A view from above.

Image courtesy of: Only A Day Away

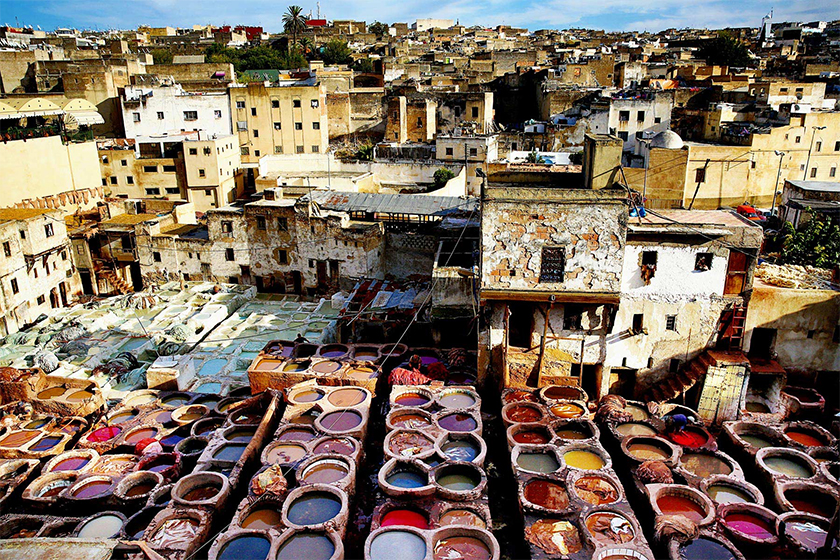

Leather tanneries are unique in most parts of the world; however not necessarily in Fez, Morocco. Amazingly photogenic, rows of oversized jugs filled with paint in earthy tones look inviting as they sit glittering in the hot sun.

In Fez, tanneries can be entered through the leather stores that surround them. Passing through tiny and dark stores, you reach viewing terraces that look down into the pits. The largest and most well-known tannery is Chouara Tannery; however, it isn’t the oldest. Historical texts dating back to the early 12th-century reference Sidi Moussa Tannery. This ancient tannery is one of three still operational in Fez.

A tannery worker among the vats.

Image courtesy of: Wikipedia

The tanneries often have an unpleasant smell due to the animal hides that are in various stages of the drying process. Among the animal hides “represented” are goat, sheep, cow, and camel. Numerous stone vats are filled with different colors of dye and white liquids. Initially, the hides are processed by being soaked in a number of white liquids that are made from a mixture of cow urine, pigeon feces (contains ammonia), quicklime (necessary in order to remove the hair), salt, and water. This step is vital in order to clean and soften the tough skins. The next step is to wait 2-3 days in order to prepare the hides to adequately absorb the dyes.

Once they are ready, the hides are soaked in the dye. These “organic” dyes use additives such as cedar wood for brown, poppy for red, indigo for blue, mint for green, and henna for orange. The hides are dried under the sun one more time, and then sold to craftsmen who start to produce the leather goods which Morocco is known for.

The conditions inside the tanneries are difficult.

Image courtesy of: Journal of Nomads

The entire production process has remained the same since medieval times…no modern machinery is used and the entire undertaking uses only manual labor. Two hundred men work at the Chouara Tannery…their jobs range from scraping hair off the skins using razor-sharp knives to dying the hides in the vats.

Since the 1800s, chromium has been a major ingredient in the tanning process. The materials’ properties produce leather that is versatile and thus, usable for a number of different purposes. The leather tanned with chromium can adhere to high temperatures. It also absorbs less water and dyes more easily and quickly. However the downside, is that this is a carcinogen.

Hides drying.

Image courtesy of: Amusing Planet

For many years, tanneries have been recognized as causing pollution because of the waste runoff and strong smells that they create. In addition to chromium, tanneries also produce other organic wastes that pollute the soil and the rivers downstream.

Every 25 days, the dyes lose their potency and need to be refreshed. Unfortunately, this means that the old water is dumped into the Fez River. Chemical-laden water from hundreds of vats becomes integrated into the surrounding environment. Steven Lange, an expert on tanning and director of the Leather Research Laboratory at the University of Cincinnati said, “We do want to make sure that our industry doesn’t have a negative impact on the environment. In the US, we have the strict laws, and all the tanneries here, they have their processes controlled. Modern tanneries now will have water collection systems to minimize water usage and to reclaim the water and reuse the water. They will have a process in place to capture any leftover chrome from the wash processes, to recycle it and use it again.”

Different colored leather bags line the walls inside one showroom at Chouara Tannery.

Image courtesy of: Only A Day Away

There are 55 newer tanneries outside of Fez that use high-tech filtering systems which produce less pollution and thus, are much safer for the environment. The modern tanneries have water collection systems that minimize water usage because they recycle water. They also have a way of capturing the leftover chrome from the wash process, recycle it, and reuse it.

Hopefully with an awareness of environmental factors, the tannery industry can continue to flourish in Fez for hundreds of years. With end-products so stunning, this is an art-form that can not ever become extinct!