Geotextiles: Which Types of These Permeable Textile Materials Should Your Business Invest In?

Over the years, the construction and civil engineering sector has been adopting innovative and robust materials to enhance the stability and durability of various structures. Geotextiles have emerged as promising solutions in these sectors by offering promising fabrics that can be used to construct several types of structures such as roads, dams, drains, landfills, and many more, without hampering the soil properties. They play a pivotal role in constructing such structures as they offer beneficial properties for filtration, separation, drainage, reinforcement, and stabilization purposes. In this article, we will discuss the major types and applications of geotextiles, promoting civil engineering applications.

Major types of geotextiles:

Geotextiles are mainly made up of polymers such as polyester or polypropylene. The major categories of geotextiles are classified based on the way they are prepared. They are divided into three main categories which are as follows:

Woven Fabric geotextile: These types of geotextiles are mainly manufactured using the same techniques as weaving clothing. They are made by interlocking polypropylene fabric strips to offer enhanced strength and stability to the infrastructural work requiring geotextiles. Such fabrics look like plastics, but they can withstand a large amount of tension. In addition, they are ideal for separation and reinforcement purposes because of their impermeability.

Non-Woven geotextile: These geotextiles are made from short-staple fibers that can be bonded through thermal, chemical, and mechanical techniques. The geo-fibers made from mechanical or thermal techniques are 0.5 to 1mm thick, but the chemically bonded non-woven fibers are thicker up to 3mm. These fibers are mainly used for separation, protection, and filtration purposes in various environmental and civil projects such as roadways, landfills, and railroads. The process of manufacturing geotextiles uses endless filaments to ensure the use of high-quality materials. This makes these geotextiles resistant to all chemicals and biological reactions occurring in the soil and construction materials.

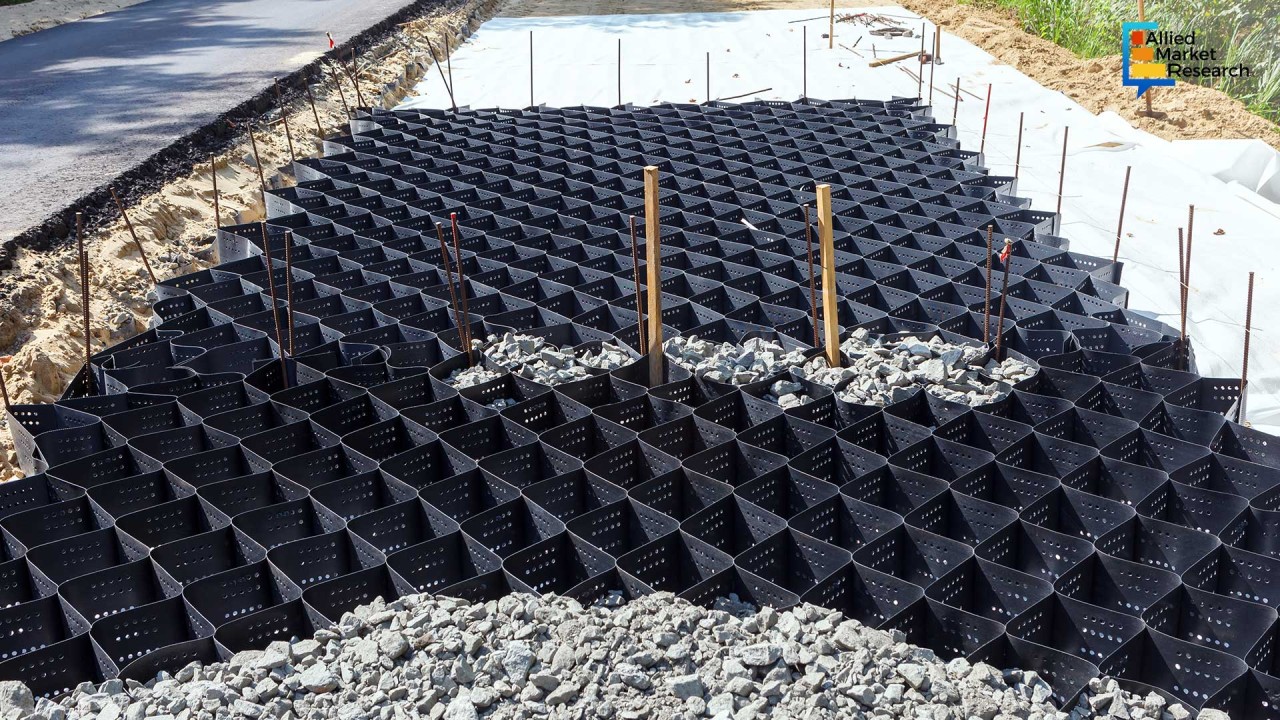

Knitted geotextile: Such types of geotextiles are prepared by interlocking a series of geosynthetics together. The manufacturing method of these types of geotextiles includes a knitted technique in combination with other methods of geosynthetic manufacturing such as weaving. These types of fabrics offer good flexibility and affordable price ranges. Though they offer a narrow use-case, they offer optimum drainage and soil erosion control.

Beyond reinforcement: Diverse applications

Geotextiles are mainly used to improve soil properties by mixing soil with some engineered materials. The purpose behind this is to strengthen the soil’s abrasion and load-bearing capabilities. Apart from such reinforcements, geotextiles play a significant role in maintaining the properties of two different types of soils. For example, when water enters the soil layer, these modified textile fabrics can prevent water from mixing with soil. This separates the sub-grade level soil from the lower course soil during road construction. Another major application of geotextiles is filtration. Filtration is one of the vital functions that is used in many civil engineering earthworks. Geotextiles restrict the permeability of material into the soil and promote the lateral flow of drain water. This solves major drainage problems around residential houses and on the streets. Furthermore, non-woven geotextile fabrics can be used to prevent fluid flow from both sides. This application is called sealing. Impermeable geotextiles are majorly used to prevent contamination of pollutants from groundwater.

Predictions of top companies

Recently, Sonya Oodit, the CEO of Tropic Construction Solutions, said in an interview that the company is going to import other kinds of construction materials such as “Geogrids (commonly known as geosynthetic material)” to meet the growing demand for road fabrics used for separation and filtration purposes during road construction. She also added that along with its previous offerings - geotextile fabric - woven PP80 (polypropylene), the company is aiming to offer geocells that can create durable materials for stabilizing and protecting roads and sea defense.

BontexGeo Group, a leading producer of geosynthetics for civil engineering applications acquired 100% shares of Minas de Riotinto, a leading provider of geosynthetics and fibers. This acquisition promotes the production and sale of nonwoven geotextiles across Europe. Furthermore, the companies together aim to expand their portfolio by strengthening the distribution channels of technical textiles.

To sum up, the increasing demand for innovative geotextiles with promising capabilities for various infrastructural developments will bring numerous growth opportunities for the global geotextile industry in the coming years. Moreover, stringent government regulations on the commercial use of geotextiles can drive the sector to have extensive goals in the future.