except for the new Nos 3 and 5 that came from Southern<br />

Cross)�<br />

Franco Scarpa came to South Africa in 1961 for the adventure,<br />

although he had two brothers working at <strong>Saiccor</strong>� He joined Durban<br />

Engineering but was persuaded by his brother Renzo to join <strong>Saiccor</strong><br />

in 1963� He worked in the workshop, then the liquor plant, but left<br />

in 1965� He worked on his own as a plumber for a few years, then<br />

joined Breckenridge, and from there went to Milano Motors before<br />

joining Coilco Engineering in 1974� In 1978 he joined ND Engineering<br />

and is still there� He was at the construction ‘coal face’ of every digester<br />

from No 18, including the rebuild of No’s 1-8� <strong>The</strong>re probably is not<br />

anyone in the world who knows more about building stainless steel<br />

digesters than Franco�<br />

Willem Deyzel of Lloyds Register was also an integral part of the<br />

digester building team�<br />

Another plant that was extremely troublesome from 1956 onwards<br />

was the Lurgi pyrites ‘roaster’ and the precipitator that followed it�<br />

Bruno Trevisan, the electrical engineer, was horrified in 1975 when<br />

he heard the gas producer had electrostatic precipitators, because he<br />

experienced so much trouble with the one following the pyrites<br />

roaster� Early in 1958 it was decided to buy a sulphur burner, No 1<br />

Liquor preparation, showing No 1 Simon Carves burner, 1959<br />

31

<strong>The</strong> <strong>First</strong> Fifty <strong>Years</strong><br />

Simon Carves, which was started in February 1959� In October 1959<br />

the Lurgi ‘roaster’ was converted to burn sulphur, and no further<br />

pyrites came to <strong>Saiccor</strong>�<br />

<strong>The</strong> blockage constant (KW) of the pulp produced in the first three<br />

months of <strong>Saiccor</strong>’s operation averaged 24-28, which exceeded<br />

Courtaulds’ limit of 20� <strong>The</strong> ash, calcium and silica also exceeded the<br />