Chemical beneficiation is based on the differences in the chemical properties of minerals and mineral components, using chemical methods to change the mineral composition and other ways to enrich the target components.

For example, dilute sulfuric acid is used to leach copper ores containing malachite. Change the mineral composition. That is, malachite becomes a copper sulfate solution. Metal copper (sponge copper) can be obtained by replacing the copper ions in the solution with iron filings. Chemical beneficiation is one of the effective methods to process and comprehensively utilize certain lean, fine, miscellaneous, and other refractory mineral raw materials. It is also one of the important methods to fully use mineral resources and solve the three wastes (waste water, waste residue, and waste gas) treatment, turn waste into wealth, and protect the environment.

Chemical Beneficiation Process

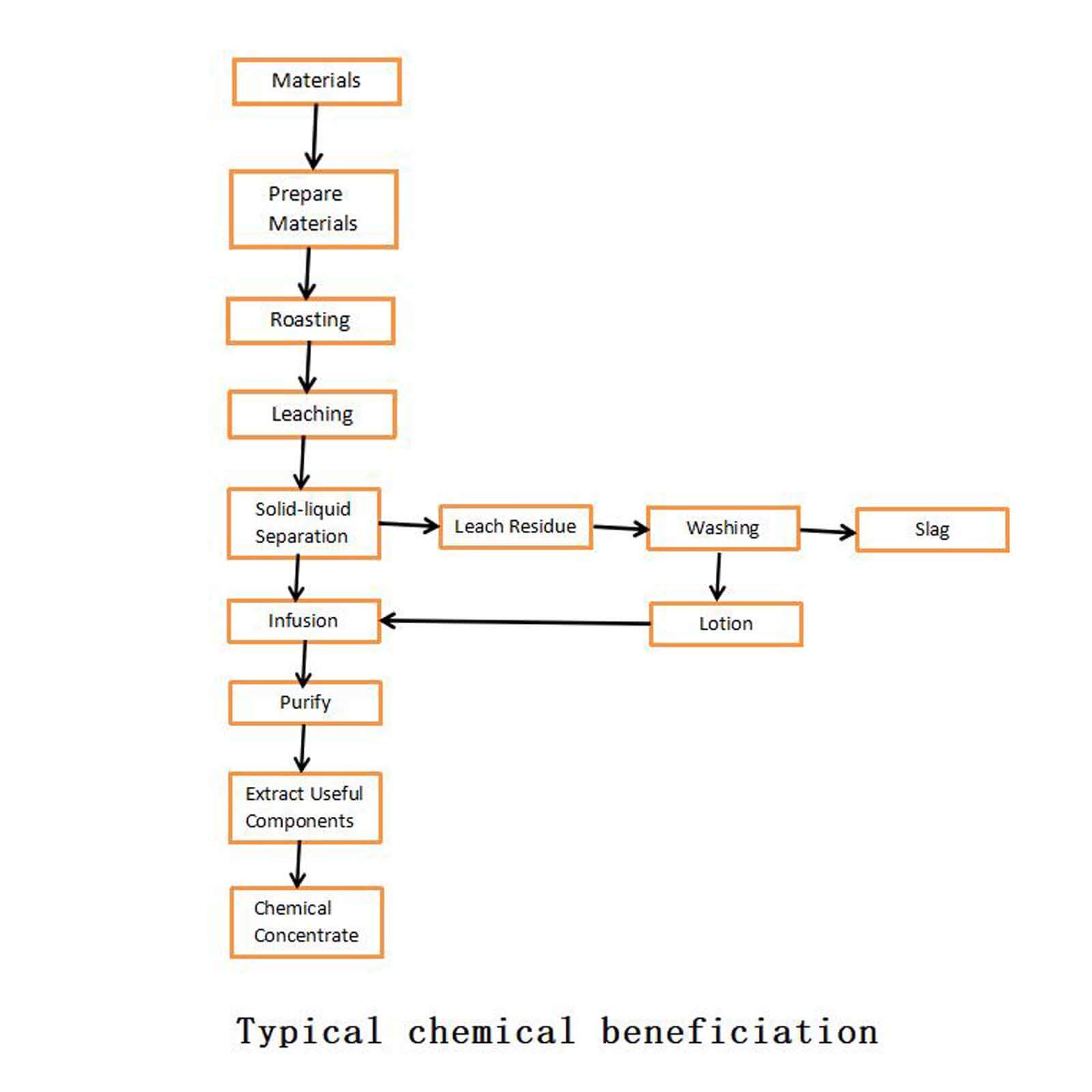

Chemical beneficiation has different operations according to different technological processes. A typical chemical beneficiation process generally includes the following six primary operations.

(1) Preparatory work

This operation is the same as the physical beneficiation method, including crushing and screening materials, grinding and grading, ingredient mixing, and other mechanical processing processes. The purpose is to grind the material to a specific particle size, prepare suitable fineness and concentration for the next operation, and sometimes use physical beneficiation to remove some harmful impurities or enrich the target minerals in advance so that the mineral raw materials and chemical reagents are mixed, Mix well. If the fire method is used, sometimes the material must be dried or sintered to create favorable conditions for the next operation.

(2) Roasting operation

The purpose of roasting is to change the chemical composition of the ore or remove harmful impurities so that we can transform the target mineral (component) into a form that is easy to be leached or beneficial to physical beneficiation and prepares conditions for the next operation. The roasted products include calcined sand, dry dust, wet dust collection liquid, and mud, from which corresponding methods can recover functional components according to their composition and properties.

(3) Leaching operation

This operation is to selectively dissolve the functional components or impurity components in the leaching solvent according to the properties of the raw materials and the process requirements so that the valuable components are separated from the impurity components, or the functional components are separated, which is the next step. Create conditions for recovering useful components from leaching solution or leaching residue.

(4) Solid-liquid separation operation

This is the same as the dehydration operation of physical beneficiation products, but the solid-liquid separation of chemical beneficiation leached pulp is more complicated. Generally, sedimentation, filtration, and classification are used to process leached ore pulp to obtain a clarified solution or contain an explanation of a small number of fine mineral particles.

(5) Purification work

In order to obtain high-grade chemical concentrates, the leaching solution is often purified and separated by chemical precipitation, ion exchange, or solvent extraction to remove impurities and get a purified solution with a high content of valuable components.

(6) Production of chemical concentrates

Chemical concentrates are obtained by extracting valuable metals (components) from the leaching solution. Generally, chemical precipitation, metal replacement, electrowinning, carbon adsorption, ion exchange, or solvent extraction can be used; in some cases, physical beneficiation can also be used. The principle process of typical chemical beneficiation is as follows.

It has successfully used chemical beneficiation to process many metallic minerals and non-metallic mineral raw materials such as iron, manganese, lead, copper, zinc, tungsten, aluminum, tin, gold, silver, tantalum, niobium, cobalt, nickel, uranium, thorium, rare earth, aluminum, phosphorus, graphite, diamond, kaolin, and other solid mineral raw materials. It can also extract valuable components from mine water, wastewater, and seawater.

The processing object of characteristic chemical beneficiation is the same as that of physical beneficiation. Still, the adaptability of the chemical beneficiation method is stronger than that of the physical beneficiation method, and its separation principle and product form are different from physical beneficiation. The separation principle of chemical beneficiation is similar to the traditional metallurgical process. And chemical beneficiation and metallurgical process all use the basic principles of inorganic chemistry, organic chemistry, physical chemistry, and chemical process to solve their respective process problems. The mineral dressing widely uses in developing various refractory ferrous metals, non-ferrous metals, precious metals, and non-metallic mineral resources.

Applying chemical beneficiation is an effective method to deal with poor, fine, miscellaneous, and other refractory mineral raw materials and recycle unused mineral resources. Its separation efficiency is higher than that of physical beneficiation. However, the chemical beneficiation process consumes a lot of chemicals, and the requirements for equipment materials and solid-liquid separation are higher than those of physical beneficiation. Therefore, under normal conditions, it should use existing physical beneficiation methods to process mineral raw materials as much as possible.

When to consider the use of a chemical beneficiation process?

- It cannot be processed by physical beneficiation alone.

- When the physical beneficiation method fails to obtain reasonable technical and economic indicators

Precautions when using the chemical beneficiation process

- Use closed-loop processes as much as possible. Fully regenerate the medicament and recycle water to reduce medicament consumption and environmental pollution.

- The joint process of physical beneficiation and chemical beneficiation should be adopted as much as possible. Various beneficiation methods are used to process mineral raw materials to make the most economical and comprehensive utilization of mineral resources.

LATEST PRODUCTS

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…

Slurry Magnetic Separator

【Capacity】10-100 m3/h 【Feeding Material Densi…