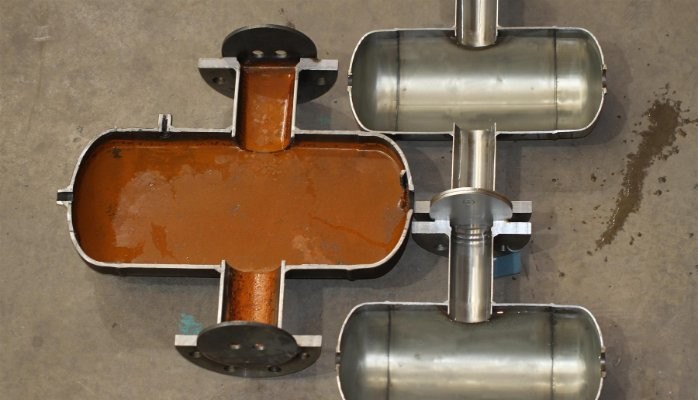

VACUUM DEGASSERS & DIRT SEPARATORS

With high static heads over 15 metres and upwards the use of Dirt Separators only coupled with Vacuum Degassers should be considered. In Chilled water it is slightly lower than 15 metres. If you are wondering about the top picture - it shows how poor carbon steel made air/dirt separators are. A half body filled with water for a month. The stainless body is completely clean. The flow rate/pressure drop is much superior with the smooth surface of the Stainless Steel. The SS units can handle a higher water velocity too and still work to release air on a combined A&D unit when the CS unit has stopped with the static head.

HENRY's LAW - in 1803 William Henry, a chemist, published his findings, which became known as 'Henry's Law'. It states that gas (air in this case) is released from a fluid (water) as the temperature increases or the pressure decreases. This is why Air and Dirt Separators are used in commercial heating and cooling systems today.

The picture left is a Stainless Steel Dirt Separator only, for use in conjunction with the Vacuum Degasser above. Normal particle removal down to 10 microns can be achieved with standard units. To increase ferrous particles (magnetite) by adding the Magnetic version you can achieve magnetite removal down to 5 microns and even below. The Vacuum Degasser will remove air from a system with up to 150 cubic metres of water. Beyond this a second unit needs to be added and so on.

Please view www.supaflex.com or contact me - Eddy Warren Tel. 0845 872 9537 Mobile 07798521063 email eddy.warren@supaflex.com - also see www.interflex.co.uk - Supaflex (Pipeline Division) Interflex Hose & Bellows Ltd.

Early in 2014, after a CPD Seminar at lunchtime in London for a well known and respected Consulting Engineer I was asked by the person in charge of FM for the building if I had a moment to go to the plant room with him. He'd noticed me carrying out the display sample of a Combined Magnetic A&D Separator as the picture below. The whole building is occupied by several tenants. He showed me an A&D unit in the LPHW and one in the CHW. Both had been completely lagged over, including the flushing valve in the base. His question " Should I be opening these periodically, they've been in for about a year" ????? I was a little taken aback. Then I spotted even worse, it is a two storey building with a static head on the system of barely 7 metres. Vacuum Degassers had been installed on both the LPHW and the CHW. I asked myself, surely not designed by a competent Consulting Engineer or a competent D&C Contractor. A mega amount of the client's money had been wasted. I've not found out to this day who was behind it. All of the equipment was from an EU source.

MSc-Renewable Energy ,LEED GA, MCIBSE

10moThanks for sharing; Any system with static head less 15m, a simple dirt separator would be suffice. Also, i dont think any logic of using a vacuum degasser in an open domestic hot water system, as the system is always open via feed intake and Y-strainers at crucial position in the system is enough to capture all the dirt and sediments. Correct me if i am mistaken here.