Model YLAA Air-Cooled Scroll Chillers Style A - Aireyork

Model YLAA Air-Cooled Scroll Chillers Style A - Aireyork

Model YLAA Air-Cooled Scroll Chillers Style A - Aireyork

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

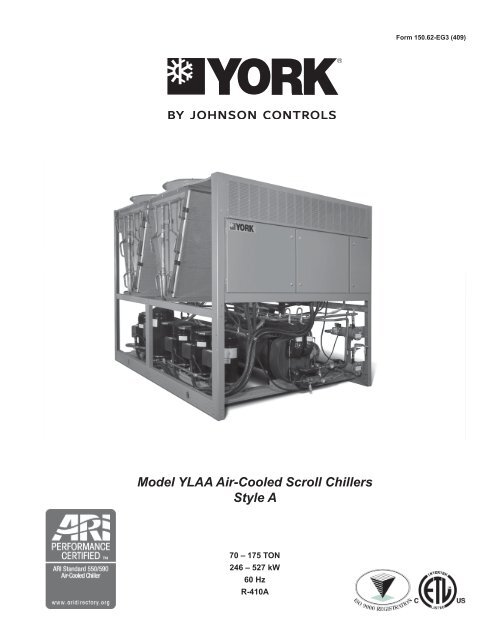

<strong>Model</strong> <strong>YLAA</strong> <strong>Air</strong>-<strong>Cooled</strong> <strong>Scroll</strong> <strong>Chillers</strong><br />

<strong>Style</strong> A<br />

70 – 175 TON<br />

246 – 527 kW<br />

60 Hz<br />

R-410A<br />

Form 150.62-EG3 (409)

Table of contents<br />

Form 150.62-EG3 (409) ......................................................................................................................................................................................... 1<br />

Introduction ........................................................................................................................................................................................................... 3<br />

Specifications ....................................................................................................................................................................................................... 4<br />

Microcomputer Control Center ........................................................................................................................................................................... 5<br />

Accessories and Options .................................................................................................................................................................................... 7<br />

Design Parameters ............................................................................................................................................................................................. 10<br />

Water Pressure Drop ...........................................................................................................................................................................................11<br />

Selection Criteria and Procedures .................................................................................................................................................................... 12<br />

Pump Selection Criteria ..................................................................................................................................................................................... 14<br />

Pump Pressure Drop Curves............................................................................................................................................................................. 16<br />

Single Pump Curves........................................................................................................................................................................................... 18<br />

Dual Pump Curves.............................................................................................................................................................................................. 19<br />

Ratings - 60 Hz .................................................................................................................................................................................................... 20<br />

Part Load Ratings - Standard Efficiency .......................................................................................................................................................... 28<br />

Part Load Ratings - High Efficiency .................................................................................................................................................................. 29<br />

Physical Data - English ...................................................................................................................................................................................... 30<br />

Dimensions - Four Fan Units ............................................................................................................................................................................. 32<br />

Dimensions - Five Fan Units ............................................................................................................................................................................. 33<br />

Dimensions - Six Fan Units ............................................................................................................................................................................... 34<br />

Dimensions - Eight Fan Units ............................................................................................................................................................................ 35<br />

Dimensions - Ten Fan Units .............................................................................................................................................................................. 36<br />

Isolator Locations ............................................................................................................................................................................................... 37<br />

Isolator Details .................................................................................................................................................................................................... 40<br />

Electrical Notes................................................................................................................................................................................................... 43<br />

Electrical Data w/o Pumps ................................................................................................................................................................................. 44<br />

Wiring Lugs ......................................................................................................................................................................................................... 48<br />

Electrical Data w/ Pumps ................................................................................................................................................................................... 50<br />

Wiring Diagram ................................................................................................................................................................................................... 60<br />

Elementary Wiring ............................................................................................................................................................................................. 62<br />

Condenser Fan Mapping and Sequencing ....................................................................................................................................................... 64<br />

Compressor Wiring ............................................................................................................................................................................................ 65<br />

Power Options Connection Diagram ................................................................................................................................................................ 66<br />

Power Panel ........................................................................................................................................................................................................ 67<br />

Dual Pump Wiring ............................................................................................................................................................................................... 68<br />

Wiring .................................................................................................................................................................................................................. 69<br />

MicroPanel Connections .................................................................................................................................................................................... 70<br />

Application Data ................................................................................................................................................................................................. 73<br />

Guide Specifications .......................................................................................................................................................................................... 74<br />

York Chiller<br />

NOMENCLATURE<br />

The model number denotes the following characteristics of the unit:<br />

A = Americas<br />

Four Digit Unit Number<br />

0070<br />

T E<br />

E 410A<br />

Unit Designator<br />

S = Standard Efficiency<br />

H = High Efficiency<br />

Y = Standard Efficiency (round tube)<br />

Z = High Efficiency (round tube)<br />

jOHNSON CONTROLS

Introduction<br />

jOHNSON CONTROLS<br />

FORM 150.62-EG3 (409)<br />

Johnson Controls, the leader in equipment<br />

controls and HVAC equipment is proud to<br />

offer the YORK air-cooled scroll chiller.<br />

This all-in-one package is a true plug and<br />

play system that provides superb efficiency<br />

and performance. The chiller is completely self-contained and is designed for outdoor (roof or ground<br />

level) installation. An optional hydronic pump kit makes service replacement or new building installations<br />

very convenient. Each unit includes zero-ozone-depletion refrigerant (R-410A), hermetic scroll compressors,<br />

a liquid evaporator, air cooled condenser, and a weather resistant microprocessor control center,<br />

all mounted on a formed steel base.<br />

ENviRONMENTAL REspONsibiLiTy …sTANdARd<br />

TEMPO makes you the leader in environmental practices<br />

through innovation, not added cost. With the combination of R-<br />

410A refrigerant and a 0-50% reduction of refrigerant used vs.<br />

similar chillers, the TEMPO chiller provides you with the most<br />

ecologically friendly equipment. Partnered with it’s low sound<br />

properties (for noise pollution prevention), this chiller is a true<br />

earth-friendly offering.<br />

REdUCEd TOTAL COsT OF OWNERsHip...<br />

Industry leading energy efficiency, easy maintenance and<br />

durability minimize your cost of ownership. Efficiency; environmentally<br />

responsibility that pays you back…<br />

• Real world energy efficiency is measured in IPLV (part load)<br />

performance<br />

• Tempo’s industry leading IPLV’s deliver cash to your bottom<br />

line<br />

• Serviceability…Easier maintenance pays twice: sustained<br />

chiller efficiency and lower cost maintenance contracts<br />

• Corrosion resistant condenser coils extend life and improve<br />

performance<br />

MORE bUiLdiNG…LEss CHiLLER<br />

TEMPO offers a lighter, smaller and quieter chiller minimizing<br />

your installed cost and maximizing usable building space.<br />

Tempo<br />

• More space for you<br />

New pace…New World<br />

Try keeping up with our Tempo!<br />

• Smaller chiller footprint saves valuable space<br />

• Tempo is the lowest weight chiller available, lighter than our<br />

previous generation chiller by 0- 5%<br />

• Hydronic pump kit option can save both space and cost by<br />

integrating the chilled water pumps as a factory mounted<br />

chiller option<br />

• Standard low sound and affordable sound attenuation options<br />

allow flexibility in locating chiller and reduce cost for<br />

field constructed sound barriers<br />

MANy AppLiCATiONs, ONE TEMpO!<br />

Performance, sound and hydronic pump kits are all configurable<br />

to suit your many needs… Performance can be configured with<br />

standard and high full-load efficiency models (an industry first)<br />

• Multiple sound configurations…only spend on what you<br />

need.<br />

• Pumps can be factory mounted<br />

• Hydronic pump kits can be configured for a wide range of flow<br />

and head pressure with single or dual (standby) pump<br />

• Standard corrosion resistance for coastal applications<br />

• Small weight and footprint allow you maximum choice in locating<br />

the chiller

Specifications<br />

GENERAL<br />

The 70 - 175 Ton ( 46 - 61 ) yLAA models are shipped<br />

complete from the factory ready for installation and use.<br />

The unit is pressure-tested, evacuated, and fully charged<br />

with a zero Ozone Depletion Potential Refrigerant R-<br />

410A and includes an initial oil charge. After assembly, a<br />

complete operational test is performed with water flowing<br />

through the evaporator to assure that the refrigeration<br />

circuit operates correctly.<br />

The unit structure is heavy-gauge, galvanized steel. This<br />

galvanized steel is coated with baked-on powder paint,<br />

which, when subjected to ASTM B117 1000 hour, salt<br />

spray testing, yields a minimum ASTM 1654 rating of<br />

“6”. Units are designed in accordance with NFPA 70 (National<br />

Electric Code), ASHRAE/ANSI 15 Safety code for<br />

mechanical refrigeration, ASME and rated in accordance<br />

with ARI Standard 550/590.<br />

COMpREssORs<br />

The chiller has suction-gas cooled, hermetic, scroll compressors.<br />

The <strong>YLAA</strong> compressors incorporate a compliant<br />

scroll design in both the axial and radial direction. All rotating<br />

parts are statically and dynamically balanced. A large internal<br />

volume and oil reservoir provides greater liquid tolerance.<br />

Compressor-crankcase heaters are also included for extra<br />

protection against liquid migration.<br />

EvApORATOR<br />

The evaporator is equipped with a heater controlled by<br />

a separate thermostat. The heater provides freeze protection<br />

for the evaporator down to - 0 o F (- 9°C) ambient.<br />

The evaporator is covered with 3/4” flexible, closed-cell,<br />

foam insulation (K=0. 5).<br />

The water baffles are constructed of galvanized steel to<br />

resist corrosion. The removable heads allow access to<br />

the internally enhanced, seamless, copper tubes. Vent<br />

and drain connections are included.<br />

Water inlet and outlet connections are grooved for compatibility<br />

with field supplied ANSI/AWWA C-606 couplings.<br />

CONdENsER<br />

Coils - Condenser coils are made of a single material to<br />

avoid galvanic corrosion due to dissimilar metals. Coils<br />

and headers are brazed as one piece. Integral sub cooling<br />

is included. The design working pressure of the coil<br />

is 650 PSIG (45 bar). Condenser coil shall be pressure<br />

washable up to 1500 psi washer.<br />

Fans – The condenser fans are composed of corrosion<br />

resistant aluminum hub and glass-fiber-reinforced polypropylene<br />

composite blades molded into a low-noise airfoil<br />

section. They are designed for maximum efficiency and<br />

are statically and dynamically balanced for vibration-free<br />

operation. They are directly driven by independent motors,<br />

and positioned for vertical air discharge. The fan guards<br />

are constructed of heavy-gauge, rust-resistant, coated<br />

steel. All blades are statically and dynamically balanced<br />

for vibration-free operation.<br />

Motors – The fan motors are Totally Enclosed <strong>Air</strong>-Over, squirrel-cage<br />

type, current protected. They feature ball bearings<br />

that are double-sealed and permanently lubricated.<br />

Ambient Kit (High) – Required if units are to operate<br />

when the ambient temperature is above 115°F (46°C).<br />

Includes discharge pressure transducers.<br />

4 jOHNSON CONTROLS

Microcomputer Control Center<br />

All controls are contained in a NEMA R/1 cabinet with<br />

hinged outer door and includes:<br />

Liquid Crystal Display with Light Emitting Diode backlighting<br />

for outdoor viewing:<br />

Two display lines<br />

Twenty characters per line<br />

Color coded 1 -button non-tactile keypad with sections<br />

for:<br />

dispLAy/pRiNT of typical information:<br />

Chilled liquid temperatures<br />

Ambient temperature<br />

System pressures (each circuit)<br />

Operating hours and starts (each compressor)<br />

Print calls up to the liquid crystal display:<br />

Operating data for the systems<br />

History of fault shutdown data for up to<br />

the last six fault shutdown conditions<br />

An RS- port, in conjunction with this<br />

FIG.1 – CONTROL PANEL COMPONENTS<br />

jOHNSON CONTROLS<br />

FORM 150.62-EG3 (409)<br />

press-to-print button, is provided to permit<br />

the capability of hard copy print-outs via a<br />

separate printer (by others).<br />

ENTRy section to:<br />

ENTER setpoints or modify system values<br />

sETpOiNTs updating can be performed to:<br />

Chilled liquid temperature setpoint and range<br />

Remote reset temperature range<br />

Set daily schedule/holiday for start/stop<br />

Manual override for servicing<br />

Low and high ambient cutouts<br />

Number of compressors<br />

Low liquid temperature cutout<br />

Low suction pressure cutout<br />

High discharge pressure cutout<br />

Anti-recycle timer (compressor start cycle<br />

time)<br />

Anti-coincident timer (delay compressor<br />

starts)<br />

UNiT section to:<br />

Set time<br />

Set unit options<br />

UNiT ON/OFF switch<br />

The microprocessor control center is capable of displaying<br />

the following:<br />

• Return and leaving liquid temperature<br />

• Low leaving liquid temperature cutout setting<br />

• Low ambient temperature cutout setting<br />

• Outdoor air temperature<br />

• English or Metric data<br />

• Suction pressure cutout setting<br />

• Each system suction pressure<br />

• Discharge pressure (optional)<br />

• Liquid Temperature Reset via a johnson Controls ISN<br />

DDC or Building Automation System (by others) via:<br />

- a 4-20 milliamp or 0 -10 VDC input<br />

• Anti-recycle timer status for each system<br />

• Anti-coincident system start timer condition<br />

• Compressor run status<br />

• No cooling load condition<br />

• Day, date and time<br />

• Daily start/stop times<br />

• Holiday status<br />

• Automatic or manual system lead/lag control<br />

• Lead system definition<br />

• Compressor starts & operating hours<br />

5

Microcomputer Control Center - continued<br />

(each compressor)<br />

• Status of hot gas valves, evaporator heater<br />

and fan operation<br />

• Run permissive status<br />

• Number of compressors running<br />

• Liquid solenoid valve status<br />

• Load & unload timer status<br />

• Water pump status<br />

Provisions are included for: pumpdown at shutdown;<br />

optional remote chilled water temperature reset and two<br />

steps of demand load limiting from an external building<br />

automation system. Unit alarm contacts are standard.<br />

The operating program is stored in non-volatile memory<br />

(EPROM) to eliminate chiller failure due to AC powered<br />

failure/battery discharge. Programmed setpoints are retained<br />

in lithium battery-backed RTC memory for 5 years<br />

minimum.<br />

COMMUNiCATiONs<br />

• Native communication capability for BACnet (MS/TP)<br />

and Modbus<br />

• Optional communciation available for N and LON via<br />

eLink option<br />

HiGH AMbiENT KiT<br />

Allows units to operate when the ambient temperature<br />

is above 115°F (46°C). Includes sun shield panels and<br />

FAN<br />

CONTACTOR<br />

XTBF1<br />

FAN<br />

FUSE<br />

COMPRESSOR<br />

CONTACTORS<br />

FAN<br />

CONTACTORS<br />

FiG. 2 – POWER PANEL COMPONENTS<br />

DISCONNECT<br />

SWITCH<br />

GROUND<br />

LUG<br />

discharge pressure transducers.<br />

bUiLdiNG AUTOMATiON sysTEM iNTERFACE<br />

The factory addition of a Printed Circuit Board to accept a<br />

4-20 milliamp or 0-10VDC input to reset the leaving chiller<br />

liquid temperature from a Building Automation System.<br />

(Factory-mounted)<br />

- (The standard unit capabilities include remote startstop,<br />

remote water temperature reset via up to two<br />

steps of demand (load) limiting depending on model.)<br />

- (The standard control panel can be directly connected<br />

to a johnson Controls Building Automated System via<br />

the standard on-board RS communication port.)<br />

pOWER pANEL<br />

Each panel contains:<br />

• Compressor power terminals<br />

• Compressor motor starting contactors per l.E.C.<br />

• Control power terminals to accept incoming for<br />

115-1-60 control power<br />

• Fan contactors & overload current protection<br />

The power wiring is routed through liquid-tight conduit to<br />

the compressors and fans.<br />

FAN<br />

CONTACTORS<br />

COMPRESSOR<br />

CONTACTORS<br />

FAN<br />

FUSE<br />

FAN<br />

CONTACTOR<br />

COMPRESSOR<br />

OVERLOADS<br />

6 jOHNSON CONTROLS

Accessories and Options<br />

pOWER OpTiONs:<br />

COMpREssOR pOWER CONNECTiONs – Single-point<br />

terminal block connection(s) are provided as standard.<br />

The following power connections are available as options.<br />

(See electrical data for specific voltage and options availability.)<br />

(Factory-mounted)<br />

siNGLE-pOiNT sUppLy TERMiNAL bLOCK – Includes<br />

enclosure, terminal-block and interconnecting wiring to<br />

the compressors. Separate external protection must be<br />

supplied, by others, in the incoming compressor-power<br />

wiring. (Do not include this option if either the Single-Point<br />

Non-Fused Disconnect Switch or Single-Point Circuit<br />

Breaker options have been included.)<br />

siNGLE-pOiNT NON-FUsEd disCONNECT sWiTCH<br />

– Unit-mounted disconnect switch(es) with external, lockable<br />

handle (in compliance with Article 440-14 of N.E.C.),<br />

can be supplied to isolate the unit power voltage for<br />

servicing. Separate external fusing must be supplied, by<br />

others in the power wiring, which must comply with the<br />

National Electrical Code and/or local codes.<br />

siNGLE-pOiNT NON-FUsEd disCONNECT sWiTCH<br />

WiTH iNdividUAL sysTEM bREAKERs - Includes<br />

unit-mounted disconnect switch with external, lockable<br />

handles (in compliance with Article 440-14 of N.E.C.) to<br />

isolate unit power voltage for servicing. Factory interconnecting<br />

wiring is provided from the disconnect switch to<br />

factory supplied system circuit breakers.<br />

siNGLE-pOiNT CiRCUiT bREAKER – A unit mounted<br />

circuit breaker with external, lockable handle (in compliance<br />

with N.E.C. Article 440-14), can be supplied to isolate<br />

the power voltage for servicing. (This option includes the<br />

Single-Point Power connection.)<br />

CONTROL TRANsFORMER – Converts unit power voltage<br />

to 115-1-60 (0.5 or 1.0 KVA capacity). Factory mounting<br />

includes primary and secondary wiring between the<br />

transformer and the control panel. (Factory-mounted)<br />

pOWER FACTOR CORRECTiON CApACiTORs – Will<br />

correct unit compressor power factors to a 0.90-0.95.<br />

(Factory-mounted)<br />

CONTROL OpTiONs:<br />

AMbiENT KiT (LOW) – Units will operate to 0°F (-1°C).<br />

This accessory includes all necessary components to permit<br />

chiller operation to 0°F (-18°C). (This option includes<br />

the Discharge Pressure Transducer / Readout Capability<br />

option.) For proper head pressure control in applications<br />

below 0°F (-1°C) where wind gusts may exceed 5 mph,<br />

jOHNSON CONTROLS<br />

FORM 150.62-EG3 (409)<br />

it is recommended that Optional Condenser Louvered<br />

Enclosure Panels also be included. (Factory-mounted)<br />

LANGUAGE LCd ANd KEypAd dispLAy – Spanish,<br />

French, German, and Italian unit LCD controls and keypad<br />

display available. Standard language is English.<br />

COMpREssOR, pipiNG, EvApORATOR<br />

OpTiONs:<br />

FLANGEs (ANsi/AWWA C-606 COUpLiNGs TypE)<br />

– Consists of ( ) Flange adapter for grooved end pipe<br />

(standard 150 psi [10.5 bar] evaporator). (Not available<br />

on optional DX evaporator 300 PSIG DWP waterside.)<br />

(Field-mounted)<br />

LOW TEMpERATURE bRiNE – Required for brine<br />

chilling below 0°F (-1°C) leaving brine temperature.<br />

Option includes resized thermal expansion valve. (Factory-mounted)<br />

CHiCAGO COdE RELiEF vALvEs – Unit will be provided<br />

with relief valves to meet Chicago code requirements.<br />

(Factory-Mounted)<br />

sERviCE sUCTiON isOLATiON vALvE – Service suction<br />

discharge (ball-type) isolation valves are added to unit<br />

per system (discharge service ball-type isolation valve is<br />

standard on each circuit). (Factory-Mounted)<br />

HOT GAs by-pAss – Permits continuous, stable operation<br />

at capacities below the minimum step of compressor<br />

unloading to as low as 5% capacity (depending<br />

on both the unit and operating conditions) by introducing<br />

an artificial load on the evaporator. Hot gas by-pass is<br />

installed on only refrigerant system #1 on two-circuited<br />

units. (Factory-Mounted)<br />

FLOW sWiTCH – The flow switch or its equivalent must<br />

be furnished with each unit.<br />

150 psig (10.5 bar) dWp – For standard units. johnson<br />

Controls model F61MG-1C Vapor-proof SPDT, NEMA<br />

R switch (150 PSIG [10.5 bar] DWP), - 0°F to 50°F<br />

(- 9°C to 1 1°C), with 1" NPT connection for upright<br />

mounting in horizontal pipe. (Field-mounted)<br />

diFFERENTiAL pREssURE sWiTCH – Alternative to an<br />

above mentioned flow switch. Pretempco model DPS300A-<br />

P40PF-8 58 -5 ( 00 psi max. working pressure), SPDT 5<br />

amp 125/250VAC switch, Range 3 - 40 PSID, deadband<br />

0.5 - 0.8 psi, with 1/4” NPTE Pressure Connections.<br />

HydRO-KiT – Factory installed Hydro-Kit suitable for water<br />

glycol systems with up to 5% glycol at leaving tempera-<br />

7

Accessories and Options - continued<br />

tures down to 0 F. The Hydro-kit option is available in a<br />

single or dual configuration (dual as standby duty only), with<br />

totally enclosed permanently lubricated pump motors.<br />

The hydro-kit option comes standard with a balancing valve,<br />

flow switch, pressure ports, suction guide, strainer, bleed<br />

and drain valves and frost protection.<br />

Expansion tanks are optional within the Hydro-Kit option.<br />

CONdENsER ANd CAbiNET OpTiONs:<br />

Condenser coil protection against corrosive environments<br />

is available by choosing any of the following options. For<br />

additional application recommendations, refer to FORM<br />

150.1 -ES1. (Factory-Mounted)<br />

pOsT-COATEd dippEd CONdENsER COiLs – The<br />

unit is built with dipped-cured condenser coils. This is the<br />

choice for corrosive applications (with the exception of<br />

strong alkalies, oxidizers and wet bromine, chlorine and<br />

fluorine in concentrations greater than 100 ppm).<br />

ENCLOsURE pANELs (UNiT) – Tamperproof Enclosure<br />

Panels prevent unauthorized access to units. Enclosure<br />

Panels can provide an aesthetically pleasing alternative<br />

to expensive fencing. Additionally, for proper head pressure<br />

control, johnson Controls recommends the use of<br />

Condenser Louvered Panels for winter applications where<br />

wind gusts may exceed five miles per hour. The following<br />

types of enclosure panels are available:<br />

WiRE pANELs (FULL UNiT) – Consists of welded<br />

wire-mesh guards mounted on the exterior of the unit.<br />

Prevents unauthorized access, yet provides free air flow.<br />

(Factory-Mounted)<br />

WiRE/LOUvEREd pANELs – Consists of welded wiremesh<br />

panels on the bottom part of unit and louvered<br />

panels on the condenser section of the unit. (Factory-<br />

mounted).<br />

LOUvEREd pANELs (CONdENsER COiL ONLy)<br />

– Louvered panels are mounted on the sides and ends of<br />

the condenser coils for protection. (Factory-Mounted)<br />

LOUvEREd pANELs (FULL UNiT) – Louvered panels<br />

surround the front, back, and sides of the unit. They<br />

prevent unauthorized access and visually screen unit<br />

components. Unrestricted air flow is permitted through<br />

generously sized louvered openings. This option is applicable<br />

for any outdoor design ambient temperature up<br />

to 115°F (46°). (Factory-Mounted)<br />

COiL ENd HAiL GUARd – Louvered panel attached to<br />

exposed coil end. (Factory-Mounted)<br />

sOUNd ATTENUATiON – One or both of the following<br />

sound attenuation options are recommended for residential<br />

or other similar sound sensitive locations:<br />

COMpREssOR ACOUsTiC sOUNd bLANKET – Each<br />

compressor is individually enclosed by an acoustic sound<br />

blanket. The sound blankets are made with one layer of<br />

acoustical absorbent textile fiber of 5/8" (15mm) thickness;<br />

one layer of anti-vibrating heavy material thickness of 1/8"<br />

(3mm). Both are closed by two sheets of welded PVC,<br />

reinforced for temperature and UV resistance. (Factory-<br />

Mounted)<br />

ULTRA QUiET FANs – Lower RPM, 8-pole fan motors<br />

are used with steeper-pitch fans. (Factory-Mounted)<br />

vibRATiON isOLATORs – Level adjusting, spring type 1"<br />

(25.4mm) or seismic deflection or neoprene pad isolators<br />

for mounting under unit base rails. (Field-mounted)<br />

8 jOHNSON CONTROLS

COMPRESSORS<br />

MICROCHANNEL<br />

COILS<br />

FORMED<br />

BASE<br />

RAIL<br />

FiG.3 – GENERAL UNIT COMPONENTS<br />

jOHNSON CONTROLS<br />

FAN DECK<br />

POWER<br />

PANEL<br />

EVAPORATOR<br />

CONTROL<br />

PANEL<br />

TXV<br />

VALVES<br />

FORM 150.62-EG3 (409)<br />

LIQUID<br />

TIGHT<br />

CONDUIT<br />

FILTER<br />

DRIERS<br />

SIGHT<br />

GLASS<br />

9

Design Parameters<br />

Unit Designation<br />

NOTEs:<br />

Nominal Evaporator Water Flow<br />

Temperature (°F) Water Flow (gpm) <strong>Air</strong> On Condenser (°F)<br />

MIN 1 MAX 2 MIN MAX MIN 3 MAX 4<br />

<strong>YLAA</strong>0070SE 40 55 60 285 0 125<br />

<strong>YLAA</strong>0080SE 40 55 100 355 0 125<br />

<strong>YLAA</strong>0090SE 40 55 140 625 0 125<br />

<strong>YLAA</strong>0100SE 40 55 100 385 0 125<br />

<strong>YLAA</strong>0115SE 40 55 100 385 0 125<br />

<strong>YLAA</strong>0120SE 40 55 150 625 0 125<br />

<strong>YLAA</strong>0135SE 40 55 120 625 0 125<br />

<strong>YLAA</strong>0150SE 40 55 120 625 0 125<br />

<strong>YLAA</strong>0155SE 40 55 150 625 0 125<br />

<strong>YLAA</strong>0170SE 40 55 120 625 0 125<br />

High Efficiency<br />

<strong>YLAA</strong>0091HE 40 55 100 385 0 125<br />

<strong>YLAA</strong>0101HE 40 55 100 385 0 125<br />

<strong>YLAA</strong>0125HE 40 55 100 385 0 125<br />

<strong>YLAA</strong>0141HE 40 55 150 625 0 125<br />

<strong>YLAA</strong>0156HE 40 55 120 625 0 125<br />

<strong>YLAA</strong>0175HE 40 55 180 650 0 125<br />

1. For leaving brine temperature below 40°F (4°C), contact your nearest Johnson Controls Office for application requirements.<br />

2. For leaving water temperature higher than 55°F (13°C), contact the nearest Johnson Controls Office for application guidelines. 3. The evaporator<br />

is protected against freezing to - 0°F (- 9°C) with an electric heater as standard.<br />

. For operation at temperatures below 0°F (-1°C), the optional Low Ambient Kit will need to be installed on the system (for <strong>YLAA</strong>00140080 models<br />

only).<br />

4. For operation at temperatures above 115°F (46°C), the optional High Ambient Kit will need to be installed on the system.<br />

10 jOHNSON CONTROLS

Water Pressure Drop<br />

100.0<br />

10.0<br />

jOHNSON CONTROLS<br />

<strong>YLAA</strong> Evaporator Pressure Drop (IP Units)<br />

A<br />

FORM 150.62-EG3 (409)<br />

1.0<br />

10 100 10<br />

Water Flow Rate (GPM)<br />

EvApORATOR yLAA MOdELs<br />

A 70SE<br />

B 80SE<br />

C 91HE, 100SE,101HE, 115SE, 1 5HE<br />

D 1 0SE, 141HE, 155SE<br />

E 90SE<br />

F 1 5SE, 150SE, 156HE, 170HE<br />

G 175HE<br />

C<br />

E<br />

G<br />

B<br />

D<br />

F<br />

11

Selection Criteria and Procedures<br />

GUidE TO sELECTiON<br />

Capacity ratings for yORK <strong>YLAA</strong> Packaged <strong>Air</strong>-<strong>Cooled</strong><br />

Liquid <strong>Chillers</strong>, shown on pages 18 through cover the<br />

majority of design applications for these units. For unusual<br />

applications or uses beyond the scope of this catalog,<br />

please consult your nearest Johnson Controls Office or<br />

representative.<br />

sELECTiON RULEs<br />

1. Ratings – Ratings may be interpolated, but must not<br />

be extrapolated. The Ratings given on pages 18 through<br />

and the DESIGN PARAMETERS given on page 10<br />

indicate the limits of application for these chillers.<br />

. Evaporator Water – Ratings are based upon .4 GPM<br />

per ton which is equal to a 10°F chilled water range and<br />

a 0.0001 fouling factor for the evaporator at sea level.<br />

Tables on pages 18 through give capacity, compressor<br />

kW required, evaporator GPM and unit EER.<br />

. Condenser – Ratings are given in terms of air on condenser<br />

in degrees Fahrenheit.<br />

4. Performance Data Correction Factors – Ratings are<br />

based on 0.0001 evaporator fouling factor, 10°F chilled<br />

water range and at sea level. For operation at different<br />

conditions, apply the appropriate correction factor from<br />

the following table.<br />

FOULiNG FACTOR<br />

ALTITUDE<br />

SEA LEVEL<br />

2000 FT.<br />

4000 FT.<br />

6000 FT.<br />

TEMP<br />

SPLIT<br />

TONS<br />

0.0001 0.00025<br />

COMPR<br />

kW<br />

TONS<br />

COMPR<br />

kW<br />

8 0.994 0.999 0.991 0.998<br />

10 1.000 1.000 0.993 0.999<br />

12 1.005 1.001 0.999 0.999<br />

14 1.008 1.002 1.005 1.000<br />

8 0.990 1.010 0.984 1.009<br />

10 0.995 1.010 0.990 1.009<br />

12 0.999 1.011 0.995 1.010<br />

14 1.004 1.015 0.998 1.011<br />

8 0.983 1.021 0.977 1.020<br />

10 0.989 1.024 0.983 1.021<br />

12 0.994 1.025 0.988 1.024<br />

14 0.997 1.026 0.993 1.025<br />

8 0.978 1.035 0.973 1.034<br />

10 0.982 1.037 0.978 1.035<br />

12 0.987 1.037 0.980 1.036<br />

14 0.992 1.038 0.986 1.037<br />

6. Ethylene Glycol Correction Factors – The following<br />

factors are to be applied to the standard ratings for units<br />

cooling ethylene glycol.<br />

ETHyLENE GLyCOL<br />

%<br />

WEiGHT<br />

TONs<br />

kW<br />

COMpR<br />

GpM°F/<br />

TON<br />

pREss<br />

dROp<br />

FREEZE<br />

pT<br />

10 0.985 0.997 24.1 1.034 26<br />

20 0.981 0.996 24.9 1.062 16<br />

30 0.974 0.995 26.1 1.096 5<br />

40 0.966 0.991 27.5 1.134 -10<br />

50 0.957 0.989 29.1 1.172 -32<br />

7. Propylene Glycol Correction Factors – The following<br />

factors are to be applied to the standard ratings for units<br />

cooling propylene glycol.<br />

pROpyLENE GLyCOL<br />

%<br />

WEiGHT<br />

1 jOHNSON CONTROLS<br />

TONs<br />

kW<br />

COMpR GpM°F/<br />

TON<br />

pREss<br />

dROp<br />

FREEZE<br />

pT<br />

10 0.983 0.996 24.2 1.048 27<br />

20 0.974 0.995 24.4 1.086 19<br />

30 0.961 0.990 25.1 1.134 8<br />

40 0.946 0.98 26.0 1.186 -5<br />

50 0.928 0.984 27.2 1.247 -25<br />

METHOD OF SELECTION<br />

To select a johnson Controls - <strong>YLAA</strong> Packaged <strong>Air</strong>-<strong>Cooled</strong><br />

Liquid Chiller, the following data must be known:<br />

1. Design Capacity in tons refrigeration (TR).<br />

. Entering and Leaving Liquid Temperatures.<br />

. Outside ambient air temperature in degrees F.<br />

4. GPM of chilled liquid.<br />

Determine capacity requirements from the following<br />

formula:<br />

EXAMpLE – WATER CHiLLiNG<br />

1. GIVEN: Provide a capacity of 90 Tons at 42°F<br />

leaving water 10°F range, 0.0001FF, 80°F air on<br />

the condenser, at sea level and 60 Hz.<br />

. FIND: Unit Size Compressor kW Input<br />

. From the Ratings on pages 18 - :<br />

sELECT: <strong>YLAA</strong>0090SE (English Units)<br />

91.4 Tons<br />

8 Compressor KW<br />

1 .4 Unit EER<br />

4. Calculate Compressor kW at 50 Tons:<br />

kW = (90-91.4) x 80.7 = 80.7 kW

5. Calculate GPM:<br />

jOHNSON CONTROLS<br />

90 Tons x 4<br />

GPM = 16 GPM<br />

10°F Range<br />

6. From Page 10, read 10 ft of water evaporator<br />

pressure drop for GPM:<br />

7. A <strong>YLAA</strong>0090 is suitable.<br />

EXAMpLE – bRiNE CHiLLiNG<br />

1. GivEN: Provide a capacity of 80 tons cooling<br />

0% by weight Ethylene Glycol from 50°F to 40°F,<br />

0.000 5FF, 95°F air on the condenser, 60 Hz and<br />

4000 altitude.<br />

. dETERMiNE:<br />

Unit Size kW Input<br />

Ethylene Glycol GPM Evaporator Pressure<br />

Drop<br />

. See Ethylene Glycol correction factors, for 0%<br />

by weight Ethylene Glycol.<br />

REAd: .974 Tons factor<br />

.995 Compr. kW factor 6.1 Gal./°F/Tons factor<br />

4. See Performance Data Correction Factors for<br />

0.000 5 fouling factor and 4000 ft. altitude.<br />

REAd: .98 Tons factor 1.0 1 kW factor<br />

5. From RATINGS on pages 18 - :<br />

sELECT: <strong>YLAA</strong>0090 (English Units)<br />

91.4 Tons 8 .0 Compressor kW<br />

FORM 150.62-EG3 (409)<br />

6. Determine <strong>YLAA</strong>0090 brine cooling capacity<br />

and Compressor kW requirement:<br />

A. Tons = 91.4 x .974 x .98 = 87.51<br />

B. Compr. kW = 8 .0 x .995 x 1.0 1 = 8 .<br />

Determine average full load Compressor kW at<br />

80 tons: (80/87.51) x 8 . = 76.15kW<br />

8. Determine Ethylene Glycol GPM:<br />

Tons x Gal. °F/min/Ton factor<br />

GPM = Range 80.0 x 6.1<br />

GPM = 10 GPM = 08.8<br />

9. Determine Evaporator Pressure Drop:<br />

A. See Ethylene Glycol correction factors for<br />

0% by weight Ethylene Glycol.<br />

READ: 1.096 Pressure Drop Factor<br />

B. See pages 18-19 at 88.7 GPM for the<br />

<strong>YLAA</strong>0090. READ: 6.8 Ft. H O Pressure<br />

Drop<br />

C. Evaporator Pressure Drop = 6.8 x 1.096 or<br />

7.5 Ft. H O<br />

10. <strong>YLAA</strong>0090 is suitable.<br />

1

Pump Selection Criteria<br />

pUMp sELECTiON<br />

Multiple pump sizes are available for each <strong>YLAA</strong> model<br />

providing the ability to closely match the system requirements.<br />

Within the YORKworks CE chiller selection program<br />

is an integral pump selection program that can be<br />

used for a quick and easy pump selection. Please contact<br />

your local johnson Controls sales rep for assistance with<br />

this selection program. If this program is not available or<br />

if a manual selection is desired, the following steps can<br />

be followed to make a pump selection for the hydro kit<br />

option.<br />

1. Determine whether a single pump or dual pump<br />

(standby) option is required.<br />

For this example, single pump hydro kits will be<br />

used.<br />

2. Determine the required flow (GPM). This value will<br />

be calculated with the chiller selection. Pump design<br />

flow must be within the limits of the chiller.<br />

ex. 100 Ton Chiller: 5 gpm (<strong>YLAA</strong><br />

0101HE) single pump option<br />

. Calculate the external system pressure loss (ft) for all<br />

piping and components external to the chiller.<br />

ex. 45 ft<br />

4. Determine the internal pressure loss to the chiller (ft)<br />

due to the evaporator from the Water Pressure Drop<br />

charts. Combine this with the external system pressure<br />

loss (ft) to determine the preliminary pressure<br />

loss.<br />

ex. Internal Pressure Loss due to evapora<br />

tor:1 ft (from chart on page 11)<br />

Preliminary pressure loss: 45 ft (exter<br />

nal) + 1 ft (evaporator) = 57 ft<br />

5. Review the available hydro kit options for the <strong>YLAA</strong><br />

model (See Table 1) selected using the Hydro Kit by<br />

<strong>Model</strong>s Chart. Use the flow and head calculated in<br />

steps and 4 to select a preliminary design point. If<br />

the preliminary design point does not fall directly on the<br />

curve, select the next step larger size of impeller.<br />

ex. Preliminary design point: 5 gpm/57<br />

ft<br />

Preliminary selection: Hydro Kit<br />

B/3x3x10@ 1740 rpm; 9.00 in impeller<br />

diameter with 7.5Hp motor.<br />

6. Using the Hydro Kit pressure loss charts found on<br />

page 16-17, determine the internal pressure loss to<br />

the chiller due to the hydro kit piping for the selected<br />

Hydro Kit. Add this to the preliminary pressure loss<br />

(from step 4) to determine the total pressure loss:<br />

ex. For Hydro Kit B on <strong>YLAA</strong>0101 unit, the<br />

hydro kit pressure loss is 15 ft.<br />

Total pressure loss = 57 ft + 15 ft = 7<br />

ft<br />

7. Check to see if the Hydro-Kit selection is valid. Using<br />

the total pressure loss (from step 6), plot the flow<br />

(GPM) and the total pressure loss on the hydro kit<br />

selected in step 5. If the pump selection is no longer<br />

adequate, re-select a hydro kit and go back to step<br />

6. (Note: if a design point does not fall directly on<br />

the curve, one can select the next step larger size of<br />

impeller and use the circuit balancing valve to adjust<br />

the system head requirements and correct for small<br />

variations from the selected pump curve.) If the pump<br />

selection is satisfactory, proceed to step 8.<br />

ex. Total Pressure Loss = 7 ft. with GPM = 5<br />

Selection is still valid for a Hydro-Kit B ( x x10,<br />

1800rpm, 9” impeller @ 7.5Hp)<br />

8. The pump efficiency can be read from the pump<br />

curve using the dashed efficiency lines labeled as a<br />

percentage.<br />

ex. Efficiency: 68 % (from pump curve)<br />

9. The pump is selected<br />

ex. Hydro Kit B at 68%<br />

10. The pump NPSHr required can also be read from the<br />

pump curves. When selecting a pump one must make<br />

sure that the system designed NPSHa available is<br />

greater than the NPSHr required by the pump plus<br />

the fluid vapor pressure.<br />

ex. NPSHr = 6 ft (From Pump Curve for<br />

Hydro Kit B)<br />

NPSHa = 0 ft (From System Design<br />

- Figure )<br />

VP = 0.4 ft (Water at 50ºF)<br />

NPSHr + VP < NPSHa<br />

6 ft + 0.4 ft < 30 ft<br />

If the system flow or pressure exceeds that of the hydro<br />

kit pump curves provided, an integral hydro kit is not<br />

available for your application and a separate pump must<br />

be provided.<br />

14 jOHNSON CONTROLS

TAbLE1 – HYDRO KIT OPTIONS<br />

jOHNSON CONTROLS<br />

FORM 150.62-EG3 (409)<br />

Kit Series Kit Type Pump Size Pump HP Motor RPM Impeller Dia (in)<br />

<strong>Model</strong>s Where Used<br />

A 4380 Single 3X3X8 5.0 1800 7.5 70,80,90,91<br />

B 4380 Single 3X3X10 7.5 1800 9.0 70,80,90,91,101<br />

C 4380 Single 3X3X10 10.0 1800 10.0 70,80,115,120,135<br />

D 4380 Single 3X3X6 15.0 3600 5.9 70,80,90,91,101,115,120,135<br />

E 4380 Single 3X3X8 20.0 3600 6.3 90,91,101,115,120,135<br />

F 4380 Single 3X3X8 7.5 1800 8.0 101,115,120,135<br />

G 4380 Single 4X4X8 10.0 1800 7.6 150,155<br />

H 4380 Single 4X4X6 10.0 3600 4.9 150,155<br />

I 4380 Single 4X4X6 15.0 3600 5.5 150,155<br />

J 4380 Single 4X4X6 20.0 3600 6.0 150,155<br />

K 4382 Dual 4X4X8 7.5 1800 7.9 70,80,90,91,101,115,120,135<br />

L 4382 Dual 4X4X6 10.0 3600 5.3 70,80,90,91,101,115,150,155<br />

M 4382 Dual 4X4X6 15.0 3600 5.6 70,80,90,91,120,135,150,155<br />

N 4382 Dual 3X3X8 15.0 3600 6.6 70,80,90,91,<br />

O 4382 Dual 4X4X6 15.0 3600 5.9 101,115,120,165<br />

P 4382 Dual 3X3X8 20.0 3600 7.2 101,115,120<br />

R 4382 Dual 4X4X8 20.0 3600 6.3 135,150,155<br />

15

Pump Pressure Drop Curves<br />

Pd (ft)<br />

Pd (ft)<br />

Pd (ft)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Hydro Kits A, B, C, D, N<br />

Hydro Kit N<br />

<strong>YLAA</strong>0070<br />

Hydro Kits K, L, M<br />

Flow (GPM)<br />

<strong>YLAA</strong>0080<br />

Hydro Kits K, L, M<br />

0 200 400 600<br />

Flow (GPM)<br />

Hydro Kits A, B, C, D<br />

<strong>YLAA</strong>0090<br />

Hydro Kits A,B,D,E,N<br />

Hydro Kits K, L, M<br />

0 200 400 600<br />

Flow (GPM)<br />

<strong>YLAA</strong>0091<br />

16 jOHNSON CONTROLS<br />

Pd (ft)<br />

Pd (ft)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Hydro Kits A,B,D,E,N<br />

0 200 400 600<br />

Hydro Kits B,D,E, F, P<br />

Flow (GPM)<br />

<strong>YLAA</strong>0101<br />

Hydro Kits K, L, M<br />

Hydro Kits K, L, O<br />

0 200 400 600<br />

Flow (GPM)

Pd (ft)<br />

Pd (ft)<br />

Pd (ft)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Hydro Kit P<br />

jOHNSON CONTROLS<br />

<strong>YLAA</strong>0115<br />

0 200 400 600<br />

Hydro Kit P<br />

Flow (GPM)<br />

<strong>YLAA</strong>0120<br />

Hydro Kits C,D,E, F<br />

Hydro Kits K, L, O<br />

Hydro Kits C,D,E, F, K, M, O<br />

0 200 400 600<br />

Flow (GPM)<br />

<strong>YLAA</strong>0135<br />

Hydro Kits C,D,E, F<br />

0 200 400 600<br />

Flow (GPM)<br />

Hydro Kit K,M,O,R<br />

Pd (ft)<br />

Pd (ft)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

<strong>YLAA</strong>0150<br />

Hydro Kits G,H,I,J,L,M,R<br />

FORM 150.62-EG3 (409)<br />

0 200 400 600<br />

Flow (GPM)<br />

<strong>YLAA</strong>0155<br />

Hydro Kits G,H,I,J,L,M,R<br />

0 100 200 300 400 500 600 700<br />

Flow (GPM)<br />

17

Single Pump Curves<br />

Kit D<br />

Kit A & F Kit E<br />

Kit B & C<br />

18 jOHNSON CONTROLS<br />

Kit G<br />

Kit N, I, & J

Dual Pump Curves<br />

jOHNSON CONTROLS<br />

Kit K<br />

FORM 150.62-EG3 (409)<br />

Kit L, M, & O Kit R<br />

Kit N & P<br />

19

Ratings - 60 Hz<br />

MODEL: <strong>YLAA</strong>0070SE<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

IPLV= 15.1<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 69.3 59.9 12.5 67.6 63.2 11.6 65.7 66.7 10.7 63.9 70.5 9.9 61.9 74.5 9.1 59.6 78.5 8.4<br />

42.0 71.6 60.5 12.8 69.8 63.8 11.9 67.9 67.3 11.0 65.9 71.1 10.2 63.9 75.1 9.4 61.5 79.1 8.6<br />

44.0 73.9 61.1 13.1 72.0 64.4 12.1 70.1 68.0 11.3 68.1 71.7 10.4 66.0 75.8 9.6 63.5 79.7 8.8<br />

45.0 75.0 61.4 13.2 73.1 64.7 12.3 71.2 68.3 11.4 69.1 72.1 10.5 67.0 76.1 9.7 64.5 80.1 8.9<br />

46.0 76.2 61.8 13.4 74.3 65.0 12.4 72.3 68.6 11.5 70.2 72.4 10.7 68.1 76.4 9.8 65.5 80.4 9.0<br />

48.0 78.6 62.4 13.6 76.6 65.7 12.7 74.5 69.2 11.8 72.4 73.0 10.9 70.2 77.1 10.1 67.6 81.0 9.2<br />

50.0 81.1 63.0 13.9 79.0 66.3 13.0 76.8 69.9 12.0 74.6 73.7 11.1 72.4 77.7 10.3 69.7 81.7 9.5<br />

MODEL: <strong>YLAA</strong>0080SE<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

IPLV= 15.1<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 76.8 66.3 12.6 74.7 70.0 11.7 72.6 74.0 10.8 70.5 78.2 10.0 68.2 82.8 9.2 65.6 87.3 8.4<br />

42.0 79.3 67.0 12.9 77.2 70.7 12.0 75.0 74.6 11.1 72.8 78.9 10.2 70.5 83.5 9.4 67.8 88.0 8.6<br />

44.0 81.8 67.7 13.2 79.6 71.4 12.2 77.4 75.4 11.3 75.1 79.6 10.4 72.8 84.2 9.6 70.0 88.7 8.8<br />

45.0 83.1 68.1 13.3 80.9 71.7 12.4 78.7 75.7 11.4 76.3 80.0 10.6 73.9 84.6 9.7 71.1 89.1 8.9<br />

46.0 84.4 68.4 13.5 82.2 72.1 12.5 79.9 76.1 11.6 77.5 80.4 10.7 75.1 84.9 9.8 72.2 89.4 9.0<br />

48.0 87.0 69.2 13.8 84.7 72.9 12.8 82.4 76.9 11.8 79.9 81.2 10.9 77.5 85.7 10.1 74.5 90.2 9.2<br />

50.0 89.7 70.0 14.0 87.3 73.7 13.0 84.9 77.7 12.1 82.4 81.9 11.2 79.9 86.5 10.3 76.8 91.0 9.4<br />

MODEL: <strong>YLAA</strong>0090SE<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

IPLV= 15.5<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 91.0 76.9 13.1 88.5 81.0 12.1 85.9 85.5 11.2 83.2 90.3 10.3 80.4 95.4 9.4 77.1 100.4 8.6<br />

42.0 94.0 77.8 13.3 91.4 82.0 12.4 88.7 86.5 11.4 85.9 91.3 10.5 83.1 96.4 9.7 79.7 101.4 8.8<br />

44.0 96.9 78.7 13.6 94.3 82.9 12.6 91.5 87.4 11.7 88.7 92.2 10.8 85.8 97.3 9.9 82.4 102.4 9.1<br />

45.0 98.4 79.2 13.7 95.7 83.4 12.7 92.9 87.9 11.8 90.1 92.7 10.9 87.2 97.8 10.0 83.7 102.9 9.2<br />

46.0 100.0 79.7 13.9 97.2 83.9 12.9 94.4 88.5 11.9 91.5 93.2 11.0 88.6 98.3 10.1 85.1 103.4 9.3<br />

48.0 103.0 80.7 14.1 100.2 84.9 13.1 97.3 89.5 12.1 94.3 94.3 11.2 91.4 99.4 10.3 87.7 104.4 9.5<br />

50.0 106.1 81.8 14.4 103.2 86.0 13.4 100.2 90.6 12.4 97.2 95.4 11.4 94.2 100.4 10.5 90.5 105.5 9.7<br />

MODEL: <strong>YLAA</strong>0091HE<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

IPLV= 14.9<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 92.4 70.1 13.8 90.0 73.8 12.9 87.6 77.8 12.0 85.2 82.1 11.1 82.6 86.8 10.2 79.5 91.5 9.4<br />

42.0 95.5 70.7 14.2 93.1 74.4 13.2 90.6 78.5 12.3 88.0 82.8 11.4 85.4 87.5 10.5 82.2 92.2 9.6<br />

44.0 98.6 71.4 14.5 96.1 75.2 13.5 93.6 79.2 12.6 90.9 83.5 11.7 88.2 88.2 10.8 84.9 92.9 9.9<br />

45.0 100.2 71.8 14.7 97.7 75.5 13.7 95.1 79.5 12.7 92.4 83.9 11.8 89.7 88.5 10.9 86.3 93.2 10.0<br />

46.0 101.8 72.2 14.9 99.2 75.9 13.9 96.6 79.9 12.9 93.9 84.2 11.9 91.1 88.9 11.0 87.7 93.6 10.2<br />

48.0 105.1 72.9 15.2 102.4 76.6 14.2 99.7 80.6 13.2 96.9 85.0 12.2 94.0 89.6 11.3 90.6 94.3 10.4<br />

50.0 108.4 73.7 15.5 105.6 77.4 14.5 102.8 81.4 13.5 100.0 85.8 12.5 97.0 90.4 11.6 93.4 95.1 10.7<br />

0 jOHNSON CONTROLS

MODEL: <strong>YLAA</strong>0070SE IPLV= 15.1<br />

LCWT (°F)<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

jOHNSON CONTROLS<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 57.1 82.6 7.7 54.6 87.0 7.0 52.0 91.6 6.4<br />

42.0 59.0 83.2 7.9 56.4 87.6 7.2 53.8 92.2 6.5<br />

44.0 60.9 83.9 8.1 58.3 88.3 7.4 55.5 92.9 6.7<br />

45.0 61.9 84.2 8.2 59.2 88.6 7.5 56.4 93.2 6.8<br />

46.0 62.9 84.5 8.3 60.2 88.9 7.5 57.3 93.6 6.9<br />

48.0 64.9 85.2 8.5 62.1 89.6 7.7 59.2 94.2 7.0<br />

50.0 66.9 85.9 8.7 64.0 90.3 7.9 61.0 94.9 7.2<br />

MODEL: <strong>YLAA</strong>0080SE IPLV= 15.1<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 62.9 92.0 7.6 60.1 96.9 7.0 48.9 80.4 6.7<br />

42.0 65.0 92.7 7.8 62.1 97.7 7.1 50.6 80.9 6.9<br />

44.0 67.1 93.4 8.0 64.1 98.4 7.3 52.3 81.4 7.1<br />

45.0 68.2 93.8 8.1 65.2 98.8 7.4 53.2 81.7 7.2<br />

46.0 69.2 94.2 8.2 66.2 99.2 7.5 54.1 82.0 7.3<br />

48.0 71.4 95.0 8.4 68.3 100.0 7.7 55.9 82.6 7.5<br />

50.0 73.7 95.8 8.6 70.5 100.8 7.9 57.8 83.2 7.7<br />

MODEL: <strong>YLAA</strong>0090SE IPLV= 15.5<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 73.8 105.7 7.9 70.4 111.2 7.2 48.8 72.0 7.4<br />

42.0 76.3 106.7 8.1 72.8 112.2 7.3 50.6 72.5 7.7<br />

44.0 78.8 107.7 8.3 75.3 113.2 7.5 52.4 73.0 7.9<br />

45.0 80.1 108.2 8.4 76.5 113.7 7.6 53.3 73.3 8.0<br />

46.0 81.4 108.7 8.5 77.7 114.3 7.7 54.2 73.5 8.1<br />

48.0 84.1 109.8 8.7 80.3 115.3 7.9 56.0 74.1 8.3<br />

50.0 86.7 110.9 8.8 71.9 93.6 8.6 57.9 74.7 8.5<br />

MODEL: <strong>YLAA</strong>0091HE IPLV= 14.9<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 76.3 96.4 8.6 73.1 101.5 7.9 69.8 107.0 7.2<br />

42.0 78.9 97.1 8.8 75.6 102.2 8.1 72.2 107.7 7.4<br />

44.0 81.6 97.8 9.1 78.2 103.0 8.3 74.7 108.4 7.6<br />

45.0 82.9 98.1 9.2 79.5 103.3 8.4 76.0 108.8 7.7<br />

46.0 84.3 98.5 9.3 80.8 103.7 8.5 77.2 109.2 7.8<br />

48.0 87.0 99.2 9.6 83.4 104.4 8.7 79.8 109.9 8.0<br />

50.0 89.8 100.0 9.8 86.1 105.2 9.0 82.4 110.7 8.2<br />

FORM 150.62-EG3 (409)<br />

1

Ratings - 60 Hz - continued<br />

MODEL: <strong>YLAA</strong>0100SE IPLV= 14.3<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 101.0 87.5 12.6 98.3 92.2 11.7 95.6 97.4 10.8 92.7 102.9 10.0 89.8 108.8 9.2 86.3 114.6 8.4<br />

42.0 104.3 88.4 12.9 101.5 93.2 12.0 98.7 98.3 11.1 95.8 103.8 10.2 92.8 109.7 9.4 89.2 115.6 8.6<br />

44.0 107.6 89.3 13.2 104.7 94.2 12.3 101.8 99.3 11.3 98.9 104.8 10.5 95.8 110.7 9.6 92.1 116.5 8.8<br />

45.0 109.3 89.8 13.3 106.4 94.7 12.4 103.4 99.8 11.5 100.4 105.3 10.6 97.3 111.2 9.8 93.6 117.1 9.0<br />

46.0 111.0 90.3 13.5 108.0 95.2 12.5 105.1 100.3 11.6 102.0 105.8 10.7 98.8 111.7 9.9 95.1 117.6 9.1<br />

48.0 114.4 91.4 13.8 111.4 96.2 12.8 108.3 101.3 11.8 105.2 106.9 10.9 101.9 112.8 10.1 98.1 118.6 9.3<br />

50.0 117.9 92.5 14.0 114.8 97.3 13.0 111.7 102.4 12.1 108.4 108.0 11.2 105.1 113.9 10.3 101.1 119.7 9.5<br />

MODEL: <strong>YLAA</strong>0101HE IPLV= 15.4<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 103.5 83.9 13.2 100.8 88.5 12.3 98.1 93.4 11.4 95.2 98.7 10.5 92.3 104.4 9.7 88.8 110.0 8.9<br />

42.0 106.9 84.7 13.5 104.1 89.3 12.6 101.3 94.2 11.7 98.4 99.6 10.8 95.4 105.2 9.9 91.8 110.9 9.1<br />

44.0 110.3 85.6 13.8 107.5 90.2 12.9 104.6 95.1 11.9 101.6 100.4 11.0 98.5 106.1 10.2 94.8 111.8 9.3<br />

45.0 112.1 86.0 14.0 109.2 90.6 13.0 106.3 95.5 12.1 103.2 100.9 11.2 100.1 106.6 10.3 96.3 112.2 9.5<br />

46.0 113.8 86.5 14.1 110.9 91.1 13.2 107.9 96.0 12.2 104.8 101.3 11.3 101.7 107.0 10.4 97.9 112.7 9.6<br />

48.0 117.4 87.4 14.5 114.4 92.0 13.4 111.3 97.0 12.5 108.2 102.3 11.6 104.9 108.0 10.7 101.0 113.6 9.8<br />

50.0 121.1 88.4 14.8 118.0 93.0 13.7 114.8 98.0 12.7 111.5 103.3 11.8 108.2 109.0 10.9 104.2 114.6 10.0<br />

MODEL: <strong>YLAA</strong>0115SE IPLV= 14.6<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 120.1 104.1 12.6 117.0 109.6 11.7 113.7 115.6 10.9 110.4 122.0 10.0 106.9 128.7 9.2 102.8 135.3 8.5<br />

42.0 123.9 105.3 12.9 120.7 110.9 12.0 117.4 116.8 11.1 113.9 123.2 10.3 110.4 129.9 9.5 106.2 136.5 8.7<br />

44.0 127.9 106.5 13.2 124.5 112.1 12.2 121.1 118.0 11.3 117.6 124.4 10.5 113.9 131.1 9.7 109.6 137.8 8.9<br />

45.0 129.9 107.1 13.3 126.5 112.7 12.4 123.0 118.6 11.5 119.4 125.0 10.6 115.7 131.8 9.8 111.3 138.4 9.0<br />

46.0 131.8 107.7 13.4 128.4 113.3 12.5 124.9 119.3 11.6 121.2 125.7 10.7 117.5 132.4 9.9 113.0 139.1 9.1<br />

48.0 135.9 108.9 13.7 132.3 114.6 12.7 128.7 120.5 11.8 124.9 127.0 10.9 121.1 133.7 10.1 116.5 140.4 9.3<br />

50.0 140.0 110.2 14.0 136.3 115.9 13.0 132.6 121.9 12.1 128.7 128.3 11.2 124.8 135.1 10.3 120.0 141.8 9.5<br />

MODEL: <strong>YLAA</strong>0120SE IPLV= 14.8<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 126.7 106.1 13.1 123.2 111.7 12.1 119.7 117.5 11.3 116.0 123.9 10.4 112.3 130.5 9.6 107.8 137.1 8.8<br />

42.0 130.8 107.3 13.4 127.2 112.9 12.4 123.6 118.8 11.5 119.8 125.2 10.6 115.9 131.9 9.8 111.4 138.4 9.0<br />

44.0 135.0 108.6 13.6 131.3 114.2 12.7 127.5 120.1 11.8 123.6 126.5 10.9 119.7 133.2 10.0 115.0 139.8 9.2<br />

45.0 137.1 109.3 13.8 133.3 114.9 12.8 129.5 120.8 11.9 125.6 127.2 11.0 121.5 133.9 10.1 116.8 140.5 9.3<br />

46.0 139.2 110.0 13.9 135.4 115.6 12.9 131.5 121.5 12.0 127.5 127.9 11.1 123.4 134.6 10.2 118.6 141.2 9.4<br />

48.0 143.4 111.3 14.2 139.5 117.0 13.2 135.6 122.9 12.2 131.4 129.3 11.3 127.3 136.0 10.5 122.3 142.6 9.6<br />

50.0 147.7 112.7 14.4 143.7 118.4 13.4 139.6 124.5 12.4 135.4 130.8 11.5 131.1 137.5 10.7 126.0 144.1 9.8<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

jOHNSON CONTROLS

MODEL: <strong>YLAA</strong>0100SE IPLV= 14.3<br />

LCWT (°F)<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

jOHNSON CONTROLS<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 82.8 120.7 7.7 79.2 127.2 7.0 75.5 133.9 6.4<br />

42.0 85.6 121.7 7.9 81.8 128.2 7.2 78.1 134.9 6.5<br />

44.0 88.4 122.7 8.1 84.5 129.2 7.4 80.7 135.9 6.7<br />

45.0 89.8 123.2 8.2 85.9 129.7 7.5 62.0 91.9 7.4<br />

46.0 91.2 123.7 8.3 87.3 130.2 7.6 53.3 70.2 8.1<br />

48.0 94.1 124.8 8.5 90.1 131.3 7.7 55.2 70.6 8.4<br />

50.0 97.0 125.9 8.7 92.9 132.4 7.9 57.1 71.1 8.6<br />

MODEL: <strong>YLAA</strong>0101HE IPLV= 15.4<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 85.3 115.9 8.1 81.7 122.1 7.4 68.9 106.7 7.1<br />

42.0 88.1 116.8 8.3 84.4 123.0 7.6 71.3 107.3 7.3<br />

44.0 91.1 117.7 8.6 87.2 123.9 7.8 73.8 108.1 7.5<br />

45.0 92.5 118.1 8.7 88.6 124.4 7.9 75.1 108.4 7.6<br />

46.0 94.0 118.6 8.8 90.1 124.9 8.0 76.3 108.8 7.7<br />

48.0 97.0 119.6 9.0 93.0 125.8 8.2 78.9 109.5 7.9<br />

50.0 100.1 120.6 9.2 95.9 126.9 8.4 58.3 69.4 8.8<br />

MODEL: <strong>YLAA</strong>0115SE IPLV= 14.6<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 98.6 142.2 7.8 94.3 149.5 7.1 89.9 157.2 6.4<br />

42.0 101.8 143.5 8.0 97.4 150.8 7.3 92.9 158.4 6.6<br />

44.0 105.1 144.8 8.1 100.6 152.1 7.4 95.9 159.7 6.8<br />

45.0 106.8 145.4 8.2 102.2 152.7 7.5 56.5 71.0 8.4<br />

46.0 108.5 146.1 8.3 103.8 153.4 7.6 57.5 71.3 8.5<br />

48.0 111.8 147.4 8.5 107.0 154.7 7.8 59.5 71.7 8.7<br />

50.0 115.2 148.8 8.7 110.3 156.1 8.0 61.6 72.2 9.0<br />

MODEL: <strong>YLAA</strong>0120SE IPLV= 14.8<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 103.3 144.0 8.0 98.6 151.2 7.3 93.8 158.8 6.7<br />

42.0 106.7 145.4 8.2 101.9 152.6 7.5 54.8 70.6 8.1<br />

44.0 110.2 146.7 8.4 105.3 154.0 7.7 56.8 71.1 8.4<br />

45.0 111.9 147.4 8.5 107.0 154.7 7.8 57.8 71.3 8.5<br />

46.0 113.7 148.1 8.6 108.6 155.4 7.9 58.8 71.6 8.6<br />

48.0 117.2 149.6 8.8 112.1 156.9 8.1 60.9 72.1 8.9<br />

50.0 120.8 151.1 9.0 115.5 158.4 8.2 63.0 72.6 9.1<br />

FORM 150.62-EG3 (409)

Ratings - 60 Hz - continued<br />

MODEL: <strong>YLAA</strong>0125HE IPLV= 14.9<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 122.3 96.0 13.4 119.3 101.1 12.5 116.2 106.6 11.6 113.0 112.4 10.8 109.6 118.7 10.0 105.5 125.0 9.2<br />

42.0 126.4 96.9 13.7 123.2 102.0 12.8 120.0 107.5 11.9 116.7 113.4 11.0 113.3 119.6 10.2 109.1 125.9 9.4<br />

44.0 130.5 97.9 14.1 127.3 103.0 13.1 123.9 108.5 12.2 120.5 114.3 11.3 117.0 120.6 10.5 112.7 126.9 9.6<br />

45.0 132.6 98.3 14.2 129.3 103.5 13.3 125.9 108.9 12.3 122.4 114.8 11.5 118.8 121.1 10.6 114.5 127.4 9.8<br />

46.0 134.7 98.8 14.4 131.3 104.0 13.4 127.9 109.4 12.5 124.4 115.3 11.6 120.7 121.6 10.7 116.3 127.9 9.9<br />

48.0 138.9 99.8 14.7 135.5 105.0 13.7 132.0 110.5 12.8 128.3 116.4 11.9 124.6 122.7 11.0 120.0 129.0 10.1<br />

50.0 143.2 100.9 15.0 139.7 106.0 14.0 136.1 111.5 13.1 132.3 117.4 12.1 128.4 123.8 11.2 123.8 130.1 10.4<br />

MODEL: <strong>YLAA</strong>0135SE IPLV= 15.4<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 133.9 112.1 12.8 130.4 118.1 11.9 126.8 124.4 11.0 123.1 131.3 10.2 119.3 138.6 9.4 114.8 145.7 8.7<br />

42.0 138.2 113.3 13.1 134.6 119.3 12.2 131.0 125.6 11.3 127.2 132.5 10.5 123.2 139.8 9.7 118.6 147.0 8.9<br />

44.0 142.7 114.5 13.4 139.0 120.5 12.5 135.2 126.9 11.6 131.3 133.8 10.7 127.3 141.1 9.9 122.5 148.2 9.1<br />

45.0 144.9 115.1 13.5 141.2 121.1 12.6 137.3 127.5 11.7 133.4 134.4 10.8 129.3 141.7 10.0 124.4 148.9 9.2<br />

46.0 147.2 115.8 13.7 143.4 121.8 12.7 139.5 128.2 11.8 135.5 135.1 10.9 131.3 142.3 10.1 126.4 149.6 9.3<br />

48.0 151.8 117.1 14.0 147.8 123.1 13.0 143.9 129.5 12.1 139.7 136.4 11.2 135.5 143.7 10.3 130.4 150.9 9.5<br />

50.0 156.4 118.4 14.2 152.4 124.5 13.3 148.2 131.0 12.3 144.0 137.8 11.4 139.7 145.1 10.6 134.4 152.3 9.7<br />

MODEL: <strong>YLAA</strong>0141HE IPLV= 14.4<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 137.9 110.7 13.3 134.3 116.5 12.4 130.5 122.7 11.5 126.8 129.3 10.7 122.8 136.5 9.8 118.0 143.7 9.0<br />

42.0 142.4 111.8 13.6 138.7 117.6 12.7 134.9 123.9 11.8 130.9 130.6 10.9 126.9 137.7 10.1 122.0 144.9 9.2<br />

44.0 147.0 113.0 14.0 143.2 118.9 13.0 139.3 125.1 12.1 135.2 131.9 11.2 131.1 139.0 10.3 126.1 146.1 9.5<br />

45.0 148.3 113.4 14.0 145.5 119.5 13.1 141.5 125.8 12.2 137.4 132.5 11.3 133.2 139.6 10.4 128.1 146.8 9.6<br />

46.0 151.7 114.3 14.3 146.9 119.9 13.2 143.8 126.4 12.3 139.6 133.2 11.4 135.3 140.3 10.6 130.2 147.4 9.7<br />

48.0 156.5 115.6 14.6 152.4 121.4 13.6 148.1 127.7 12.6 144.0 134.5 11.7 139.6 141.6 10.8 134.3 148.8 9.9<br />

50.0 161.2 116.9 14.8 157.1 122.8 13.8 152.9 129.1 12.9 148.5 135.9 11.9 144.0 143.0 11.0 138.5 150.1 10.2<br />

MODEL: <strong>YLAA</strong>0150SE IPLV= 15.2<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 147.8 128.1 12.5 144.0 135.0 11.6 140.0 142.3 10.8 135.9 150.1 10.0 131.7 158.4 9.2 126.7 166.5 8.4<br />

42.0 152.6 129.5 12.8 148.6 136.4 11.9 144.6 143.7 11.0 140.3 151.5 10.2 136.0 159.8 9.4 130.8 168.0 8.7<br />

44.0 157.4 130.9 13.1 153.3 137.8 12.2 149.2 145.1 11.3 144.8 153.0 10.4 140.4 161.3 9.6 135.0 169.5 8.9<br />

45.0 159.9 131.6 13.2 155.7 138.5 12.3 151.5 145.9 11.4 147.1 153.7 10.6 142.6 162.0 9.7 137.2 170.3 9.0<br />

46.0 162.4 132.3 13.4 158.1 139.3 12.4 153.8 146.6 11.5 149.4 154.5 10.7 144.8 162.8 9.9 139.3 171.1 9.1<br />

48.0 167.3 133.8 13.6 163.0 140.8 12.7 158.5 148.2 11.8 154.0 156.0 10.9 149.2 164.4 10.1 143.6 172.6 9.3<br />

50.0 172.4 135.4 13.9 167.9 142.4 12.9 163.3 149.8 12.0 158.6 157.7 11.1 153.8 166.0 10.3 148.0 174.3 9.5<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

4 jOHNSON CONTROLS

MODEL: <strong>YLAA</strong>0125HE IPLV= 14.9<br />

LCWT (°F)<br />

NOTES:<br />

1. kW = Compressor Input Power<br />

. EER = Chiller EER (includes power from compressors, fans, and the control panels 0.8 kW)<br />

. LCWT = Leaving Chilled Water Temperature<br />

4. Ratings are based upon .4 GPM evaporator water per ton and 0.0001 fouling factor<br />

5. Rated in accordance with ARI Standard 550/590<br />

6. The shaded points are certified in accordance with ARI Standard 550/590-98<br />

jOHNSON CONTROLS<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 101.5 131.5 8.4 97.2 138.4 7.7 92.9 145.7 7.0<br />

42.0 104.9 132.5 8.6 100.5 139.4 7.9 96.1 146.7 7.2<br />

44.0 108.3 133.5 8.8 103.9 140.4 8.1 99.3 147.7 7.4<br />

45.0 110.1 134.0 9.0 105.6 140.9 8.2 100.9 148.2 7.5<br />

46.0 111.9 134.5 9.1 107.3 141.4 8.3 102.6 148.7 7.6<br />

48.0 115.4 135.6 9.3 110.7 142.5 8.5 105.9 149.8 7.8<br />

50.0 119.1 136.6 9.5 114.2 143.6 8.7 109.3 150.9 8.0<br />

MODEL: <strong>YLAA</strong>0135SE IPLV= 15.4<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 110.1 153.3 7.9 105.3 161.3 7.2 84.3 124.1 7.4<br />

42.0 113.8 154.6 8.1 108.9 162.6 7.4 87.3 125.0 7.6<br />

44.0 117.5 155.9 8.3 112.5 163.9 7.6 90.3 125.8 7.8<br />

45.0 119.4 156.5 8.4 114.3 164.5 7.7 91.8 126.2 7.9<br />

46.0 121.3 157.2 8.5 116.2 165.2 7.8 93.4 126.6 8.0<br />

48.0 125.2 158.6 8.7 119.9 166.6 8.0 96.5 127.5 8.2<br />

50.0 129.1 160.0 8.9 123.6 168.0 8.2 99.6 128.4 8.4<br />

MODEL: <strong>YLAA</strong>0141HE IPLV= 14.4<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 113.2 151.1 8.3 108.3 159.0 7.5 103.3 167.2 6.9<br />

42.0 117.1 152.3 8.5 112.0 160.2 7.7 106.9 168.5 7.1<br />

44.0 121.0 153.6 8.7 115.8 161.5 7.9 110.5 169.8 7.2<br />

45.0 123.0 154.3 8.8 117.7 162.1 8.0 112.3 170.4 7.3<br />

46.0 125.0 154.9 8.9 119.6 162.8 8.1 114.2 171.1 7.4<br />

48.0 129.0 156.3 9.1 123.5 164.1 8.3 97.7 127.4 8.3<br />

50.0 133.0 157.6 9.3 127.4 165.5 8.5 100.9 128.3 8.5<br />

MODEL: <strong>YLAA</strong>0150SE IPLV= 15.2<br />

LCWT (°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

105.0 110.0 115.0<br />

TONS KW EER TONS KW EER TONS KW EER<br />

40.0 121.5 175.2 7.7 116.2 184.2 7.1 94.6 147.5 7.1<br />

42.0 125.5 176.6 7.9 120.1 185.7 7.2 97.9 148.5 7.3<br />

44.0 129.6 178.1 8.1 124.0 187.2 7.4 101.2 149.6 7.4<br />

45.0 131.6 178.9 8.2 126.0 188.0 7.5 102.8 150.1 7.5<br />

46.0 133.7 179.7 8.3 128.0 188.8 7.6 104.5 150.7 7.6<br />

48.0 137.9 181.3 8.5 132.0 190.4 7.8 107.9 151.8 7.8<br />

50.0 142.1 182.9 8.7 136.1 192.0 7.9 111.4 153.0 8.0<br />

FORM 150.62-EG3 (409)<br />

5

Ratings - 60 Hz - continued<br />

MODEL: <strong>YLAA</strong>0155SE IPLV= 15.1<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 151.2 129.4 12.7 147.2 136.2 11.8 143.1 143.5 10.9 138.8 151.3 10.1 134.4 159.5 9.3 129.2 167.7 8.6<br />

42.0 156.1 130.8 13.0 152.0 137.7 12.1 147.7 144.9 11.2 143.3 152.8 10.3 138.8 161.0 9.5 133.4 169.2 8.8<br />

44.0 161.1 132.3 13.3 156.8 139.2 12.3 152.5 146.5 11.4 147.9 154.3 10.6 143.3 162.5 9.8 137.7 170.8 9.0<br />

45.0 163.6 133.0 13.4 159.3 139.9 12.5 154.8 147.2 11.6 150.2 155.1 10.7 145.5 163.3 9.9 139.9 171.5 9.1<br />

46.0 166.1 133.8 13.5 161.7 140.7 12.6 157.2 148.0 11.7 152.6 155.9 10.8 147.8 164.1 10.0 142.1 172.4 9.2<br />

48.0 171.2 135.3 13.8 166.7 142.3 12.8 162.0 149.7 11.9 157.3 157.5 11.0 152.4 165.8 10.2 146.4 174.0 9.4<br />

50.0 172.7 136.0 13.9 171.7 143.9 13.1 166.9 151.4 12.2 162.0 159.2 11.3 157.0 167.5 10.4 151.0 175.7 9.6<br />

MODEL: <strong>YLAA</strong>0156HE IPLV= 15.5<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 152.1 119.7 13.4 148.4 126.0 12.5 144.5 132.8 11.6 140.5 140.1 10.7 136.4 147.9 9.9 131.3 155.7 9.1<br />

42.0 157.1 120.8 13.7 153.3 127.1 12.8 149.3 134.0 11.9 145.2 141.3 11.0 140.9 149.1 10.2 135.7 156.9 9.4<br />

44.0 162.2 122.0 14.0 158.3 128.3 13.1 154.2 135.2 12.2 149.9 142.5 11.3 145.5 150.3 10.4 140.2 158.2 9.6<br />

45.0 164.8 122.6 14.2 160.8 129.0 13.2 156.6 135.8 12.3 152.3 143.1 11.4 147.9 151.0 10.6 142.4 158.8 9.7<br />

46.0 167.4 123.2 14.4 163.3 129.6 13.4 159.1 136.4 12.5 154.7 143.7 11.6 150.2 151.6 10.7 144.7 159.4 9.9<br />

48.0 172.7 124.5 14.7 168.5 130.9 13.7 164.1 137.7 12.7 159.6 145.0 11.8 155.0 152.9 11.0 149.3 160.8 10.1<br />

50.0 178.0 125.7 15.0 173.7 132.1 14.0 169.2 139.0 13.0 164.6 146.4 12.1 159.8 154.2 11.2 154.0 162.1 10.3<br />

MODEL: <strong>YLAA</strong>0170SE IPLV= 15.1<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 176.1 148.9 12.8 171.7 157.0 11.9 167.1 165.6 11.0 162.4 174.7 10.2 157.5 184.5 9.4 151.6 194.2 8.6<br />

42.0 181.8 150.5 13.0 177.3 158.5 12.1 172.6 167.1 11.3 167.7 176.3 10.4 162.6 186.1 9.6 156.6 195.8 8.8<br />

44.0 187.5 152.1 13.3 182.9 160.0 12.4 178.1 168.7 11.5 173.0 177.9 10.7 167.8 187.7 9.8 161.6 197.5 9.1<br />

45.0 190.5 152.9 13.5 185.8 160.8 12.6 180.9 169.5 11.6 175.8 178.7 10.8 170.5 188.6 10.0 164.2 198.3 9.2<br />

46.0 193.4 153.7 13.6 188.7 161.7 12.7 183.7 170.3 11.8 178.5 179.6 10.9 173.1 189.4 10.1 166.7 199.2 9.3<br />

48.0 199.3 155.3 13.9 194.5 163.3 13.0 189.3 172.0 12.0 184.0 181.3 11.1 178.5 191.2 10.3 172.0 200.9 9.5<br />

50.0 205.4 157.0 14.2 200.4 165.0 13.2 195.1 173.7 12.3 189.6 183.1 11.4 184.0 192.9 10.5 177.2 202.7 9.7<br />

MODEL: <strong>YLAA</strong>0175HE IPLV= 15.1<br />

LCWT<br />

(°F)<br />

AIR TEMPERATURE ON - CONDENSER (°F)<br />

75.0 80.0 85.0 90.0 95.0 100.0<br />

TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER<br />

40.0 183.4 151.1 13.1 178.7 159.1 12.2 173.8 167.6 11.3 168.7 176.8 10.5 163.4 186.5 9.6 157.1 196.1 8.9<br />