Companies that have installed local exhaust ventilation systems have to undertake a “thorough examination and test” (TExT) at least once every 14 months. The objective of the TExT is to find any significant defects and to have them remedied to regain control. In most cases they will employ an external organisation to carry out these tests so that they can meet their legal obligations. There are a large number of companies offering this service – sadly not all of them do a proper job. Sometimes this is due to a lack of competence but it may also be because the test engineers are under pressure to test systems quickly to maximise the number of tests they can carry out during the day. Unfortunately that leads to corners being cut and too many testing companies carry out a minimal, rather than a thorough test.

One of our consultants was visiting a client recently to carry out ventilation testing on a system used to control fume generated during brazing operations in a plumbing shop. It consisted of 8 individual flexible arm captor hoods connected to a main duct from the fan (see photograph below). As I’ve discussed in a previous post, captor hoods are rarely effective at controlling contaminants and other types of hood are usually preferable. The ductwork design, with no attempt at balancing, means that it would be difficult to achieve the same velocity in each branch. However, in this case, the design would probably be adequate providing management ensured that the users positioned the hoods are carefully over the plume of fume generated during brazing and the appropriate capture velocity could be achieved in each leg.

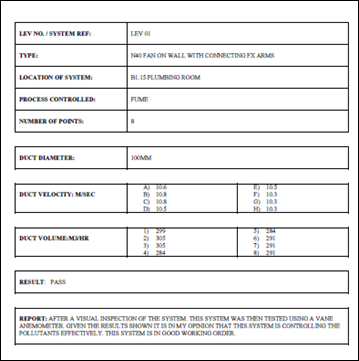

The system had previously been tested by another company and our consultant asked to see the report. He needed this so he could compare his results with those from the previous test so that he could determine whether there was any deterioration in the system’s performance. The report he was given (see below) was a good example – of an inadequate test report.

Guidance on what should be done during a TExT is provided in the Health and Safety Executive’s document HSG258 Controlling airborne contaminants at work: A guide to local exhaust ventilation. This advises that a TExT will normally involve three stages:

- A thorough visual examination to verify the LEV is in efficient working order, in good repair and in a clean condition.

- Measuring and examining the technical performance to check conformity with commissioning data. Even on a simple system this would normally include determining hood capture and face velocities and duct velocities and measuring static pressure at behind all hoods and across the air cleaner (where present) and fan.

- An assessment to check the control of worker exposure is adequate. At the very least, this will involve the use of smoke tubes or a dust lamp.

Of course it isn’t always possible to carry out all the tests recommended in HSG258 due to design, safety and practical considerations. Nevertheless a proper TExT, even on a simple system, will involve a number of different measurements and tests.

For the multi branch system, as in this case, I’d expect a TExT to involve, as a minimum, the following:

- a thorough visual examination

- a smoke test on each hood as a way of checking on how effective they were at capturing the fume generated by the brazing process

- capture velocities measured on each hood at the point further from the hood where the contaminant could be generated

- face velocities measured at each hood

- static pressures measured behind each hood

- measurement of the duct velocity in the main branch (it may not be necessary to measure duct velocities in each branch

- the static pressure across the fan

- checking the fan to ensure that it is rotating in the correct direction

The test carried out by the engineer from the previous company involved only a visual examination and measurement of duct velocities. According to the report, an assessment of control had been made from these results. Not only was the scope of the testing inadequate, the report states that the duct velocity had been measured using a vane anemometer. This is an inappropriate instrument for this type of test. I suspect the engineer had placed the anemometer at the entry to the duct inside the hood. Not only is this not the best way to measure duct velocity, It would be difficult to position the anemometer properly to measure the flow into the duct.

The “duct” velocities given in the report are all around 10 m/s. That would be adequate for conveying fume, but would the contaminants be captured effectively? No face or capture velocities are provided. If the hoods were used as receptors, and were positioned very carefully above the plume of contaminants, there was a chance that the system would achieve adequate control. But this would need to be verified by observations of the process and, ideally, a smoke test. Neither was done. It’s probably more likely that the arms would be used a capture hoods. In that case it would be necessary to check that the capture velocity was adequate. With moveable hoods of this type the best approach would be to determine the distance from the hood face where the minimum acceptable capture velocity could be achieved and include that in the report so that the user could be informed. There is nothing in the test report to suggest any of these important measurements were done.

In my view, the original report was inadequate. More time was needed to carry out a proper thorough examination and test. No doubt their company charged the client considerably less than we did – but, as with most things in life, you get what you pay for.

Even when an outside company is employed to carry out TExT the legal obligation to ensure that the test is thorough remains with the owner of the system. So they need to ensure that they’re using a competent company who will carry out the test properly in accordance with HSE’s guidelines. Its important for employers to ensure that they employ a company who will do a proper job.

We all hold P601 and our standard company reports were sent back to include even more information to pass the requirements!!!!! With today’s H & S requirements constantly increasing you would think the more information the better?? I’m a little confused following a discussion with the HSE!!! In a nutshell there is a claim on occupation asthma and we are the company that do the LEV tests on this system and have been aiding the investigation on possible causes of the end users complaints. They were present whilst we undertook a new test requested by our client to prove that the system is protecting the operator…which it is. This was pretty good as we could show the HSE officer what we do and what we look for etc. It has been quiet for a while but she has just popped up with some feedback! Apparently our report is too long and too confusing for the A.N.Other. This is a multi-branched system in a foundry. They reckon that 2-3 pages are adequate per system???

There are alot of systems in this place and each are very different. After spending a week on site we go away and do the reports. Overall we provide a covering letter, an 8 page report & log book for each and Additional documentation which explains the reports in detail, HSG258 & COSHH and details our competence etc. We are not alone in this-we have stumbled across another company at the latest LEV meeting who have had almost an identical response from the HSE-that their reports contain information which need to be in the User manual and is confusing!! The HSE want them to simplify the reports.

In my opinion I don’t think we should tone down the TExT or the reports. How many times do you go to site but the baseline data isn’t available? And if old reports are produced they are one piece of paper? At least with the information we supply it is a document which has to be kept for at least 5 years and therefore any future testing companies will have all the information available to them regardless.

I would value your opinion or anyone’s opinion.

Hi

I’d like to try and help you resolve this issue if I can but it’s a little difficult to do that just via comments on the post. I’m not entirely sure from your query whether it’s the client, HSE or BOHS, or all of them, who are causing you the difficulty.

Reporting requirements should have been covered on the P601 course so I guess you could look at your course notes (apologies if you’ve already done this) or speak to the course provider. If it was us, give me a ring.

HSE used to have a model TExT report form on their website and it would be worth looking at that, although it does appear to have been removed from their website. If HSE are criticising what you have done you need to ask them for more detail on what they want and perhaps to show you something that would be acceptable..

The report needs to be “suitable and sufficient” so you need to include all relevant information. But could you provide a summary report to the client with the basic information? Something like Page 1 of the old HSE model report.

If you can’t resolve the issue get back in touch and I’ll see what I can do to help.