Rexroth IndraDrive C Drive Controllers HCS02.1 ... - Bosch Rexroth

Rexroth IndraDrive C Drive Controllers HCS02.1 ... - Bosch Rexroth

Rexroth IndraDrive C Drive Controllers HCS02.1 ... - Bosch Rexroth

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Electric <strong>Drive</strong>s<br />

Linear Motion and<br />

and Controls Hydraulics<br />

Assembly Technologies Pneumatics Service<br />

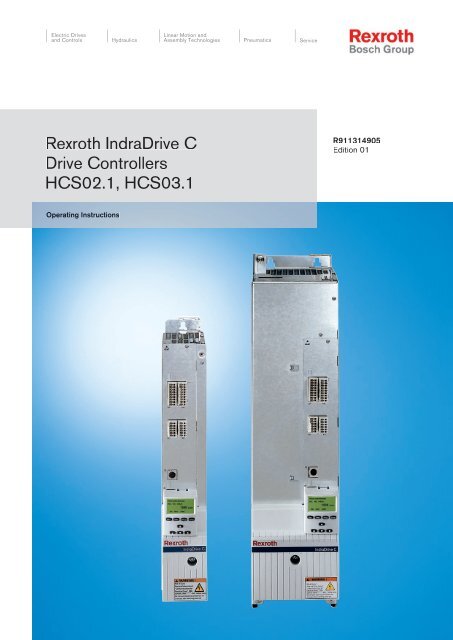

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> C<br />

<strong>Drive</strong> <strong>Controllers</strong><br />

<strong>HCS02.1</strong>, HCS03.1<br />

Operating Instructions<br />

R911314905<br />

Edition 01

About this Documentation <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Title<br />

Type of Documentation<br />

Document Typecode<br />

Internal File Reference<br />

Purpose of Documentation<br />

Record of Revisions<br />

Copyright<br />

Validity<br />

Published by<br />

Note<br />

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> C<br />

<strong>Drive</strong> <strong>Controllers</strong><br />

<strong>HCS02.1</strong>, HCS03.1<br />

Operating Instructions<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Document Number, 120-2400-B327-01/EN; Mat. No.: R911314905<br />

This documentation describes the mounting, installation, commissioning,<br />

parameterization and troubleshooting of <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> controllers on<br />

the basis of the power sections HCS02 or HCS03 and the control sections<br />

BASIC OPENLOOP or BASIC PROFIBUS with comfort control panel.<br />

Description Release<br />

Date<br />

Notes<br />

DOK-INDRV*-FU*********-IB01-EN-P 06-2006 First Release<br />

© <strong>Bosch</strong> <strong>Rexroth</strong> AG 2006<br />

Copying this document, giving it to others and the use or communication<br />

of the contents thereof without express authority, are forbidden. Offenders<br />

are liable for the payment of damages. All rights are reserved in the event<br />

of the grant of a patent or the registration of a utility model or design<br />

(DIN 34-1).<br />

The data specified above only serve to describe the product. No<br />

statements concerning a certain condition or suitability for a certain<br />

application can be derived from our information. The given information<br />

does not release the user from the obligation of own judgement and<br />

verification. It must be remembered that our products are subject to a<br />

natural process of wear and aging.<br />

<strong>Bosch</strong> <strong>Rexroth</strong> AG<br />

Bgm.-Dr.-Nebel-Str. 2 • D-97816 Lohr a. Main<br />

Telephone +49 (0)93 52/40-0 • Tx 68 94 21 • Fax +49 (0)93 52/40-48 85<br />

http://www.boschrexroth.de/<br />

Dept. EDY1 (RR/US/BB)<br />

This document has been printed on chlorine-free bleached paper.<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Contents I<br />

Contents<br />

1 Introducing the Products 1-1<br />

1.1 Introduction ................................................................................................................................... 1-1<br />

Terms, Basic Principles ........................................................................................................... 1-1<br />

1.2 <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Hardware Platform ........................................................................................ 1-6<br />

<strong>Drive</strong> <strong>Controllers</strong>...................................................................................................................... 1-6<br />

Motors and Measuring Systems.............................................................................................. 1-7<br />

Master Communication............................................................................................................ 1-8<br />

1.3 <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Firmware Platform ......................................................................................... 1-8<br />

Type Code ............................................................................................................................... 1-8<br />

Functions Overview ................................................................................................................. 1-9<br />

1.4 <strong>Rexroth</strong> IndraDyn Motors............................................................................................................ 1-12<br />

Housing Motors...................................................................................................................... 1-12<br />

Kit Motors............................................................................................................................... 1-12<br />

1.5 Third-Party Motors at <strong>Indra<strong>Drive</strong></strong> <strong>Controllers</strong>.............................................................................. 1-13<br />

General Information on Third-Party Motors........................................................................... 1-13<br />

Requirements on Third-Party Motors .................................................................................... 1-14<br />

Requirements on the Encoder of the Third-Party Motor ....................................................... 1-17<br />

Notes on Selection and Commissioning................................................................................ 1-17<br />

1.6 Approval, Listing ......................................................................................................................... 1-18<br />

Conformities........................................................................................................................... 1-18<br />

C-UL-US-Listing..................................................................................................................... 1-18<br />

2 Important Directions for Use 2-1<br />

2.1 Appropriate Use............................................................................................................................ 2-1<br />

Introduction .............................................................................................................................. 2-1<br />

Areas of Use and Application .................................................................................................. 2-2<br />

2.2 Inappropriate Use ......................................................................................................................... 2-2<br />

3 Safety Instructions for Electric <strong>Drive</strong>s and Controls 3-1<br />

3.1 General Information ...................................................................................................................... 3-1<br />

Using the Safety Instructions and Passing them on to Others................................................ 3-1<br />

Instructions for Use.................................................................................................................. 3-1<br />

Explanation of Warning Symbols and Degrees of Hazard Seriousness ................................. 3-3<br />

Hazards by Improper Use........................................................................................................ 3-4<br />

3.2 Instructions with Regard to Specific Dangers............................................................................... 3-5<br />

Protection Against Contact with Electrical Parts ..................................................................... 3-5<br />

Protection Against Electric Shock by Protective Low Voltage (PELV) .................................... 3-6<br />

Protection Against Dangerous Movements ............................................................................. 3-7<br />

DOK-INDRV*-FU*********-IB01-EN-P

II Contents <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Protection Against Magnetic and Electromagnetic Fields During Operation and<br />

Mounting .................................................................................................................................. 3-9<br />

Protection Against Contact with Hot Parts ............................................................................ 3-10<br />

Protection During Handling and Mounting............................................................................. 3-11<br />

Battery Safety ........................................................................................................................ 3-11<br />

Protection Against Pressurized Systems .............................................................................. 3-12<br />

4 Identification, Transport, Storage, Installation Conditions 4-1<br />

4.1 Identification.................................................................................................................................. 4-1<br />

Type Code ............................................................................................................................... 4-1<br />

Type Plates.............................................................................................................................. 4-4<br />

4.2 Transport and Storage.................................................................................................................. 4-6<br />

Transport of the Devices ......................................................................................................... 4-6<br />

Storage of the Devices ............................................................................................................ 4-6<br />

4.3 Installation Conditions................................................................................................................... 4-7<br />

Ambient and Operating Conditions.......................................................................................... 4-7<br />

Compatibility with Foreign Matters .......................................................................................... 4-9<br />

5 Electrical Data 5-1<br />

5.1 Power Sections............................................................................................................................. 5-1<br />

Type Current and Connected Load ......................................................................................... 5-1<br />

Control Voltage Supply............................................................................................................ 5-2<br />

Power Voltage Supply- Mains Connection .............................................................................. 5-3<br />

Limited Length of Motor Power Cables ................................................................................... 5-4<br />

5.2 Control Sections ........................................................................................................................... 5-6<br />

Relay Contact Type 1 .............................................................................................................. 5-6<br />

Relay Contact Type 2 .............................................................................................................. 5-6<br />

Relay Contact Type 3 .............................................................................................................. 5-7<br />

Digital Inputs/Outputs .............................................................................................................. 5-7<br />

Analog Inputs/Outputs ............................................................................................................. 5-9<br />

5.3 Additional Components............................................................................................................... 5-15<br />

Mains Filter HNF.................................................................................................................... 5-15<br />

Mains Filter (-Combination) HNK........................................................................................... 5-16<br />

Mains Choke HNL01.1E (feeding)......................................................................................... 5-16<br />

Mains Choke HNL01.1E-****-S (Current-Compensated) ...................................................... 5-17<br />

Braking Resistor HLR ............................................................................................................ 5-17<br />

Motor Filter HMF.................................................................................................................... 5-26<br />

6 Mounting and Installation 6-1<br />

6.1 Mounting ....................................................................................................................................... 6-1<br />

Dimensions – Power Sections................................................................................................. 6-1<br />

Dimensions – Mains Filter HNF............................................................................................... 6-7<br />

Dimensions – Mains Choke HNL01.1E (infeeding) ................................................................. 6-9<br />

Dimensions – Standard Braking Resistors HLR01.1............................................................. 6-12<br />

Dimensions – Reinforced Braking Resistors HLR01.1.......................................................... 6-14<br />

Dimensions – Motor Filter HMF............................................................................................. 6-17<br />

Combination of <strong>Drive</strong> <strong>Controllers</strong> of the <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> C Product Range .................... 6-22<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Contents III<br />

Multiple-Line Arrangement of <strong>Drive</strong> <strong>Controllers</strong> .................................................................... 6-24<br />

6.2 Electrical Installation ................................................................................................................... 6-25<br />

Rules for Design of Installations with <strong>Drive</strong> <strong>Controllers</strong> in Compliance with EMC ................ 6-25<br />

EMC-Optimal Installation in Facility and Control Cabinet...................................................... 6-26<br />

Ground Connections.............................................................................................................. 6-32<br />

Installing Signal Lines and Cables......................................................................................... 6-33<br />

General Measures of Radio Interference Suppression for Relays, Contactors,<br />

Switches, Chokes, Inductive Loads....................................................................................... 6-34<br />

Installing the 24V Supply ....................................................................................................... 6-35<br />

Connection Diagram.............................................................................................................. 6-36<br />

Connections and Connectors ................................................................................................ 6-38<br />

Accessories HAS................................................................................................................... 6-67<br />

7 Commissioning and Parameterization 7-1<br />

7.1 Basics ........................................................................................................................................... 7-1<br />

Control Panels ......................................................................................................................... 7-1<br />

Parameters .............................................................................................................................. 7-1<br />

Master Communication Interfaces........................................................................................... 7-3<br />

Parameterization Mode / Operating Mode .............................................................................. 7-4<br />

Default Settings in the Motor Encoder Data Memory ("Load Defaults Procedure")................ 7-9<br />

7.2 Parameterization......................................................................................................................... 7-12<br />

Control Panels ....................................................................................................................... 7-12<br />

Menu Structure ...................................................................................................................... 7-16<br />

7.3 Overview of Parameters – Base Package.................................................................................. 7-36<br />

S-0-0000 – S-0-0100 ............................................................................................................. 7-36<br />

S-0-0101 – S-0-0200 ............................................................................................................. 7-41<br />

S-0-0201 – S-0-0300 ............................................................................................................. 7-45<br />

S-0-0301 – S-0-0400 ............................................................................................................. 7-47<br />

S-0-0401 – S-0-1000 ............................................................................................................. 7-50<br />

P-0-0001 – P-0-0689 (General Functions) ............................................................................ 7-51<br />

P-0-0690 – P-0-0899 (Synchronization Mode)...................................................................... 7-85<br />

P-0-1100 – P-0-1299 (Velocity Control) ................................................................................ 7-87<br />

P-0-1500 – P-0-1599 (General Device Parameters)............................................................. 7-96<br />

P-0-2000 – P-0-2999 (General Device Parameters .............................................................. 7-96<br />

P-0-3600 – P-0-4095 (General Device Parameters)............................................................. 7-97<br />

7.4 Basic Functions ........................................................................................................................ 7-108<br />

Serial Communication ......................................................................................................... 7-108<br />

Master Communication........................................................................................................ 7-110<br />

Profile Types........................................................................................................................ 7-114<br />

Motor Control....................................................................................................................... 7-117<br />

Scaling of Physical Data...................................................................................................... 7-118<br />

7.5 Voltage-Controlled Operation (Open-Loop U/f Control) ........................................................... 7-121<br />

Overview.............................................................................................................................. 7-121<br />

Automatic Setting of Motor Control Parameters.................................................................. 7-122<br />

7.6 Closed-Loop Axis Control (Closed-Loop Operation) ................................................................ 7-131<br />

Automatic Setting of Axis Control........................................................................................ 7-136<br />

7.7 Positioning Block Mode ............................................................................................................ 7-137<br />

DOK-INDRV*-FU*********-IB01-EN-P

IV Contents <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

8 Diagnostic and Service Functions 8-1<br />

8.1 Diagnostic System ........................................................................................................................ 8-1<br />

Diagnostic Status Messages ................................................................................................... 8-1<br />

Diagnostic Command Messages............................................................................................. 8-1<br />

Warnings.................................................................................................................................. 8-1<br />

General Description of Error Messages and Error Reactions ................................................. 8-2<br />

8.2 Recommended Actions for Operating States, Activities and Reactions of the <strong>Drive</strong><br />

Controller ...................................................................................................................................... 8-5<br />

8.3 Troubleshooting .......................................................................................................................... 8-21<br />

Check <strong>Drive</strong> Components...................................................................................................... 8-21<br />

Replacing Devices................................................................................................................. 8-21<br />

Cables.................................................................................................................................... 8-23<br />

Replacing the Firmware......................................................................................................... 8-24<br />

Firmware Release Update..................................................................................................... 8-25<br />

Firmware Version Upgrade.................................................................................................... 8-29<br />

Possible Problems during Firmware Replacement ............................................................... 8-35<br />

8.4 Service and Maintenance ........................................................................................................... 8-36<br />

Deactivation........................................................................................................................... 8-36<br />

Dismantling ............................................................................................................................ 8-36<br />

Disposal ................................................................................................................................. 8-37<br />

Environmental Protection ...................................................................................................... 8-37<br />

9 Service & Support 9-1<br />

9.1 Helpdesk....................................................................................................................................... 9-1<br />

9.2 Service-Hotline ............................................................................................................................. 9-1<br />

9.3 Internet.......................................................................................................................................... 9-1<br />

9.4 Vor der Kontaktaufnahme... - Before contacting us... .................................................................. 9-1<br />

9.5 Kundenbetreuungsstellen - Sales & Service Facilities ................................................................. 9-2<br />

10 Index 10-1<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-1<br />

1 Introducing the Products<br />

1.1 Introduction<br />

Terms, Basic Principles<br />

Data Memory<br />

Condition As Supplied<br />

Storing the Application-Specific<br />

Parameter Values<br />

Saving Parameter Values<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Parameters<br />

Communication between master and drive takes place, with a few<br />

exceptions, by means of parameters.<br />

Parameters are used for:<br />

• determining the configuration<br />

• parameterizing the control loop<br />

• triggering and controlling drive functions and commands<br />

• transmitting command values and actual values (according to<br />

requirements, cyclically or acyclically)<br />

All operating data are mapped to parameters!<br />

The operating data stored in parameters can be identified by means of<br />

the IDN. They can be read and transferred, if required. The user write<br />

access to parameters depends on the properties of the respective<br />

parameter and the current communication phase. Specific parameter<br />

values (operating data) are checked for validity by the drive firmware.<br />

Data Storage and Parameter Handling<br />

Several non-volatile data memories are available in an <strong>Indra<strong>Drive</strong></strong> device:<br />

• in the controller<br />

• in the motor encoder (depending on motor type)<br />

In addition, a volatile data memory (working memory) is available in the<br />

controller.<br />

Condition as supplied of the <strong>Rexroth</strong> drive components:<br />

• The controller memory contains the drive firmware and the controllerspecific<br />

parameter values.<br />

• The motor encoder memory contains the encoder-specific and,<br />

depending on the motor type, the motor-specific parameter values.<br />

The application-specific parameter values are stored in the controller. Due<br />

to the limited number of writing cycles of non-volatile storage media,<br />

application-specific parameter values can be stored in the working<br />

memory (volatile memory), too.<br />

Saving application-specific parameter values is required in the following<br />

cases:<br />

• after initial commissioning of the machine axis or the motor<br />

• before replacing the controller for servicing (if possible)<br />

Application-specific parameter values can be saved via:<br />

• "IndraWorks D" commissioning tool → saving the parameter values on<br />

external data carrier<br />

• control master → saving the parameter values on master-side data<br />

carrier<br />

• comfort control panel

1-2 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Parameter IDN Lists<br />

Loading Parameter Values<br />

Checksum of Parameter Values<br />

Kinds of Passwords<br />

The drive supports master-side saving of parameter values by listing<br />

parameter identification numbers (IDNs). Using these lists guarantees<br />

complete storage of the application-specific parameter values. It is also<br />

possible to determine IDN lists defined by the customer.<br />

Loading parameter values is required in the following cases:<br />

• initial commissioning of the motor (loading basic parameter values and<br />

motor-specific parameter values)<br />

• serial commissioning of machine axes at series machines (loading the<br />

values saved after initial commissioning)<br />

• reestablishing a defined original status (repeated loading of the values<br />

saved after initial commissioning)<br />

• replacing the controller for servicing (loading the current parameter<br />

values saved before servicing)<br />

• Possibilities of loading parameter values to the controller:<br />

• motor encoder data memory → loading the parameter values by<br />

command or via the control panel during initial motor commissioning<br />

• "IndraWorks D" commissioning tool → loading the parameter values<br />

from external data carrier<br />

• control master → loading the parameter values from master-side data<br />

carrier<br />

By means of checksum comparison, the control master can determine<br />

whether the values of the application-specific parameter values currently<br />

active in the drive correspond to the values saved on the master side.<br />

Password<br />

<strong>Indra<strong>Drive</strong></strong> controllers provide the possibility to protect parameter values<br />

against accidental or unauthorized change by means of a password. With<br />

regard to write protection, there are 3 groups of parameters that can be<br />

written:<br />

• Parameters that are write-protected as a standard, such as motor<br />

parameters, hardware code parameters, encoder parameters, error<br />

memory etc. ("administration parameters"). The values of these<br />

parameters guarantee correct function and performance of the drive.<br />

• Parameters the customer can combine in groups and protect them<br />

with a so-called customer password. This allows protecting parameter<br />

values, that are used for adjusting the drive to the axis, after having<br />

determined them.<br />

• All other parameters that can be written and are not contained in the<br />

above-mentioned groups. They are not write-protected.<br />

The drive firmware allows activating and deactivating the write protection<br />

for parameter values by means of three hierarchically different<br />

passwords:<br />

• Customer password<br />

The parameter values of a parameter group combined by the<br />

customer can be protected.<br />

• Control password<br />

Parameters protected by a customer password can be written;<br />

"administration parameters" remain write-protected.<br />

• Master password<br />

All parameters that can be written, including "administration<br />

parameters" and parameters protected by a customer password, can<br />

be changed.<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-3<br />

Kinds of Commands<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Commands<br />

Commands are used to activate and control complex functions or<br />

monitoring features in the drive. The higher-level master can start,<br />

interrupt or clear commands.<br />

Each command is assigned to a parameter by means of which the<br />

execution of the command can be controlled. During the execution of the<br />

command the display of the control panel reads "Cx", "C" representing the<br />

diagnostic command message and "x" representing the number of the<br />

command.<br />

Note: Each command that was started must be actively cleared<br />

again.<br />

All commands available in the drive are stored in the S-0-0025, IDN-list<br />

of all procedure commands parameter.<br />

There are 3 different kinds of commands:<br />

• <strong>Drive</strong> control commands<br />

• can cause automatic drive motion,<br />

• can be started only when drive enable has been set,<br />

• deactivate the active operating mode during its execution.<br />

• Monitoring commands<br />

• activate or deactivate monitors or functions in the drive.<br />

• Administration commands<br />

• carry out administration tasks,<br />

• cannot be interrupted.<br />

See also "Command Processing" in chapter "Master Communication"<br />

Operating Modes<br />

The selection of operating modes defines which command values will be<br />

processed in which way, in order to lead to the desired drive motion. The<br />

operating mode does not determine how these command values are<br />

transmitted from the master to the slave.<br />

One of the four or eight (for SERCOS) operating modes defined in<br />

parameters is always active when the following conditions have been<br />

fulfilled:<br />

• control section and power section are ready for operation<br />

• drive enable signal sees a positive edge<br />

• drive follows command value<br />

• "<strong>Drive</strong> Halt" function has not been activated<br />

• no drive control command is active<br />

• no error reaction is carried out<br />

The display of the control panel reads "AF" when an operating mode was<br />

activated.<br />

Note: All implemented operating modes are stored in the S-0-0292,<br />

List of all operating modes parameter.<br />

See also chapter "Operating Modes"

1-4 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Warning Classes<br />

Error Classes<br />

Warnings<br />

Depending on the active operating mode and the parameter settings,<br />

many monitoring functions are carried out. If a status is detected that still<br />

allows correct operation but in case this status persists will cause an error<br />

to occur and therefore cause the drive to be automatically switched off,<br />

the drive firmware generates a warning message.<br />

Note: Warnings do not cause automatic shutdown (exception: fatal<br />

warning).<br />

Warnings are classified in different warning classes which determine<br />

whether the drive, when the warning is generated, carries out an<br />

automatic reaction or not.<br />

Note: The warning class can be recognized by the diagnostic<br />

message.<br />

The following classes of warnings are distinguished:<br />

• without drive reaction → diagn. message no. E2xxx, E3xxx, E4xxx<br />

• with drive reaction → diagn. message no. E8xxx<br />

Note: Warnings cannot be cleared. They persist until the condition<br />

that activated the warning is no longer fulfilled.<br />

Errors<br />

Depending on the active operating mode and the parameter settings,<br />

many monitoring functions are carried out. If a status is detected that<br />

affects or prevents correct operation the drive firmware generates an<br />

error message.<br />

Errors are classified in different error classes. There are 6 error classes<br />

with different drive error reactions.<br />

Note: The error class can be recognized by the diagnostic message<br />

number.<br />

Diagnostic message<br />

number Error class<br />

F2xxx non-fatal error<br />

F3xxx non-fatal safety technology error<br />

F4xxx interface error<br />

F6xxx travel range error<br />

F7xxx safety technology error<br />

F8xxx fatal error<br />

F9xxx fatal system error<br />

E-xxxx fatal system error "processor exception"<br />

Fig. 1-1: Overview of error classes<br />

Note: Apart from the mentioned error classes that can occur during<br />

operation, errors can occur when the devices are booted and<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-5<br />

Error Reactions of the <strong>Drive</strong><br />

Clearing Error Messages<br />

Clearing Error Messages when<br />

<strong>Drive</strong> Enable Was Set<br />

Error Memory<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

during firmware download. These errors are not displayed at<br />

the control panel with a diagnostic message number of the<br />

"Fxxxx" pattern, but with a short text. Boot errors and firmware<br />

download errors are separately described in the<br />

documentation "Troubleshooting Guide" (diagnostic message<br />

description).<br />

If the drive controller is in control and an error status is detected, the<br />

execution of a drive error reaction is automatically started. The diagnostic<br />

message number "Fxxxx" flashes on the display of the control panel.<br />

The drive reaction in the case of interface errors and non-fatal errors is<br />

determined in parameter P-0-0119, Best possible deceleration At the<br />

end of each error reaction, the drive is torque-free.<br />

See also "Error Reactions" in chapter "<strong>Drive</strong> Functions"<br />

Error messages are not cleared automatically but by the following action:<br />

• activating the S-0-0099, C0500 Reset class 1 diagnostics command<br />

- or -<br />

• actuating the "Esc" button on the control panel<br />

If the error status persists the error message is immediately generated<br />

again.<br />

If a drive error occurs while operating with drive enable having been set,<br />

the drive carries out an error reaction. The drive automatically deactivates<br />

itself at the end of each error reaction; in other words, the output stage is<br />

switched off and the drive switches from an energized to a de-energized<br />

state.<br />

To reactivate the drive:<br />

• clear the error message and<br />

• input a positive edge for drive enable again.<br />

The diagnostic message numbers of occurring errors are written to an<br />

error memory. This memory contains the diagnostic message numbers of<br />

the last 50 errors that occurred and the time when they occurred. Errors<br />

caused by a shutdown of the control voltage (e.g. F8070 +24Volt DC<br />

error) are not stored in the error memory.<br />

The diagnostic message numbers in the error memory are mapped to the<br />

P-0-0192, Diagnostic numbers of error memory parameter and can be<br />

displayed by means of the control panel. By means of the "IndraWorks D"<br />

commissioning tool it is possible to display the diagnostic message<br />

numbers and the respective times at which the errors occurred.

1-6 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

1.2 <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Hardware Platform<br />

<strong>Drive</strong> <strong>Controllers</strong><br />

Power section<br />

Control section<br />

300 mm Design<br />

400 mm Design<br />

Overview<br />

The drive controller consists of two essential parts:<br />

• power section<br />

• control section<br />

The power section incorporates the control section and has the following<br />

connections:<br />

• mains voltage connection (at supply modules and HCS devices)<br />

• motor connection (with optional motor holding brake and motor<br />

temperature monitor)<br />

• 24 V control voltage<br />

• DC bus connection<br />

• module bus connection<br />

• connection for external braking resistor (at HCS devices)<br />

The control section is a separate component that is plugged into the<br />

power section. The drive controller is supplied complete with factoryinstalled<br />

(possibly configured) control section.<br />

Power Sections<br />

<strong>Indra<strong>Drive</strong></strong> C<br />

• <strong>HCS02.1</strong>E-W0012<br />

• <strong>HCS02.1</strong>E-W0028<br />

• <strong>HCS02.1</strong>E-W0054<br />

• <strong>HCS02.1</strong>E-W0070<br />

• HCS03.1E-W0070<br />

• HCS03.1E-W0100<br />

• HCS03.1E-W0150<br />

• HCS03.1E-W0210<br />

Control Sections<br />

• BASIC OPENLOOP (single axis; type CSB01.1N-FC-…)<br />

• BASIC PROFIBUS (single axis CSB01.1N-PB-…)<br />

Supported Control Section Configurations<br />

The configurable control sections differ with regard to the scope of their<br />

configurability. It basically depends on the control section type and the<br />

corresponding firmware variant. The following abbreviations are used:<br />

Options for master communication:<br />

• PB → PROFIBUS-DP<br />

• FC → FC Interface<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-7<br />

Motors and Measuring Systems<br />

Third party motors<br />

Motor Encoders and External<br />

Optional Encoders<br />

Measuring Encoders<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Supported Motors<br />

The table below contains an overview of the <strong>Rexroth</strong> motors which can be<br />

operated at <strong>Indra<strong>Drive</strong></strong> controllers.<br />

Housing motors Kit motors<br />

synchronous asynchronous synchronous asynchr.<br />

MHD<br />

MKD<br />

MKE<br />

MSK (IndraDyn S)<br />

MAL<br />

SF (<strong>Bosch</strong>)<br />

2AD<br />

ADF<br />

MAD (IndraDyn A)<br />

MAF (IndraDyn A)<br />

MLF (IndraDyn L)<br />

MBS (Standard)<br />

MBSxx2 (IndraDyn H)<br />

MBT (IndraDyn T)<br />

LSF<br />

Fig. 1-2: Appropriate <strong>Rexroth</strong> motors for <strong>Indra<strong>Drive</strong></strong><br />

Third party motors must meet the specified requirements.<br />

Supported Measuring Systems<br />

1MB<br />

In addition to the encoders integrated in the <strong>Rexroth</strong> motors, the<br />

<strong>Indra<strong>Drive</strong></strong> firmware can evaluate the following measuring systems as<br />

motor encoders or as external optional control encoders:<br />

• <strong>Bosch</strong> <strong>Rexroth</strong> GDS or GDM encoders (single-turn or multi-turn type)<br />

• resolvers according to <strong>Rexroth</strong> signal specification (single-turn or<br />

multi-turn type)<br />

• encoders with sine signals and EnDat2.1 interface (1 Vpp )<br />

• encoders with sine signals (1 V pp )<br />

• encoders with square-wave signals (TTL)<br />

• Hall sensor box and encoder with sine signals (1 Vpp )<br />

• Hall sensor box and encoder with square-wave signals (TTL)<br />

• encoders with sine signals and HIPERFACE interface (1 Vpp )<br />

For measuring purposes the firmware can evaluate the following<br />

measuring systems (measuring encoders, no control encoders):<br />

• <strong>Bosch</strong> <strong>Rexroth</strong> GDS or GDM encoders (single-turn or multi-turn type)<br />

• encoders with sine signals and EnDat2.1 interface (1 Vpp )<br />

• encoders with sine signals (1 V pp )<br />

• encoders with square-wave signals (TTL)<br />

• encoders with sine signals and HIPERFACE interface (1 Vpp )<br />

• motor encoders of MSK, MHD, 2AD, ADF, MAD, MAF motors<br />

• SSI encoders<br />

Note: Resolvers cannot be evaluated as measuring encoders!

1-8 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Master Communication<br />

PROFIBUS Interface<br />

• cyclic data exchange of command and actual value (max. 32 byte<br />

each direction; min. cycle time of 500 µs)<br />

• parameter channel for parameterization and diagnosing via field bus<br />

• safe process data channel (PROFIsafe), optional<br />

• free configuration of telegram contents possible (many cyclic<br />

configurable parameter IDN)<br />

1.3 <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Firmware Platform<br />

Type Code<br />

The individual functional packages can be combined to form the following<br />

firmware types that can be ordered:<br />

variant …<br />

(depending on<br />

control section)<br />

of<br />

package Base<br />

Basic single-axis<br />

<strong>Indra<strong>Drive</strong></strong>-Firmware<br />

FWA-INDRV* -MPB- 04 VRS- D5- x- xxx- xx<br />

Control<br />

section<br />

Basic<br />

single-axis<br />

General Features<br />

Structure of the Firmware Type<br />

Designation<br />

Firmware Types That Can Be<br />

Ordered<br />

Firmware<br />

range Base<br />

package<br />

Version<br />

Version<br />

Release<br />

Language<br />

Open-/closedloop<br />

Fig. 1-3: Basic structure of the firmware type designation<br />

Alternative<br />

expansion<br />

packages<br />

Additive<br />

expansion<br />

packages<br />

The following overview shows the available scope of functions of the<br />

respective base package:<br />

Release<br />

Language<br />

Open/closedloop<br />

Alternative<br />

functional<br />

packages<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- NNN -NN<br />

Scope of functional packages<br />

base package (open-loop)<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- SNC -NN base package (open-loop) + synchronization<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- MSP -NN base package (open-loop) + main spindle<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- ALL -NN base package (open-loop) + all altern. functions<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- NNN -ML base package (open-loop) + IndraMotion MLD-S<br />

FWA-INDRV*- MPB- 04 VRS- D5- 0- *** -ML base package (open-loop) + *** + IndraMotion MLD-S<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- NNN -NN base package (closed-loop)<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- SRV -NN base package (closed-loop) + servo function<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- SNC -NN base package (closed-loop) + synchronization<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- MSP -NN base package (closed-loop) + main spindle<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- ALL -NN base package (closed-loop) + all altern. functions<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- NNN -ML base package (closed-loop) + IndraMotion MLD-S<br />

FWA-INDRV*- MPB- 04 VRS- D5- 1- *** -ML base package (closed-loop) + *** + IndraMotion MLD-S<br />

IndraMotion<br />

MLD-S<br />

*** selected option "alternative functional packages" according to<br />

availability<br />

Fig. 1-4: Overview of firmware types and functional packages they are<br />

containing<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-9<br />

Functions Overview<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Supported Operating Modes<br />

The drive firmware supports the following operating modes:<br />

• torque/force control<br />

• velocity control<br />

• position control with cyclic command value input<br />

• drive-internal interpolation<br />

• drive-controlled positioning<br />

• positioning block mode<br />

• synchronization modes:<br />

• velocity synchronization with real/virtual master axis<br />

• phase synchronization with real/virtual master axis<br />

• electronic cam shaft with real/virtual master axis<br />

• electronic motion profile with real/virtual master axis<br />

Note: The operating modes supported by the firmware depend on<br />

the hardware and firmware and are contained in parameter<br />

S-0-0292, List of all operating modes.<br />

<strong>Drive</strong> Functions<br />

These are the most important drive functions of the MPX-04 firmware:<br />

• <strong>Drive</strong> Halt<br />

• establishing the position data reference<br />

• drive-controlled homing<br />

• setting absolute measuring<br />

• shifting the position data reference<br />

• drive error reactions<br />

• best possible deceleration<br />

• package reaction on error<br />

• NC reaction on error<br />

• E-Stop function<br />

• compensation functions/corrections<br />

• friction torque compensation<br />

• encoder correction<br />

• axis error correction<br />

• quadrant error correction<br />

• spindle positioning<br />

• drive-integrated command value generator<br />

• parameter set switching<br />

• probe function<br />

• encoder emulation<br />

• programmable position switch<br />

• drive-integrated PLC (IndraMotion MLD-S)<br />

• integrated safety technology

1-10 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Control<br />

section type/<br />

firmware<br />

CSB01.1/MPB<br />

Functional<br />

packages<br />

all, except for<br />

"synchronization"<br />

and<br />

"IndraMotion"<br />

Overview<br />

• monitoring functions<br />

• limitations that can be parameterized<br />

• output of control signals<br />

• numerous diagnostic possibilities<br />

• drive-internal generation of diagnostic messages<br />

• analog output<br />

• status displays, status classes<br />

• oscilloscope function<br />

• monitoring function<br />

• patch function<br />

• code of optional card<br />

• parameter value check<br />

• operating hours counter, logbook function, error memory<br />

Performance Data<br />

For the control performance of the <strong>Indra<strong>Drive</strong></strong> range we basically<br />

distinguish three levels with regard to the clock rates (cycle times):<br />

• Basic performance<br />

→ standard control performance by medium internal clock rates for the<br />

control loops and the signal processing of inputs/outputs or driveintegrated<br />

PLC (IndraMotion MLD-S)<br />

In this documentation the clock rate data refer to the following<br />

characteristic values:<br />

• current loop clock TA_current<br />

• velocity loop clock TA_velocity<br />

• position loop clock TA_position<br />

• cycle time of PLC (IndraMotion MLD-S) TMLD-S<br />

• cycle time of master communication TMastCom<br />

The table below contains an overview of the clock rates depending on the<br />

respective control performance. The detailed assignment of the clock rate<br />

to control section design, performance level and parameter setting is<br />

contained in the table in section "Control Section Design and<br />

Performance" (see below).<br />

Performance TA_Strom TA_Geschw TA_Lage TMLD-S TFKM<br />

Basic 62,5/83,3/125 µs 250 µs 500 µs 2000 µs 500/1000 µs<br />

Fig. 1-5: Clock rates (depending on the available performance)<br />

Perform.<br />

level TA_current TA_velocity TA_posit. TMLD-S TMastCom<br />

Switching<br />

frequency 1)<br />

P-0-0556<br />

bit 2 bit 5<br />

Basic 125 µs 250 µs 500 µs -- 1000 µs 4000 Hz 0 0<br />

Basic 125 µs 250 µs 500 µs -- 1000 µs 8000 Hz 0 0<br />

1) : can be set via P-0-0001<br />

P-0-0556: config word of axis controller<br />

Fig. 1-6: Performance depending on the control section design<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-11<br />

Selecting Performance via<br />

Parameter P-0-0556<br />

Restricted Performance with<br />

Certain Functional Packages<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

For certain applications it is necessary to use the same clock rates in all<br />

axes so that the slowest drive sets the clock. It is therefore possible to<br />

specifically reduce the performance via bit 2 and bit 5 of parameter<br />

P-0-0556, Config word of axis controller.<br />

• For BASIC control sections it is possible to select the performance<br />

levels "Basic" or "Economy" via bit 5 of P-0-0556.<br />

See also Parameter Description "P-0-0556, Config word of axis controller"<br />

Note: The effective clock rates of the active performance level are<br />

contained in the table "Performance depending on the control<br />

section design" in section "Control Section Design and<br />

Performance" (see above).<br />

If you use extensive and complex functions, the internal clock rates for<br />

BASIC control sections (CSB with firmware MPB and CDB with<br />

firmware MPD) are automatically reduced. This applies to the use of the<br />

following functional packages:<br />

• drive-integrated PLC "IndraMotion MLD-S" (functional package "ML")<br />

• expansion package "synchronization" (functional package "SNC")<br />

If you use one of these functional packages for BASIC control sections,<br />

the clock rates (position loop, velocity loop) are reduced to the lowest<br />

performance level "Economy!"

1-12 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

1.4 <strong>Rexroth</strong> IndraDyn Motors<br />

Housing Motors<br />

Product<br />

Motor size<br />

Motor length<br />

Type Code S<br />

MSK030B-0900-NN-S1-UG0-NNNN<br />

Windings code<br />

Housing design<br />

MSK 030 B 0900 NN S1 U G 0 NNNN<br />

Product<br />

Motor size<br />

Motor length<br />

Windings code<br />

Encoder<br />

Electrical<br />

Connection<br />

Fig. 1-7: Basic structure of type code<br />

Type Code IndraDyn A<br />

MAF130B-0150-FQ-M0-LH0-05-N1<br />

Cooling mode<br />

Encoder<br />

MAF 130 B 0150 FQ M0 L H 0 05 N 1<br />

Kit Motors<br />

Product<br />

Motor size<br />

Example<br />

Example<br />

Example<br />

Motor length<br />

Electrical Connection<br />

Shaft<br />

Fig. 1-8: Basic structure of type code<br />

Type Code IndraDyn L<br />

MLP100A-0120-FS-N0CN-NNNN<br />

Windings code<br />

Cooling mode<br />

MLP 100 A 0120 F S N0 CN NNNN<br />

Encapsulation<br />

Fig. 1-9: Basic structure of type code<br />

Holding brake<br />

Encoder<br />

Shaft<br />

Mounting style<br />

Holding brake<br />

Electrical<br />

Connection<br />

Bearings<br />

Other design<br />

Vibration severity<br />

grade<br />

Other design<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-13<br />

Product<br />

Product<br />

Motor size<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Type Code IndraDyn H<br />

MRS102B-1N-0046-NNNN<br />

Motor length<br />

Mounting style<br />

Internal diameter<br />

of the rotor<br />

MRS 102 B 1N 0046 NNNN<br />

Motor size<br />

Example 1<br />

Example 2<br />

Motor length<br />

Fig. 1-10: Basic structure of type code<br />

MSS102B-0800-FA-N0CN-NNNN<br />

Windings code<br />

Cooling mode<br />

MSS 102 B 0800 F A N0 CN NNNN<br />

Cooling<br />

connector<br />

Fig. 1-11: Basic structure of type code<br />

1.5 Third-Party Motors at <strong>Indra<strong>Drive</strong></strong> <strong>Controllers</strong><br />

General Information on Third-Party Motors<br />

Special Requirements<br />

Undeliverable Motor Design<br />

Check Before Using Third-Party<br />

Motors<br />

Additional Aspects to be<br />

Observed<br />

Encoder<br />

Electrical<br />

connection<br />

Why Use Third-Party Motors at <strong>Indra<strong>Drive</strong></strong>?<br />

Today machine axes are mainly moved with electric drives. Motors of<br />

standard design are used in most cases as this is the most cost-efficient<br />

solution.<br />

Due to special requirements at machine axes, constructional or safetyrelated<br />

aspects, it may be necessary for the machine manufacturer to use<br />

a motor construction diverging from the standard.<br />

For these cases there is the demand on the drive supplier to realize, apart<br />

from the deliverable standard drive consisting of (standard) motor,<br />

controller, cable and, if required, machine control unit, drives with motors<br />

that are not included in his own product range due to the special design.<br />

At <strong>Rexroth</strong> controllers of the <strong>Indra<strong>Drive</strong></strong> range it is also possible to use<br />

third-party motors. For this purpose, check whether the third-party motor<br />

complies with the requirements of use.<br />

Which are the Important Directives?<br />

According to the legal requirements<br />

• of the EU directives EMC89/336/EEC and<br />

• the German EMC laws<br />

installations and machines have to be designed and built according to the<br />

present state of standardization. In order to comply with the machine<br />

directives regarding "electromagnetic compatibility (EMC)", a conformity<br />

test of the drive system (motor with controller and connection design) has<br />

Other design<br />

Other design

1-14 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Motor Types<br />

Synchronous Motors<br />

Requirements on Third-Party Motors<br />

to be carried out. The test of the drive system and compliance with the<br />

directives have to be guaranteed by the machine manufacturer.<br />

Third-Party Motors to be Controlled<br />

The following motor types can be controlled:<br />

• asynchronous motors, rotary<br />

• asynchronous motors, linear<br />

• synchronous motors, rotary<br />

• synchronous motors, linear<br />

These motors can be operated within the scope of the technical data of<br />

the selected <strong>Indra<strong>Drive</strong></strong> controller. If motors have been provided with a<br />

holding brake, it should be controlled via the controller. Make sure that the<br />

relevant technical data of the motor holding brake are complying with<br />

those of the holding brake output.<br />

Note: For third-party motors <strong>Bosch</strong> <strong>Rexroth</strong>, as a matter of principle,<br />

does not assume the guarantee for the power data at the<br />

motor shaft!<br />

In the case of synchronous motors, the commutation offset has to be set<br />

during commissioning. The drive firmware provides several methods for<br />

determining this offset so that it is possible to determine the value for<br />

different motor characteristics.<br />

Note: Observe the restrictions in conjunction with the commutation<br />

offset determination when using synchronous motors!<br />

See Functional Description of firmware "Motor Control:<br />

Commutation Setting" in chapter "<strong>Drive</strong> Control"<br />

Possibly available reluctance property cannot be used for synchronous<br />

third-party motors! For third-party motors it is impossible to determine failsafe<br />

motor parameter values for using the reluctance property; the<br />

respective bit of P-0-4014, Type of construction of motor therefore<br />

mustn't be set!<br />

For successful and fail-safe use of a third-party motor check<br />

• whether the third-party motor to be controlled satisfies the voltage<br />

loads,<br />

• which controller, including supply, is suitable due to the motor power to<br />

be delivered,<br />

• whether the third-party motor has the required minimum inductance,<br />

• whether the motor can be protected against inadmissible temperature<br />

rise in the case of overload (temperature evaluation),<br />

• whether the mounted position measuring system can be evaluated by<br />

the controller or which position measuring system can be selected for<br />

kit motors.<br />

Voltage Load of the Third-Party Motor<br />

The voltage load of the insulation system of a motor occurring in practical<br />

application is mainly influenced by the following characteristics:<br />

• The output variables of the drive controller which is used (feed the<br />

transmission distance).<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-15<br />

Use of Voltage-Reducing<br />

Components, Motor Filter HMF<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

• The cable parameters depending on cable design and length<br />

(determine the properties of the transmission distance, such as the<br />

attenuation).<br />

• The motor design regarding capacitive and inductive properties (form<br />

the end of the transmission distance).<br />

As a result of the variables, the insulation system of the third-party motor,<br />

as regards voltage, is loaded by the values<br />

• peak voltage Upp and<br />

• voltage change dv/dt.<br />

The occurring peak voltages at the motor are caused by reflections in the<br />

motor cable. The insulation of the motor is thereby loaded with other peak<br />

voltages and voltage changes than the ones occurring at the output of the<br />

power section.<br />

Note: Determine the occurring voltage load at the terminals of the<br />

third-party motor in the application with all involved<br />

components.<br />

Use voltage-reducing components (e.g. motor filter HMF), if one of the<br />

following criteria applies:<br />

• allowed voltage change (dv/dt) of third-party motor smaller than<br />

5 kV/µs<br />

• allowed peak voltage (crest value) of third-party motor between phasephase<br />

and phase-housing smaller than 1500 V<br />

• motor cable length smaller than 25 m<br />

• mains voltage greater than AC440V<br />

Note: Apart from the nominal current IN, especially take the<br />

maximum allowed switching frequency of the power output<br />

stage (fs) into account with which the motor filter HMF may be<br />

operated.<br />

Verify the success of the voltage-reducing measure.<br />

Minimum Inductance of Third-Party Motor<br />

Depending on the controller used, the motor has to have a minimum<br />

value for inductance. The actually available inductance of a motor can be<br />

measured directly between two motor terminals by means of an<br />

inductance measuring bridge. The measurement has to be made for a<br />

complete motor wired for normal operation but not yet connected. During<br />

the measurement one motor terminal remains open!<br />

For asynchronous motors the measured value can only be used if the<br />

rotor doesn't have closed slots!<br />

Controller type Minimum required motor inductance<br />

HCS with 3*AC230V LU-V = 60* 4/(√2 * ITyp * fs) (in mH)<br />

HMS, HMD at HMV (3*AC400V)<br />

HMS, HMD at HCS (3*AC400V)<br />

HMS, HMD at HMV (3*AC480V)<br />

HMS, HMD at HCS (3*AC480V)<br />

LU-V = 80* 4/(√2 * ITyp * fs) (in mH)<br />

LU-V = 116* 4/( √2 * ITyp * fs) (in mH)<br />

ITyp: maximum controller current acc. to type code (rms value)<br />

fs: desired switching frequency in kHz<br />

Fig. 1-12: Minimum inductances depending on controller data, supply units and<br />

supply voltage

1-16 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Use a three-phase choke in the motor feed wire, if the inductance of the<br />

third-party motor is smaller than indicated in the table above. This choke<br />

has to increase the inductance that can be measured between two motor<br />

terminals to the minimum value.<br />

Note: When the inductance is measured, different inductance values<br />

can be determined at different rotor positions within one pole<br />

pair distance of the motor. The average value is relevant for<br />

the check of the minimum value.<br />

Correct values can only be determined when the motor is in<br />

standstill!<br />

Available third-party motor Planned third-party motor<br />

LU-Vmin<br />

3x LDr<br />

LU-V<br />

U<br />

V<br />

W Motor<br />

LDr = 0,5 * (LU-Vmin - LU-V)<br />

(inductance measurement with 1 kHz)<br />

mounting of 3x LDr (three-phase choke)<br />

Calculating the leakage inductance<br />

(asynchronous motor) or inductance<br />

(synchronous motor) of the third-party<br />

motor by means of the single-phase<br />

equivalent circuit diagram<br />

(manufacturer's specification!).<br />

Determine choke by means of<br />

calculation, if necessary.<br />

It is recommended to contact <strong>Rexroth</strong>!<br />

Requirements on the choke:<br />

- In_Dr ≥ In_Mot<br />

The rated current of the choke has to be greater than or equal to<br />

the rated motor current.<br />

- Depending on the maximum speed, the choke is loaded with the respective<br />

output frequency and the PWM frequency of the controller.<br />

- The insulation class has to correspond at least to that of the motor or<br />

has to be dimensioned for higher temperatures.<br />

- The voltage load of the choke depends on the controller used.<br />

Fig. 1-13: Data for possibly required choke<br />

Temperature Evaluation of Third-Party Motor<br />

Only operate such motors with incorporated temperature sensor at<br />

<strong>Indra<strong>Drive</strong></strong> controllers so that the motor can be thermally monitored by the<br />

controller and protected against destruction by too high temperature rise<br />

(see P-0-0512, Temperature sensor).<br />

When, in exceptional cases, you want to operate third-party motors<br />

without temperature sensor at <strong>Indra<strong>Drive</strong></strong> controllers, you must determine<br />

the thermal time constants of motor housing (P-0-4035) and motor<br />

winding (P-0-4034, P-0-4037). The firmware-internal motor temperature<br />

model can thereby reflect the cooling situation of the motor correctly.<br />

Note: In case the motor housing or blower is dirty, this worsens the<br />

cooling situation of the motor and protection against thermal<br />

overload is therefore insufficient!<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-17<br />

Requirements on the Encoder of the Third-Party Motor<br />

Notes on Selection and Commissioning<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Motor Encoder of Asynchronous Third-Party Motor<br />

Asynchronous motors can also be controlled by <strong>Indra<strong>Drive</strong></strong> controllers in<br />

"open-loop" operation (without motor encoder). In "closed-loop" operation<br />

(with motor encoder) a relative measuring system is sufficient for<br />

asynchronous motors.<br />

Motor Encoder of Synchronous Third-Party Motor<br />

For fail-safe drives with synchronous third-party motors at <strong>Indra<strong>Drive</strong></strong><br />

controllers the following possible combinations or restrictions have to be<br />

taken into account when selecting the measuring system:<br />

<strong>Drive</strong> range Motor measuring system Synchronous thirdparty<br />

motor<br />

<strong>Indra<strong>Drive</strong></strong><br />

absolute<br />

relative<br />

+<br />

o<br />

+ … advantageous combination<br />

o … Combination is possible (restrictions specific to application),<br />

commissioning may be more complicated!<br />

Fig. 1-14: Possible combinations of synchronous third-party motor and motor<br />

measuring system<br />

Note: The control section integrated in the controller can evaluate<br />

measuring systems as a motor encoder if they are contained<br />

in P-0-0074, Encoder type 1 (motor encoder) (see also<br />

Project Planning Manual of the <strong>Indra<strong>Drive</strong></strong> control sections).<br />

For information on absolute and relative measuring systems<br />

see section "Measuring Systems" of Functional Description of<br />

firmware!<br />

Selecting the Controller as Regards Continuous Current<br />

The controller required for the respective motor and the supply unit are<br />

determined by comparing the motor data to the data of these devices (see<br />

documentation for HMS/HMD and HMV or HCS).<br />

Note: The continuous current of the controller should be greater than<br />

that of the motor, the continuous power of the supply must be<br />

greater than the sum of all average powers of the axes of the<br />

drive system!<br />

Selecting the Connection Technique<br />

The available power and encoder cables are described in the<br />

documentation "Connection Cables; Selection Data" (DOK-CONNEC-<br />

CABLE*STAND-AU...).<br />

Notes on Commissioning<br />

Note: For further information, notes on commissioning and<br />

supporting documents (e.g. forms for entering the required<br />

data) see Functional Description of firmware.

1-18 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

1.6 Approval, Listing<br />

Conformities<br />

Declaration of Conformity<br />

C-UL-US-Listing<br />

CE Label<br />

For <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> components there are declarations of conformity<br />

available. These declarations confirm that the components are designed<br />

according to valid EC directives. If required, you can ask your sales<br />

representative for these declarations.<br />

Low-Voltage Directive<br />

The <strong>Rexroth</strong> products of a drive system mentioned in this documentation<br />

comply with the requirements of the EC Directive 73/23/EEC (Low-<br />

Voltage Directive), annex III B.<br />

EMC Directive<br />

The <strong>Rexroth</strong> products of a drive system mentioned in this documentation<br />

comply with the requirements of the EC Directive 89/336/EEC (EMC<br />

Directive) with the amendments 91/263/EEC and 93/68/EEC.<br />

Fig. 1-15: CE label<br />

CEf1.fh7<br />

Devices approved by the UL agency carry the following label:<br />

Fig. 1-16: C-UL-US label<br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Introducing the Products 1-19<br />

C-UL-US Listed Components<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

Motors approved by the UL agency carry the following label:<br />

Fig. 1-17: C-UR-US label<br />

Product Component File Number<br />

HMS01.1N- W0020, W0036, W0054, W0070, W0150,<br />

W0210<br />

E 134201<br />

HMS02.1N- W0028, W0054 E 134201<br />

HMD01.1N- W0012, W0020, W0036 E 134201<br />

<strong>HCS02.1</strong>E- W0012, W0028, W0054, W0070 E 134201<br />

HCS03.1E- W0070, W0100, W0150, W0210 Manufacturer REFU<br />

E254781<br />

HMV01.1E- W0030-A-07, W0075-A-07, W0120-A-07 E 134201<br />

HMV01.1R- W0018-A-07, W0045-A-07, W0065-A-07 E 134201<br />

HMV02.1R- W0015 E 134201<br />

HLB01.1C- 01K0-N06R0-A-007-NNN E 134201<br />

HLB01.1D- 02K0-N03R4-A-007-NNN E 134201<br />

HLC01.1C- 01M0-A-007, 02M4-A-007 E 134201<br />

HLC01.1D- 05M0-A-007 E 134201<br />

NFD03.1- -007, -016, -030, -055, -075, -130, -180 E 172117 and CSA<br />

Cert. 1038841Master<br />

Contr. 171321<br />

HNL01.1- ..... CSA Cert.<br />

1492099Master<br />

Contr. 222887<br />

HNF01.1 In preparation E 134201<br />

HNK01.1 In preparation E 134201<br />

HLR01.1 In preparation E 134201<br />

Fig 1-18: C-UL-US listed <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> components<br />

Note: The components are listed by the file number of „Underwriters<br />

Laboratories Inc.®" (UL). The documented evidence of listing<br />

can be seen in the internet: http://www.ul.com, "Certifications",<br />

enter file number or "Company name: <strong>Rexroth</strong>.<br />

The control sections are included in the listing of the power<br />

sections. The control sections are not listed separately.

1-20 Introducing the Products <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

DOK-INDRV*-FU*********-IB01-EN-P

<strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong> Important Directions for Use 2-1<br />

2 Important Directions for Use<br />

2.1 Appropriate Use<br />

Introduction<br />

DOK-INDRV*-FU*********-IB01-EN-P<br />

<strong>Rexroth</strong> products represent state-of-the-art developments and<br />

manufacturing. They are tested prior to delivery to ensure operating safety<br />

and reliability.<br />

The products may only be used in the manner that is defined as<br />

appropriate. If they are used in an inappropriate manner, then situations<br />

can develop that may lead to property damage or injury to personnel.<br />

Note: <strong>Rexroth</strong> as manufacturer is not liable for any damages<br />

resulting from inappropriate use. In such cases, the guarantee<br />

and the right to payment of damages resulting from<br />

inappropriate use are forfeited. The user alone carries all<br />

responsibility of the risks.<br />

Before using <strong>Rexroth</strong> products, make sure that all the pre-requisites for<br />

an appropriate use of the products are satisfied:<br />

• Personnel that in any way, shape or form uses our products must first<br />

read and understand the relevant safety instructions and be familiar<br />

with appropriate use.<br />

• If the products take the form of hardware, then they must remain in<br />

their original state, in other words, no structural changes are permitted.<br />

It is not permitted to decompile software products or alter source<br />

codes.<br />

• Do not mount damaged or faulty products or use them in operation.<br />

• Make sure that the products have been installed in the manner<br />

described in the relevant documentation.

2-2 Important Directions for Use <strong>Rexroth</strong> <strong>Indra<strong>Drive</strong></strong><br />

Areas of Use and Application<br />

2.2 Inappropriate Use<br />

<strong>Drive</strong> controllers made by <strong>Bosch</strong> <strong>Rexroth</strong> are designed to control<br />

electrical motors and monitor their operation.<br />

Control and monitoring of the motors may require additional sensors and<br />

actors.<br />

Note: The drive controllers may only be used with the accessories<br />

and parts specified in this document. If a component has not<br />

been specifically named, then it may not be either mounted or<br />

connected. The same applies to cables and lines.<br />

Operation is only permitted in the specified configurations and<br />

combinations of components using the software and firmware<br />

as specified in the relevant Functional Descriptions.<br />

Every drive controller has to be programmed before commissioning,<br />

making it possible for the motor to execute the specific functions of an<br />

application.<br />

The drive controllers have been developed for use in single- and multiaxis<br />

drive and control tasks.<br />

To ensure an application-specific use, the drive controllers are available<br />

with different drive power and different interfaces.<br />

Typical applications of the drive controllers include:<br />

• handling and mounting systems,<br />

• packaging and food machines,<br />

• printing and paper processing machines and<br />

• machine tools.<br />

The drive controllers may only be operated under the assembly and<br />

installation conditions described in this documentation, in the specified<br />