SALE: Accropode Mould and Concrete Accropode Block

LEASE: Accropode Mould

SERVICE: Provide a comprehensive solution for the prefabrication and lifting engineering of breakwater protection blocks

CUSTOMIZE: Accropode Mould

product details

Industry solutions:

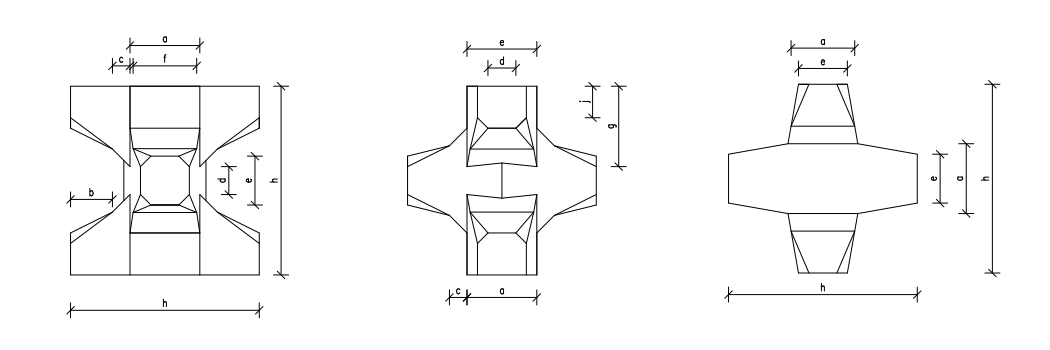

ACCROPODE (Ⅰ) DIMENSIONS

The accropodes(Chinese name: 扭王字块) are shaped like the Chinese character "王" with a 90-degree twist in the middle. The configuration size of the original hook and foot block is modified by lengthening its protrudate foot and reducing its section appropriately. The length and section of the protruding foot is between the original hook and foot block and the twisted block, which not only retains the characteristics of the original hook and foot block, but also integrates the dolos.

The accropode has six short and thick protruding feet, which are connected by the central axis to improve its strength. When thrown onto the slope, it uses the cross hooking of the adjacent block feet to increase its stability.

The shape of the accropode is square and round in terms of its protruding foot. And each of them is divided into thick and thin shapes, namely square thick type, square thin type, round thick type and round thin type.

Application Design

Accropode is developed in 1981 by French Sogreah. The material is concrete, which is cast in one-time by the fixed formwork.

The precast of accropode usually adopts the shaped composite steel formwork, and each set of formwork is assembled by 2 mutually symmetrical units. The concrete is stratified into the mold in layers and vibrated by interted vibrator. After pouring, the plaster is compacted. Under the normal temperature (25℃), the mold is dismantled and maintained after 20h. Prefabrication process: formwork inspection and cleaning → brushing release oil → formwork installation → concrete placement → demoulding → repair and maintenance → component stacking.

The accropode structure is divided into two types: A-type and B-type accropode. Compared with B-type, A-type accropode is shorter and fatter with chamfered ribs, and A-type is firmer and easier to demould. B-type block is thinner and taller. It has longer legs and is difficult to demould, which is only for small tonnage block.

Main Feature

1. The new type of breakwater protection accropode has the advantages of high strength, simple prefabrication, convenient construction and good stability, which is a promising breakwater protection block;

2. The accropode has two installation modes: random installation and regular installation in diamond shape. The block can clamp each other and has good solid stability. The main reason for the superiority of rhomboid random installation over the regular one is that the corresponding water permeability and anti-floating support ability between the blocks is improved, which enhances the stability.

Application Scenario

In 1986, a unit of navy harbor engineering test research, had improved the original hook foot block, developed into accropode. The breakwater of Qianjiang pier in Nanao County, East Guangdong Province used a new type of protective block - accropode Qianjiang pier breakwater in Nanao County, after three times of typhoon waves impact, the breakwater safe and sound. The accropode installed on the breakwater slope hooked relatively good and basically stable.

Ningbo Tianyuan Construction Engineering Co., Ltd.

Ningbo Tianyuan Cement Products Co., Ltd.

Yuehu Ginza, Nanzhan East Road, Haishu District, Ningbo City

+86 574 8698 8331

315012

Copyright © Ningbo Tianyuan Construction Engineering Co., LTD All Rights Reserved | Sitemap