SafetySpear

TM

Patent Pending

Your solution to plugging production drill holes

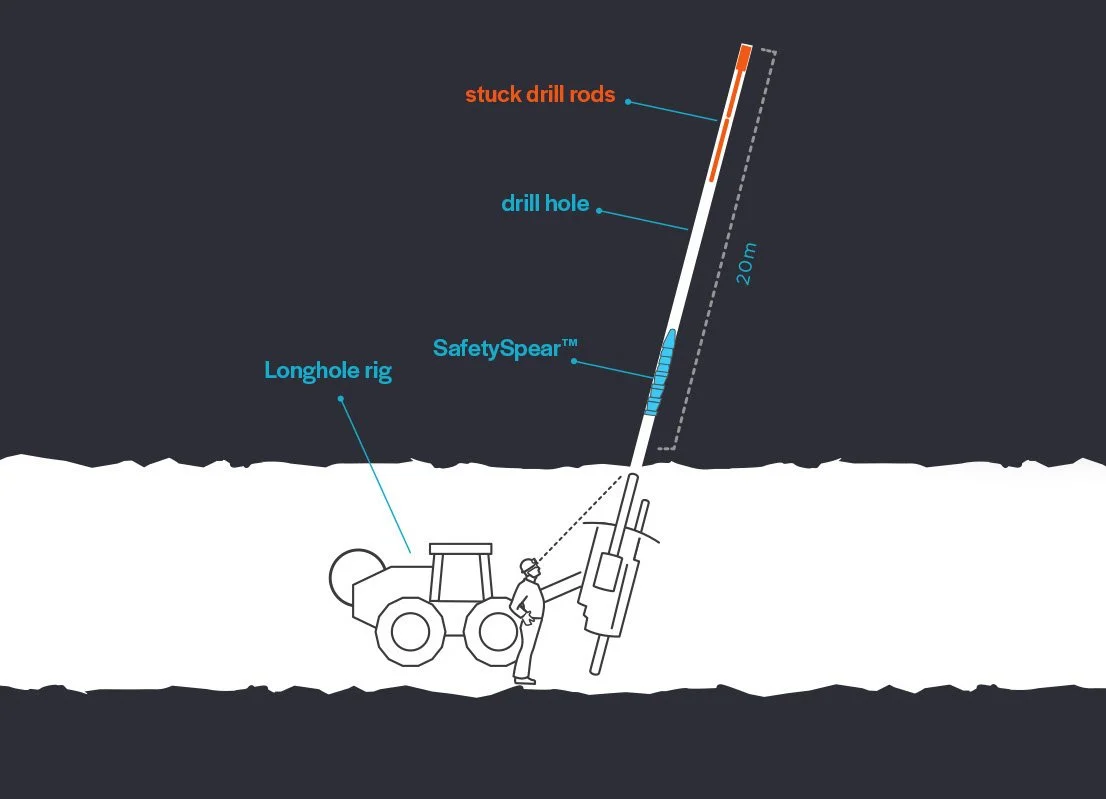

Falling drill rods are no longer a threat to mining safety thanks to the SafetySpear™

Designed and tested by experienced Long Hole Driller, Leigh Sutton, the SafetySpear™ is the answer you’ve been looking for. Lightweight, easily installed, durable and versatile, this Aussie-made invention obliterates the stuck drill rod hazard.

Take Action

Operator-designed innovation

Hard-won experience and a creative approach combine to make a practical and reliable product that drill operators will want to use. Made by a long hole driller, for long hole drillers.

Tried and tested

Tested beyond any worst-case scenario a working mine could produce, the SafetySpear™ has consistently excelled in stopping falling drill rods. Using a bespoke testing rig, and in R&D partnership with Fosterville Gold Mine, the SafetySpear™ is battle-hardened for the toughest of conditions.

Easy installation means effective risk management

The SafetySpear’s™ lightweight design means operators can easily carry several on the rig, and install them on their own. No mess, no fuss, job done.

Minimal schedule disruption and reduced costs

Designed to be installed by the same drilling rig that drilled the hole, the SafetySpear™ solves the issue of a lost drill rod in minutes. No more delayed schedules, sky-rocketing costs and ineffective hazard management.

“The SafetySpear™ is the first device that’s simple and quick to install”

Darren Manly, Senior Long Hole Driller, Fosterville Gold Mine.

Image ©Epiroc

SafetySpear™ Sizes

102mm SafetySpear™

102mm diameter for larger drill holes

89mm SafetySpear™

The original size, for medium drill holes

76mm SafetySpear™

For smaller drill holes

54-64mm SafetySpear™

For cable bolt drill holes and smaller holes

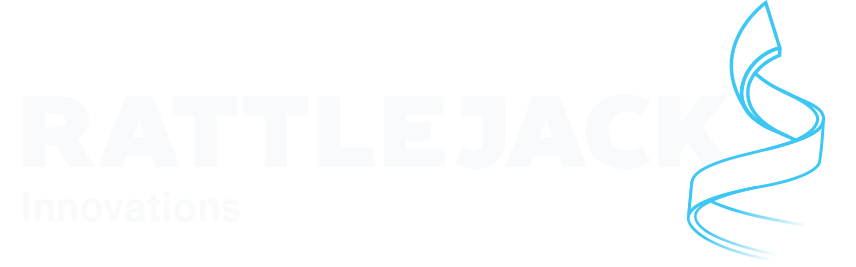

Stuck drill rods cause a lethal hazard

When drilling overhead long holes, drill rods can break and get wedged inside the hole. These drill rods can then come loose at any time, falling with devastating consequences on your operators and equipment.

Drill rod breaks and gets stuck. Operators are forced to abandon it, leaving an unmanaged hazard behind.

Traditional grouting and plating methods don’t keep your team safe

Prone to operator mistakes and inconsistent results, these methods just don’t fix the hazard. Your team, equipment, schedules and costs will all remain at risk.

Grouting - prone to seepage into adjacent holes and inconsistent suspension within the hole

Plating - minimal impact resistance causes repeated failures

The SafetySpear™ quickly and easily installed by the longhole rig, eliminating the hazard.

When traditional methods fail, the results can be catastrophic

This video shows why plating over long holes is never the answer.

The true cost of the stuck drill rod problem

Falling drill rods are an obvious danger. But trying to retrieve them, or plug the holes, causes other expensive issues. Operators risk their safety, equipment and schedules trying to manage this hazard.

“This is the device we’ve been looking for. It’s tough, reliable and easy to use.”

Darren Manley, Senior Long Hole Driller

OUT-PERFORMING EXPECTATIONS

Testing proves impressive capabilities of the SafetySpear™

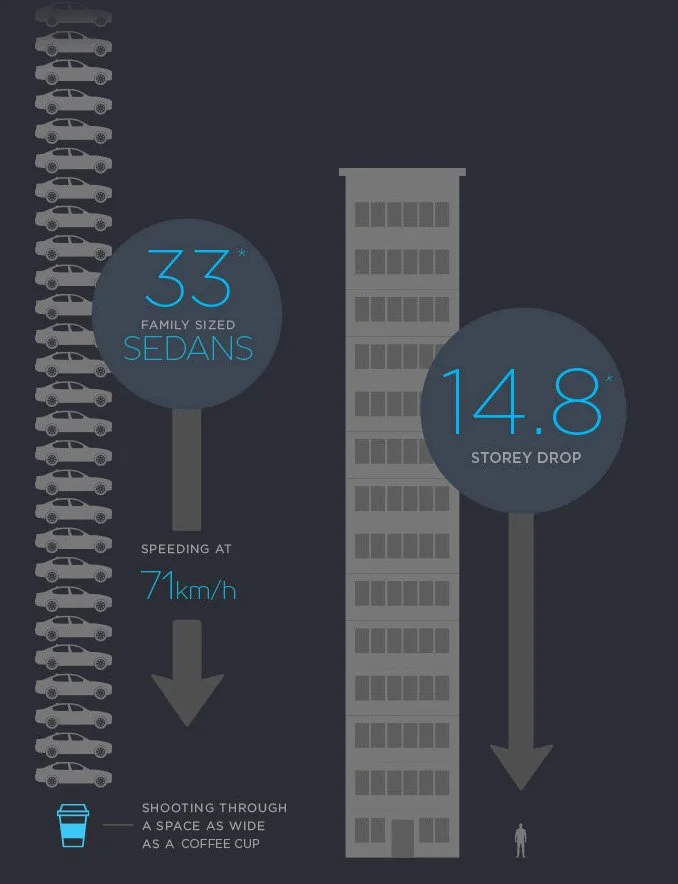

Through rigorous testing, the SafetySpear™ has showcased its ability to stop falling objects under immense force.

Common scenario at most mines

Capacity proven with our test drop rig

*Above is a sample of the tests the SafetySpear™ has been through during the testing phase and should not be interpreted as everyday operational maximum limits. While every care has been taken to be as accurate as possible, variations will exist. These figures are for illustration purposes only and are an approximation of initial contact forces/speed/energy generated. These suggested figures are for comparisons between different scenarios. It is acknowledged that some calculations in force will have different outcomes. Average storey height is 2.7 metres. Average sedan weight 1.5 tonnes

The SafetySpear™ story

After narrowly avoiding serious injury from a falling drill rod, Leigh Sutton was compelled to find a solution to this major problem. Using his long hole drilling experience, a creative approach and his own testing rig, he hit upon a lightweight, durable and reliable solution.