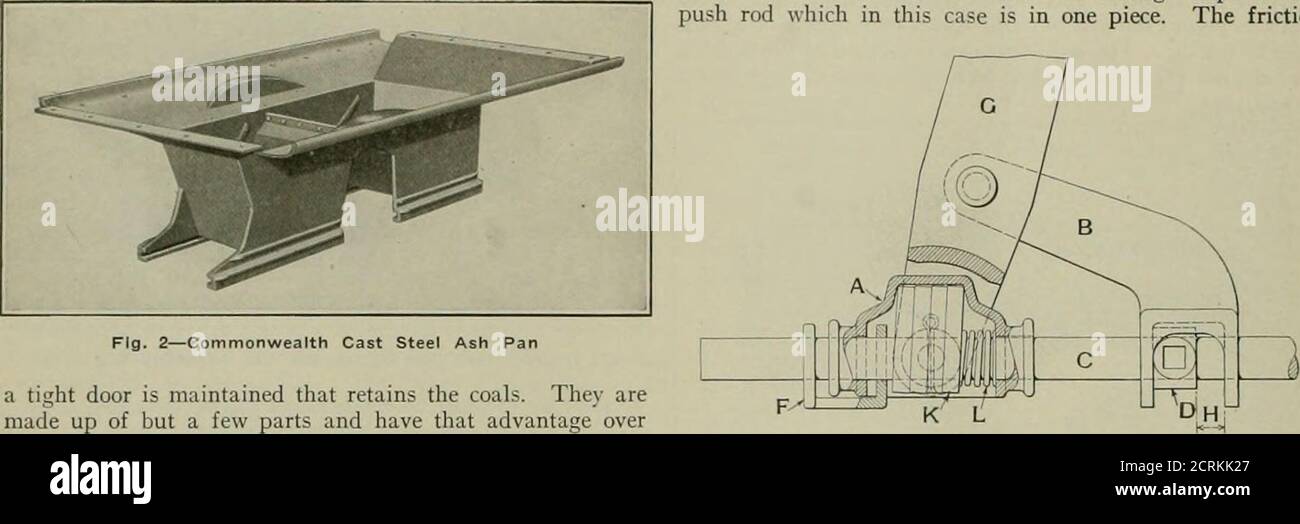

. Railway mechanical engineer . witching. The) meet all Government requirements. The cast steel ash pan is shown in Fig. 2. It is madefor single and double hoppers. These ash pans do awaywith the frequent expensive renewals and repairs character-istic of other types, as they are so designed that they do notburn out. They also prevent live coals from scattering onthe roadwa) and causing fires. As these pans do not warp. a friction sleeve operating between two lugs on the side ofthe Ijarrel member of the slack adjuster, automatically causedthe lengthening of the push rod members on the release o

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CRKK27File size:

7.2 MB (199.5 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

2735 x 914 px | 23.2 x 7.7 cm | 9.1 x 3 inches | 300dpiMore information:

This image could have imperfections as it’s either historical or reportage.

. Railway mechanical engineer . witching. The) meet all Government requirements. The cast steel ash pan is shown in Fig. 2. It is madefor single and double hoppers. These ash pans do awaywith the frequent expensive renewals and repairs character-istic of other types, as they are so designed that they do notburn out. They also prevent live coals from scattering onthe roadwa) and causing fires. As these pans do not warp. a friction sleeve operating between two lugs on the side ofthe Ijarrel member of the slack adjuster, automatically causedthe lengthening of the push rod members on the release ofthe brakes to maintain a constant clearance between thebrake shoes and the wheels. The drawing shows the application of the same principlein a device, since developed by the Gould Coupler Company, which has been materially altered and much simplified inconstruction. The slack adjuster proper is attached directlyto the lower end of the live lever and through it passes thepush rod wliich in this case is in one piece. The friction. a tight door is maintained that retains the coals. They aremade up of but a few parts and have that advantage overthe built-up types. This type of pan will last a long timeand greatly reduces the maintenance costs for this particularpart of the locomotive. TRUCK LEVER TYPE SLACK ADJUSTERFOR FREIGHT CARS In the June 14, 1916, issue of the Daily Railway AgeGazette, page 1263, there appears a description of an auto-matic slack adjuster for freight cars which was developedby the Gould Coupler Company, New York. This slackadjuster replaced the push rod in the truck brake rigging, performing the functions of the latter, as well as that of theslack adjuster. The function of the push rod was performedIjy two members, one of which telescoped within the other.In the barrel, or hollow member, was a pocket containing Details of the Slack Adjuster sleeve is mounted directly on the push rod and the adjustingrod employed in the original device has been replaced byan ad